Patents

Literature

52results about How to "Make sure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

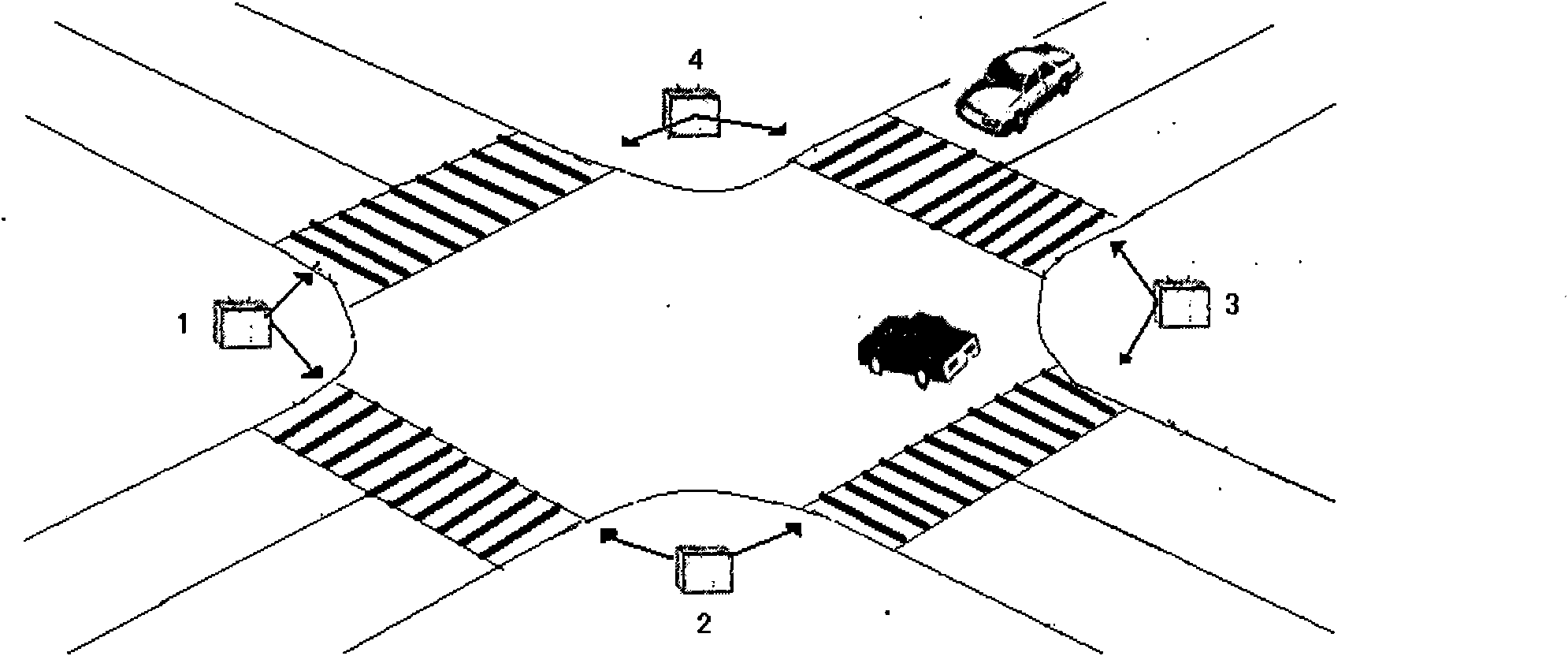

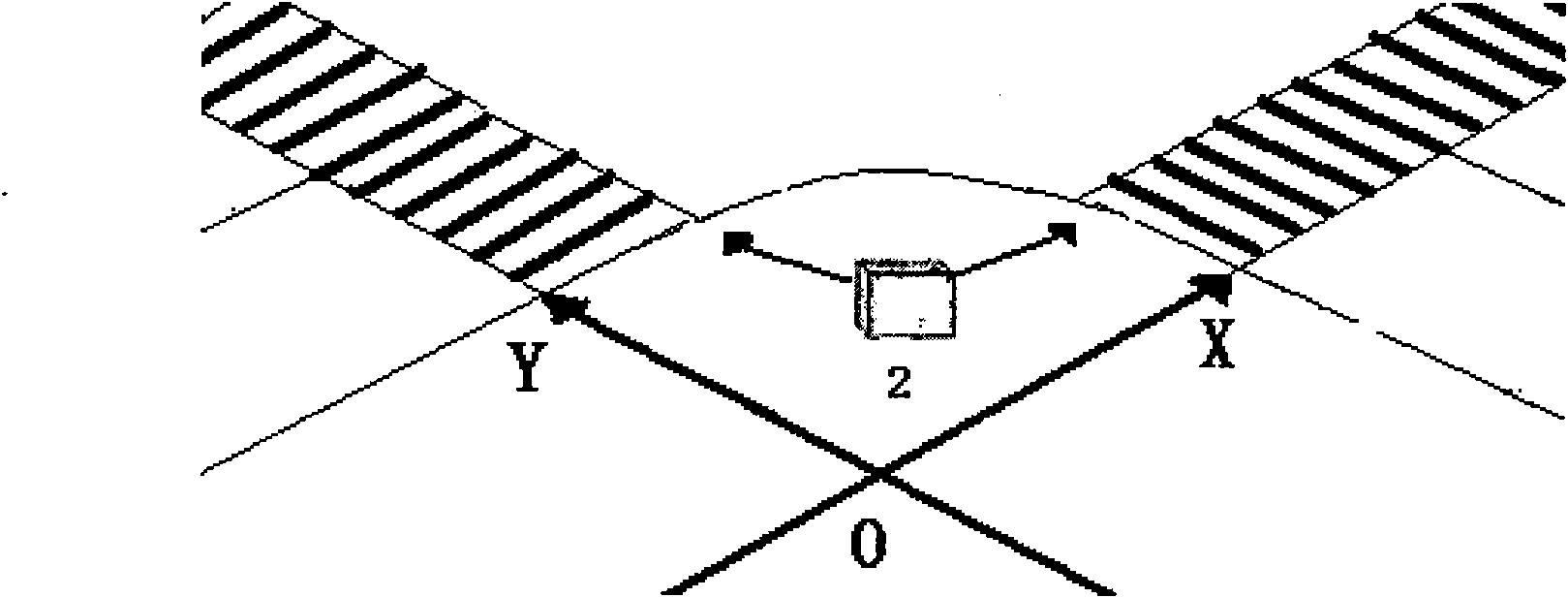

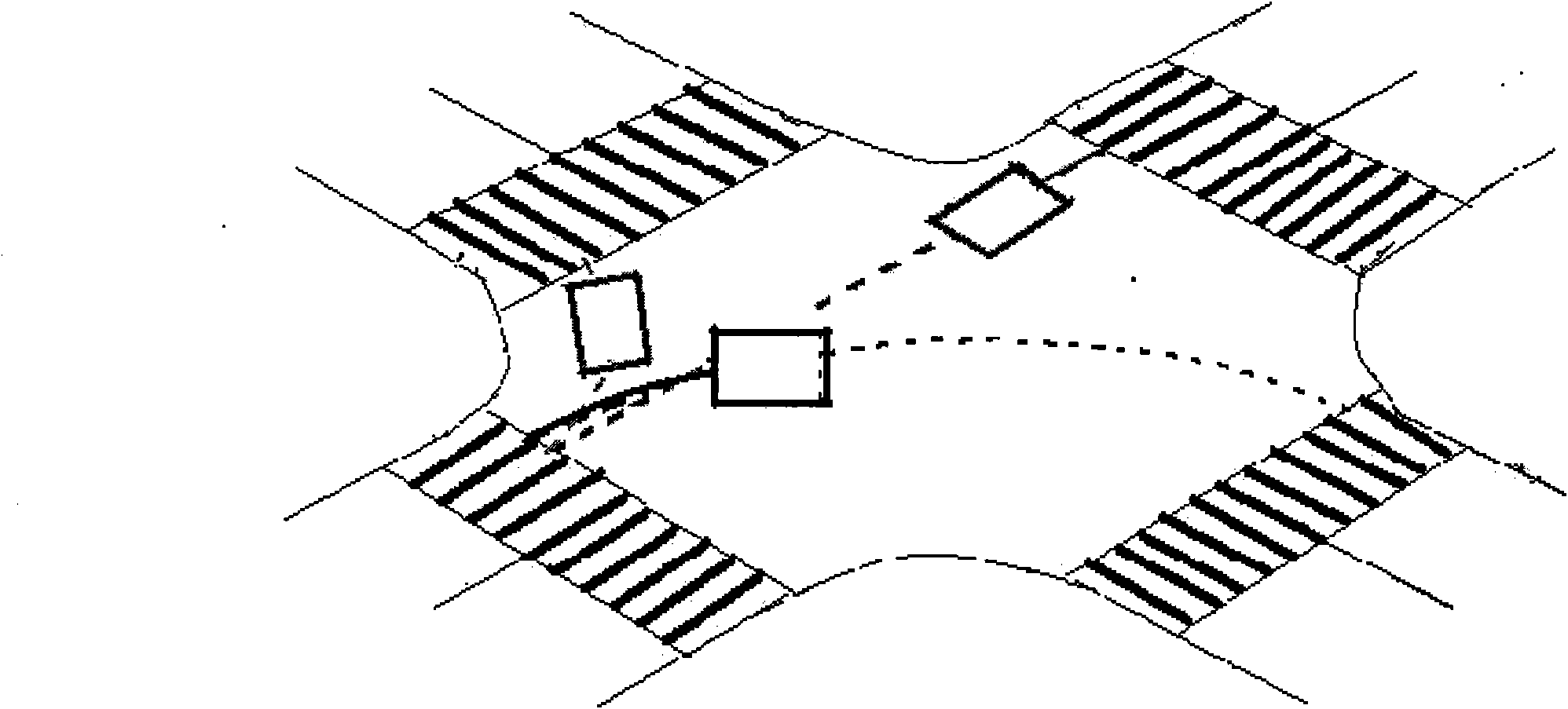

Road junction traffic conflict detection and safety evaluation method based on two-dimensional laser scanners

InactiveCN101853575ATraffic control improvementRealize evaluationDetection of traffic movementTraffic conflictLaser scanning

The invention relates to a road junction traffic conflict detection and safety evaluation method based on two-dimensional laser scanners, which is remarkably characterized by comprising the steps of: acquiring and fusing motion parameters of road junction moving objects by using a plurality of two-dimensional laser scanners; computing conflict parameters and serious degree of traffic conflict occurring among traffic participating units by the motion parameter of each moving object; and constructing an intersection safety state evaluation method based on the traffic conflict on the basis of intersection serious conflict statistic and traffic volume statistic to realize the evaluation and the monitoring of the intersection safety state. The road junction traffic conflict detection and safety evaluation method based on the two-dimensional laser scanners has the characteristics of low cost and accuracy and rapidity, brings convenience to the research of the road junction traffic conflict, is beneficial to implementing the effective improvement on the road junction traffic control, and ensures the traffic safety.

Owner:BEIHANG UNIV

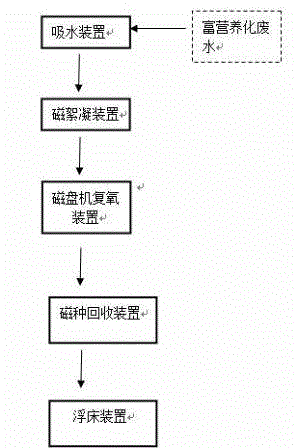

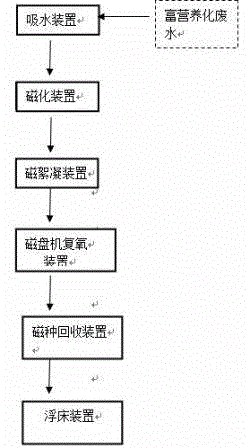

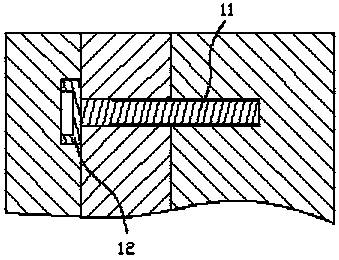

Eutrophic wastewater treatment device and method

ActiveCN103951144ARealize integrationSmall footprintMultistage water/sewage treatmentEutrophicationSludge

The invention belongs to the field of sewage treatment, and particularly relates to a eutrophic wastewater treatment device and method. The eutrophic wastewater treatment system comprises a water absorption, a magnetic flocculation device, a disk drive reoxygenation device and a floating bed device, wherein the water absorption device is used for extracting deposits of surface layer sediment of eutrophic wastewater and interstitial water thereof; the magnetic flocculation device is connected with the water absorption device and used for forming the eutrophic wastewater extracted by the water absorption device into magnetic floccules; one side of the disk drive reoxygenation device is connected with the magnetic flocculation device, and the other side is connected with the floating bed device; the disk drive reoxygenation device is composed of a disk mechanism, a magnetic seed recovery device and a nano microbubble generator; the disk mechanism is used for carrying out magnetic separation on the magnetic floccules to form magnetic sludge; the magnetic seed recovery device is used for recovering magnetic seeds; the nano microbubble generator is used for fusing the purified eutrophic wastewater into a gas-liquid homogeneous stream; and the floating bed device is an aquatic plant ecological floating bed.

