Refining device for tobacco shred conveyer

A technology of screeding device and conveyor, applied in conveyors, vibrating conveyors, transportation and packaging, etc., can solve the process parameters affecting the moisture, expansion rate and curvature of cut tobacco, reduce the effective operation rate of the equipment, and the flow rate of the next process. Instability and other problems, to achieve the effect of improving the effective operation rate of the equipment, uniform distribution, and stable flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

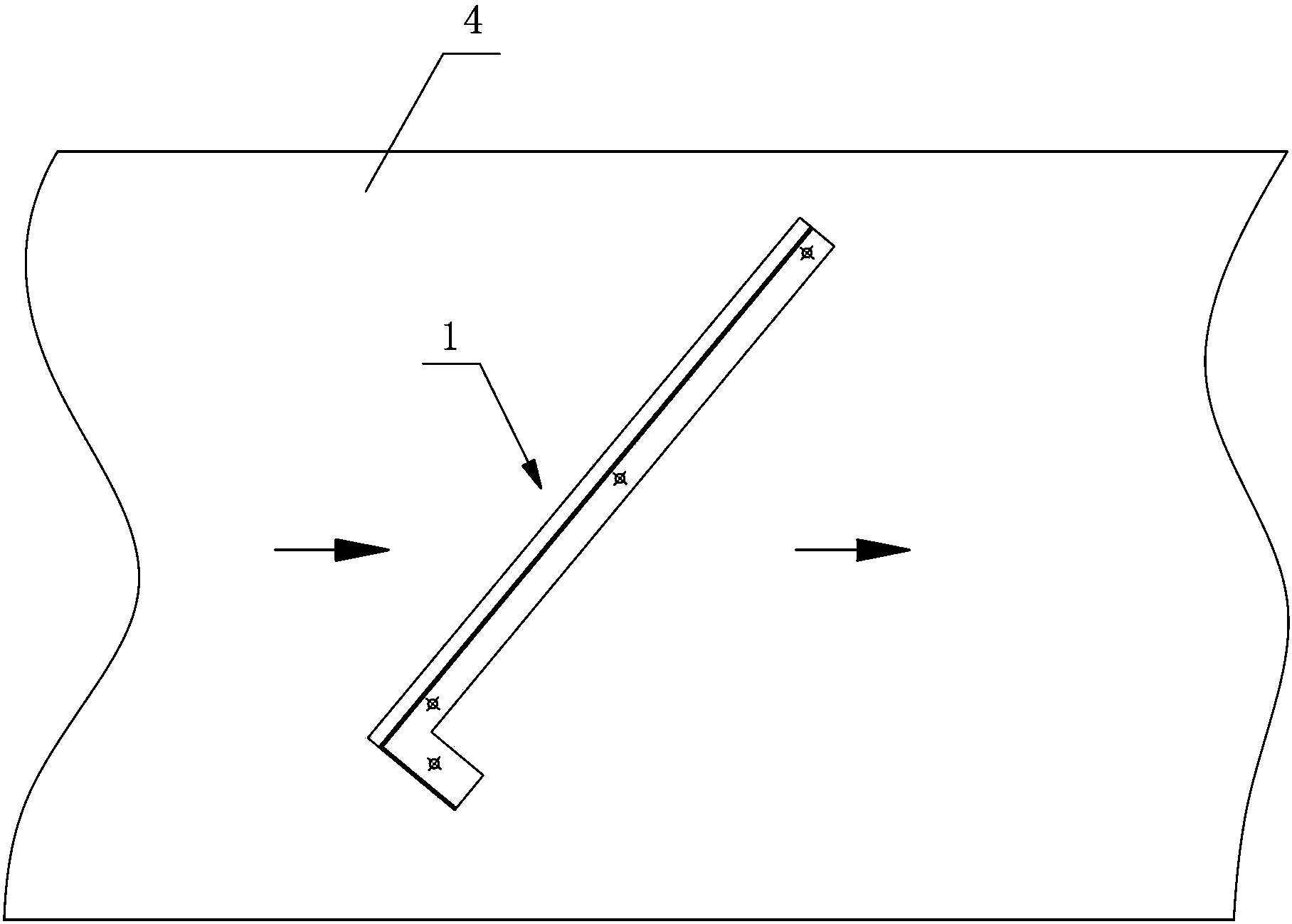

[0027] Such as figure 1 As shown, the homogenizing device of the shredded tobacco conveyor in Embodiment 1 includes a first-stage shunting device arranged on the groove bed 4 of the shredded tobacco conveyor, and the first-stage shunting device includes a first-stage shunting member 1; Figure 4 , Figure 5 and Figure 6 As shown, the primary flow divider 1 includes a first wing plate 11 that is basically vertically arranged relative to the grooved bed 4 , and a first wing 13 for fixing to the grooved bed 4 is provided at the bottom of the first wing plate 11 ; The second wing plate 12 that is vertically arranged with respect to the grooved bed 4, the second wing plate 12 is fixedly arranged on the end of the first wing plate 11, and is provided with for fixing with the grooved bed 4 at the bottom of the second wing plate 12 The second wingspan 14 ; the first wingspan 13 and the second wingspan 14 are provided with wingspan through holes 15 , fastening bolts pass through the...

