Pre-buried channel arc bending machine

A pre-buried channel and arc bending technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as curvature, unstable quality, waste of work and effort, and inability to guarantee curvature requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

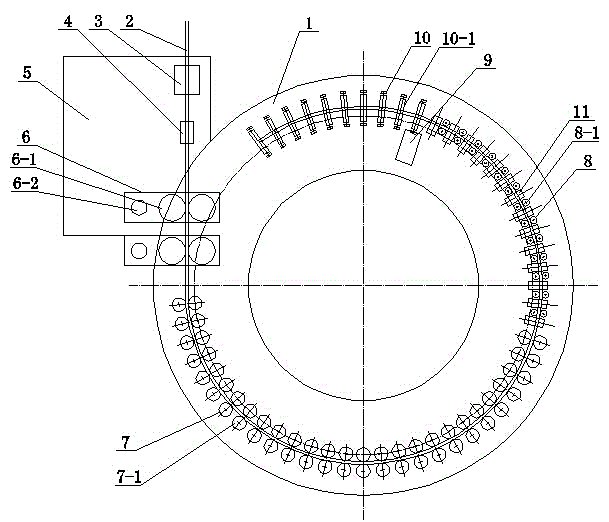

[0010] Such as figure 1 As shown, it is a pre-buried channel arc bending machine, including a full-circle workbench 1, an auxiliary workbench 5 is set on one side of the workbench 1, and the drive assembly 6 and the first forming assembly are connected to the full-circle workbench 1 7. The second forming component 8 , the high-speed circular saw 9 , and the blanking support component 10 . The drive assembly 6 is arranged at the feeding place of the workbench 1, the butt welder 3 is arranged on the feed side of the drive assembly 6, the milling cutter 4 is arranged between the butt welder 3 and the drive assembly 6, the butt welder 3 and the milling cutter 4 are connected on the auxiliary workbench 5 respectively.

[0011] The driving assembly 6 includes a power unit 6-2 and at least one pair of driving rollers 6-1, each driving roller 6-1 is vertically arranged on the table surface of the workbench 1, and the power unit 6-2 communicates with the driving roller 6-1 through a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com