Polyurethane elastomer composition for automobile slip pad

A polyurethane elastomer and anti-slip pad technology, applied in the field of polyurethane elastomers, can solve the problems of limitation, low production efficiency, long curing time, etc., and achieve the effects of high production efficiency, comfortable hardness and hand feeling, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

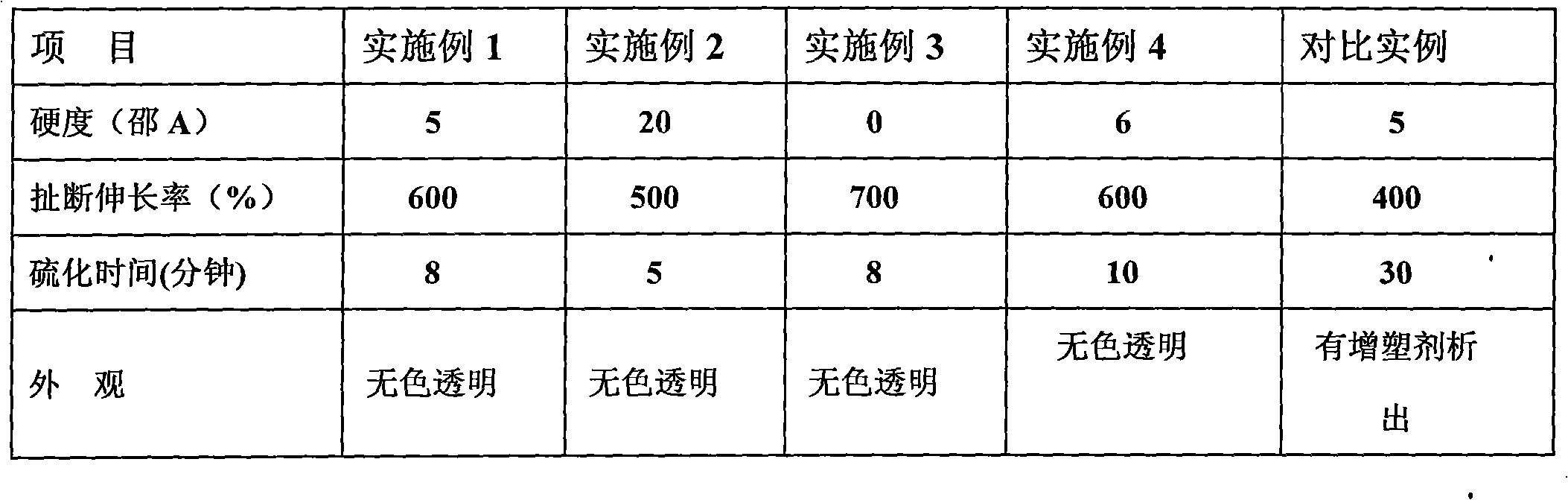

Examples

Embodiment 1

[0025] Polymer components: 20% polyether polyol with functionality 2 and molecular weight 1000, 78% polyether polyol (PPG330N) with functionality 3 and molecular weight 3000, organic bismuth catalyst 1%, UV-3290.5%, 10100.5% according to Prepared by the method of the present invention.

[0026] Prepolymer: 45% of polyether polyol with 2 functionalities and molecular weight of 1000, 55% of liquefied MDI, reacted at 70°C to 90°C for 2 to 3 small vacuums (-0.095MPa) to remove bubbles, and obtain isocyanate content 10% prepolymer.

[0027] The prepolymer and the polymer component are mixed at a ratio of 100:20, the mixing temperature is 25°C-40°C, the vulcanization temperature of the product is 60°C-70°C, and the vulcanization is 8 minutes to obtain a Shore 5A polyurethane elastomer product.

Embodiment 2

[0029] Polymer components: 5% polyether polyol with functionality 3 and molecular weight 300, 93% polyether polyol (PPG330N) with functionality 3 and molecular weight 5000, bismuth catalyst 0.5%, zinc catalyst 0.5%, UV-3280.5% , 1010 0.5% prepared according to the method of the present invention.

[0030] Prepolymer: 65% of polyether polyol with 2 functionalities and molecular weight of 3000, MDI30%, liquefied MDI5%, reacted at 70℃~90℃ for 2~3 small vacuums (-0.095MPa) to remove bubbles and obtain iso Prepolymer with 7% cyanate content.

[0031] The prepolymer and the polymer component are mixed at a ratio of 100:35, the mixing temperature is 25°C-40°C, the product vulcanization temperature is 60°C-70°C, and vulcanized for 5 minutes to obtain a Shore 20A polyurethane elastomer product.

Embodiment 3

[0033] Polymer component: polyether polyol 10% of functionality 2, molecular weight 2000, functionality 3, polyether polyol 88.5% of molecular weight 6000, bismuth catalyst 0.5%, UV-5310.5%, BHT 0.5% according to the present invention prepared by the method described above.

[0034] Prepolymer: 62% of polyether polyol with 2 functionalities and molecular weight of 2000, MDI30%, and liquefied MDI8% are reacted at 70°C to 90°C for 2 to 3 small vacuums (-0.095MPa) to remove air bubbles and obtain isocyanide Prepolymer with 10% acid group content.

[0035] The prepolymer and the polymer component are mixed at a ratio of 100:20, the mixing temperature is 25°C-40°C, the vulcanization temperature of the product is 60°C-70°C, and the vulcanization is 8 minutes to obtain a polyurethane elastomer product of Shore 0A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com