Owner:SCIMEE TECH & SCI CO LTD

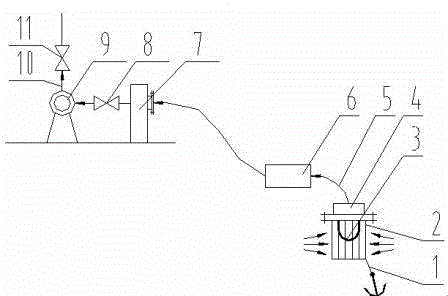

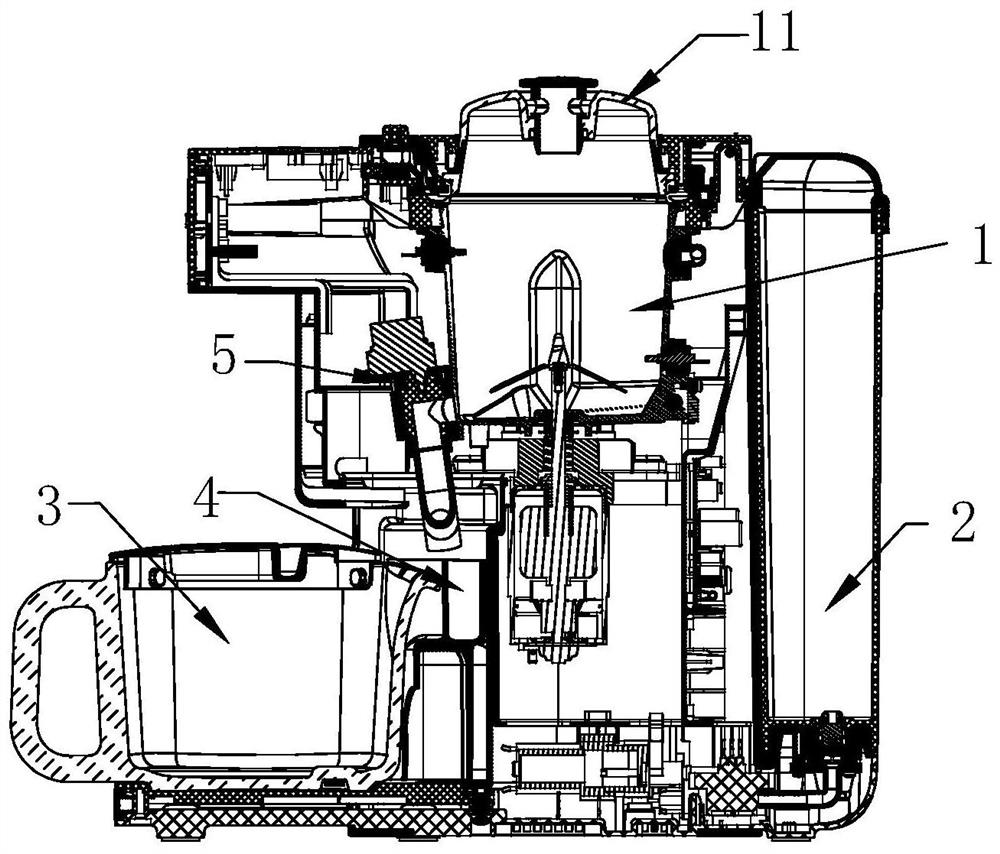

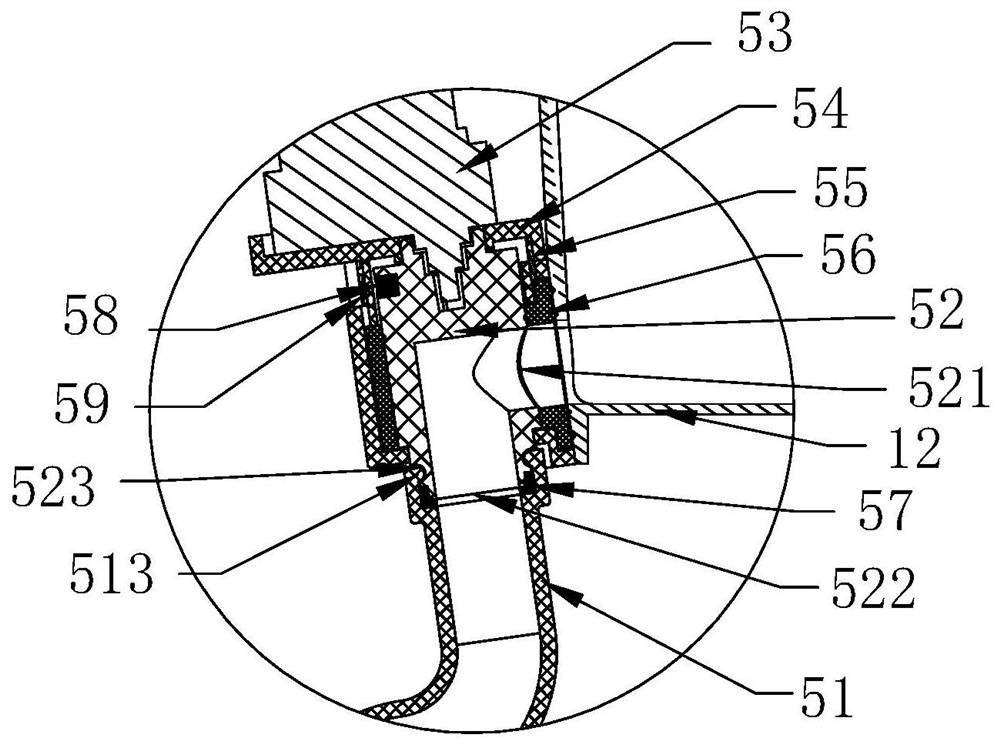

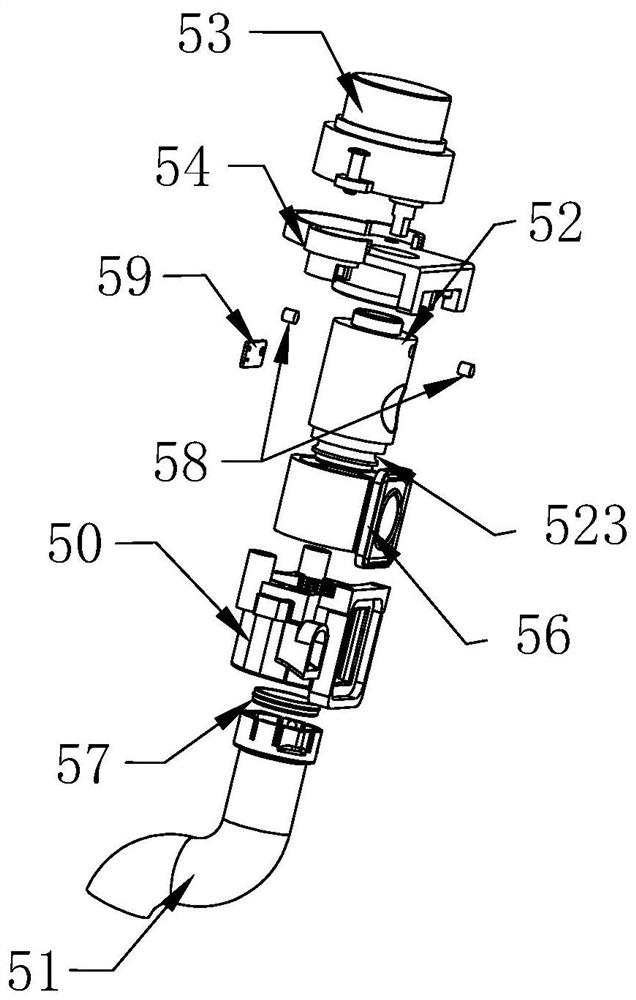

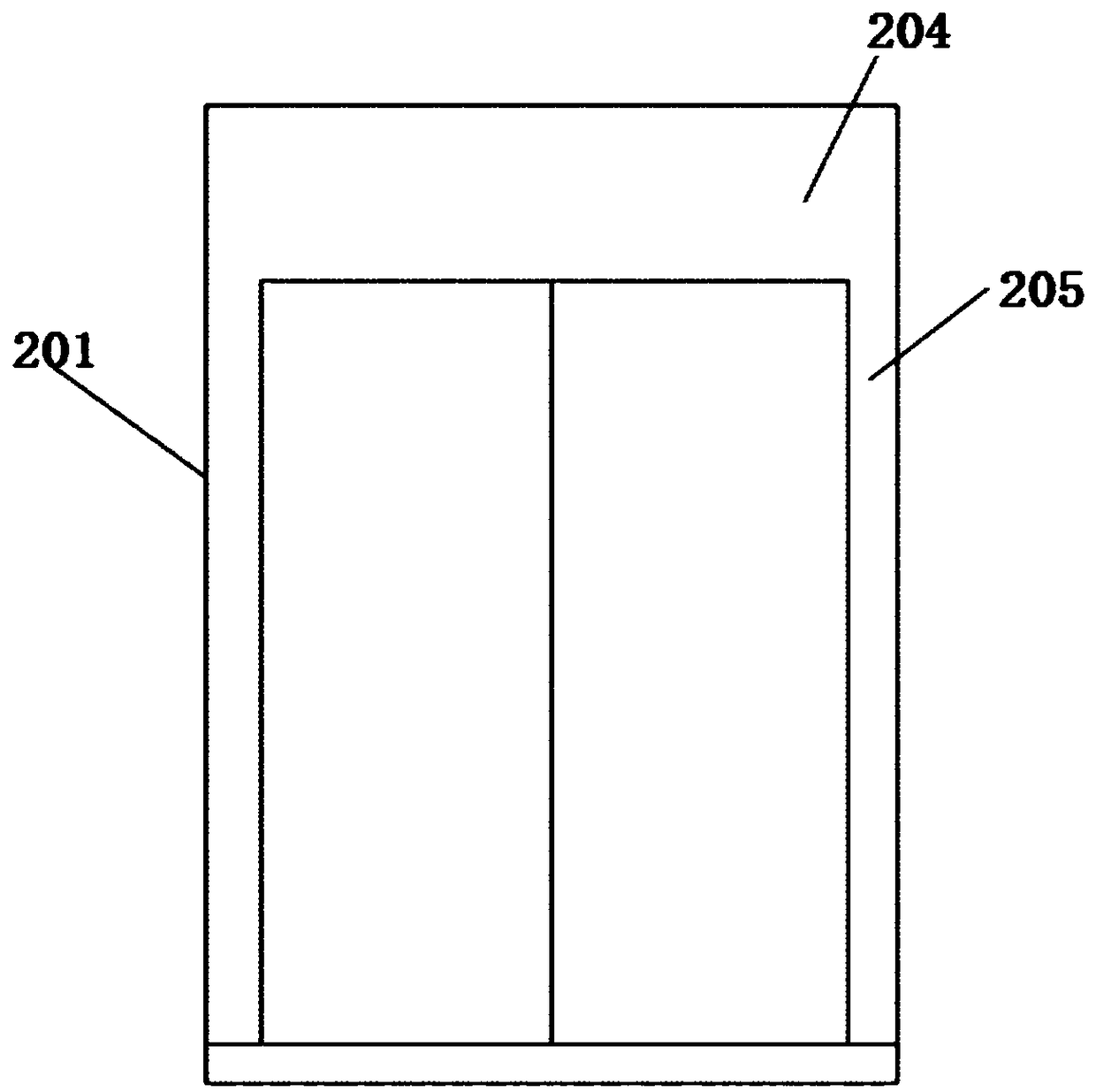

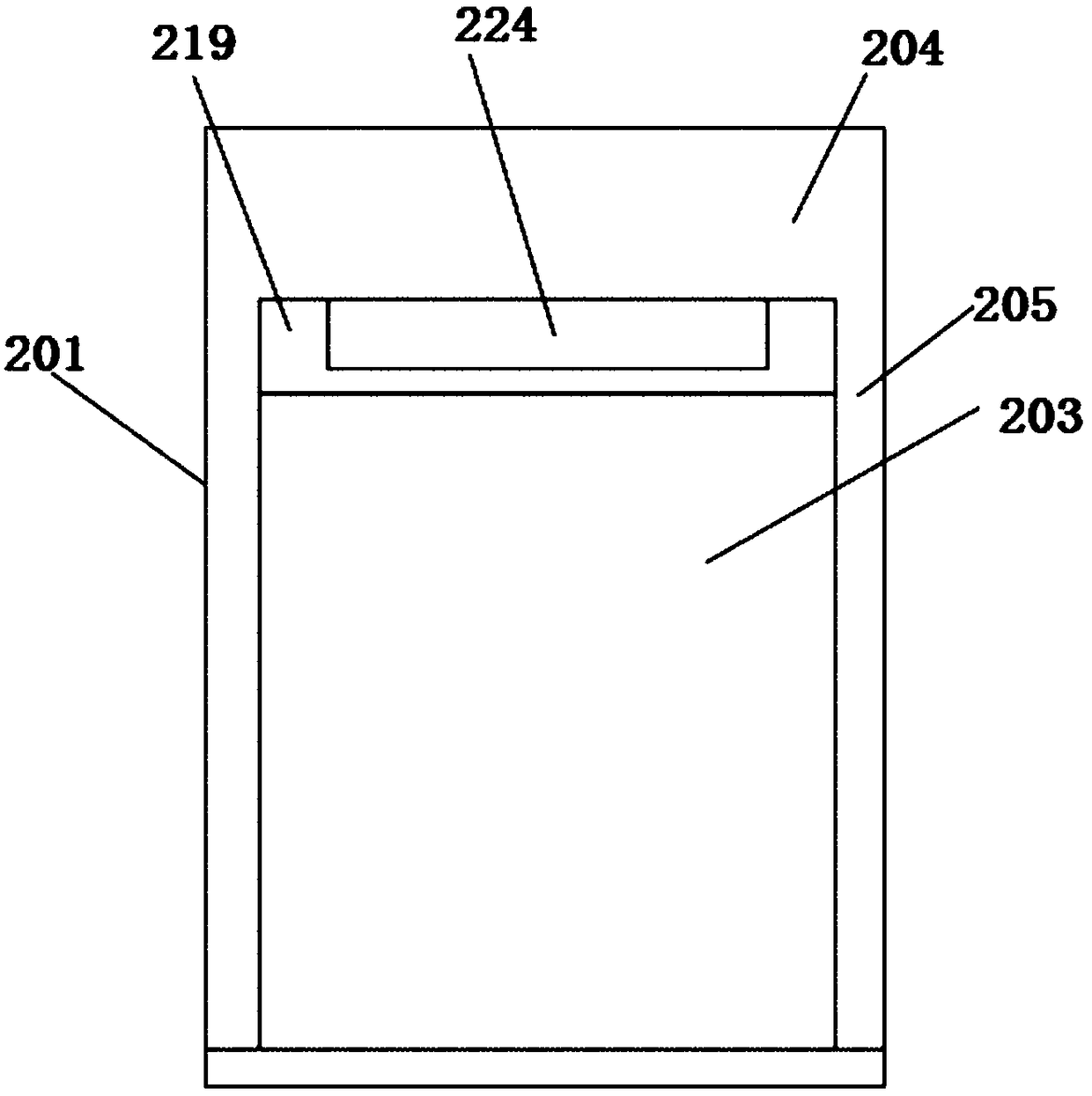

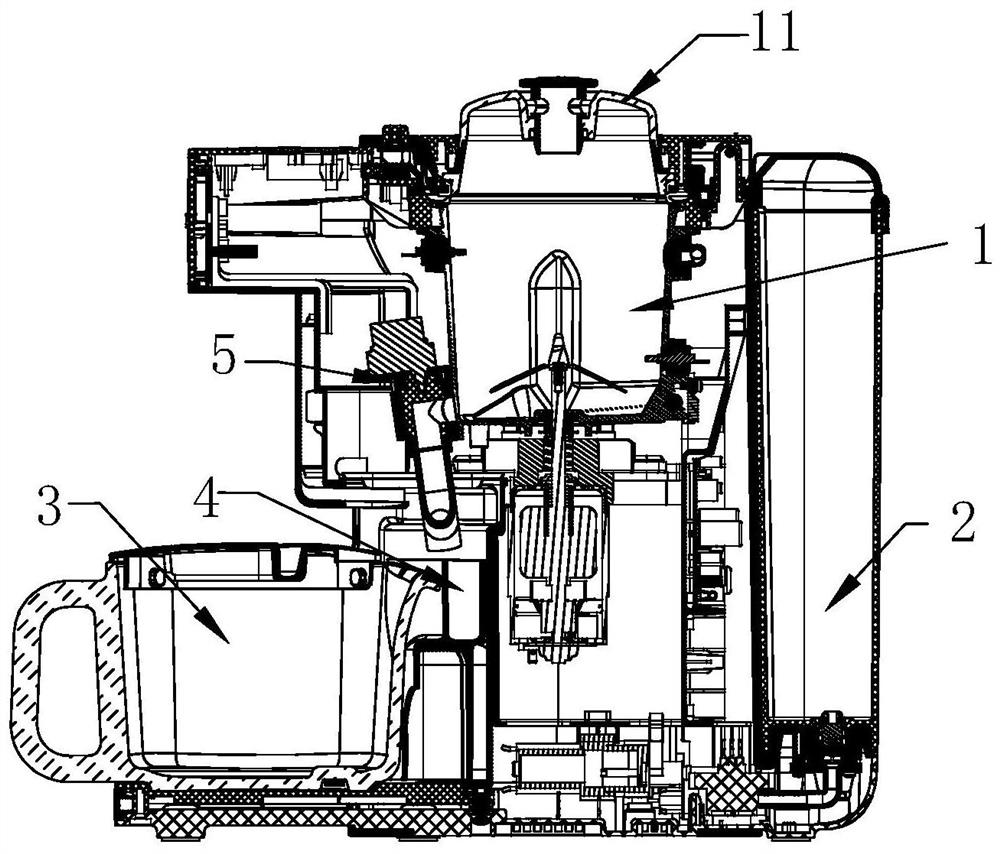

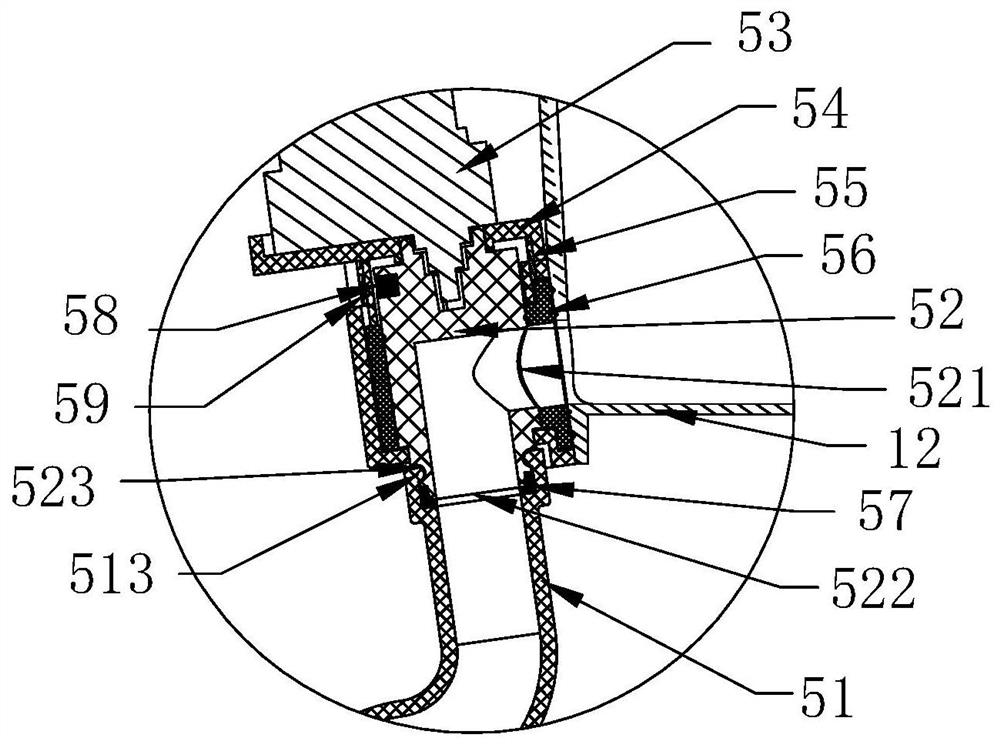

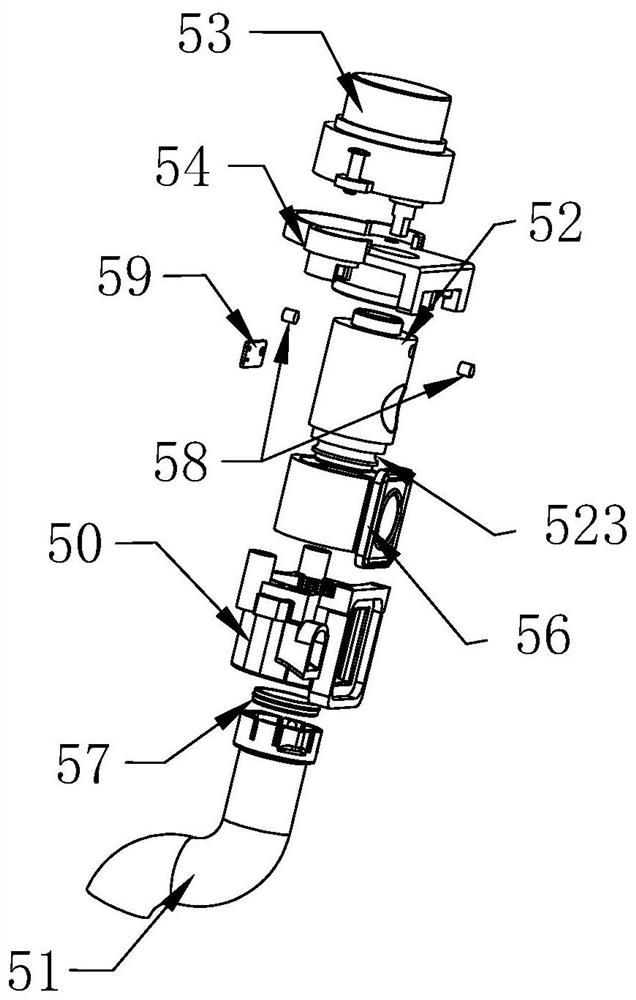

Food processor

ActiveCN113040630AReduce drive gearLow costKitchen equipmentClimate change adaptationElectric machineryRotary valve

The invention relates to a food processor which comprises a cup body used for food processing, a thick liquid receiving cup used for containing food and a waste water box used for collecting waste water, a thick liquid discharging rotary valve is arranged on the cup body, and the thick liquid discharging rotary valve discharges the food or waste water in the cup body into the thick liquid receiving cup or the waste water box. The food processor is characterized in that the thick liquid discharging rotary valve comprises a thick liquid discharging pipe, a valve element and a driving device for driving the valve element, a through hole is formed in the valve element and communicated with the thick liquid discharging pipe and the cup body, and the valve element drives the thick liquid discharging pipe to be switched between the position of the thick liquid receiving cup and the position of the waste water box. The valve element is used for driving the thick liquid discharging pipe to rotate to select the corresponding thick liquid discharging position, the step that a rotary valve motor directly drives the position of the thick liquid discharging pipe is omitted, corresponding driving gears are reduced, corresponding cost is reduced, meanwhile, accessories are reduced, correspondingly faults caused by failure of the accessories and the matching problem of the accessories disappear, and and the reliability of the product is improved.

Owner:JOYOUNG CO LTD

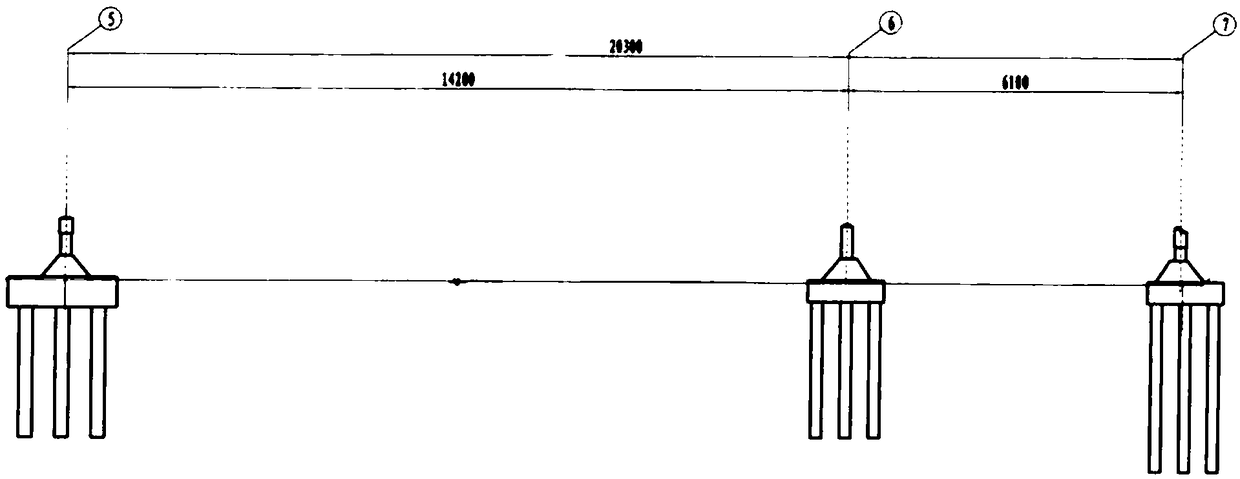

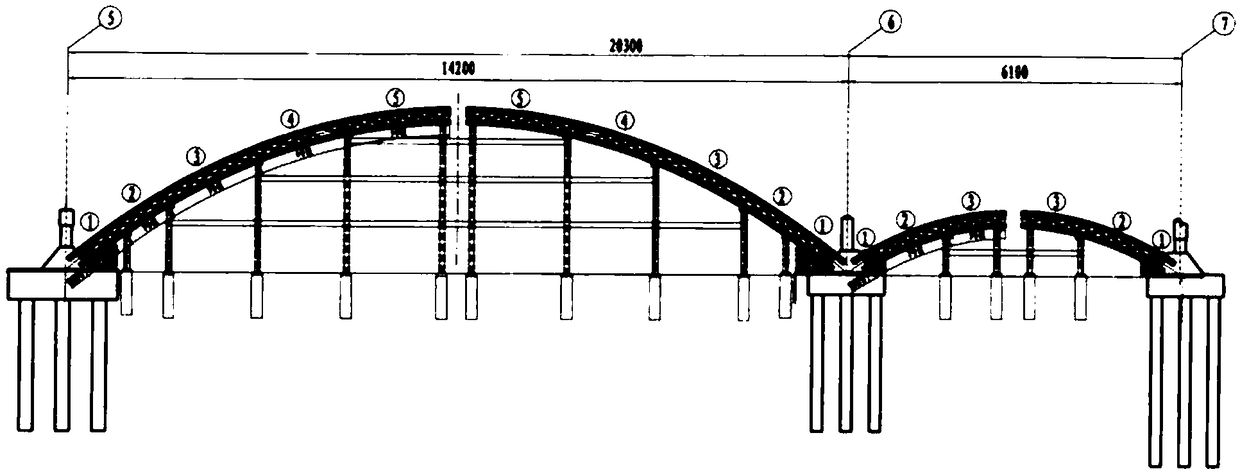

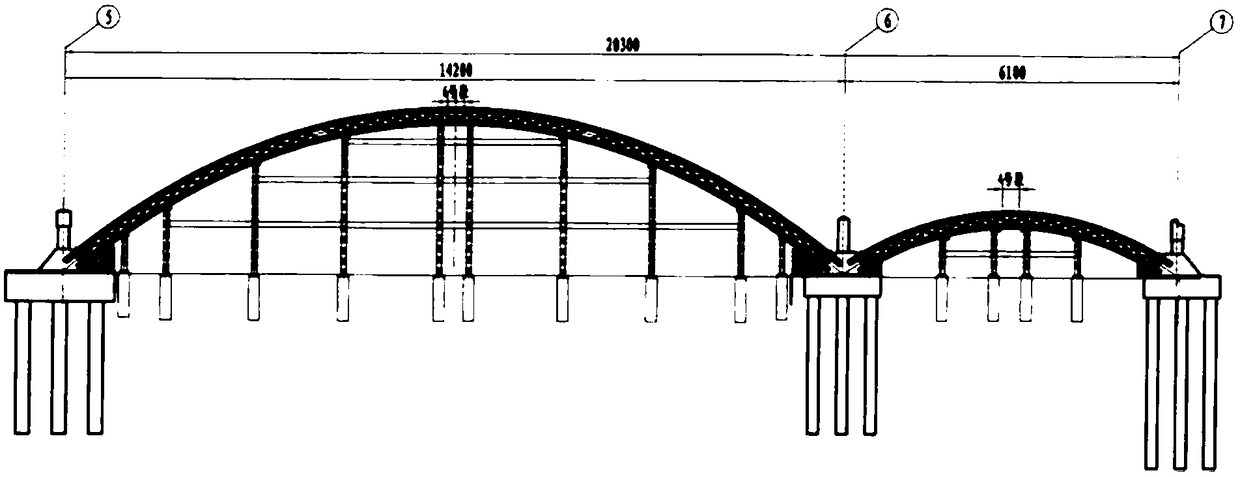

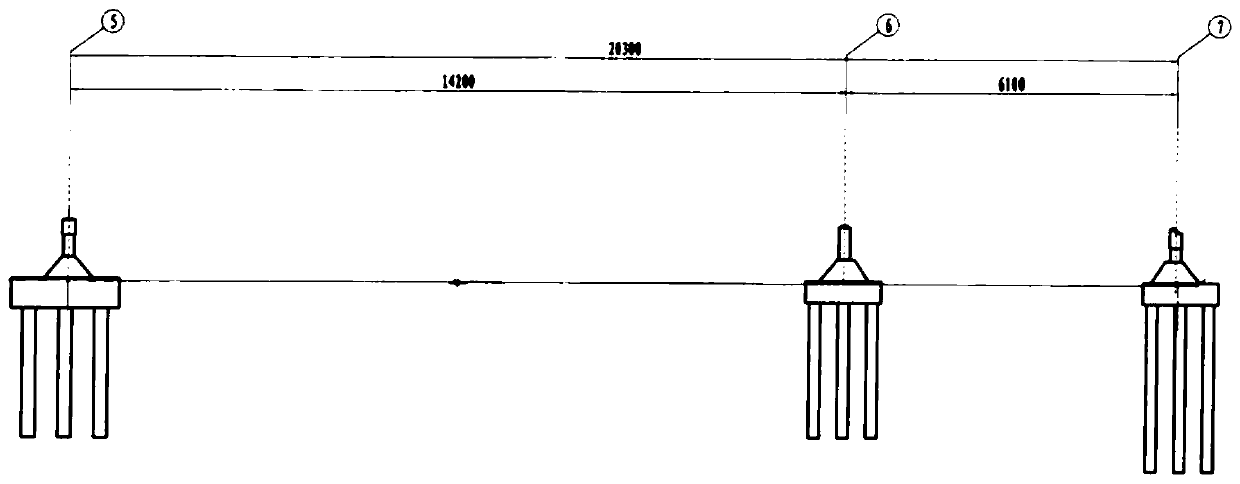

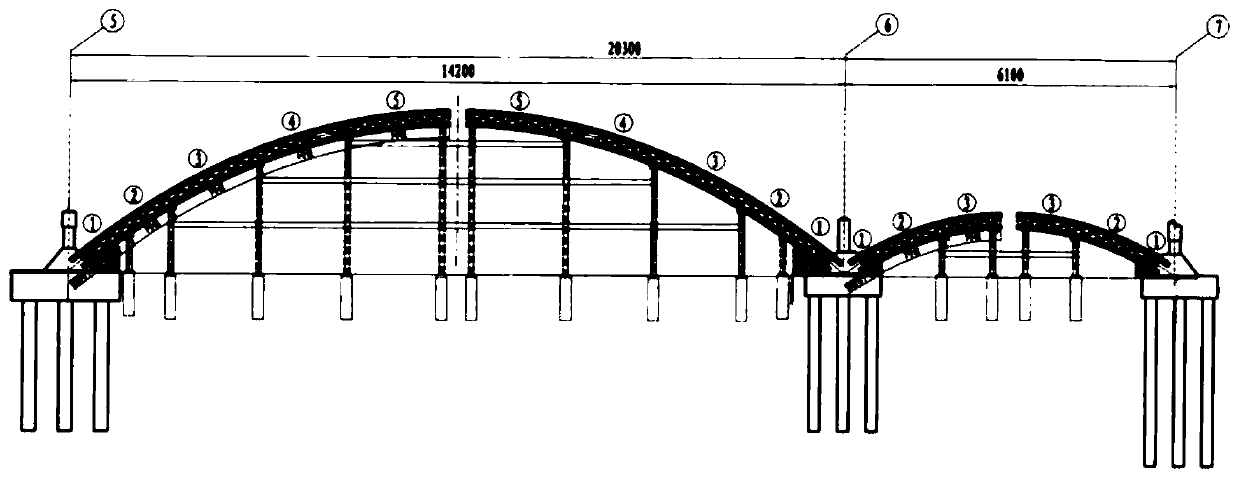

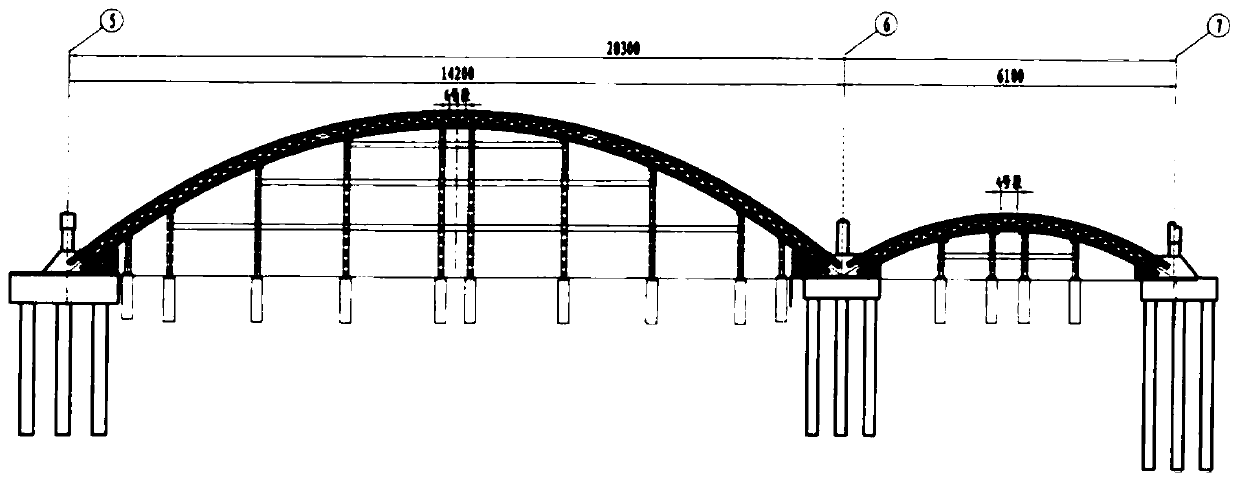

Construction method of steel curved arch bridge

ActiveCN108708265AControl stressControl deformationBridge erection/assemblyArch-type bridgeBridge deckPre embedding

The invention discloses a construction method of a steel curved arch bridge and belongs to the technical field of bridge construction. The construction method comprises the following specific steps that S1, foundation pile construction is conducted, specifically, a trestle bridge and a platform are constructed; S2, a main arch frame is constructed, specifically, arch foot section pre-embedded steel arch rib positioning steel members are mounted; S3, vault supporting mounting is constructed, specifically, closure section steel pipes are mounted, and after the line type is adjusted, steel pipesare welded; S4, pier uprights are mounted, specifically, concrete in lower pipes is symmetrically pumped; S5, a bridge deck support is mounted, specifically, bridge deck slabs are symmetrically mounted on the upstream and the downstream in the axial direction of the bridge from the two ends of a main arch and a subarch in a midspan mode; and S6, bridge deck pavement construction is conducted, specifically, bridge deck pavement auxiliary projects are symmetrically constructed, suspender cable force is copied and adjusted to a design value, steel pipe protective surface paint spraying coating isconducted, and after construction is completed, completed bridge testing and acceptance are conducted. Construction is conducted in strict accordance with the construction scheme and construction rules, control over stress and deformation during arch frame erecting can be guaranteed, and arch bridge midspan high-precision closure is guaranteed.

