Reinforcing steel bar centralized processing and distribution method, system and device and medium

A steel bar and work area technology, applied in the field of centralized processing and distribution of steel bars, can solve the problems that it is difficult to meet the conditions and requirements of on-site processing of steel bars, the quality of components is difficult to ensure, and the construction site is narrow, so as to improve the efficiency of remote communication and steel supply capacity , the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] For the processing of steel bars on the traditional construction site, the processing efficiency is low and the environment is poor. Moreover, when the construction project involves more work areas, such as multiple construction points in the subway construction project, the shortcomings of on-site processing of steel bars are more prominent. The construction space is narrow and the environment is poor. Poor, often can not meet the requirements of the environmental conditions of on-site processing of steel bars, so a better steel bar processing method is urgently needed.

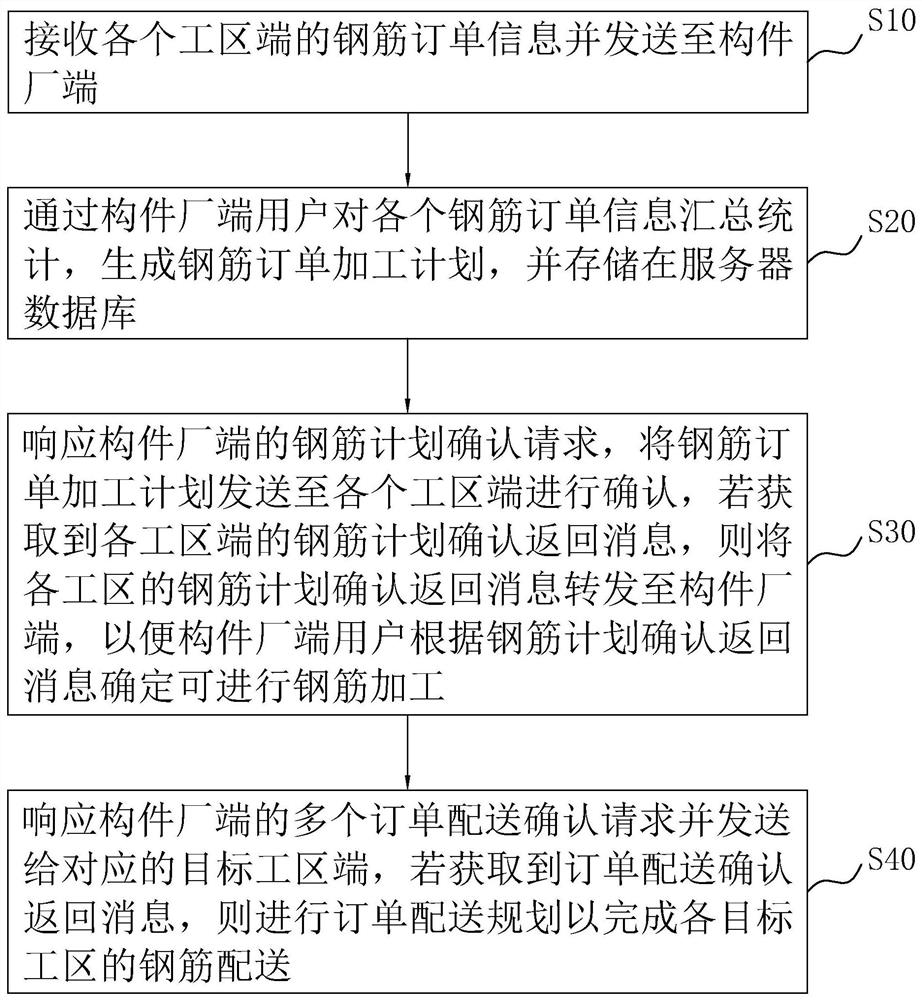

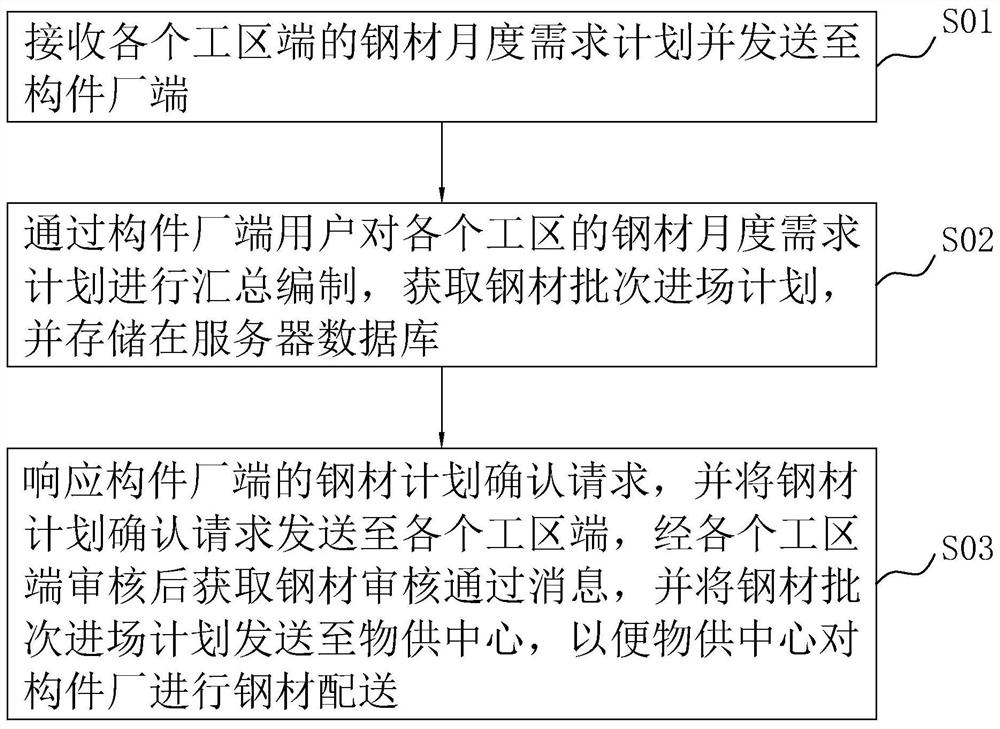

[0059] In this embodiment, unified procurement of steel, centralized processing of steel, and distribution of steel components to each work area can greatly improve the efficiency of steel supply and the utilization of resources. This application provides a method for centralized processing and distribution of steel bars, so that users with different project roles can use the method of this application...

Embodiment 2

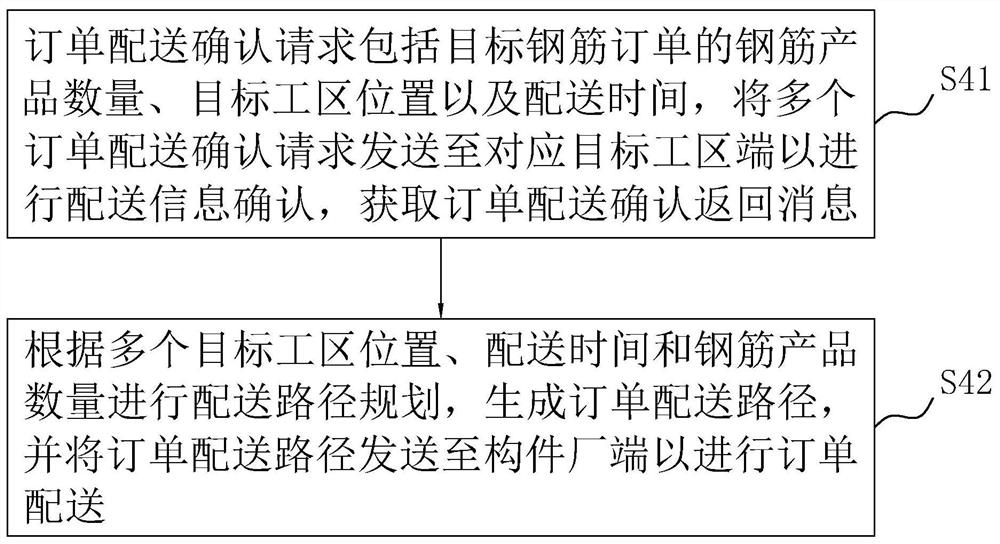