Embodiment 2

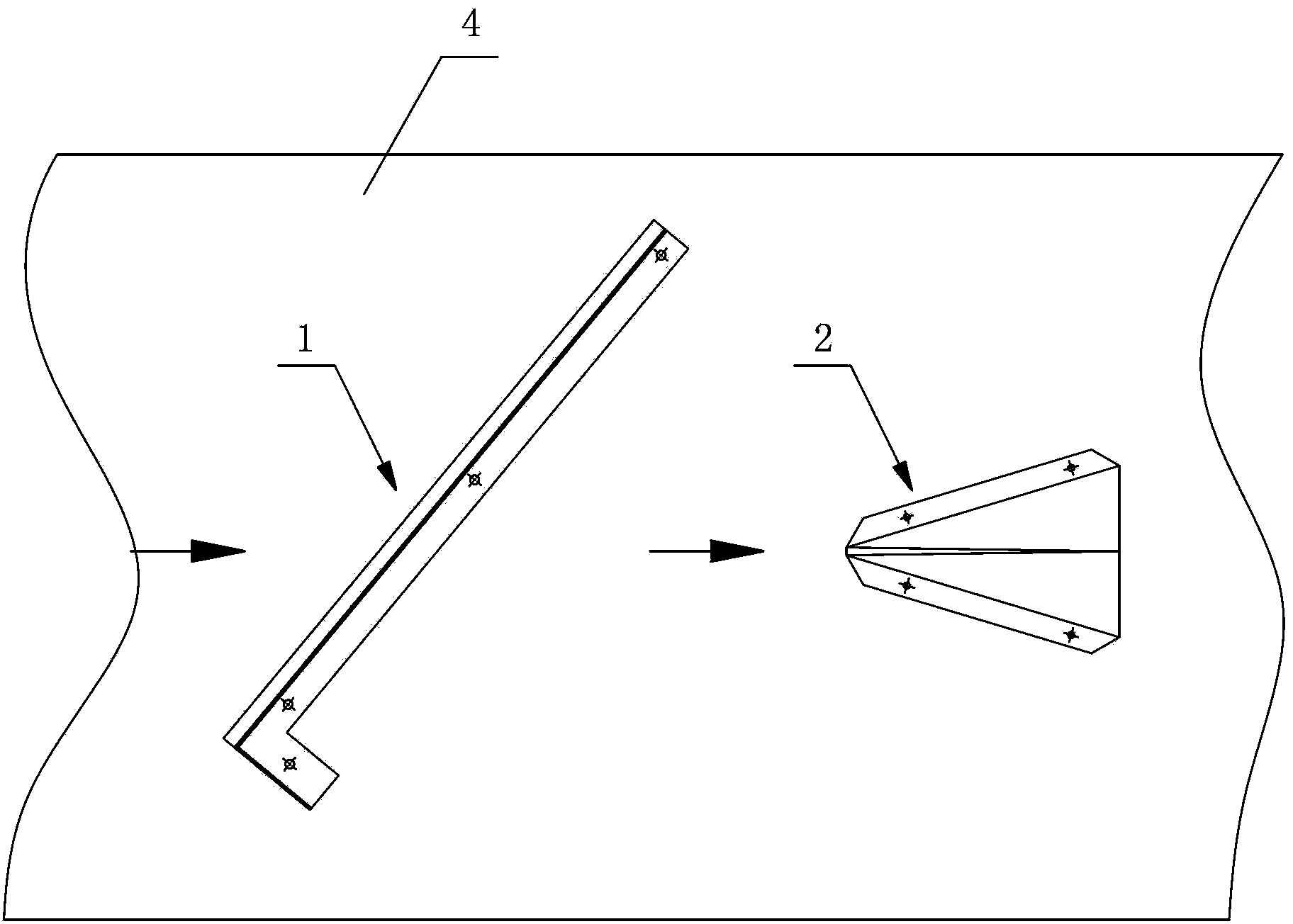

[0031] Such as figure 2 As shown, in Embodiment 2, on the basis of Embodiment 1, a second-stage shunt device is provided downstream of the first-stage shunt device, and the second-stage shunt device includes a second-stage shunt member 2; as Figure 7 , Figure 8 and Figure 9 As shown, the secondary shunt 2 includes two symmetrically arranged triangular wing plates 21 and a triangular wing plate 22 with a common side; The trapezoidal plate-shaped secondary diverter wing span 23 fixed with the grooved bed 4 is provided with a span through hole 24 on the secondary diverter span 23, and the fastening bolt passes through the wing span through hole 24 to connect the secondary diverter. Part 2 is fixed on the grooved bed 4; wherein, the cross-section of the secondary flow distribution part 2 is roughly in an inverted "V" shape. The secondary splitter 2 is basically located at the centerline of the grooved bed 4 .