Owner:武汉精潮钢结构有限公司

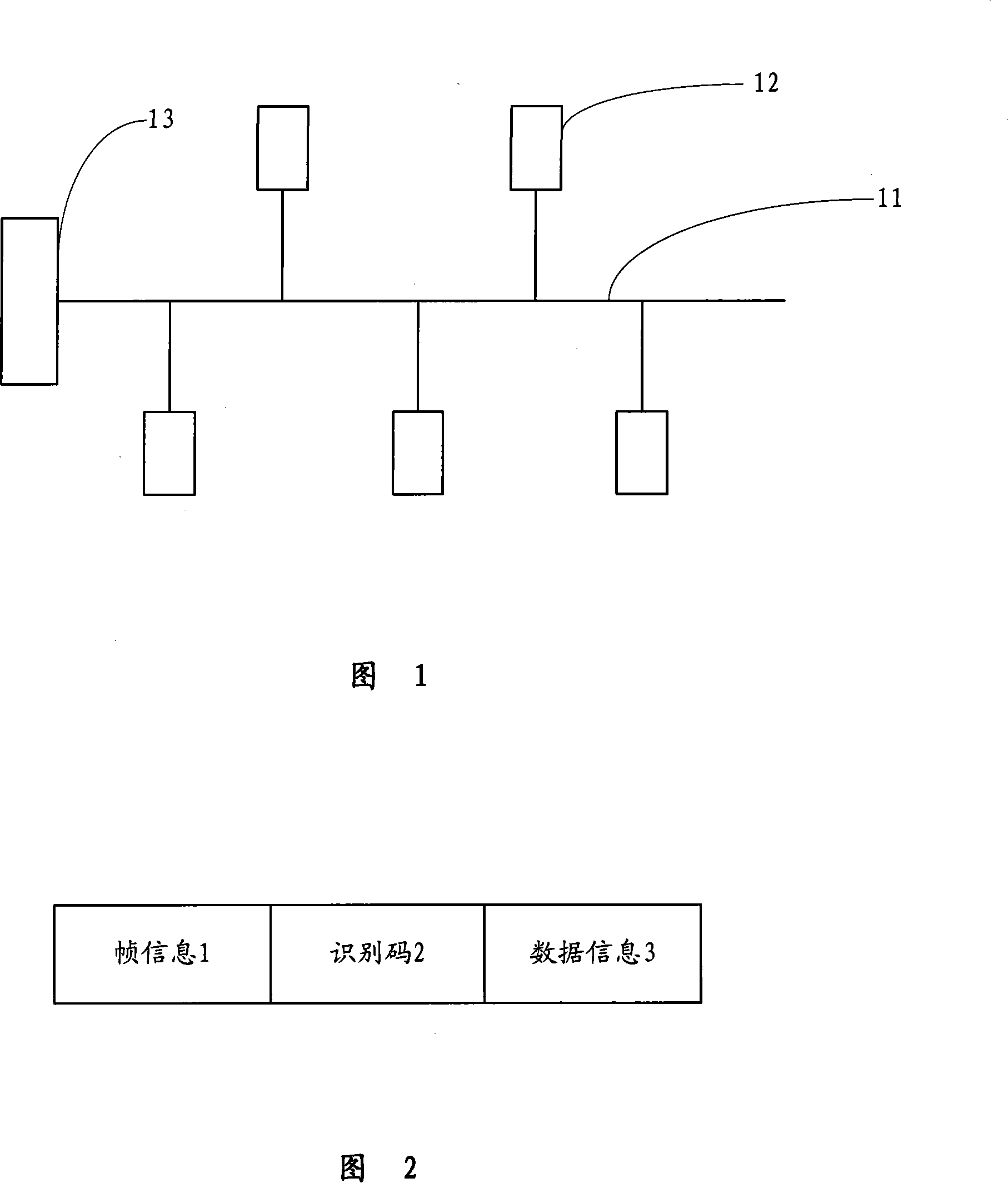

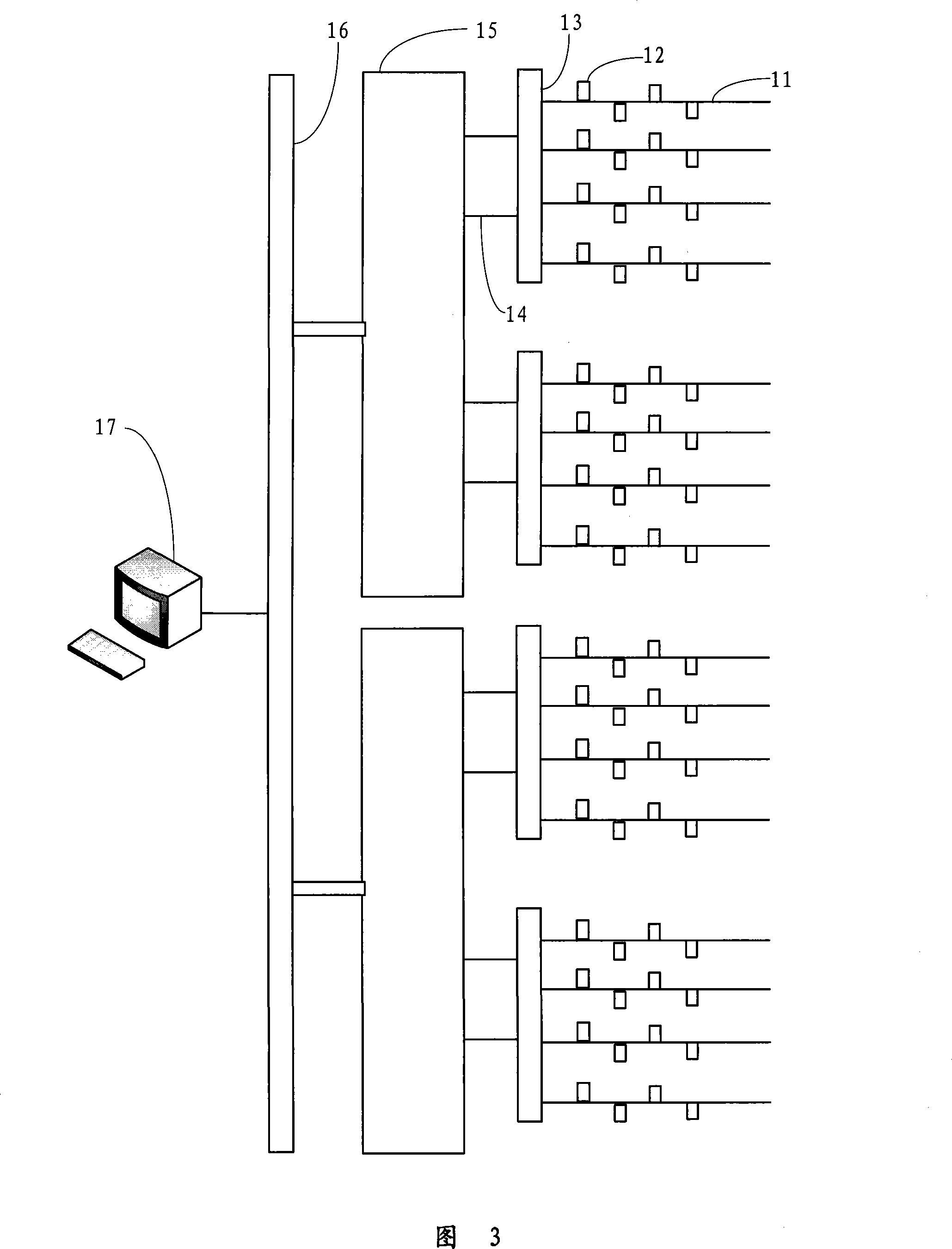

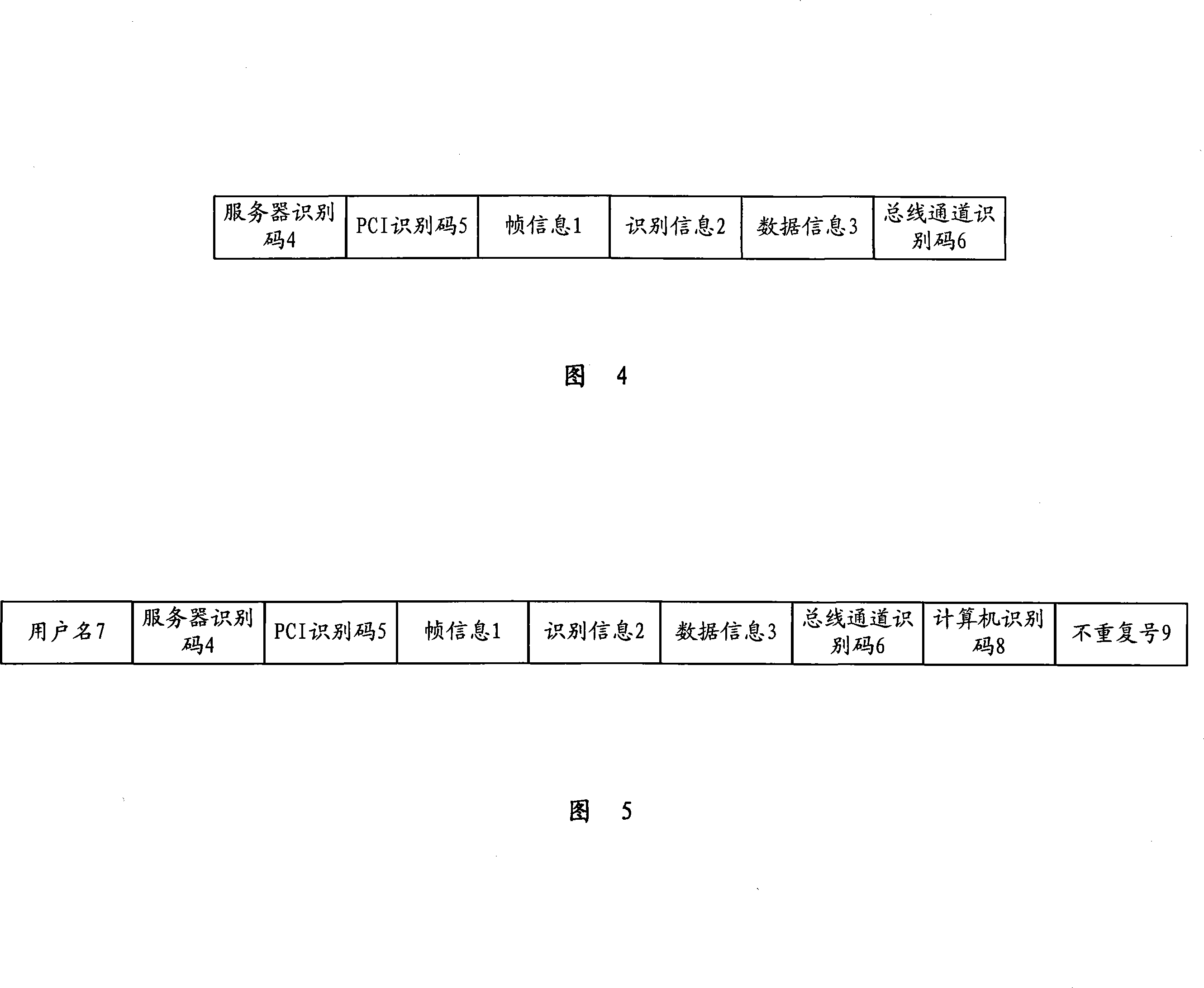

CAN bus network and CAN bus extension method

InactiveCN101159641AMake sureEfficient managementData switching by path configurationTotal factory controlArea networkTerminal equipment

The invention provides a controller area network (CAN) bus network and a CAN bus extension method. The CAN bus network comprises but controllers, a group of terminal equipments connected through a but channel, a server connected with a plurality but controllers, and a equipment management terminal connected with a plurality of servers, wherein the server is provided with a first-level extender. The CAN but extension method comprises that the equipment management terminal sends a downlink communication frame containing a first-type identification code to a specific terminal equipment, and when the downlink communication frame is sent to the first-level extender, the first-level extender deletes the first-type identification code in the downlink communication frame; and the terminal equipment sends an uplink communication frame to the equipment management terminal, and when the uplink communication frame is sent to the first-level extender, the first-level extender adds the first-type identification code in the uplink communication frame. The invention can connect a large number of terminal equipments on the CAN but network, and assure that the terminal equipments can both accurately communicate with the equipment management terminal.

Owner:EASTCOMPEACE TECH

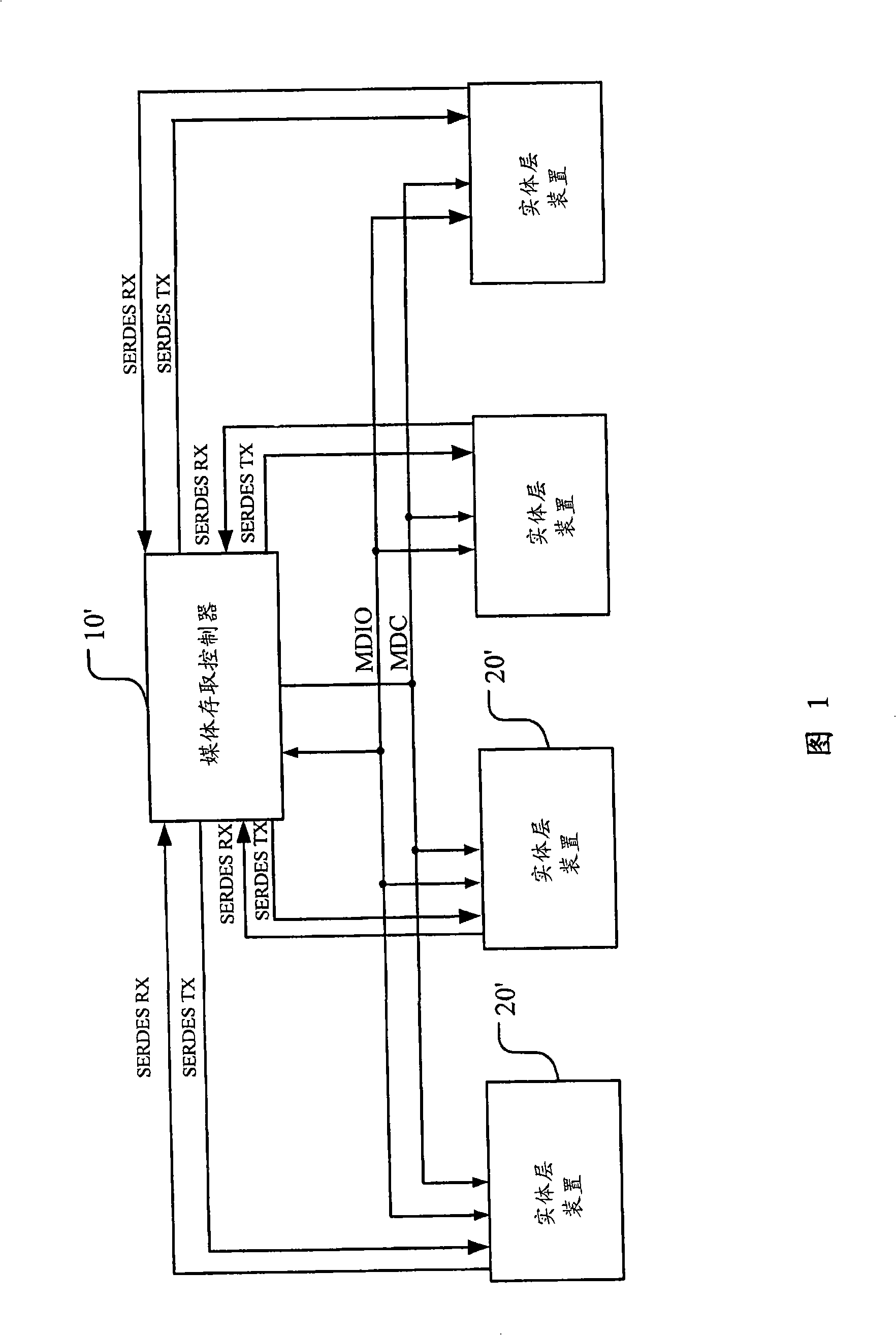

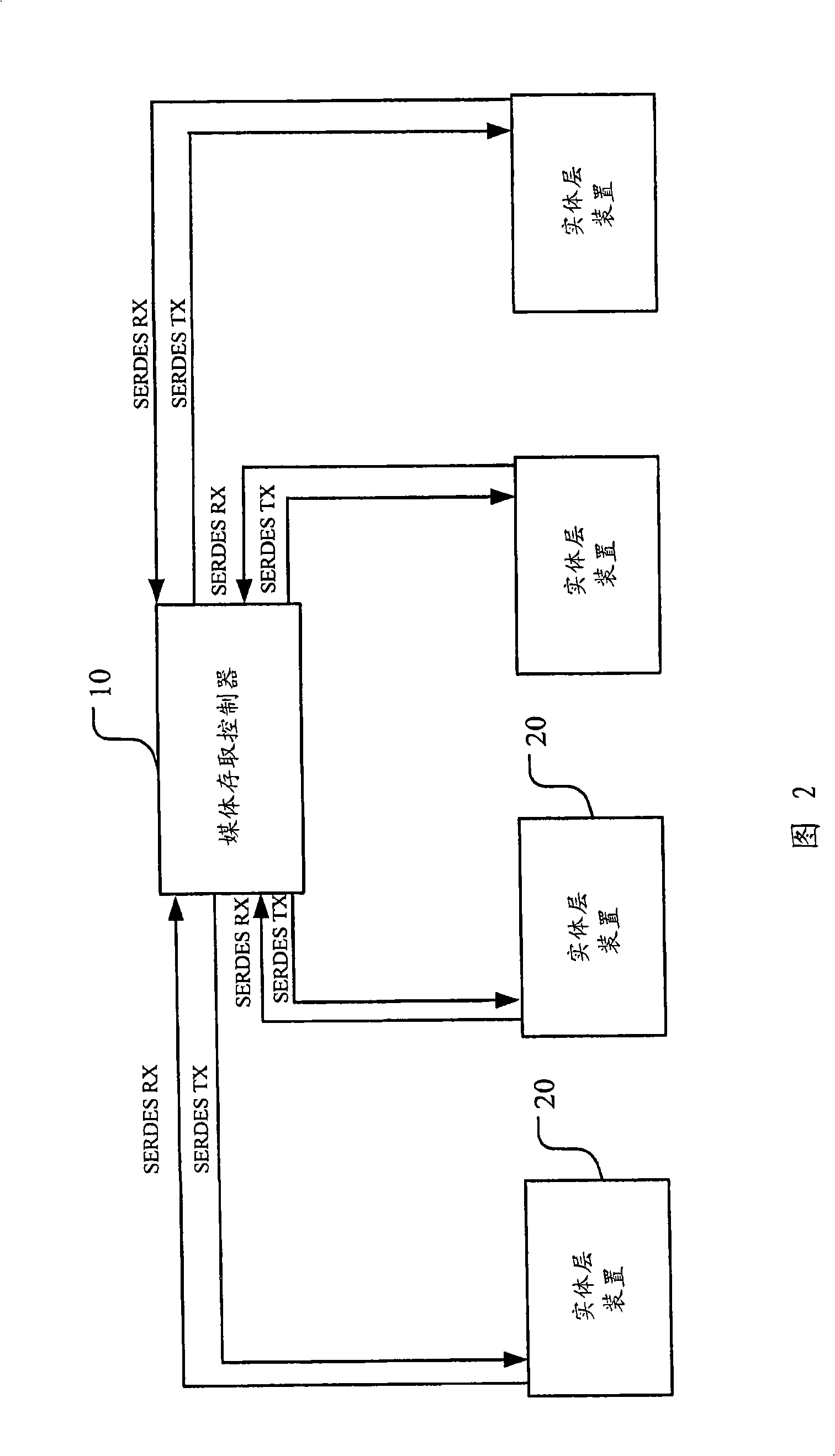

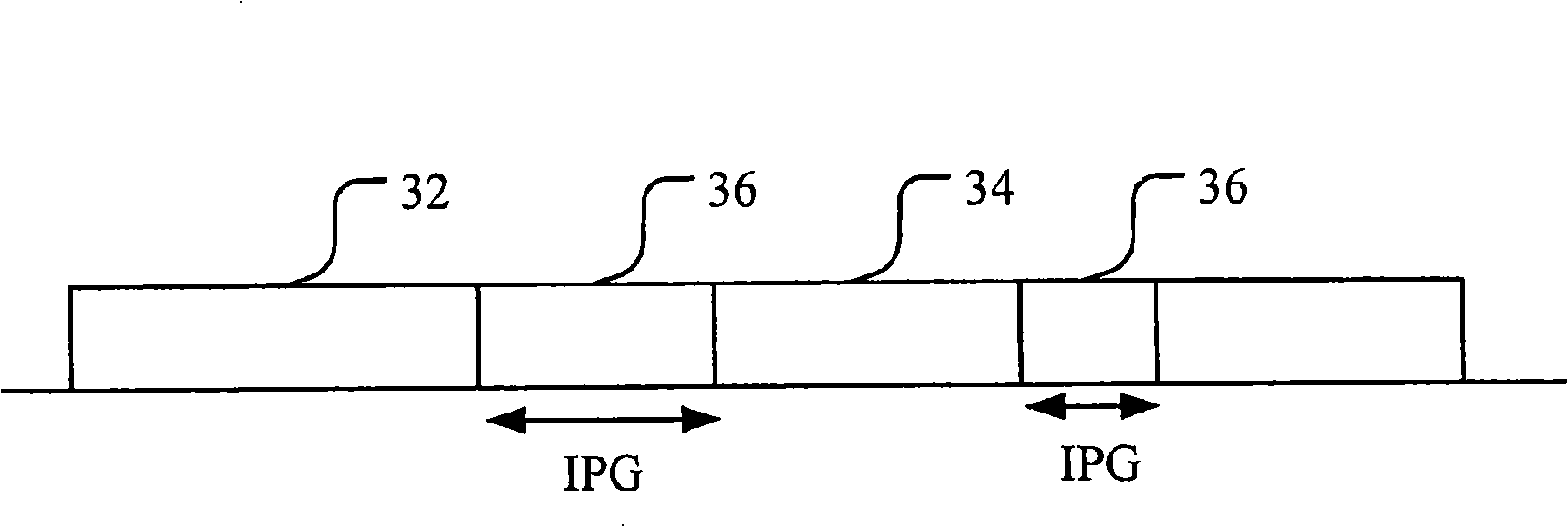

Network apparatus and transmission method thereof

ActiveCN101304296AMake sureSimplify the transmission circuitError prevention/detection by using return channelData switching networksComputer hardwareProcessor register

The invention relates to a network device and a transmission method thereof. The network device comprises a first network device and a second network device. The first network device generates a sequential command data according to at least one command, and the first network device inserts the sequential command data into the clearance between the packet data and sends to the second network device when outputting the packet data to the second network device. The second network device accesses the data in a register of the second network device according to the received sequential command data. The network device and the transmission method of the invention can simplify the transmission circuit, improve heat dissipation efficiency, ensure correct transmission signals and read the register data correctly.

