Continuous rolling process of profile steel for double-rubber ring socket steel ring of prestressed concrete pipe

A technology of concrete pipes and socket steel rings, applied in the direction of metal rolling, etc., can solve the problems of uneven deformation of rolling sections, unstable product quality control, and low production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

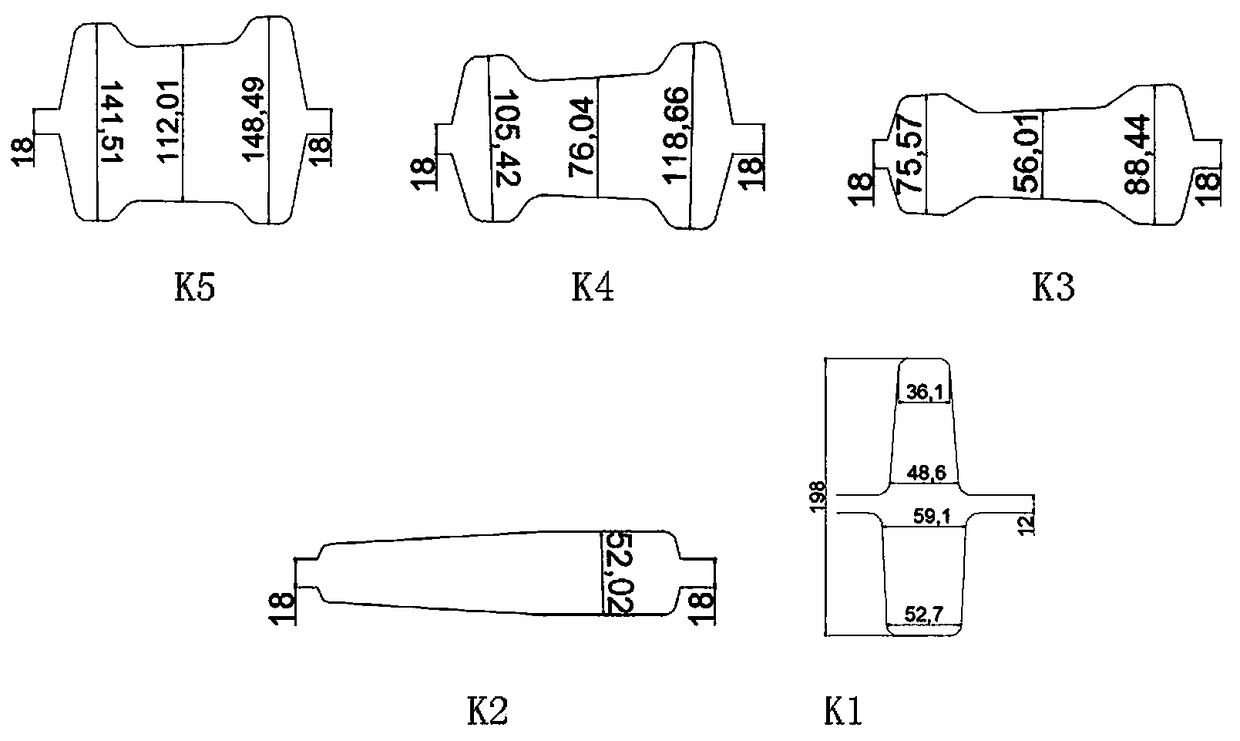

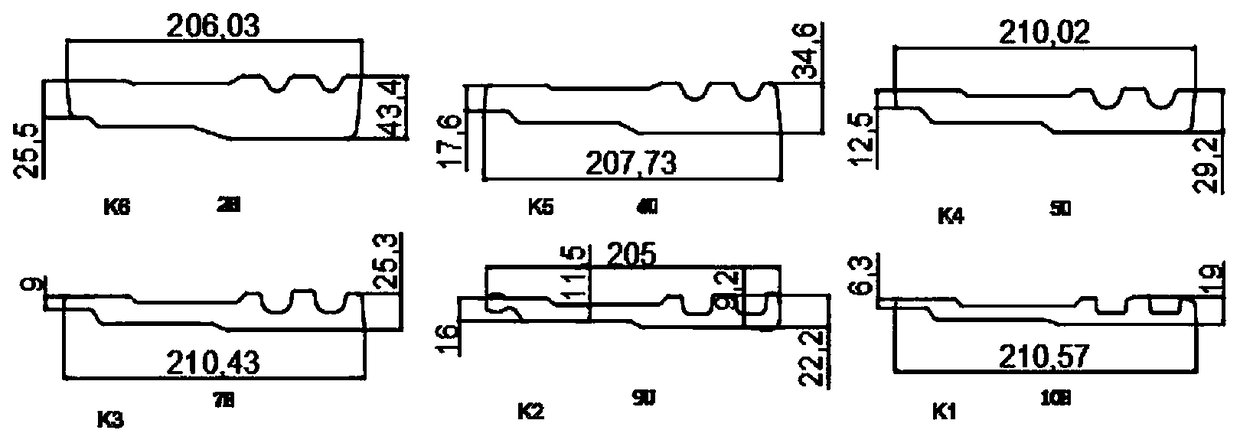

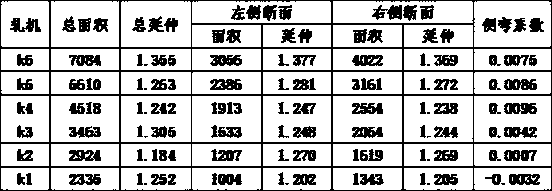

[0009] A continuous rolling process of steel rings for prestressed concrete pipe double-rubber ring sockets, such as figure 1 , figure 2 as shown,

[0010] 1) The section size of the billet is 150×150mm, the length is determined according to the length of the cooling bed and the width of the heating furnace of the application production line, the starting rolling temperature is 1030-1080°C, and the iron oxide on the surface of the billet is required to be removed from the furnace;

[0011] 2) The whole line is rolled 11 times in total. The first 3 passes of rough rolling adopt strong and wide pass, the 4th and 5th passes roll the rolled piece into the shape and size required by subsequent passes, and the finish rolling adopts closed pass. Use the principle of limiting width to ensure the size of the groove of the sealing ring and the overall width of the finished product;

[0012] 3) The finishing rolling is 6-stand continuous rolling, of which K2 adopts a four-high univers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com