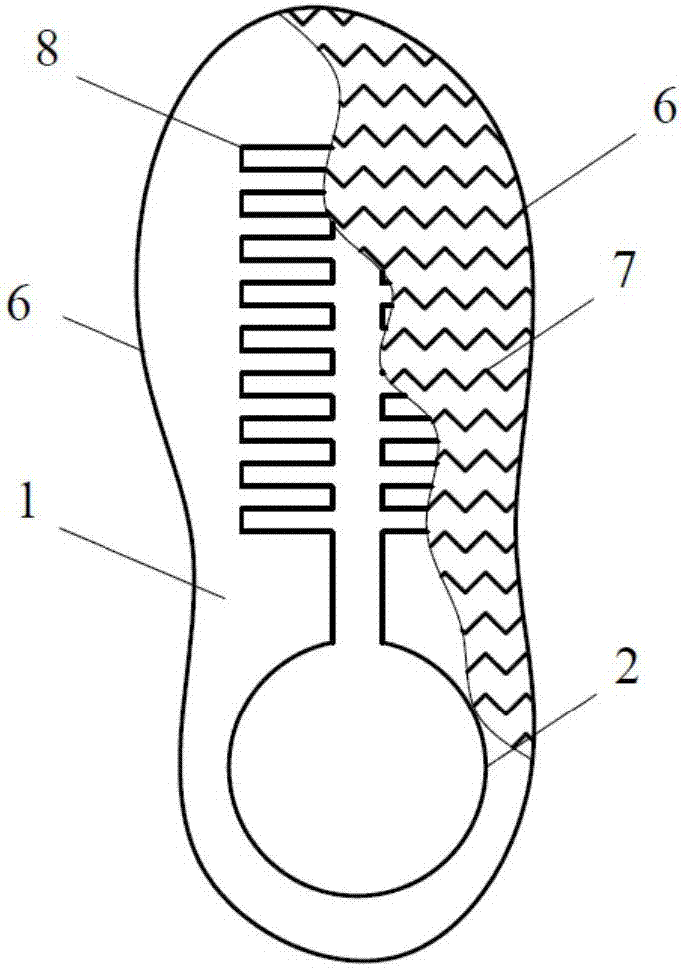

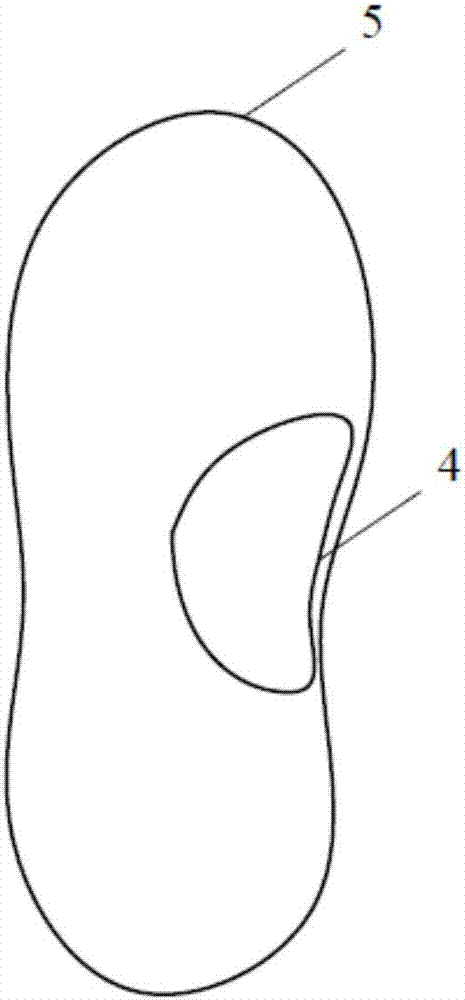

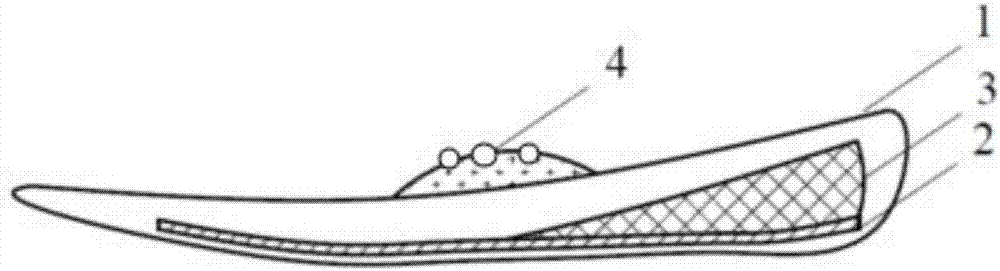

Foot orthotics insole and preparation method thereof

An insole and orthopedic technology, applied in the field of orthopedic insoles, can solve the problems of easy deformation and low comfort in use, and achieve the effects of comfortable hardness, excellent durability, and excellent cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] 1. Preparation of antibacterial essential oil microcapsules:

[0055] 1.1. Take an appropriate amount of β-cyclodextrin, dissolve it in distilled water at 45°C, and stir while dissolving until a saturated solution of β-cyclodextrin is formed;

[0056] 1.2. Take an appropriate amount of antibacterial essential oil and dissolve it in an ethanol solution with a volume fraction of 60%. The volume ratio of antibacterial essential oil to ethanol solution is 1:20. Add the mixed solution dropwise to the β-cyclodextrin saturated solution ;

[0057] 1.3. Stir continuously to mix the antibacterial essential oil and β-cyclodextrin evenly, add 2 to 3 drops of Tween-80 emulsifier, and disperse homogeneously for 20 minutes;

[0058]1.4. Stir the homogenized mixture at 45°C for 10 minutes;

[0059] 1.5. After the solution is cooled to room temperature, put it in a refrigerator at 0-4°C to freeze and solidify;

[0060] 1.6. Use a vacuum pump to carry out suction filtration under redu...

Embodiment 1

[0072] 1. Preparation of antibacterial essential oil microcapsules: Take an appropriate amount of β-cyclodextrin, dissolve it in distilled water at 45°C, and stir while dissolving until a saturated solution of β-cyclodextrin is formed. Take an appropriate amount of clove essential oil and dissolve it in ethanol solution with a volume fraction of 60%. The volume ratio of clove essential oil to ethanol solution is 1:20. Add the mixed solution dropwise to the β-cyclodextrin saturated solution. Stir continuously to mix the clove essential oil and β-cyclodextrin evenly, add 2 to 3 drops of Tween-80 emulsifier, carry out homogeneous dispersion for 20 minutes, and stir the homogenized mixture at 45°C for 10 minutes. After the solution was cooled to room temperature, it was placed in a refrigerator at 0-4°C to freeze and solidify. A vacuum pump was used for vacuum filtration, and the obtained filter residue was washed with absolute ethanol and distilled water, respectively. The micro...

Embodiment 2 to 6

[0077] The same process as in Example 1 was used to prepare starch-based antibacterial foam composite materials, and materials B to F were prepared respectively. The difference lies in the types of antibacterial essential oils and the proportioning ratio of raw materials and auxiliary agents in Examples 2 to 7, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com