Owner:REALTEK SEMICON CORP

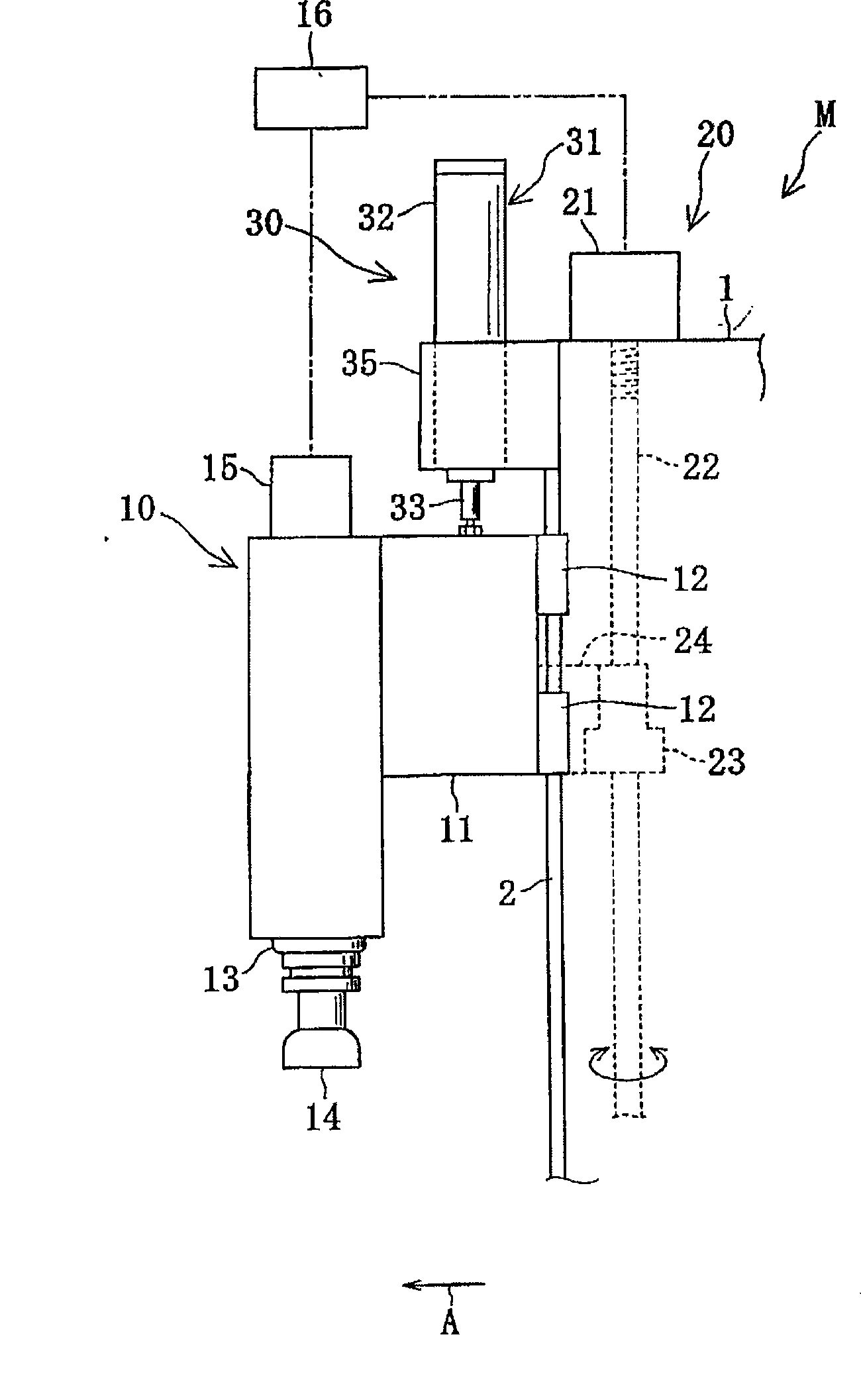

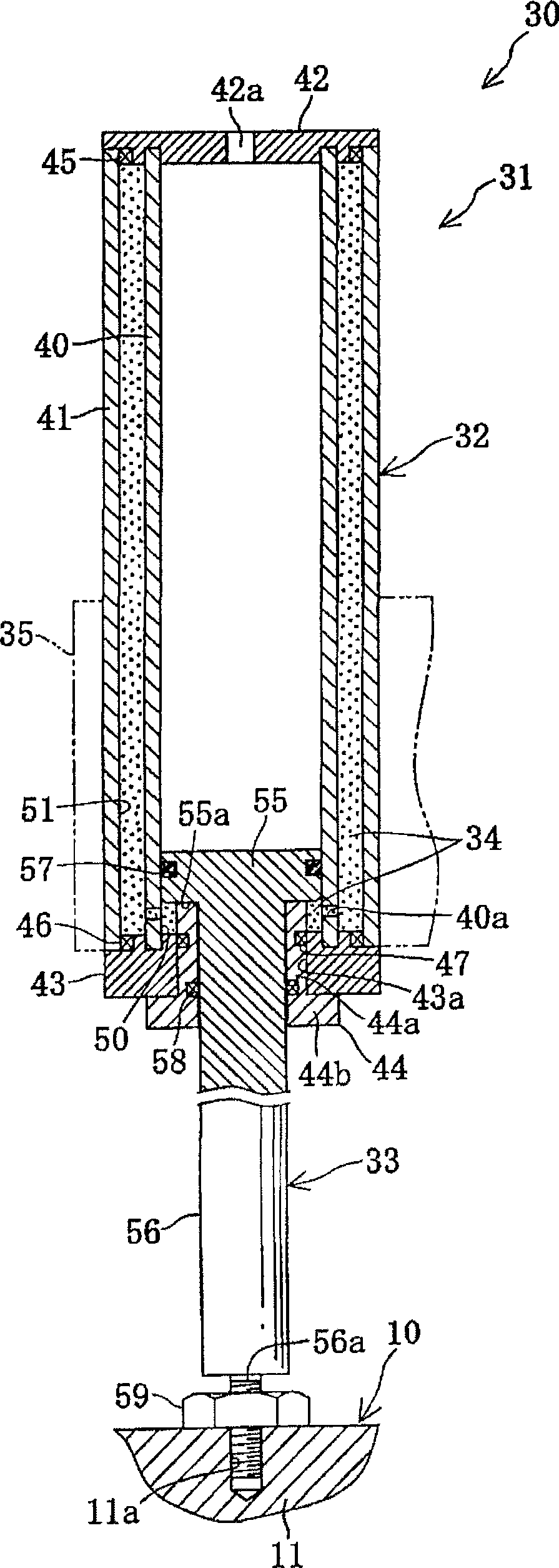

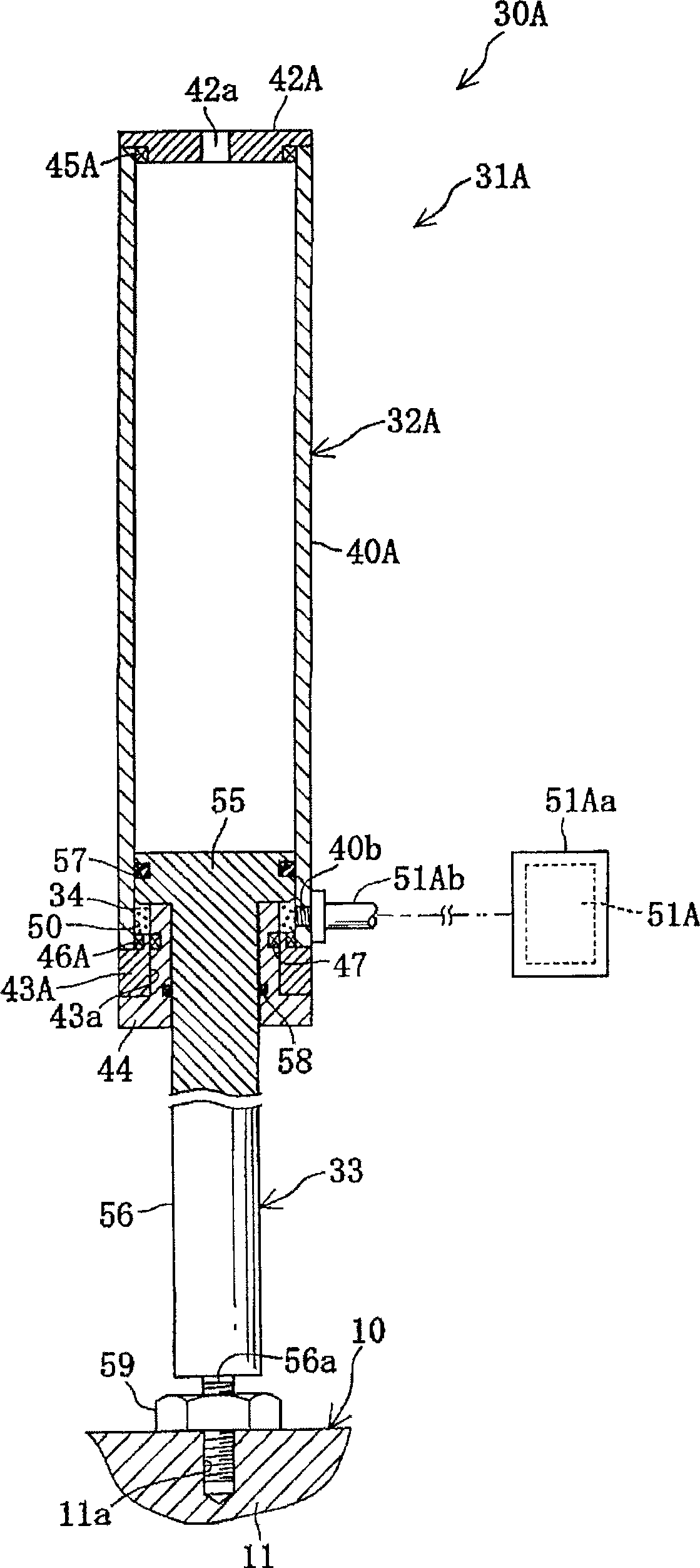

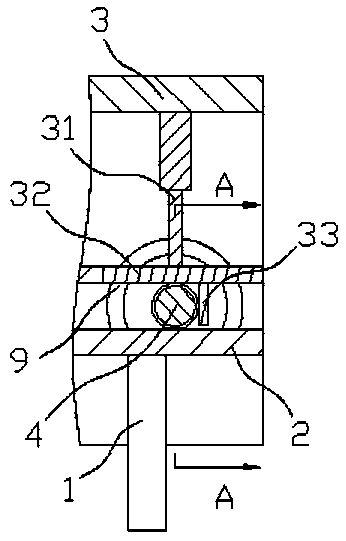

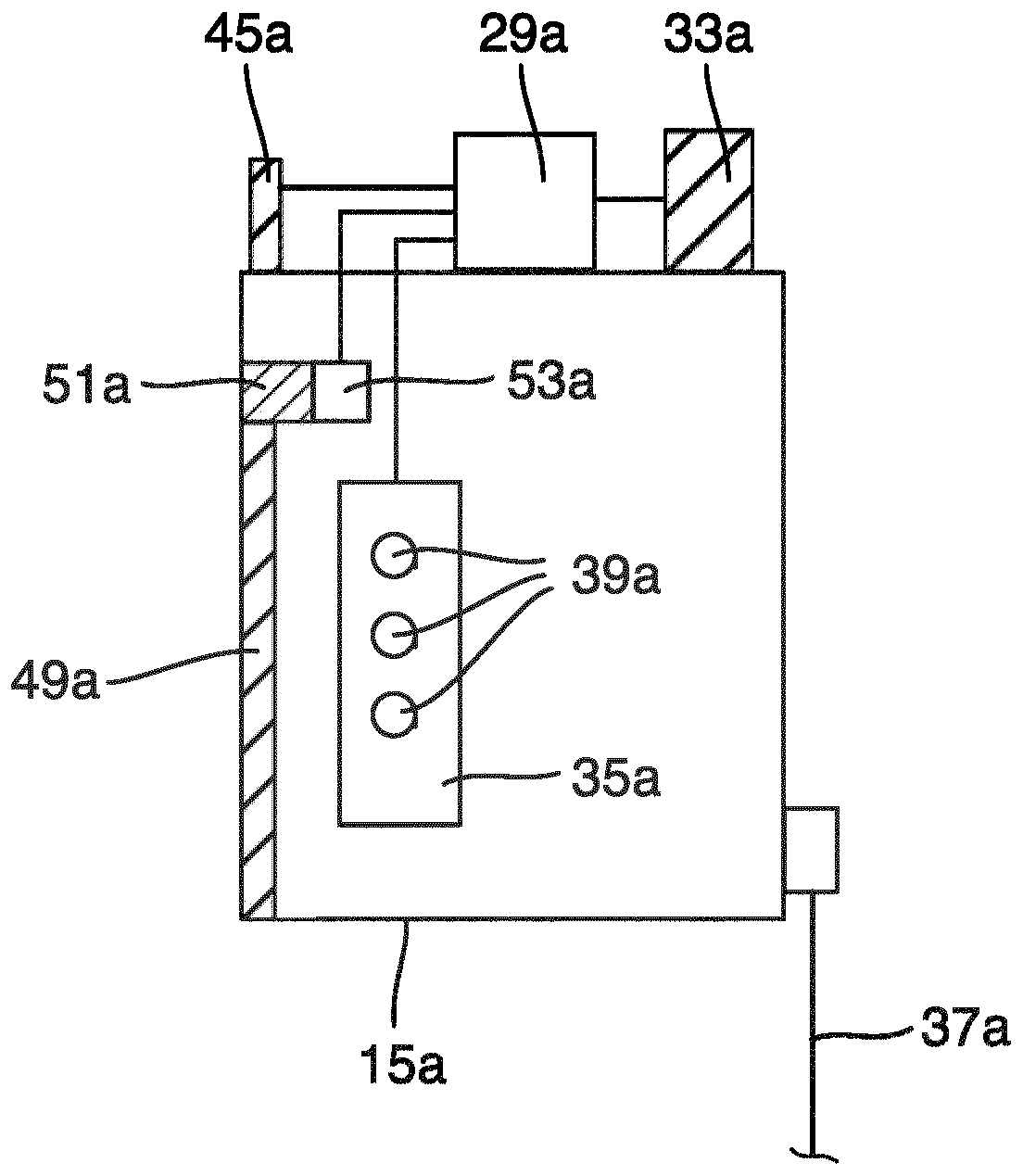

Main shaft balance device for toolroom machine

InactiveCN101394970AEnsure degrees of freedomEffective supportLarge fixed membersBoring/drilling componentsPull forceMiniaturization

A machine tool main spindle balancer that stably pulls and urges a main spindle unit upward to reliably and effectively reduce a load for lifting a means for lifting the main spindle unit, that can be easily applied to existing machine tools, that is excellent in durability and is downsized, and that can be constructed in a simple structure to make the balancer advantageous in production costs. The main spindle balancer (30) has a gas spring (31) having a cylinder body (32), a rod (33), and compressed gas. The gas spring (31) is placed above the main spindle unit (10). The lower end of the rod (33) is connected to the main spindle unit (10) so that the rod (33) can pull and urges the main spindle unit (10) upward by urging force acting on the rod (33) of the gas spring (31). The urging force by the gas spring (31) reduced a load on a lifting mechanism (20).

Owner:PASCAL ENG

Quarantine method of sugarcane seedlings to be exported

InactiveCN101906483AEnsure safetyMake sureMicrobiological testing/measurementHorticultureDiseaseSeedling

A quarantine method of sugarcane seedlings to be exported is used for quarantining the provided sugarcane varieties / materials to be exported and mainly comprises the following steps: an isolation greenhouse and a planting bucket are firstly cleaned to be sanitary before quarantining, and then disinfected by a bactericide and an insecticide and finally sterilized by an ultraviolet lamp for 30min; and in the whole quarantine period, the planted sugarcanes are checked every 1-2 months and the newly planted seed stems can be exported if the diseases are negative after complete treatment and detection. The method is characterized in that the materials to be exported are soaked in the hot water at 50+0.5 DEG C for 30min, the two ends of the sugarcane stems are dipped for a while in the paraffin oil with low melting point, marker pens are directly used for writing the names of the varieties (strains) on the seed stems and labels are attached to the seed stems, the sugarcane stems are wrapped by dry paper and the seed stems are sent in shortcut.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI

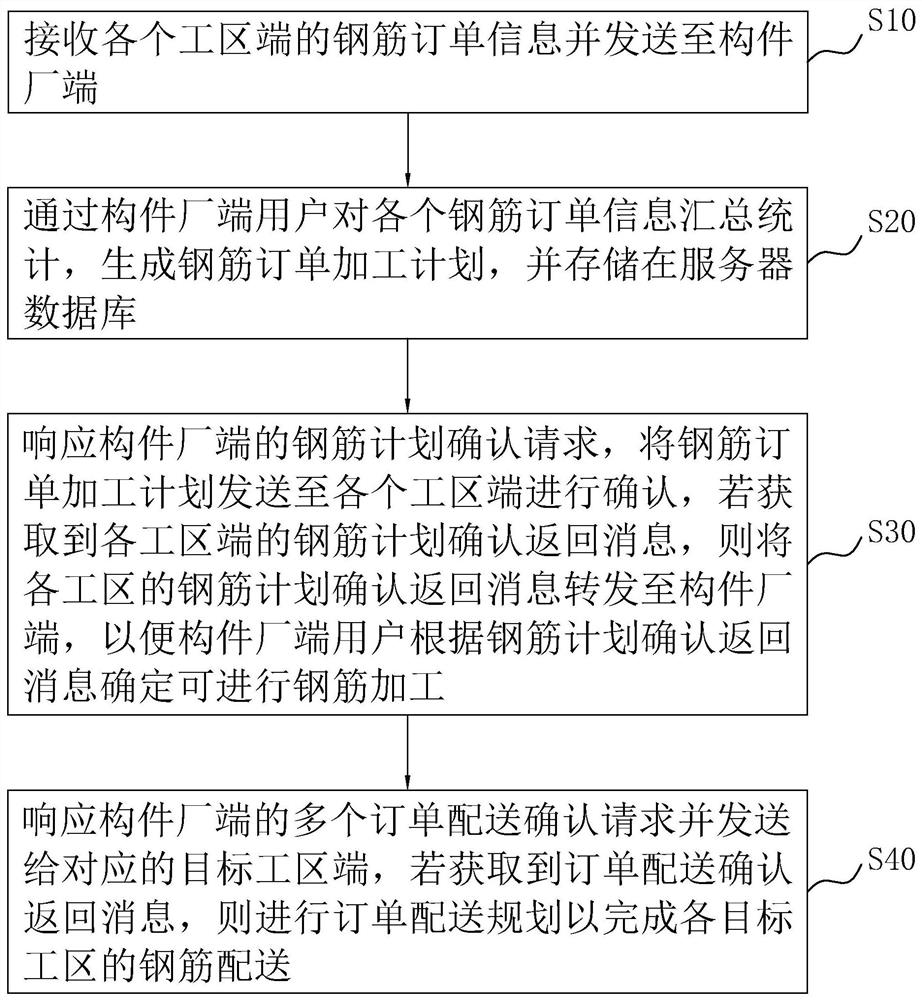

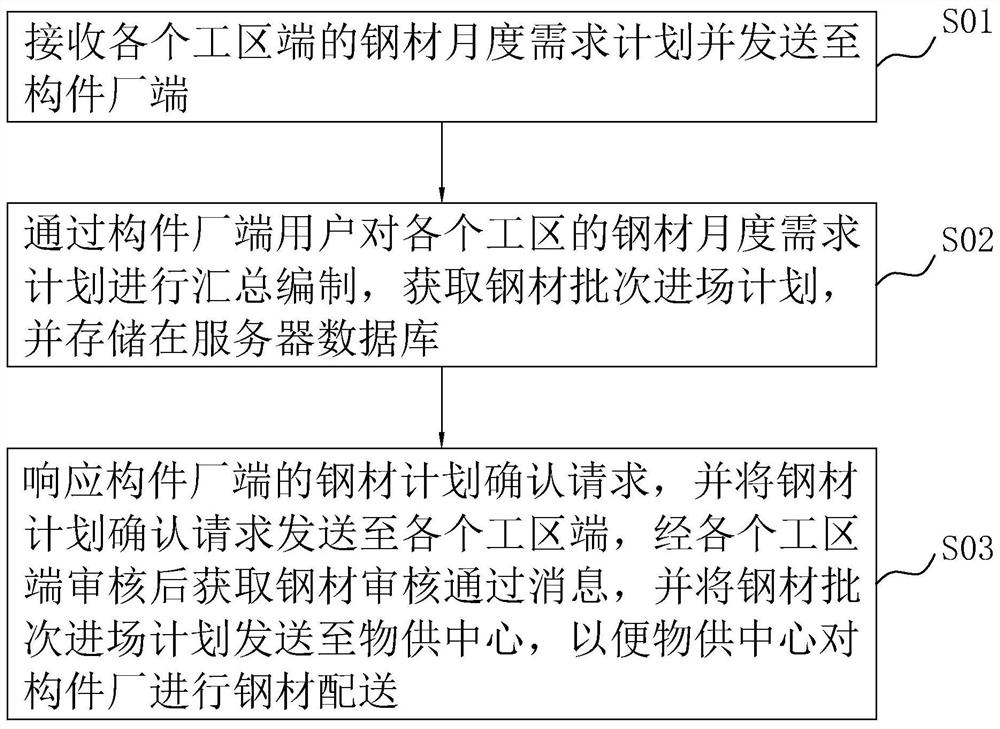

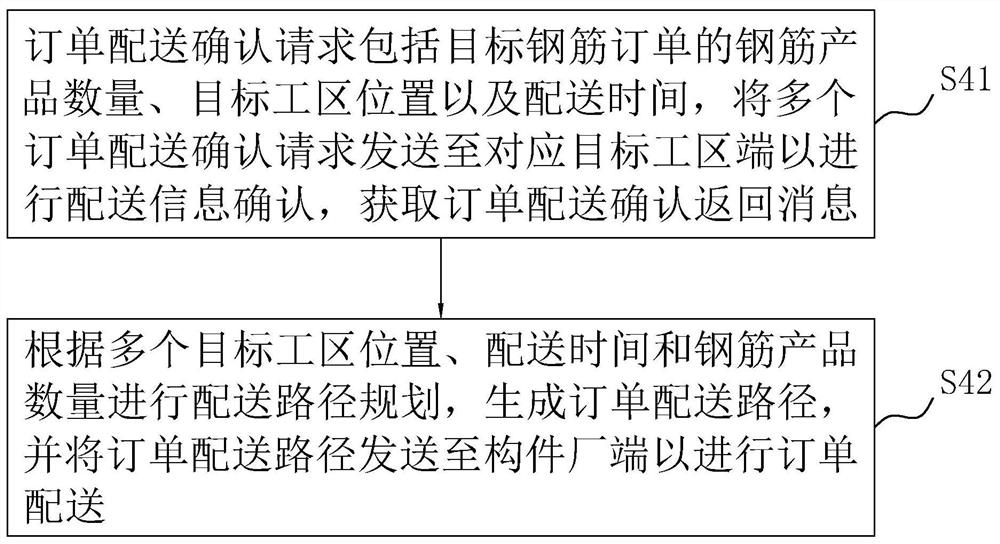

Reinforcing steel bar centralized processing and distribution method, system and device and medium

