Method and special device for relieving steel pipe heat treatment curvature

A special device and bending technology, which is applied in the heat treatment field of the steel pipe manufacturing industry, can solve the problems of long production process and investment in bending and straightening, and achieve the effects of increasing bending, reducing equipment investment, and shortening the length of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

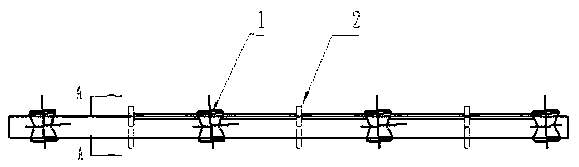

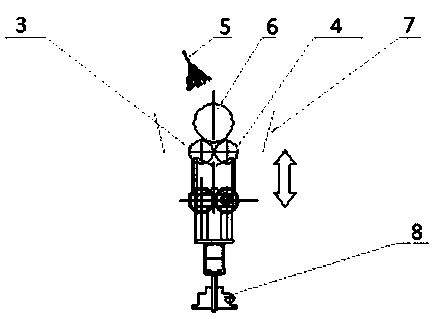

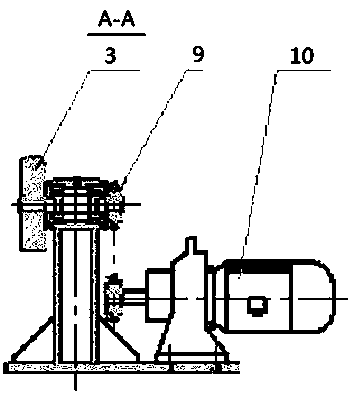

[0019] Example 1, see figure 1 , 2 3. Select the appropriate conveying roller table 1 and the lifting and rotating roller mechanism 2 according to the design requirements, and install the lifting and rotating roller mechanism 2 between the conveying roller tables 1. The lifting and rotating roller mechanism 2 includes the lifting mechanism 8 at the bottom. The active rotating roller 3 and the passive rotating roller 4 are installed on the lifting mechanism 8, and the lifting mechanism 8 drives the active rotating roller 3 and the passive rotating roller 4 to lift, and the active rotating roller 3 is connected with the transmission mechanism 10 through the driving sprocket 9 to drive the active rotating roller 3 rotation, the active rotating roller 3 drives the passive rotating roller 4 to rotate; place a steel pipe 6 on the active rotating roller 3 and the passive rotating roller 4, and install an atomizing spray at the position corresponding to the steel pipe 6 above the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com