Preparation method for super-lens with plane-shaped imaging surface by using secondary ion beam etching technology

A technology of ion beam etching and imaging surface, which is applied in the process of producing decorative surface effects, lens, microstructure technology, etc., can solve the problem that the imaging surface is a curved surface, etc., achieve uniform deposition thickness, wide application range and prospects , the effect of reducing the precipitation of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, on the arc-shaped groove that diameter depth is 150nm, prepare the hyperlens that imaging surface is plane, and manufacturing process is as follows:

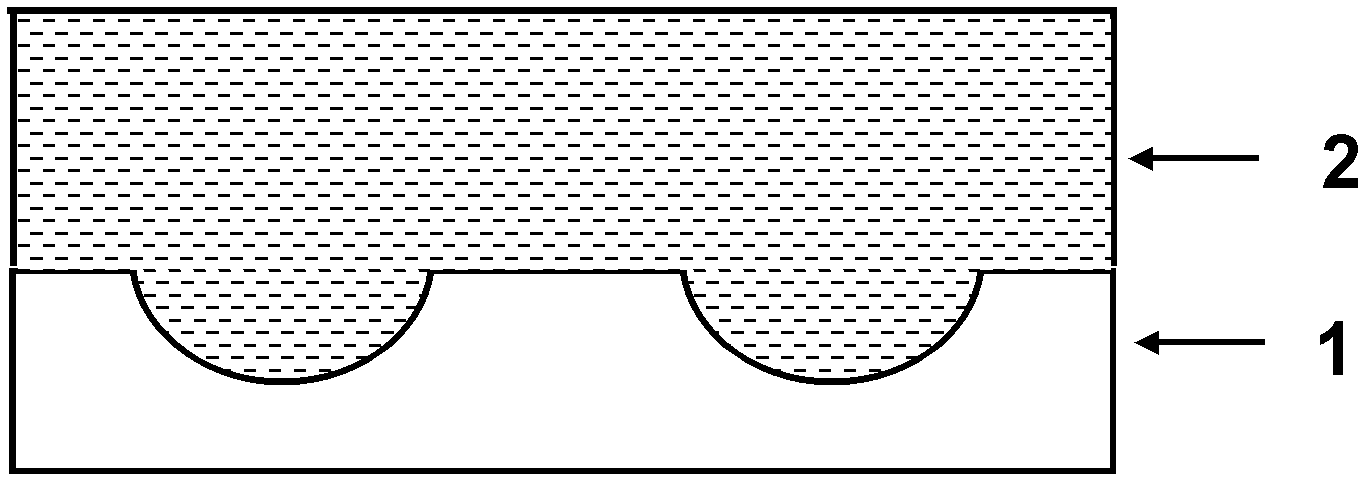

[0030] (1) On a semi-cylindrical trench prepared on a 1mm thick quartz substrate, AR-P3100 photoresist was coated by spin coating. In order to fill up the semi-cylindrical grooves, a method of coating multiple times at a spin coating speed of 2000rpm / 15sec was used. After multiple coatings, when the coating thickness of AR-P3100 reaches 4.6 microns, the semi-cylindrical grooves are filled, as figure 2 As shown, 1 represents the substrate material quartz; 2 represents various types of photoresist.

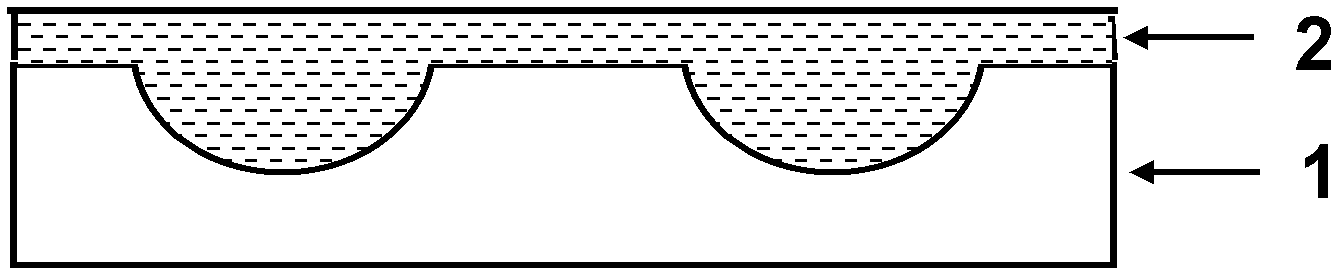

[0031] (2) Thinning the AR-P3100 photoresist by RIE etching, the etching power is 100W, the etching gas is oxygen, the flow rate is 50sccm, and the etching time is 10 minutes and 30 seconds, such as image 3 As shown, 1 represents the substrate material quartz; 2 represents various types of photoresist.

[003...

Embodiment 2

[0036] Embodiment 2, on the circular arc-shaped groove that diameter depth is 200nm, prepare the hyperlens that imaging plane is plane, and manufacturing process is as follows:

[0037] (1) On a semi-cylindrical trench prepared on a 1mm thick quartz substrate, AR-P3100 photoresist was coated by spin coating. In order to fill up the semi-cylindrical grooves, a method of coating multiple times at a spin coating speed of 2000rpm / 15sec was used. After multiple coatings, when the coating thickness of AR-P3100 reaches 4.8 microns, the semi-cylindrical grooves are filled, as figure 2 As shown, 1 represents the substrate material quartz; 2 represents various types of photoresist.

[0038] (2) Thinning the AR-P3100 photoresist by RIE etching, the etching power is 100W, the etching gas is oxygen, the flow rate is 50sccm, and the etching time is 11 minutes and 30 seconds, such as image 3 As shown, 1 represents the substrate material quartz; 2 represents various types of photoresist. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| etching power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com