ActiveCN112288357AImprove scheduling abilityImprove inventory capacityOffice automationResourcesDistribution methodOrder processing

The invention relates to a reinforcing steel bar centralized processing and distribution method, system and device and a medium. The method comprises the steps: receiving steel bar order information of all work area ends and sending the same to a component factory end; summarizing and counting the rebar order information through a component factory end user to generate a rebar order processing plan; in response to the steel bar plan confirmation request of the component factory terminal, sending the steel bar order processing plan to each work area terminal for confirmation; if a steel bar plan confirmation return message of each work area terminal is obtained, forwarding the steel bar plan confirmation return message of each work area to the component factory terminal, wherein a componentfactory-side user determines that steel bar machining can be performed according to the steel bar plan confirmation return message; responding to a plurality of order delivery confirmation requests of the component factory side, sending the requests to the corresponding target work area sides; if an order delivery confirmation return message is obtained, carrying out order delivery planning to complete steel bar delivery of each target work area. Via the reinforcing steel bar centralized processing and distribution method, the machining efficiency and the machining quality of the steel bar component can be improved, and meanwhile the steel bar machining cost is reduced.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

Lithium ion battery negative electrode substrate and preparation method thereof

InactiveCN109062281AMake sureImprove confidentialityTemperatue controlElectrical batteryConfidentiality

The invention discloses a lithium ion battery negative electrode substrate and a preparation method thereof. The lithium ion battery negative electrode substrate comprises a negative current collectorand a plurality of tabs welded to the negative current collector. The negative current collector is a copper foil, and a plurality of small holes with diameters of 20-25 [mu]m are drilled on the copper foil material by laser. A control system adopts a controller which is connected with a wireless communication module so as to be connected with a background server. In combination with other structures and preparation methods, the lithium ion battery negative electrode substrate and the preparation method thereof can effectively avoided the defects in prior art: the battery negative electrode is heavy in weight and large in volume, so that the product is heavy in weight and large in compacted thickness, and the background server is placed in the server chassis and easy to be stolen; in sucha case, the equipped electronic lock will be decrypted and the server chassis is opened, the identifier of the monitoring personnel of the vacuum baking intelligent system will be stolen by some unconscious person; and accordingly the confidentiality of the temperature information transmission in the vacuum baking intelligent system will be reduced.

Owner:中安芯界(青岛)新能源科技有限公司

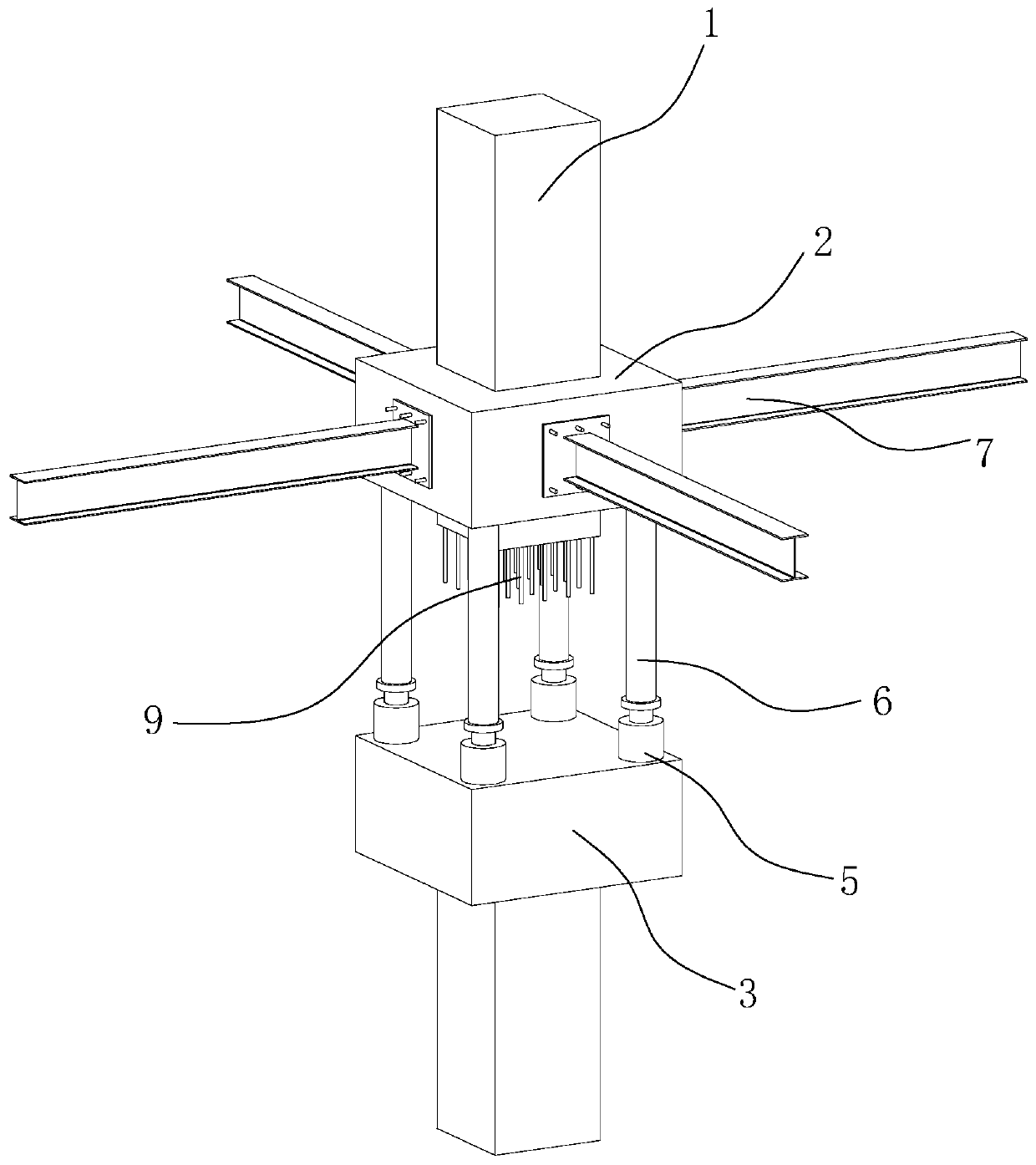

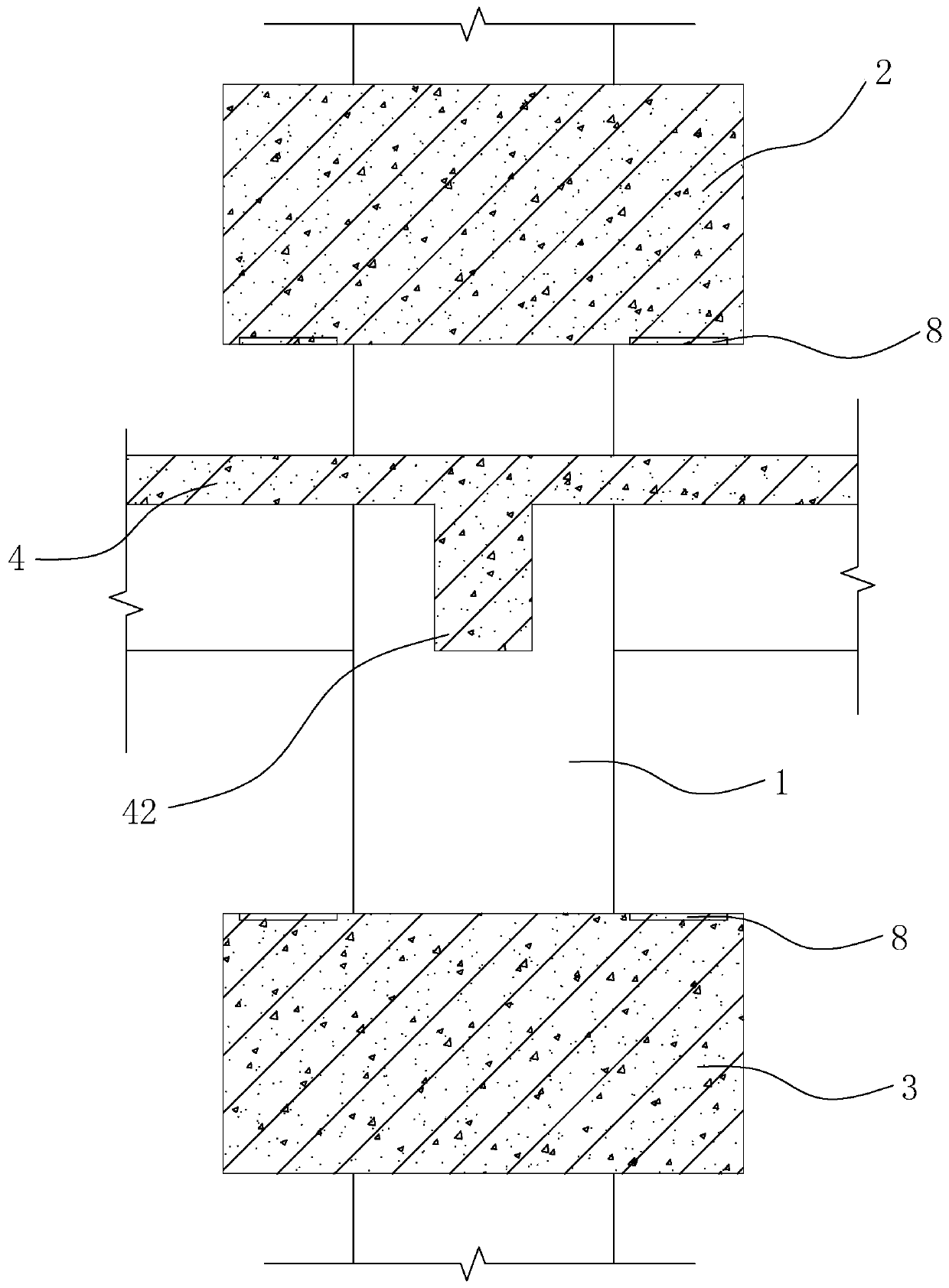

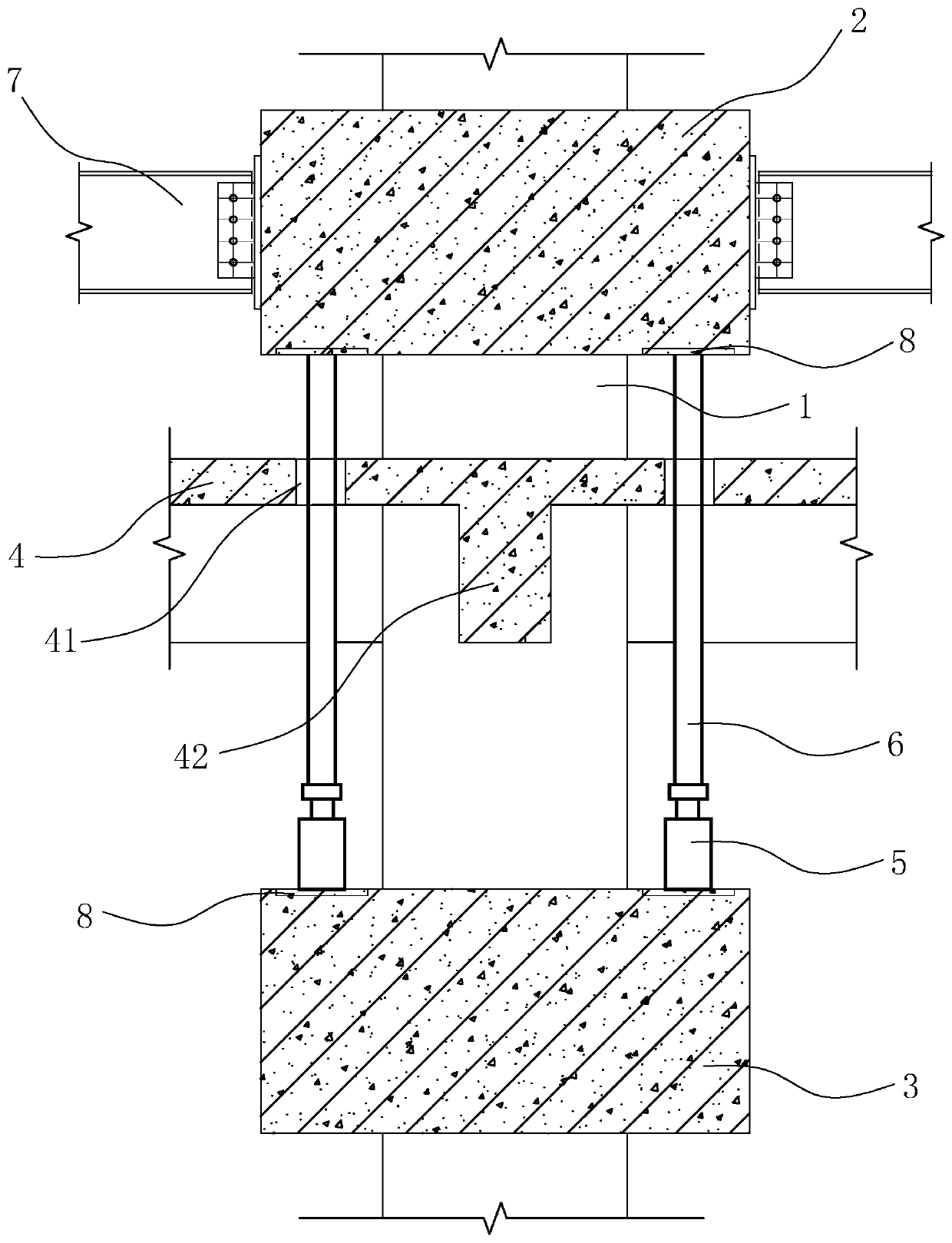

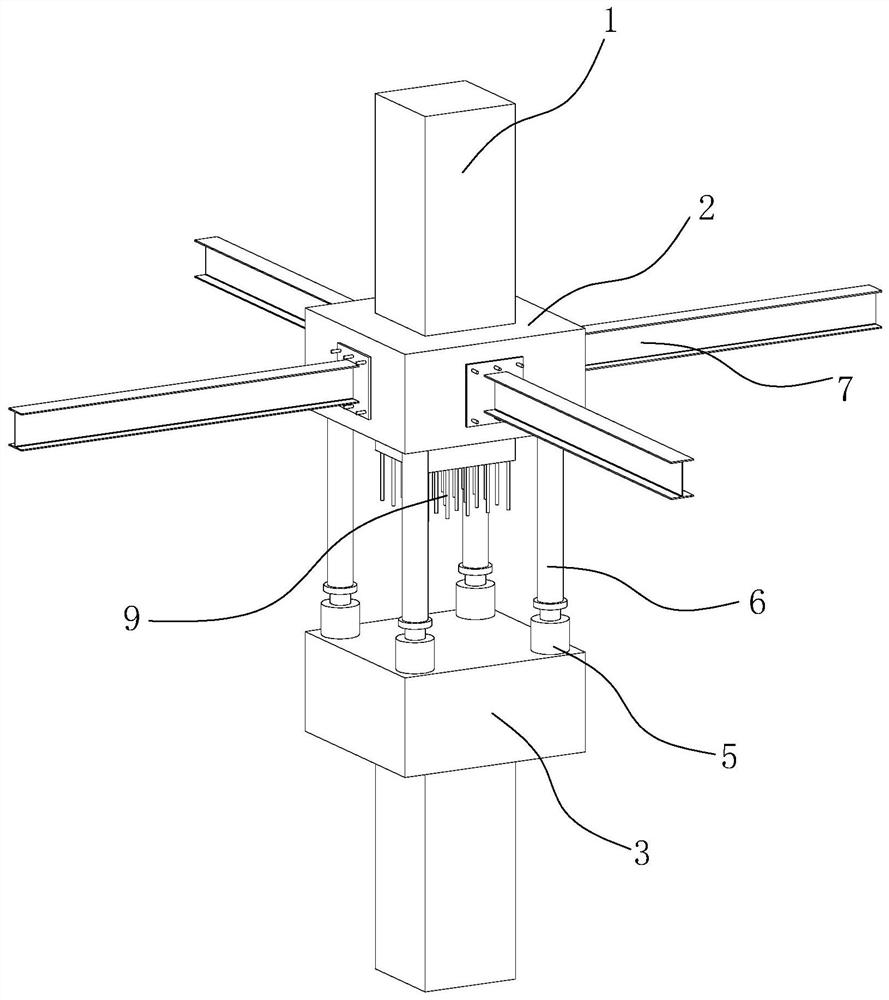

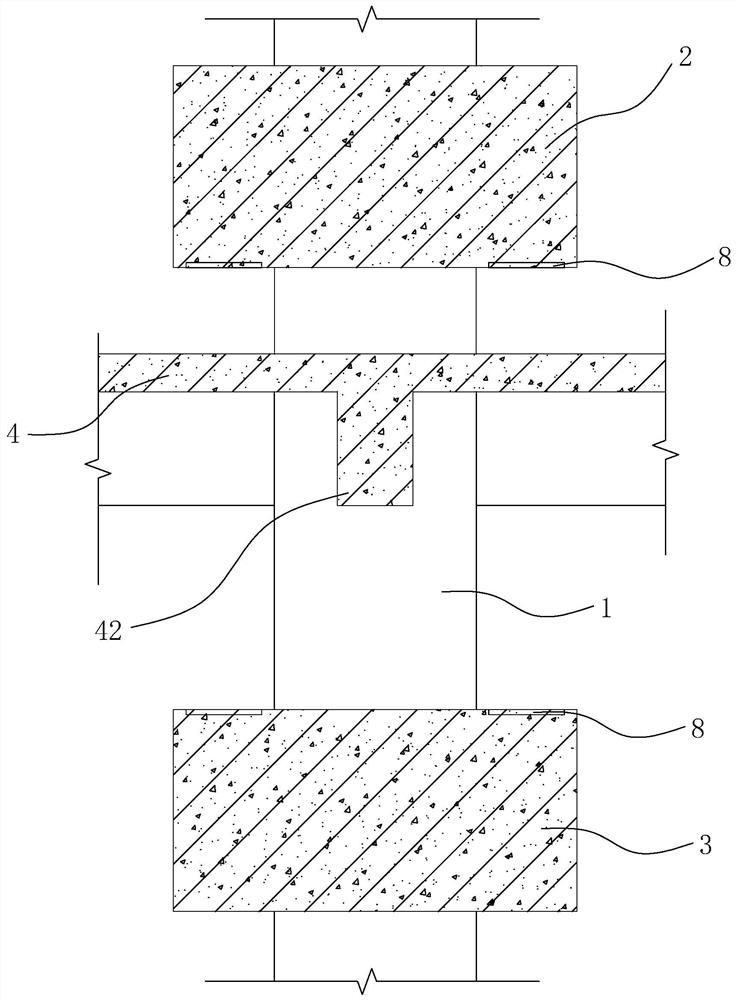

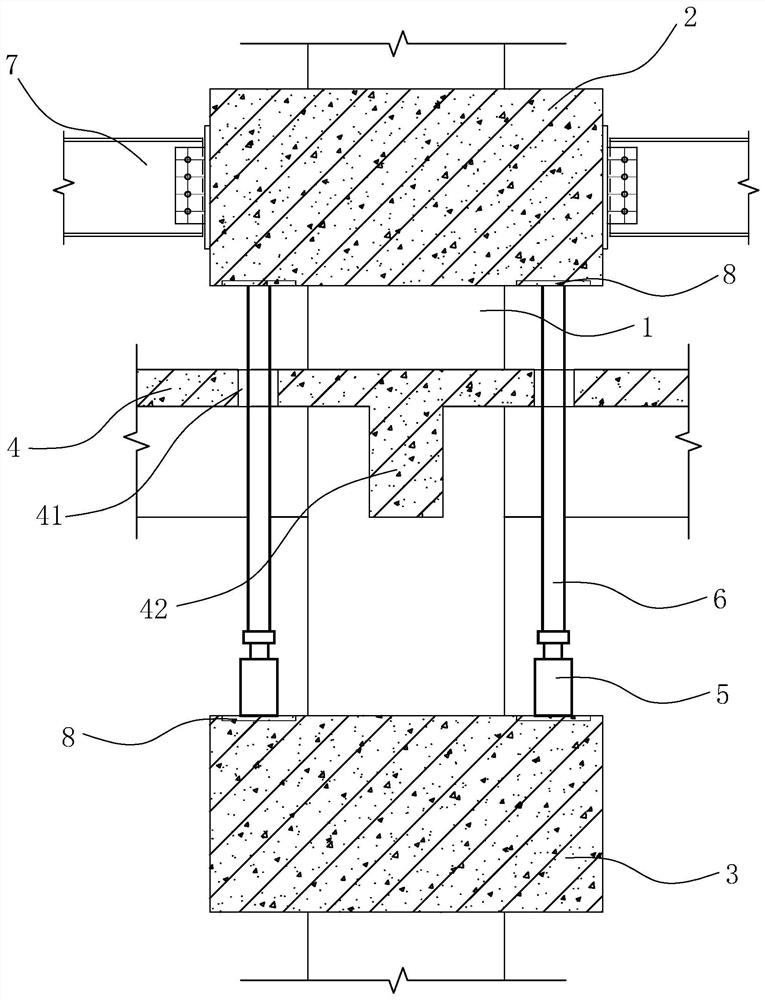

Method for changing floor frame column to on-beam column structure

The invention discloses a method for changing a floor frame column to an on-beam column structure, and belongs to the technical field of house structural transformation. Aiming at solving the problemthat an existing method has difficulty in improving a load-bearing structure, according to the following adopted technical scheme, the method for changing the floor frame column to the on-beam columnstructure comprises the following steps: 1, an upper encircling column holder and a lower encircling column holder are mounted; 2, a tie structure is mounted; 3, a to-be-cut part is removed; 4, a newfixing structure is manufactured, specifically, a new floor and a new supporting beam are manufactured; and 5, other structures are removed. According to the method, the floor frame column is changedto the on-beam column structure, the established tie structure shares the bearing weight of the floor frame column, and thus the structure keeps stable in the demolition process; and the new floor andthe new supporting beam which are connected with anchoring steel bars into a whole are established to become a new load-bearing structure, the original floor frame column below a floor is removed, thus the lower part of the floor has a large space, and the structure keeps stable all the time in all the operating steps.

