Anti-deformation crisscross column

A cross-column, anti-deformation technology, applied in the direction of columns, piers, pillars, etc., can solve problems such as distortion, poor verticality, and large thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The content of the present invention will be described below in conjunction with specific embodiments.

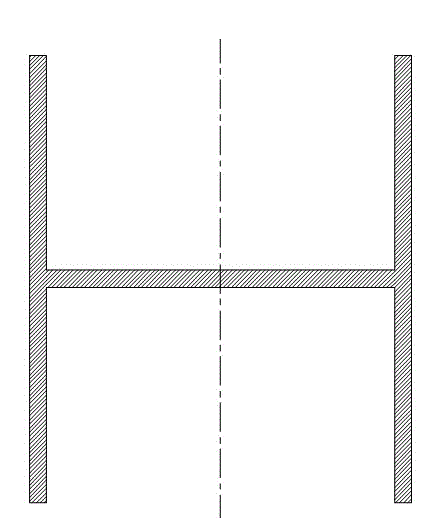

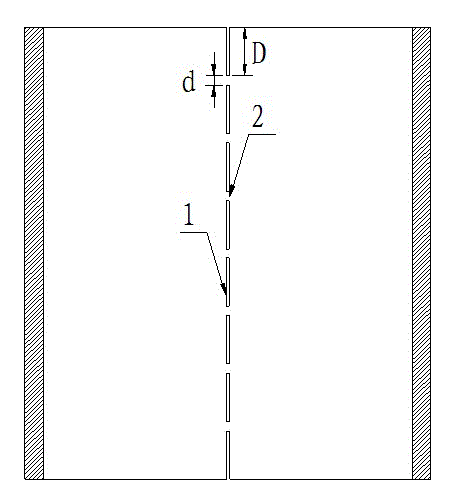

[0013] Such as figure 1 Shown is the H-shaped steel structure schematic diagram of the present invention, figure 2 It is a schematic diagram of cutting the H-shaped steel structure of the present invention. The H-shaped steel structure of the present invention is cut along the center line of the H-shaped steel structure to form a cutting line 1, the length D of the cutting line 1 is 500 mm, and then the connection is retained along the center line to form a connecting part 2, and the length d of the connecting part 2 is 100mm, and then cut along the center line to form the cutting line 1, and this cycle is repeated until all the cutting is completed.

[0014] The H-shaped steel structure cut in this way becomes two symmetrical T-shaped steels connected together. After assembly and submerged arc welding, the connecting part 2 is cut again, so that the cut H-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com