Continuous strain section assembly type wiring method for ultrahigh-strength aluminum conductor steel supported wires

An ultra-high-strength, tension-resistant technology, applied in overhead lines/cable equipment, etc., can solve the problems of increased wire manufacturing cost and construction cost, and achieve the effect of controlling loss and waste, ensuring crimping quality, and reducing high-altitude operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

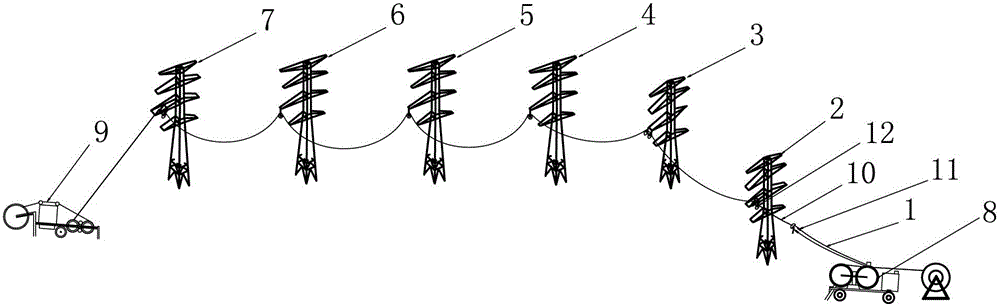

[0013] This embodiment is the wiring of the wires in the left back (facing the large) of tower No. 44 to tower No. 49 of the Lekhui-Zhanzhan 220kV double-circuit transmission line project, of which No. 44, No. 48 and No. 49 are corner towers, and the rest are straight lines Tower, each phase conductor 1 is used 2* JLRZ / EST-400 / 50-250 ultra-high-strength soft aluminum stranded wire with steel core, the method of stringing adopts the method of assembly-type stringing method for continuous tensile section of ultra-high-strength soft aluminum stranded wire with steel core according to the present invention, tower 7 of No. 44 The traction machine 9 is arranged on the side, and the tension machine 8 is arranged on the side of No. 49 tower 2. The specific operation method is as follows:

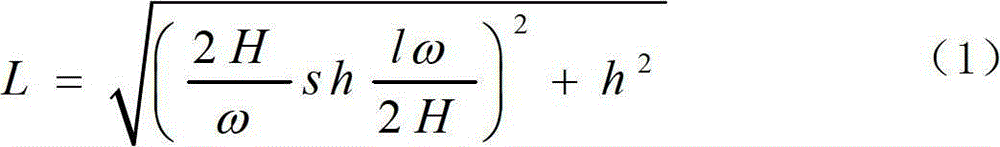

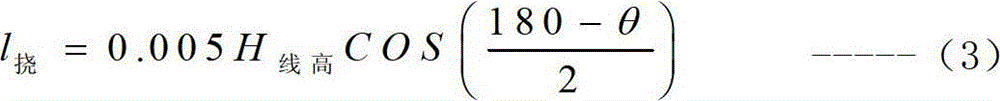

[0014] The calculation of the length of the conductor’s tensile section should be based on the normal temperature condition, that is, 15°C, no wind, no ice, and the normal tension condition. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com