Owner:HANGZHOU TONGDA GRP

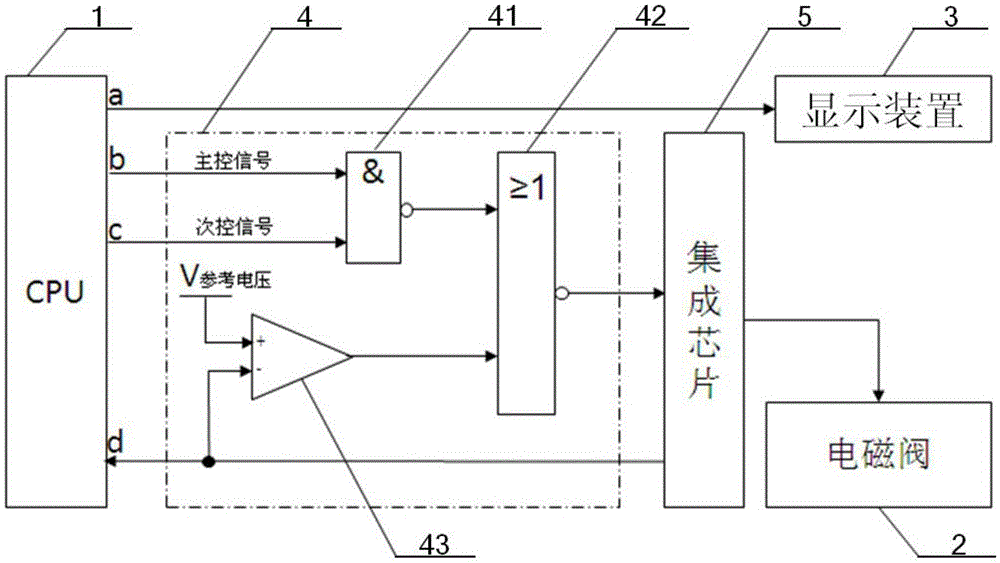

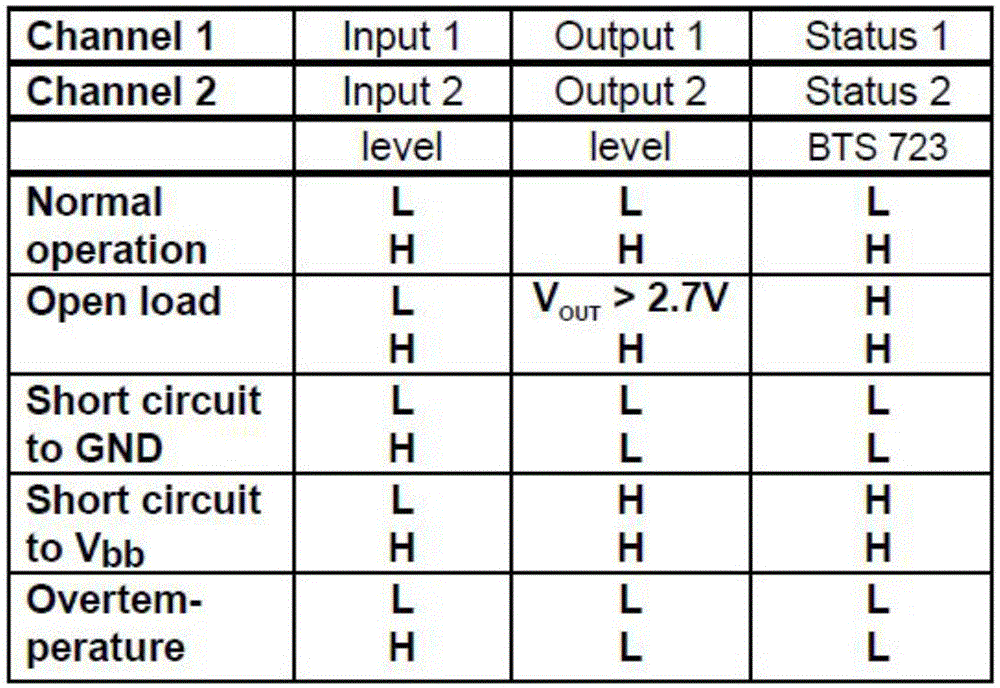

Vehicle solenoid valve fault diagnosis addressing circuit and usage method

ActiveCN105549578ARealize fault diagnosis functionImplement fault diagnosisProgramme controlElectric testing/monitoringSolenoid valveNOR gate

The invention discloses a vehicle solenoid valve fault diagnosis addressing circuit, comprising a CPU, a solenoid valve, a logic operation processing circuit, an integrated chip and a display device. The logic operation processing circuit comprises a NAND gate chip, a NOR gate chip and a comparator. In usage, the integrated chip detects the state of the solenoid valve and transmits the detection result to the CPU and the comparator in a voltage form to determine whether the fault exists; if the fault exists, the fault information is outputted to the display device and control of the solenoid valve can be promptly disconnected through a logic operation processing circuit in order to realize the fault addressing. The invention can not only perform the fault diagnosis and addressing on the solenoid valve through the hardware and the software, but is high in accuracy, strong in addressing, high in safety and strong in universality.

Owner:DONGFENG COMML VEHICLE CO LTD

Reinforced machine tool monitoring system and method based on Internet of Things

InactiveCN108608258AReduce temperature riseAvoid excessive heat build-upAutomatic control devicesFeeding apparatusCombustionMonitoring system

The invention discloses a reinforced machine tool monitoring system and method based on the Internet of Things. A hollow-cuboid-shaped storage shell can be located on a cuboid-shaped vertical sheet ofa box body I by an embedding head, the hollow-cuboid-shaped storage shell is hided behind a cover plate I, and when a background server needs to be taken out from the hollow-cuboid-shaped storage shell, a switch in the cuboid-shaped structure needs to be operated inwards while the neck side of the box body is passed through by a palm; with regard to a server case, firstly, a telescopic roll is accommodated in a cuboid-shaped support frame as a whole, a protection cover is wound on a rotary roll body, and the cuboid-shaped storage shell is also completely accommodated in a guide rail; and thedefects that the performance of an Internet-of-Things server in the server case is influenced and the risk of combustion is caused due to heat increasing, and a router is stolen because of being placed in a router case only, and an electronic lock is decrypted by a person and then the router case is opened in the case that the router case is equipped with the electronic lock, in the prior, are effectively avoided in combination with other steps.

Owner:时枫娇

Detecting mechanism of internal locking screw

InactiveCN110411404ARealize continuous eccentricity detectionMake sureUsing electrical meansMechanical measuring arrangementsComing outMechanical engineering

The invention relates to a detecting mechanism of an internal locking screw. The detecting mechanism comprises a conveying tank arranged on a support. The inclination degree of the conveying tank canbe adjusted. An upper frame is arranged at the upper portions of side plates of the conveying tank. A head portion matched groove matched with a head portion of the screw is formed in the rear portionof the conveying tank. A pressing block for forming a rod portion conveying frame together with the bottom face of the conveying tank is arranged on the front side plate of the conveying tank. A detection clamping device matched with the screw coming out of the tail end of the pressing block is arranged on the lower side of the upper frame. An eccentric detecting device matched with the screw clamped by the detection clamping device is arranged outside the rear side plate of the conveying tank. By means of the detecting mechanism of the internal locking screw, conveying is conducted through the inclined conveying tank; in cooperation with the detection clamping device, the screw can be clamped, and therefore it can be ensured that the position of the rod portion of the screw at the detecting station is determined; in cooperation with the eccentric detecting device, the continuous eccentric detecting of the screw can be realized.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

Method for laser-assisted manufacturing of precise circuit

PendingCN114158195AEasy to prepareReduce thicknessConductive material chemical/electrolytical removalMachiningMaterials science

The invention discloses a laser-assisted precise circuit manufacturing method, which comprises the following steps that a production board is provided, and circuits needing to be manufactured on the production board comprise a thick circuit with the circuit distance larger than 50 microns and a precise circuit with the circuit distance smaller than or equal to 50 microns; a film is pasted on the production board, exposure treatment is carried out, exposure of the coarse lines and the precise lines is completed, and all gap parts between the precise lines are exposed; developing and etching the production board, wherein the etching amount during etching is controlled to be greater than half of the copper thickness of the circuit, and the bottom layer base material is not exposed; ablating a gap part between the precision circuits by adopting laser to remove a film and a part of copper layer at the gap of the precision circuits; and carrying out etching treatment and film stripping on the production board again, and forming a thick circuit and a precise circuit on the production board. According to the method, the technological process is optimized, the laser ablation and chemical etching combined copper removal mode is adopted in sequence, manufacturing of the precise circuit with the distance smaller than or equal to 50 micrometers can be achieved, the material and machining cost is low, and the technological process is simple.

Owner:SIHUI FUJI ELECTRONICS TECH

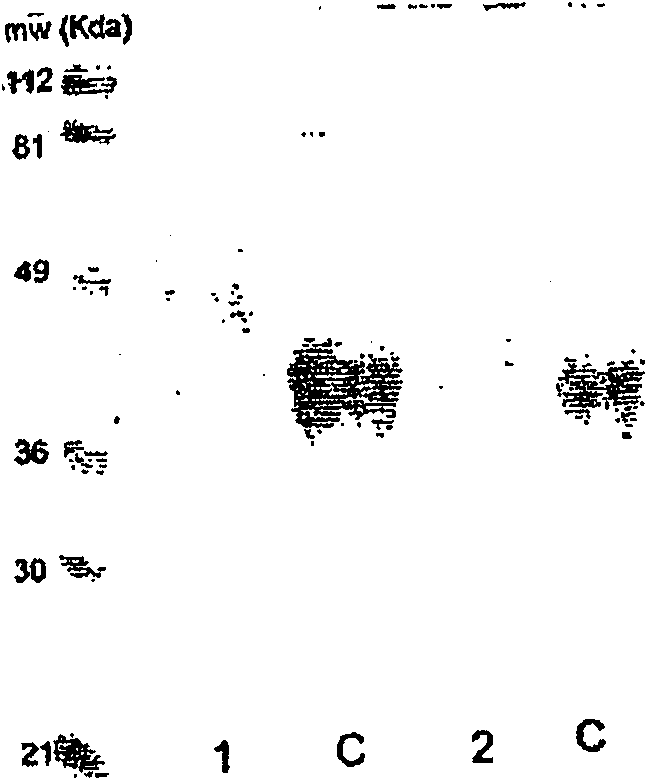

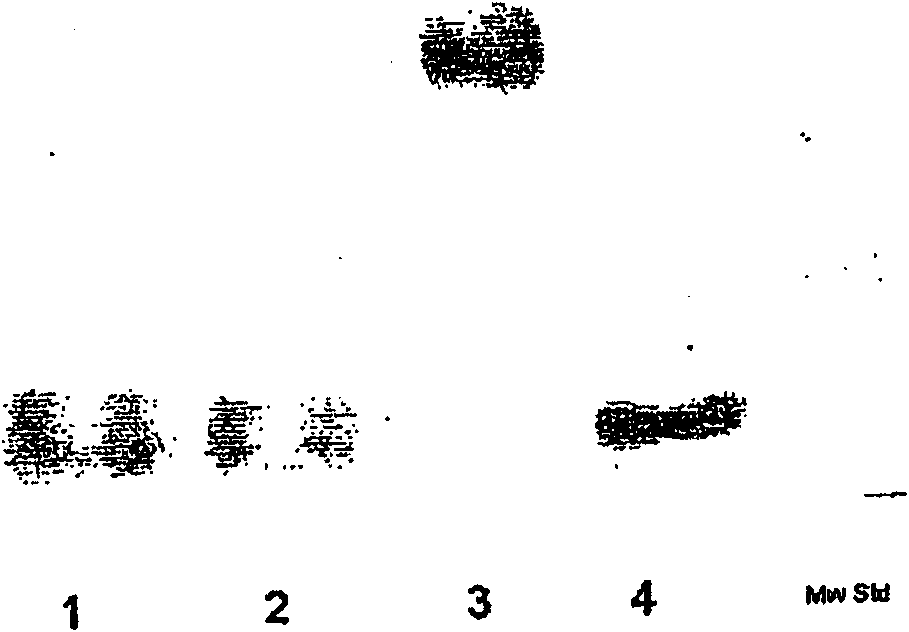

Hasylated polypeptides, especially hasylated erythropoietin

InactiveCN101580547AImprove biostabilityImprove biological activityCosmetic preparationsPowder deliveryCarbohydrate moietyThioether

The present invention relates to hydroxyalkylstarch (HAS)-polypeptide-conjugate (HAS-polypeptide) comprising one or more HAS moecules, wherein each HAS is conjugated to the polypeptide via a carbohydrate moiety or a thioether as well as to methods for the production thereof. In a preferred embodiment, the polypeptide is erythropoietin (EPO).

Owner:FRESENIUS KABI DEUT GMBH

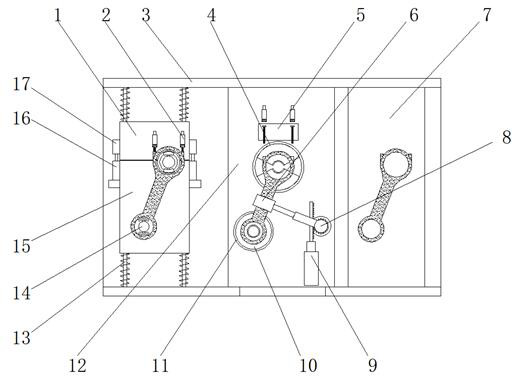

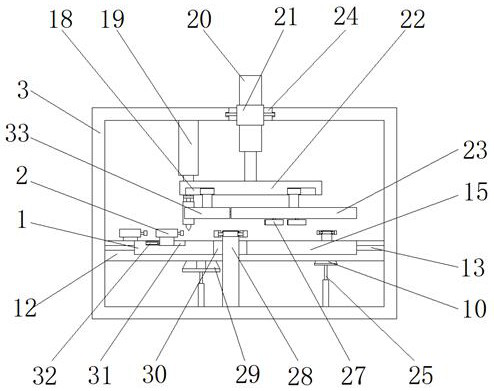

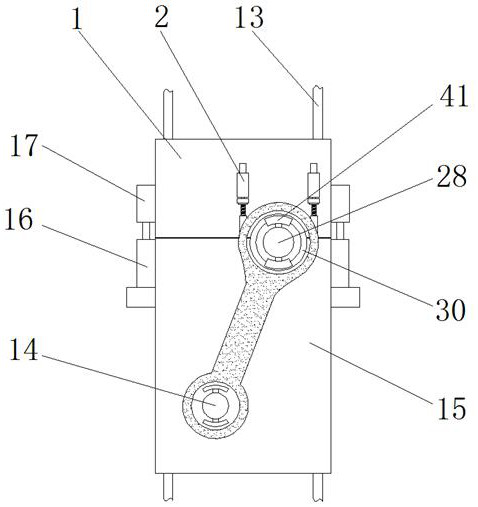

Connecting rod cracking equipment and technology

ActiveCN112222606AFacilitate step-by-step continuous productionIncrease productivityLaser beam welding apparatusEngineeringLaser cutting

The invention discloses connecting rod cracking equipment. The connecting rod cracking equipment comprises a shell and a laser grooving assembly; an inner wall laser cutting head is arranged on the laser grooving assembly; the two ends of the shell are both open; a feeding plate is arranged at one end in the shell; a hole wall pull-down plate and a rod wall pull-down plate which are aligned to each other are glidingly mounted at the other end in the shell; and two sliding rods which are arranged in parallel are arranged in the shell. According to the equipment, the feeding plate, an inspectionplate and the pull-down plates are arranged in the shell, a first suction cup, a second suction cup and a clamping plate are mounted on a mounting plate, step-by-step continuous production of a connecting rod is facilitated in the connecting rod cracking machining process, the mounting plate moves to drive the first suction cup, the second suction cup and the clamping plate to move simultaneously, the connecting rod is synchronously transferred in the steps of feeding, bolt assembling, grooving, cracking and discharging, the automation degree is high, and the production efficiency of connecting rod machining is improved.

Owner:济南吉隆锻造有限公司

Method for preparing full fermentation flower based on small size fuzhuan tea spliced into brick shape

The invention discloses a method for preparing a full fermentation flower based on a small size fuzhuan tea spliced into a brick shape. The method comprises the following steps of raw material screening->tea juice adding->normal temperature fermentation->high pressure steaming->pile fermentation->flavor mixing->steaming softening->pressing shaping->splicing->tea brick packaging->golden flower cultivating->aging. The method breaks through the limitation of the traditional production of the fuzhuan tea by using large bricks, and the tea bricks produced are small in size and convenient to carry for consumers; it is particularly important to overcome the problem of surface flowering during the production of the fuzhuan tea, the small fuzhuan tea can achieve flowering of the whole tea bricks, the number ratio of the flowering is large and the shape is beautiful; the method adopts mold batch pressing and splicing shaping, can carry out batch production of the small fuzhuan bricks of whole flowering, and can make the high-quality small fuzhuan tea bricks available to consumers.

Owner:XIAN STAR OF GROUND MEASUREMENT & CONTROL TECH CO LTD

Preparation method of in-situ graft modification rubber

The invention provides a preparation method of an in-situ graft modification rubber. According to the method, a coupling agent and inert filler are premixed in advance and absorbed, the liquid coupling agent is converted to be in a solid form, and the dispersion uniformity of the coupling agent and the reinforcing filler are effectively ensured; and then the process conditions are regulated and controlled for ensuring that a high-temperature grafting reaction is made on the basis of the dispersion uniformity of the reinforcing filler and the coupling agent, the efficiency, uniformity and stability of the reaction are ensured, and it is ensured that the reaction is sufficiently made. The method can be directly used in rubber compound production, and meanwhile, the aim of reducing the production cost can be achieved. A rubber product prepared by the method has the excellent performances of low heat generation, low pressure changes, low creep, aging resistance and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method for making suit sleeves

The invention discloses a method for making suit sleeves. The method is characterized by including the steps of 1), drawing a sleeve cap curve line of a top sleeve body; 2), drawing a sleeve valley curve line of an under sleeve body; 3), drawing front bending joints of the top sleeve body and the under sleeve body by determining partial sleeve points of cuffs of the top sleeve body and the under sleeve body; 4), determining the length of the sleeve bodies; 5), determining back bending joints of the top sleeve body and the under sleeve body; 6), determining hemlines of the cuffs to complete thesleeves. The hemlines are concealed in position, which is reasonable in processing; the curve lines M1T and the rear bending joints are intersected at the T-point, included angles on two sides are favorably close to 90 degrees, cuff vents are configured, and the sleeves are completed. The method is convenient and simple in processing and high in efficiency.