[0124] In one embodiment, a system for centralized processing and distribution of steel bars is provided, and the system for centralized processing and distribution of steel bars corresponds one-to-one to the methods for centralized processing and distribution of steel bars in the above-mentioned embodiments. Such as Figure 4 As shown, the steel bar centralized processing and distribution system includes a steel bar order acquisition module 10 , a steel bar order processing module 20 , a steel bar order confirmation module 30 and a steel bar order delivery module 40 . The detailed description of each functional module is as follows:

[0125] Reinforcement order acquisition module 10, used to receive the reinforcement order information of each work area and send it to the component factory;

[0126] The steel bar order processing module 20 is used to collect statistics on each steel bar order information by the component factory end user, generate a steel bar order processing...

Embodiment 3

[0142] In one embodiment, a computer device is provided, the computer device may be a server, and its internal structure diagram may be as follows Figure 5 shown. The computer device includes a processor, memory, network interface and database connected by a system bus. Wherein, the processor of the computer device is used to provide calculation and control capabilities. The memory of the computer device includes a non-volatile storage medium and an internal memory. The non-volatile storage medium stores an operating system, computer programs and databases. The internal memory provides an environment for the operation of the operating system and computer programs in the non-volatile storage medium. The database of the computer equipment is used to store steel bar order information, audit information, steel product demand plan, steel product batch entry plan and other information. The network interface of the computer device is used to communicate with an external terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com