Mounting method for magnetic yoke of transformer

An assembly method and transformer technology, which are applied in the field of transformers, can solve the problems affecting the quality of transformer products, the large bending degree of iron yoke assembly, and the inability to clamp the upper iron yoke, etc., so as to achieve excellent work performance, smooth iron core of the transformer upper yoke, The effect of leveling the upper iron yoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

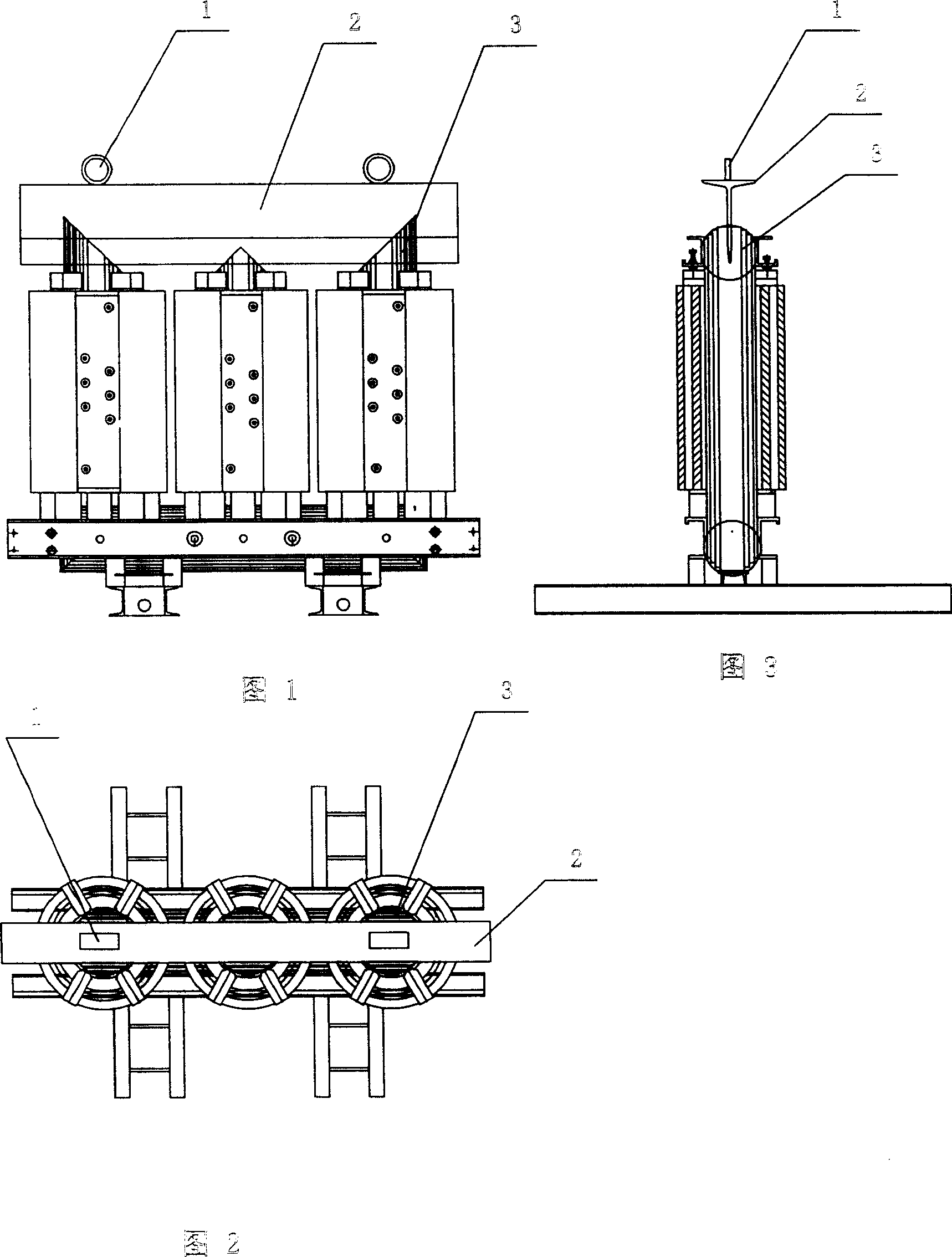

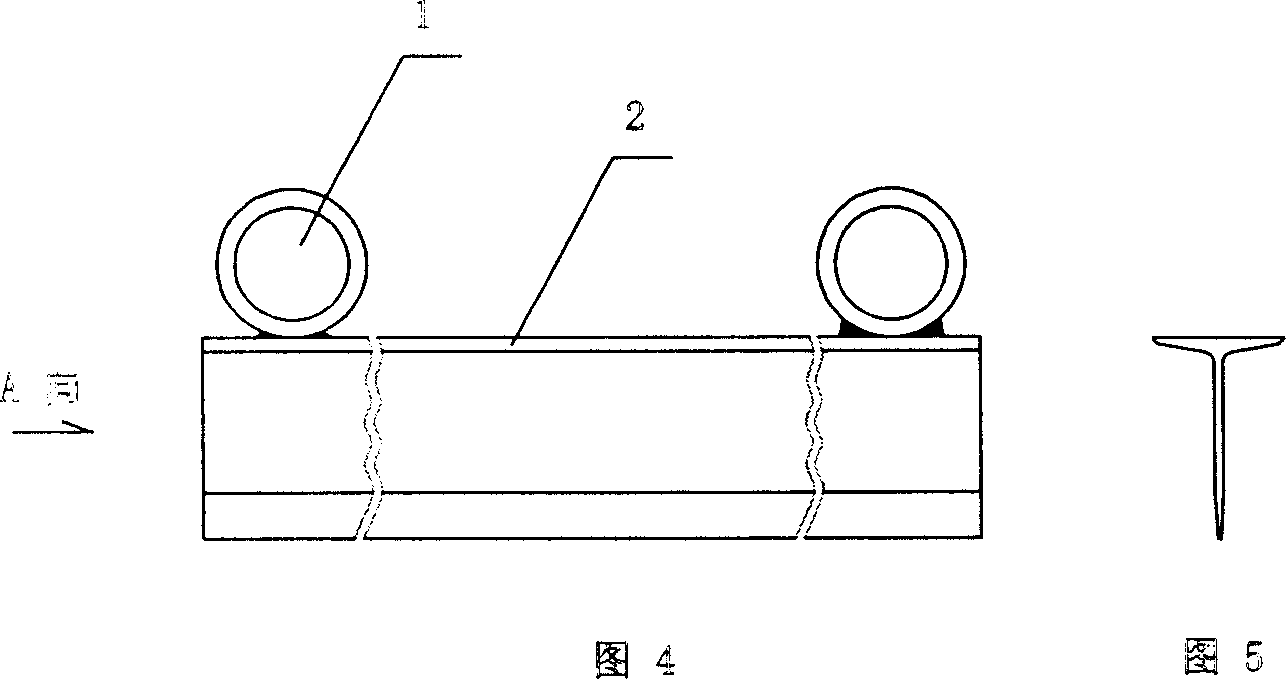

[0022] See Figure 1, Figure 2, Figure 3, Figure 4, and Figure 5.

[0023] The method of assembling the upper iron yoke of the transformer is to first insert part of the upper iron yoke silicon steel sheet into the middle of the iron core column 3, and then insert the T-shaped frame 2 at the middle position of the iron core column, and the T-shaped frame 2 is first inserted into the middle of the iron yoke silicon steel sheet, and then Insert the rest of the upper iron yoke silicon steel sheet into the iron core column 3 along both sides of the T-shaped frame 2. After inserting all the upper iron yoke silicon steel sheets into the iron core column 3, take out the T-shaped frame 2 through the hanger 1 on the T-shaped frame 2. Finally, the iron yoke silicon steel sheet is clamped with bolts, and the assembly process of the iron yoke on the transformer is completed so far.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com