Steel bar hoop-bending machine for steel bar processing

A steel bar processing and hoop bending machine technology, applied in the field of steel bar bending hoops, can solve problems such as inaccurate bending of steel bars, and achieve the effect of promoting work efficiency and reducing surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

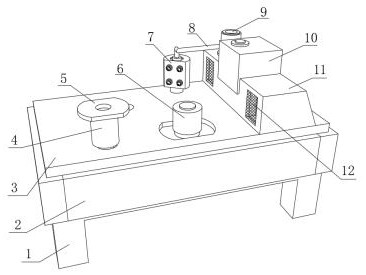

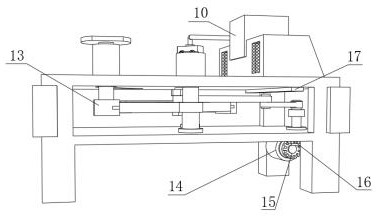

[0030] A steel bar bending machine for steel bar processing, such as Figure 1-4 As shown, it includes a workbench 3, the outer wall of the bottom of the workbench 3 is welded with a support seat 1, and the three peripheral walls of the workbench 3 are respectively fixed with baffles by bolts, and the front outer wall of the workbench 3 is fixed with a mounting plate 2 by bolts, The outer wall on one side of the top of the workbench 3 is fixed with a case 11 by bolts. Two air outlets 12 are provided on the outer wall on one side of the case 11. The top outer wall of the case 11 is clamped with a water tank 10. The outer wall of the case 11 near the side of the water tank 10 is fixed by bolts. A water pump 9 is fixed, the bottom inner wall of the workbench 3 is provided with an arc-shaped intermittent mechanism 13, and the top inner wall of the workbench 3 near the side of the chassis 11 is provided with an air guide port 17, and the top outer wall of the workbench 3 is provided...

Embodiment 2

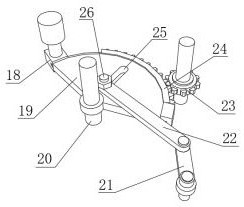

[0034] A steel bar bending machine for steel bar processing, such as Figure 4 As shown, in order to effectively promote the simultaneous bending of multiple steel bars; this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of the top center of the installation groove is welded with a clamping column, and the outer wall of the clamping column is covered The clamping seat 27 is connected, and the top outer wall of the clamping seat 27 is respectively welded with a first stopper 28 and a second stopper 29; Between, and by starting the arc-shaped intermittent mechanism 13, the effect of simultaneously bending hoops of multiple steel bars is effectively promoted, and the efficiency of bending hoops of steel bars is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com