Owner:谢亚平

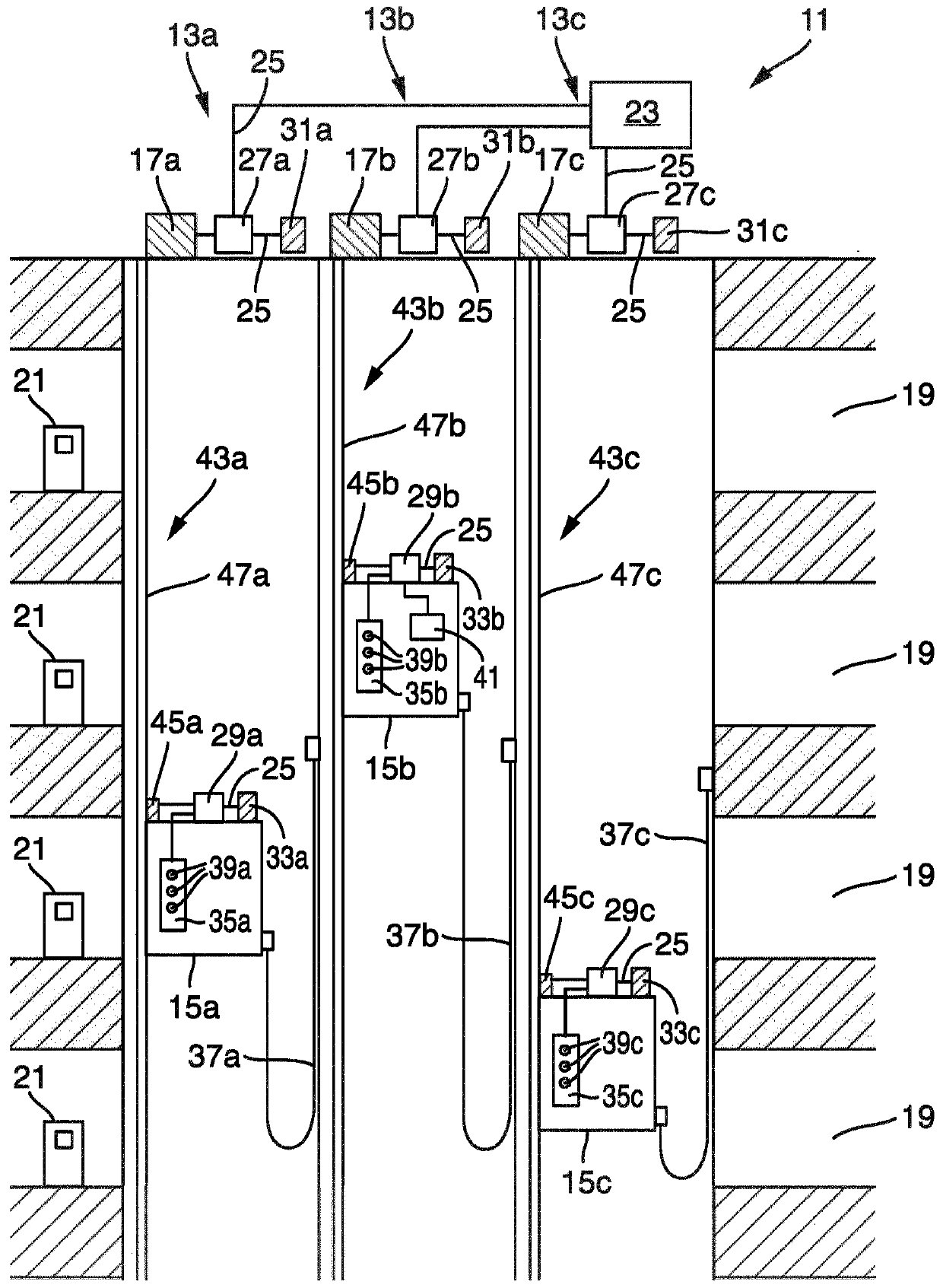

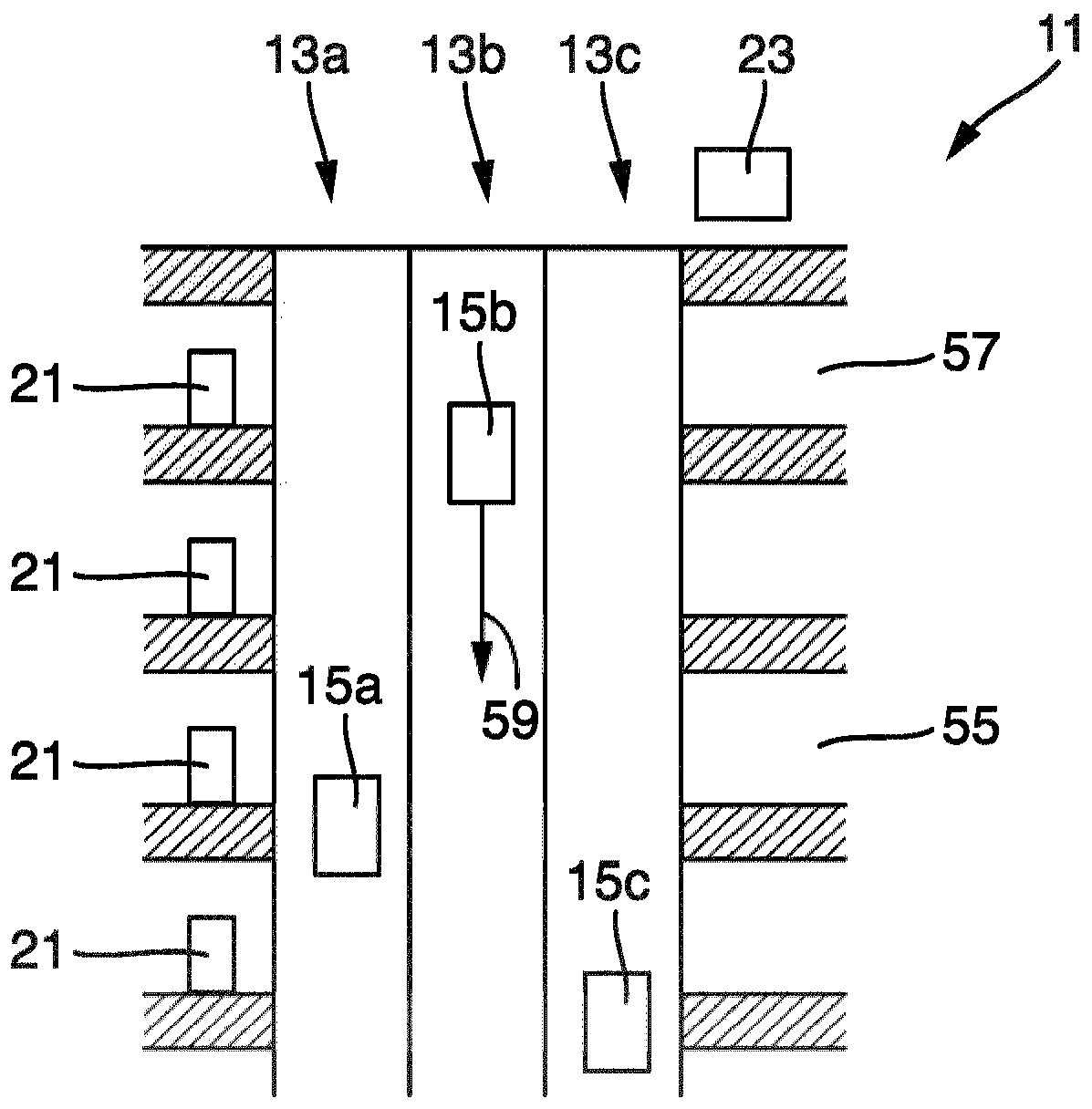

Modernization of an elevator group

InactiveCN110914187AEasy wiringWiring is easy to connectElevatorsBuilding liftsControl signalControl engineering

The present invention relates to a method for modernizing an elevator group (11). The elevator group (11) in this case comprises a plurality of elevators (13a, 13b, 13c) each having a car (15a, 15b, 15c) and an elevator controller (17a, 17b, 17c) for controlling the respective car (15a, 15b, 15c). As part of the modernization process, at least one input terminal (21) for capturing destination callsignals is fitted and a group computer (23) is installed. The group computer (23) is suitable for evaluating the destination call signals and for outputting at least one first control signal. Additionally, for each elevator (13a, 13b, 13c), a control unit (27a, 27b, 27c) for reading in the first control signal and a control module (29a, 29b, 29c) are respectively installed on the respective car (15a, 15b, 15c) for delivering an internal call, triggered by the first control signal, for the respective car (15a, 15b, 15c).

Owner:蒂森克虏伯电梯设备有限公司 +1

a food processor

The invention relates to a food processing machine, comprising a cup body for food processing, a slurry cup for holding food, and a waste water box for collecting waste water, the cup body is provided with a slurry discharge rotary valve, the discharge The pulp rotary valve discharges the food or waste water in the cup to the pulp receiving cup or the waste water box. It is characterized in that the pulp discharge rotary valve includes a pulp discharge pipe, a valve core, and Drive device, the valve core is provided with a through hole, the through hole communicates with the pulp discharge pipe and the cup body, the valve core drives the pulp discharge pipe to move, and the pulp discharge pipe is connected to the slurry cup The reciprocating movement within the limited range between the position and the position of the waste water box is used to switch the pulp discharge and the waste water. Reduce the step of the rotary valve motor directly driving the position of the slurry discharge pipe, reduce the corresponding driving gears, reduce the corresponding cost, and reduce the number of accessories at the same time, and the corresponding failures caused by the failure of the accessories and the cooperation between the accessories will disappear. Product reliability.

Owner:JOYOUNG CO LTD

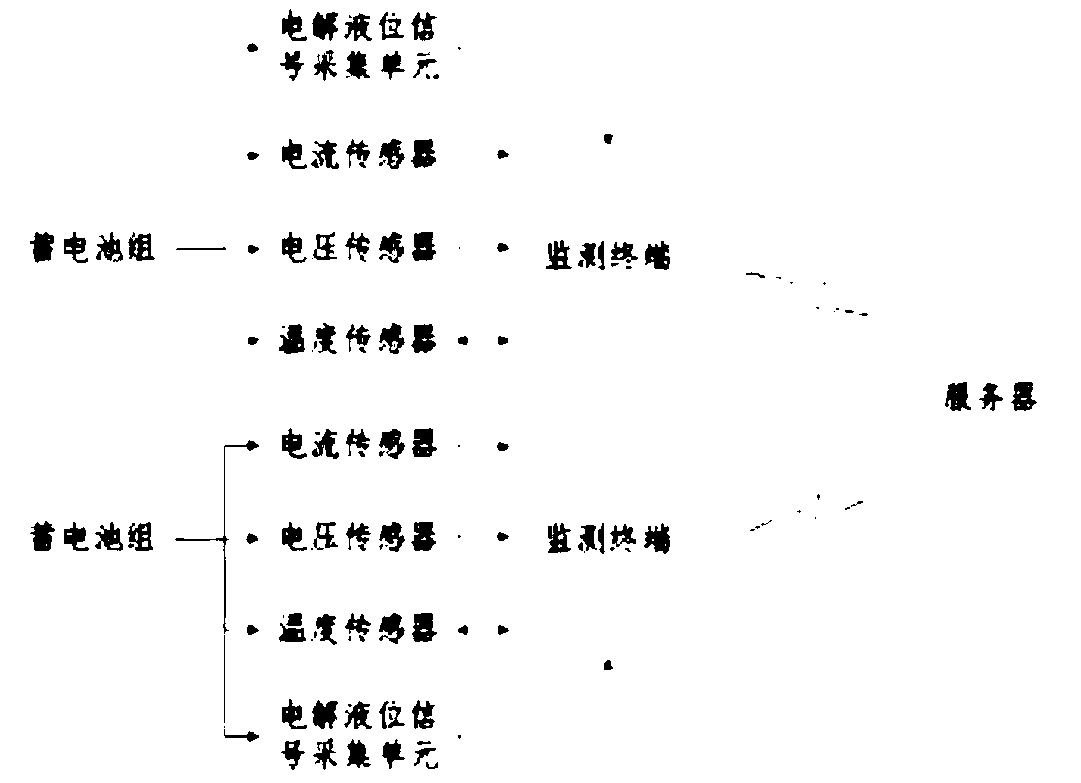

Battery-oriented control system and method thereof

InactiveCN108944493AMake sureConstant transfer rateVehicular energy storageElectric propulsionInformation transmissionControl system

The invention provides a battery-oriented control system and a method thereof. After a hollow cuboid-shaped storage shell is concealed in a cover plate I and at the moment that a server needs to be taken out from the hollow cuboid-shaped storage shell, a switch in the cuboid-shaped structure is subsequently operated inwards by using a palm via a neck edge of a box body, the switch enables an electric telescopic rod to pull a cylindrical stick to move inwards, and the cylindrical stick pushes out an embedding head via a locating opening II. Defects that the charging temperature information transmission effect is poor, the real-time performance of the transmitted charging temperature information is not enough, the server is stolen due to being only placed in a server cabinet, and the servercabinet can be opened after a matched electronic lock is unlocked by people in the prior art are effectively avoided.

Owner:南京博内特信息科技有限公司

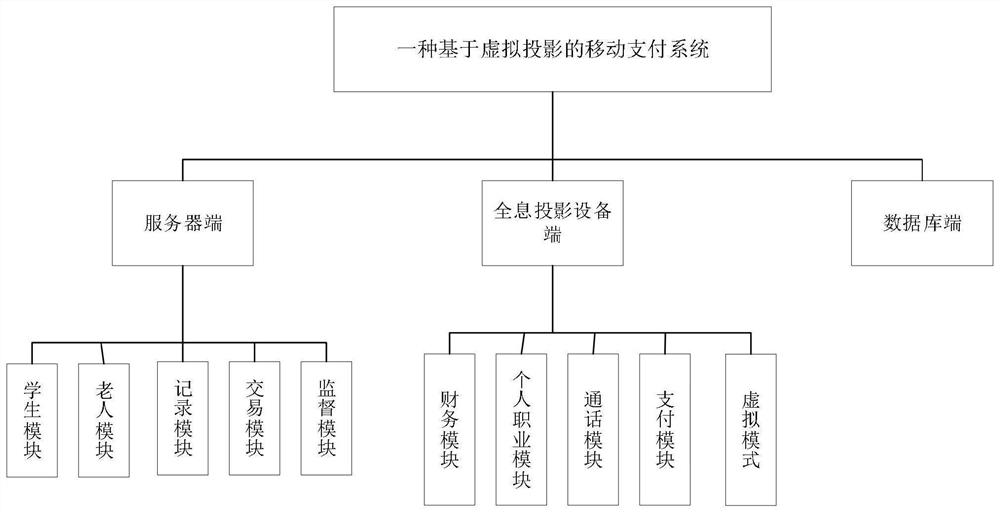

Mobile payment system based on virtual projection

InactiveCN113570375AImprove experienceEasy to useInput/output for user-computer interactionFinanceComputer securityInternet privacy

The invention discloses a mobile payment system based on virtual projection, which can be directly connected with central bank virtual currency through the system, can select commodities and directly complete online payment through a virtual projection mode, quickly circulates digital currency in classes, improves the user experience, is easy to master, is convenient to operate, and improves the user experience. The identity information of the user is collected and recognized through personal identity binding or DNA binding, it can be ensured that the identity information of the user is correct, the payment safety is improved, the payment efficiency is high, and maintenance is convenient.

Owner:朱哲毅

A kind of construction method of steel curved arch bridge

ActiveCN108708265BControl stressControl deformationBridge erection/assemblyArch-type bridgeBridge deckPre embedding

The invention discloses a construction method of a steel curved arch bridge and belongs to the technical field of bridge construction. The construction method comprises the following specific steps that S1, foundation pile construction is conducted, specifically, a trestle bridge and a platform are constructed; S2, a main arch frame is constructed, specifically, arch foot section pre-embedded steel arch rib positioning steel members are mounted; S3, vault supporting mounting is constructed, specifically, closure section steel pipes are mounted, and after the line type is adjusted, steel pipesare welded; S4, pier uprights are mounted, specifically, concrete in lower pipes is symmetrically pumped; S5, a bridge deck support is mounted, specifically, bridge deck slabs are symmetrically mounted on the upstream and the downstream in the axial direction of the bridge from the two ends of a main arch and a subarch in a midspan mode; and S6, bridge deck pavement construction is conducted, specifically, bridge deck pavement auxiliary projects are symmetrically constructed, suspender cable force is copied and adjusted to a design value, steel pipe protective surface paint spraying coating isconducted, and after construction is completed, completed bridge testing and acceptance are conducted. Construction is conducted in strict accordance with the construction scheme and construction rules, control over stress and deformation during arch frame erecting can be guaranteed, and arch bridge midspan high-precision closure is guaranteed.

Owner:武汉精潮钢结构有限公司

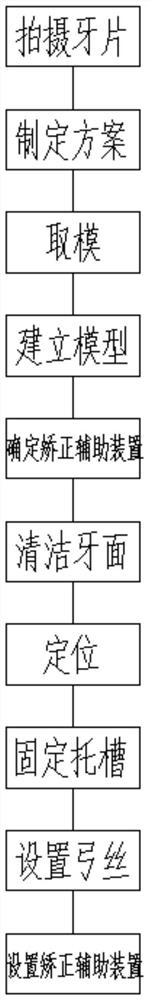

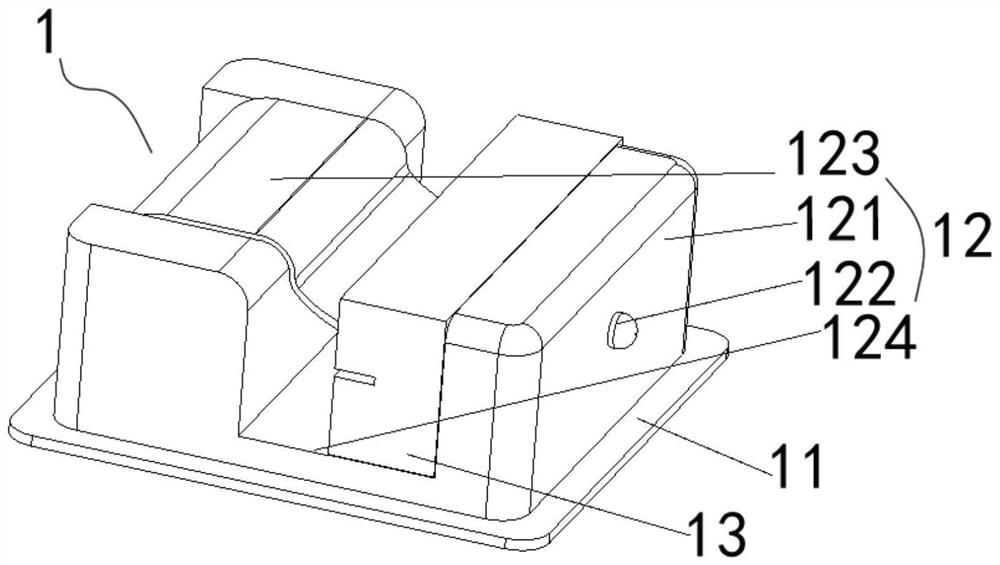

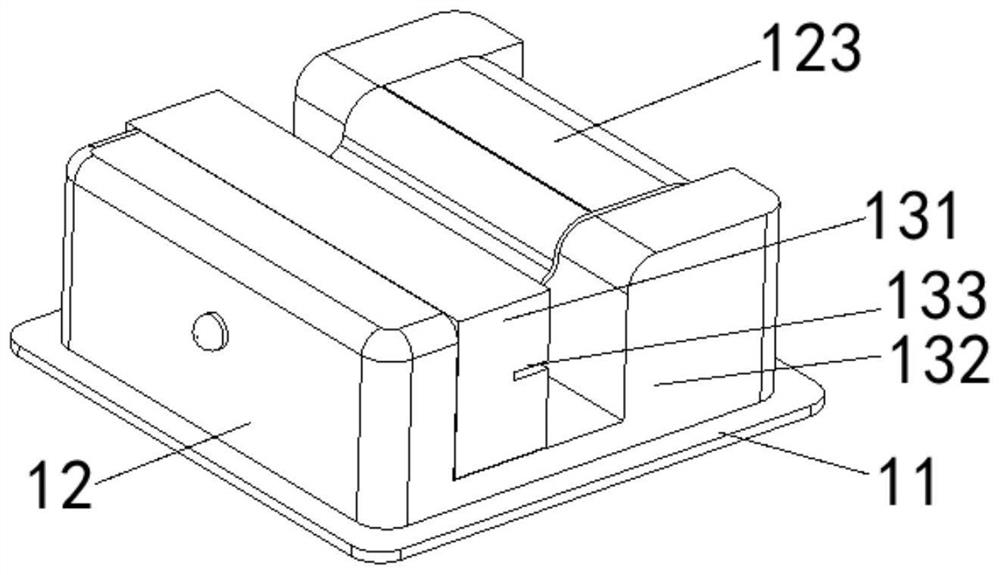

Orthodontic device and method for orthodontics

The invention discloses an orthodontic device and a method for orthodontics, comprising the following steps: taking a dental film to obtain the tooth condition, customizing an orthodontic plan according to the tooth condition, taking a model to obtain the shape of the patient's tooth surface, establishing an occlusal surface and a tooth model by a computer, and determining Orthodontic aids, cleaning the tooth surface, determining the bonding position of the brackets, fixing the brackets, setting the arch wire, and setting the orthodontic aids; efficiently and intuitively making brackets and arches corresponding to the patient's tooth condition through prototypes and computers Silk and orthodontic auxiliary devices, clean the tooth surface, and at the same time carry out slight acid etching cleaning treatment on the bonding position of the tooth surface, so as to improve the roughness of the tooth surface, facilitate the fixing of the bracket, and cushion the tooth surface to prevent the process of fixing the bracket In the case of excessive adhesive attachment area or fixed skew, the archwire is placed on the patient's tooth surface through the bracket to restrain and fasten the teeth to be treated. Carry out corresponding personalized assistance and applications.

