a food processor

A food processing machine and food processing technology, applied in kitchen utensils, household utensils, applications, etc., can solve the problems of waste water being discharged into the slurry cup and troublesome use by users, and achieve simplified algorithm design, reduced driving gears, and simplified processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

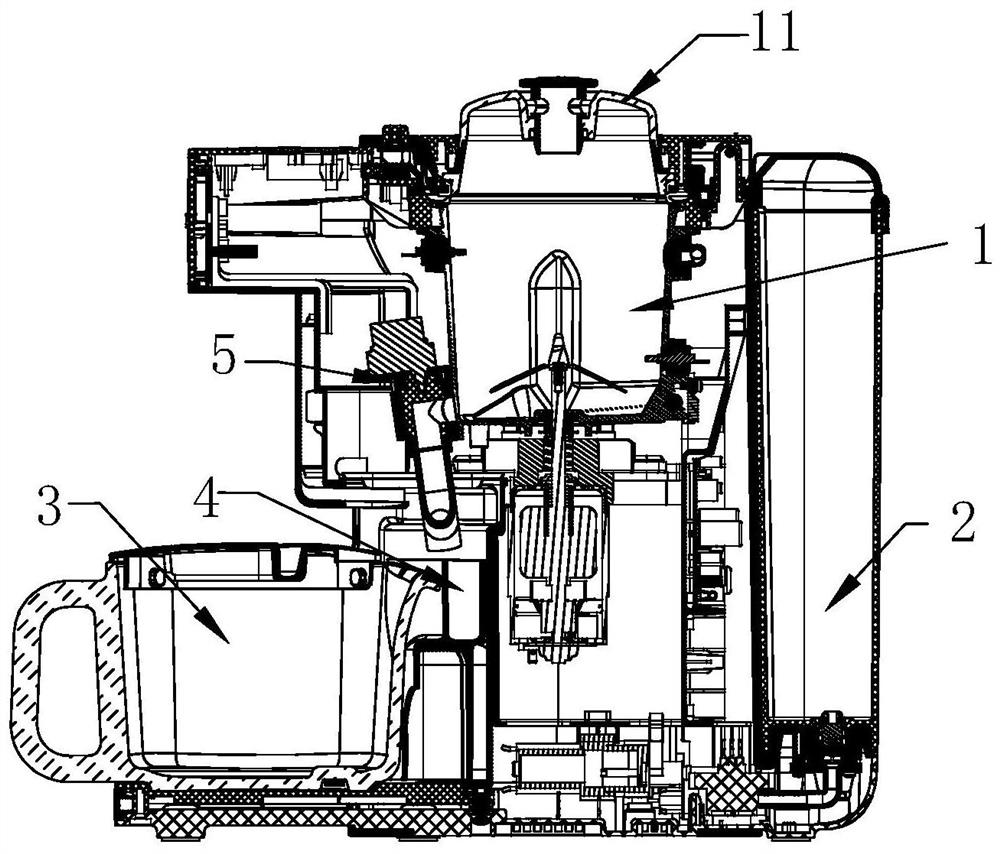

[0032] like figure 1 As shown, it is a schematic diagram of the structure of the food processing machine of the present invention. Including a cup body 1 for a food processor, the bottom of the cup body is provided with a motor, the motor shaft of the motor passes through the bottom of the cup body 1 and is connected with the crushing blade arranged inside the cup body 1. Connection, the cup body 1 is provided with a cup cover 11, the bottom of the cup cover 11 is formed with an auxiliary cavity which is upwardly recessed, the auxiliary cavity and the cup body are enclosed to form a food processing area for material crushing processing, of course, the cup The lid can also be a flat lid, and the cup lid cooperates with the cup body to form a crushing processing area. The food processor is further provided with a water tank 2, the water tank 2 supplies water into the cup 1 for food processing, and can also provide water for cleaning the area of the food processor.

[0033] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com