[0032] Wherein, the included angle between the common side and...

Embodiment 3

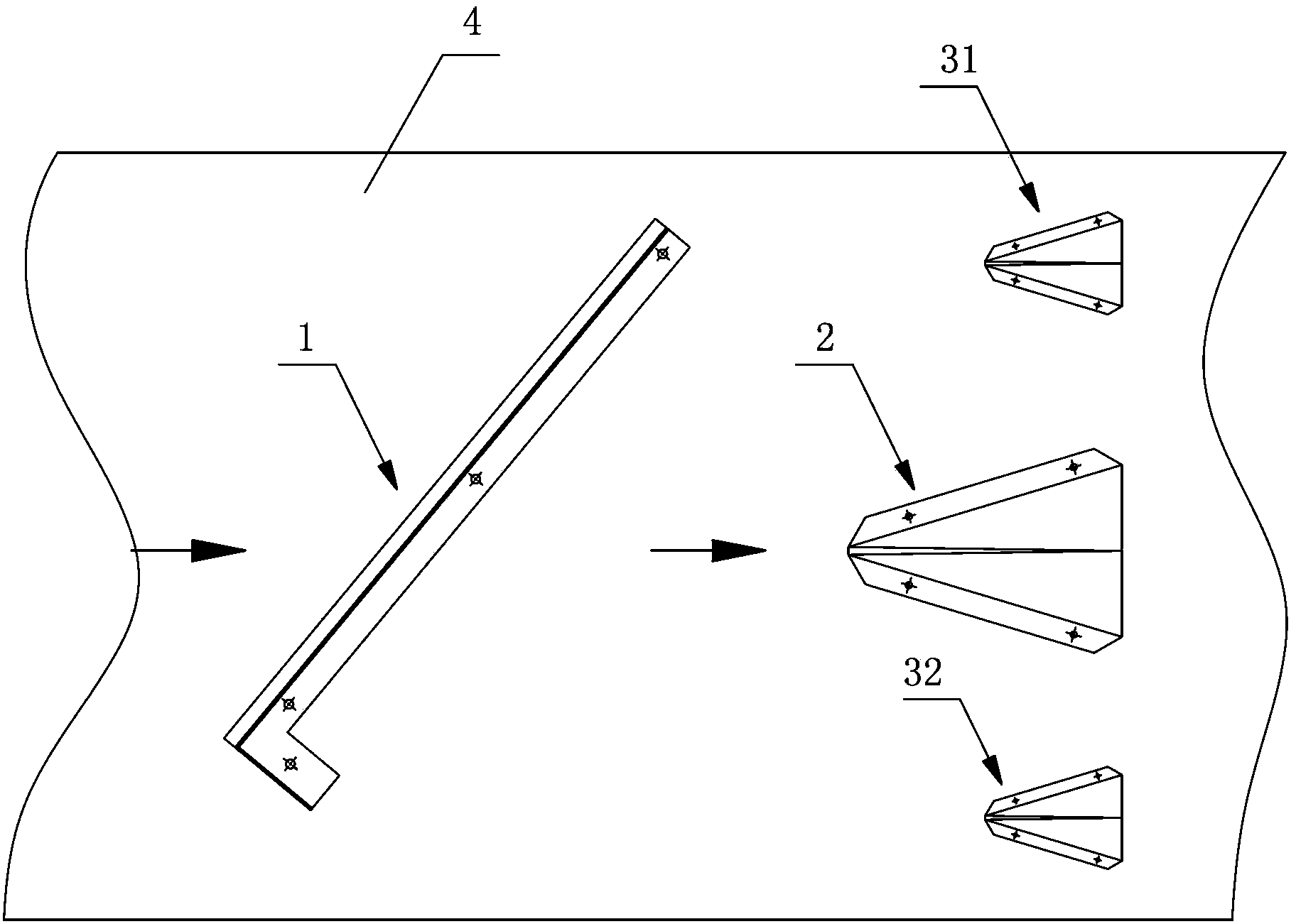

[0035] Such as image 3 As shown, the third embodiment is provided with a third-level flow diversion device on the basis of the second embodiment; the third-level flow distribution device of this embodiment includes two third-level flow dividers 31, 32 arranged on both sides of the second-level flow divider 2 , the shape of the two tertiary flow dividers 31 , 32 is basically the same as that of the secondary flow divider 2 , and the size is smaller than that of the secondary flow divider 2 . Of course, the third-level flow divider can also be arranged downstream of the second-level flow divider 2 , and the number is not limited to two, and more can be set according to actual needs.

[0036] The homogenizing device of the shredded tobacco conveyor of the present invention is not limited to the three-level splitting device, and more levels of splitting devices can be arranged after the third-level splitting device according to actual production needs.

[0037]After the leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com