Owner:北京联袂义齿技术有限公司

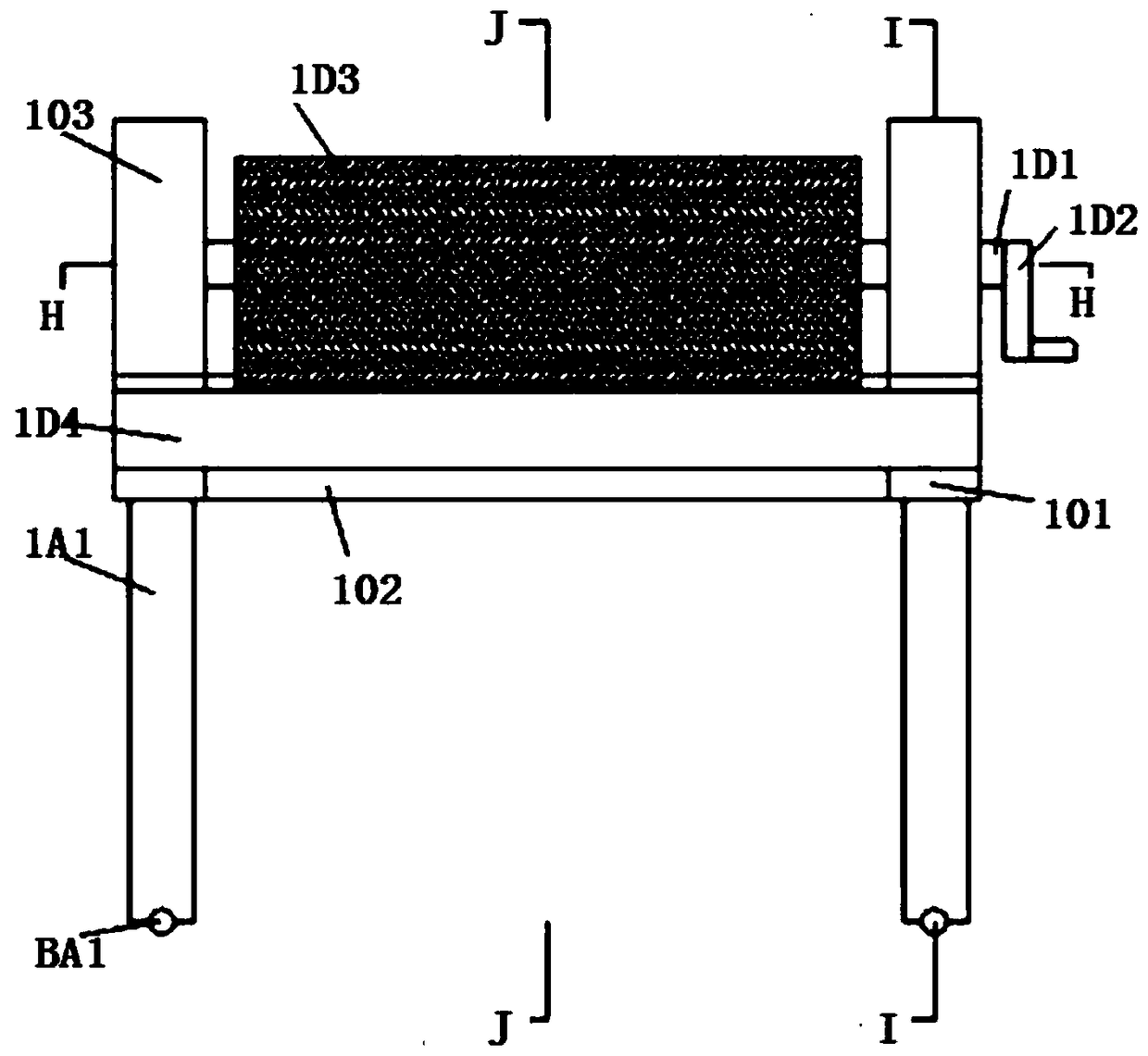

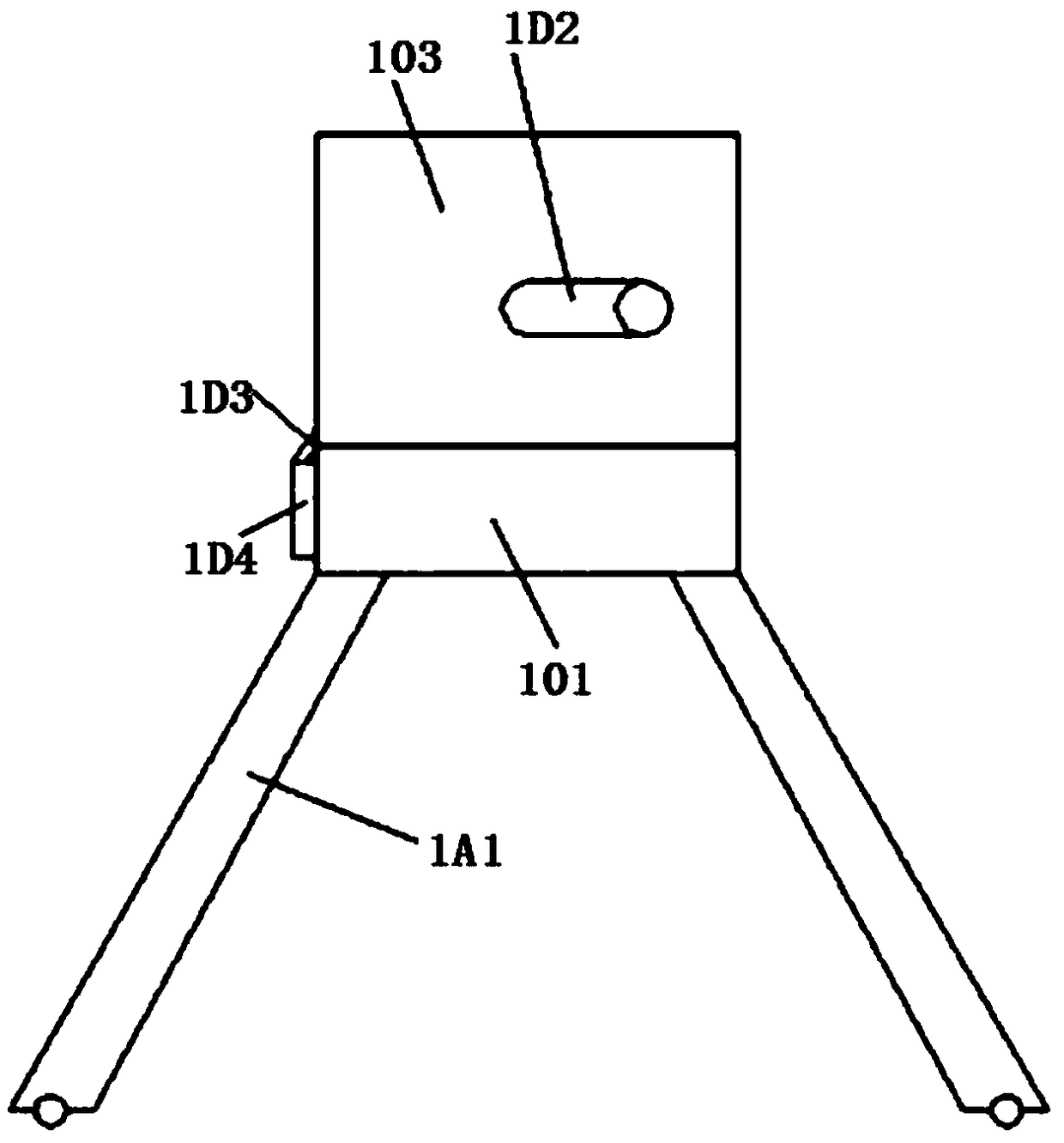

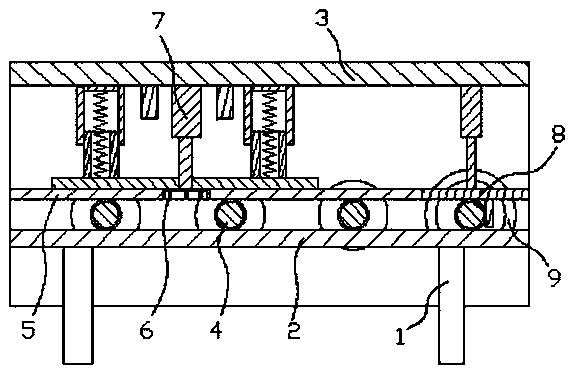

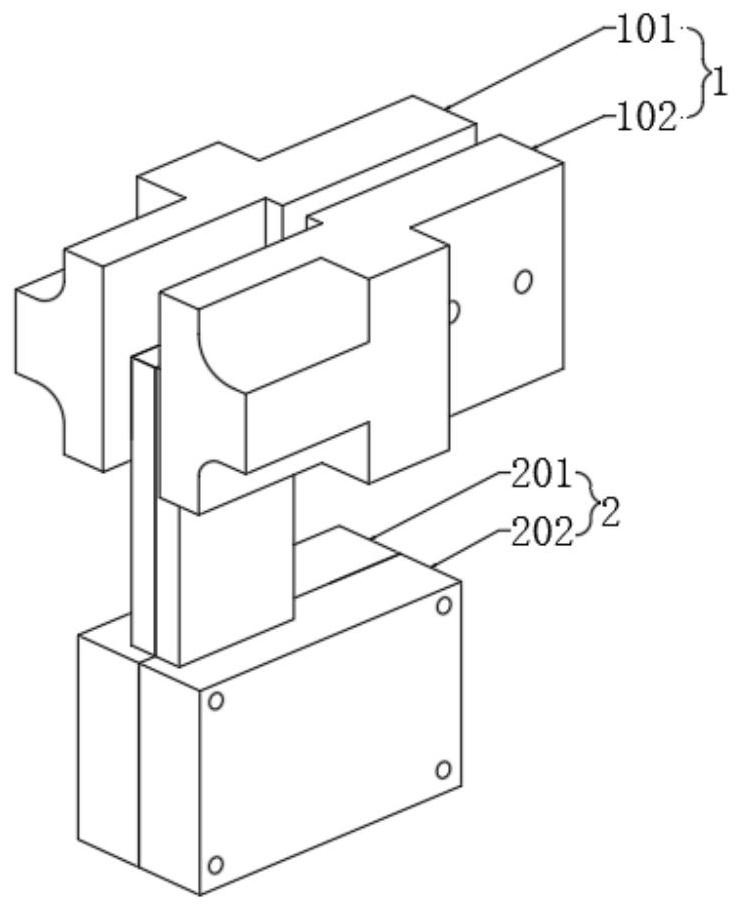

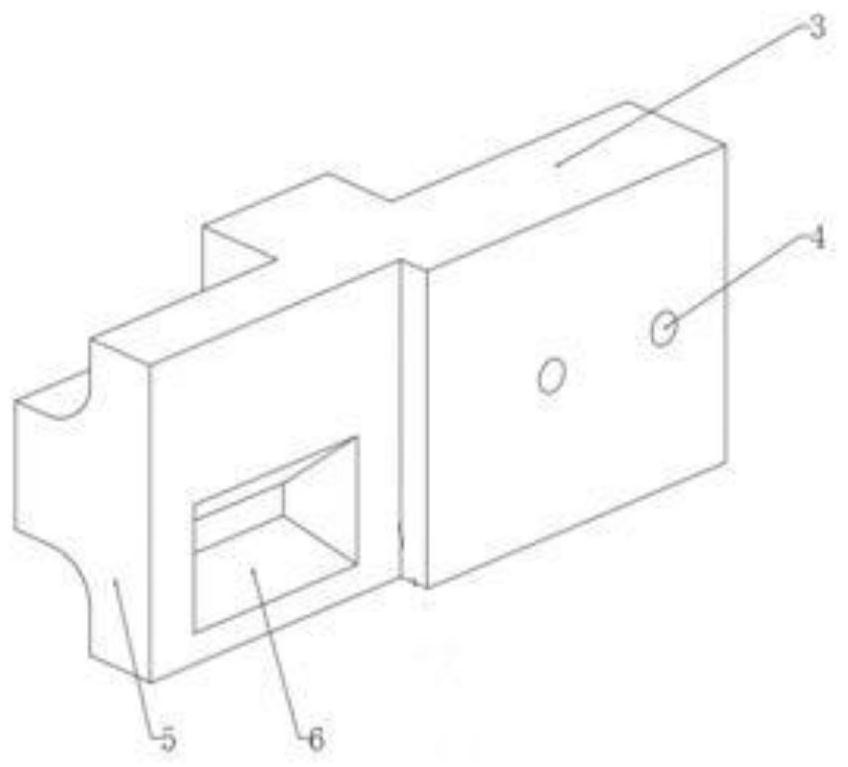

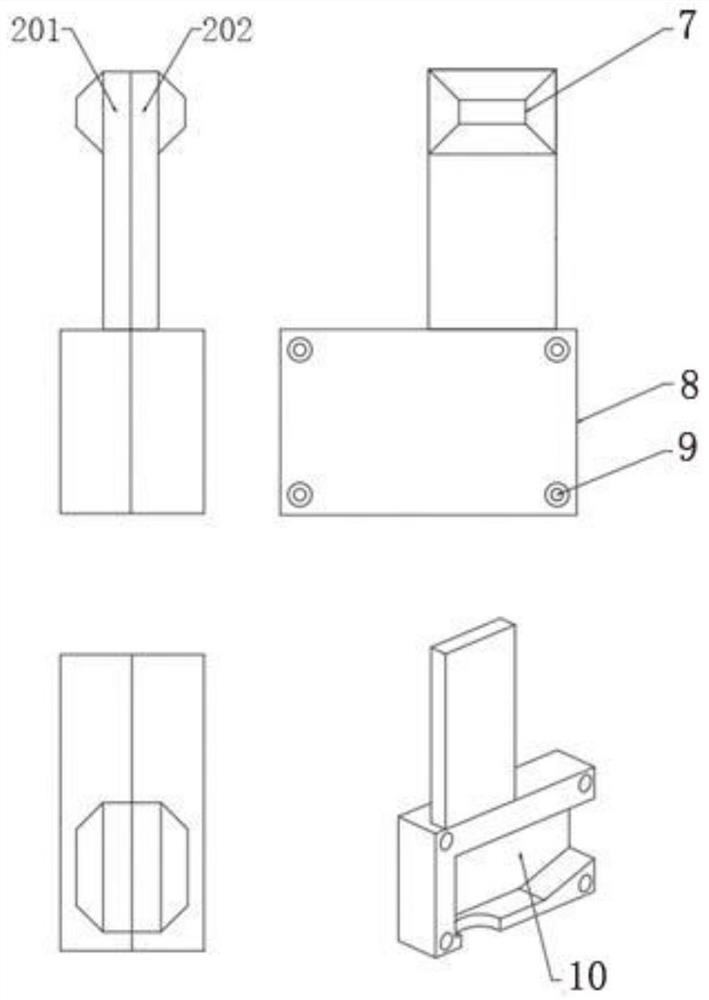

A self-adaptive digital meter plug grabbing tooling structure

ActiveCN111009810BOvercome the problem of being unable to achieve accurate positioning and pluggingEnsure uniqueCoupling device engaging/disengagingTesting/measuring connectorsEngineeringMechanical engineering

The invention relates to the field of intelligent measurement verification, in particular to an adaptive digital meter plug grabbing tooling structure, including a plug clamping tooling structure and a plug tooling structure, the plug clamping tooling structure is composed of a left unit plug clamping tooling structure and a right The unit plug clamping tooling structure is composed of, the left unit plug clamping tooling structure and the right unit plug clamping tooling structure both include a mounting end and a clamping end, and the left unit plug clamping tooling structure and the right unit plug clamping tooling structure A four-sided wedge-shaped inner surface structure is provided in the middle of one side adjacent to the clamping end of the structure.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

A Method for Changing Floor-to-ceiling Frame Columns to Beam-on-Column Structures

The invention relates to a method for changing a floor-standing frame column to a beam-on-column structure, which belongs to the technical field of house structure transformation. Aiming at the problem of difficulty in improving the load-bearing structure in existing methods, the technical solution is as follows: a method for changing a floor-to-ceiling frame column to a beam-on-column structure , including the following steps: Step 1, install the upper and lower encircling column supports; Step 2, install the tie structure; Step 3, remove the part to be cut; Step 4, make a new fixed structure: make a new floor slab and a new support beam; 5. Remove the rest of the structure. The method of the present invention changes the floor frame column into a beam-on-column structure, and the established tie structure shares the bearing weight of the floor frame column, so that the structure remains stable during the demolition process, and a new floor slab and a new support beam integrated with the anchoring steel bar are established to become a new structure. The load-bearing structure removes the original landing frame column under the floor, so that a larger space is obtained under the floor, and a relatively stable structure is always maintained in each operation step.

Owner:HANGZHOU TONGDA GRP

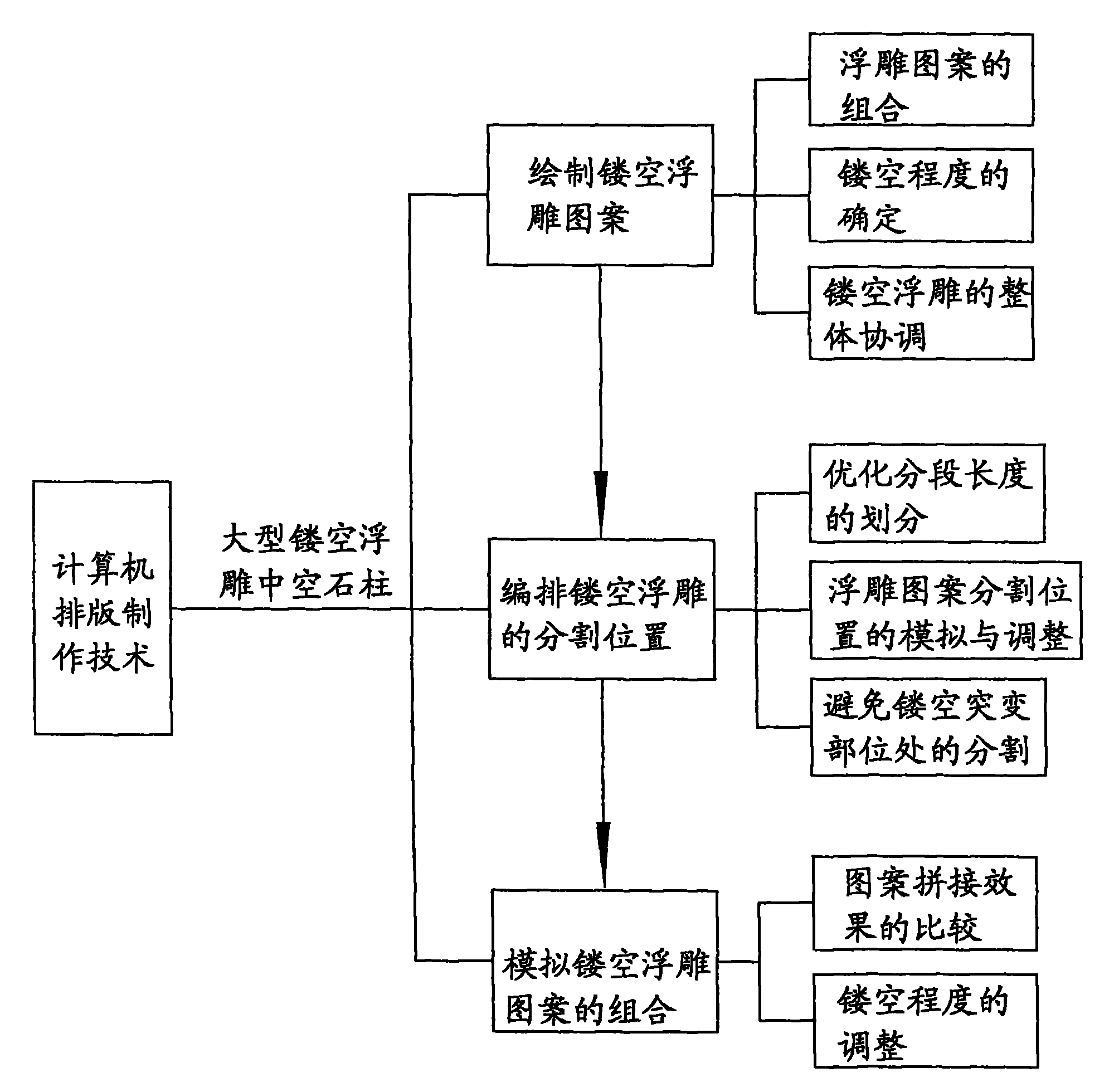

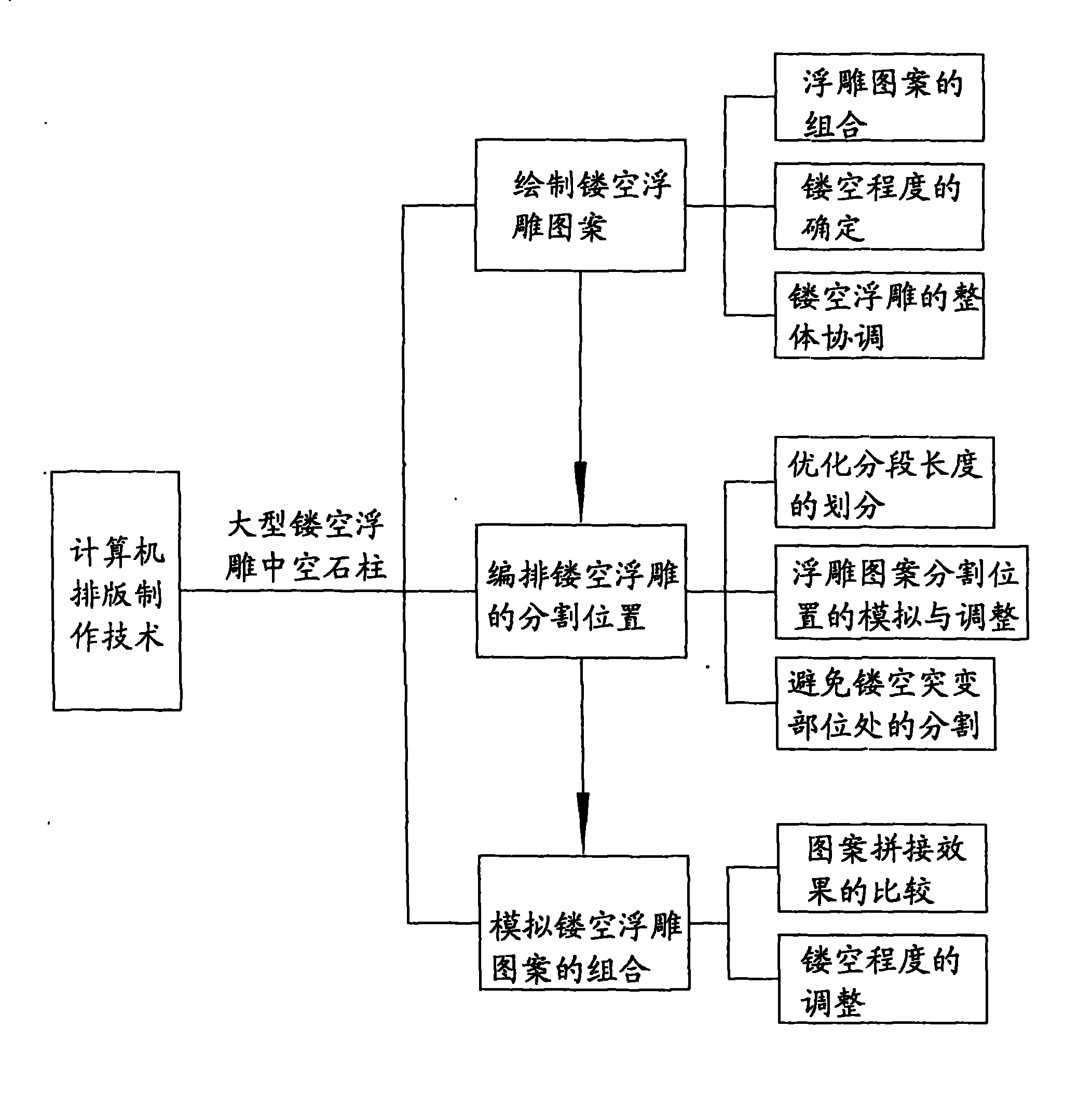

Method for manufacturing hollowed-out embossed hollow stone column through computer

InactiveCN101515303BAvoid smallImprove craftsmanshipSpecial data processing applicationsManufacturing technologyStone carving

The invention discloses a method for manufacturing a hollowed-out embossed hollow stone column through a computer. The method comprises the steps of the drawing of a hollowed-out embossed pattern by the computer, the programming of cutting positions of the hollowed-out embossment by the computer and the simulation of combination of the hollowed-out embossed patterns by the computer. As the methoduses computer drawing of a large-scale hollowed-out embossed pattern, the programming of the cutting positions, the simulation of the pattern combination and other modes and adopts computer typesetting manufacturing technology to simulate the large-scale hollowed-out embossed hollow stone column, the method simulates out the three-dimensional integral effect of the large-scale hollowed-out embossed stone column and also represents the hollowed-out depth degree of stone carving. The method simulates the hollowed-out degree of an embossed pattern through the computer, further optimizes the hollowed-out pattern to ensure the hollowed-out quality of embossment before the carving operation, also can provide intuitional reference for the three-dimensional effect of the hollowed-out embossment of the large-scale stone column, better determines the cutting position of the embossment and has the advantages of accurate positioning, easy assembly, high mounting precision, high hollowed-out quality, and the like.

Owner:FUJIAN MINNAN CONSTR ENG

A kind of preparation method of in-situ graft modified rubber

The invention provides a method for preparing in-situ graft modified rubber. In this method, the coupling agent is premixed and absorbed with the inert filler in advance, and the liquid coupling agent is converted into a solid form, which effectively ensures the coupling agent and the reinforcement The dispersion uniformity of the filler, and then by adjusting the process conditions to ensure that the high-temperature grafting reaction is carried out on the basis of the uniform dispersion of the reinforcing filler and the coupling agent, to ensure the efficiency, uniformity and stability of the reaction, and to ensure that the reaction is fully carried out. The method can be directly adopted in the production of mixed rubber, and at the same time can achieve the purpose of reducing production costs. The rubber products prepared by the method have excellent properties such as low heat generation, low pressure change, low creep, and aging resistance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com