The Method of Fixing Conductor with Compression Tension Clamp

A tension clamp, compression technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of mountain fire and other disasters, non-removable replacement, lowering of crimping quality, etc., to improve reliability and safety, avoid personal injury, etc. Potential safety hazards and the effect of improving the quality of crimping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

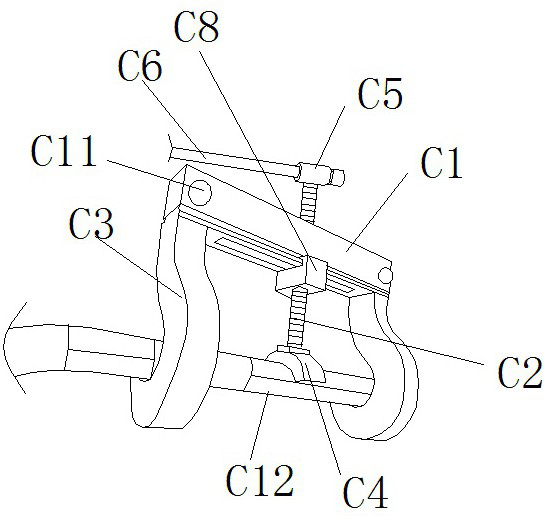

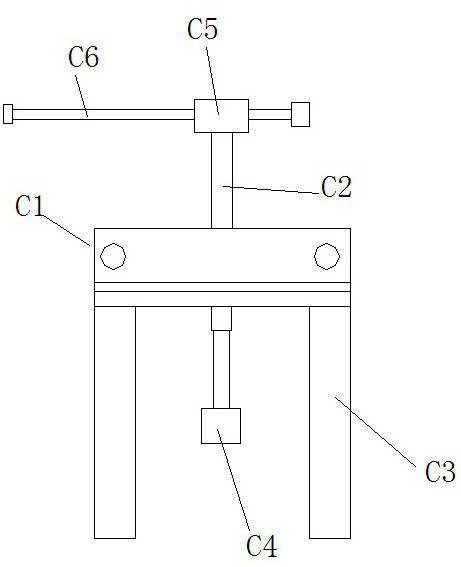

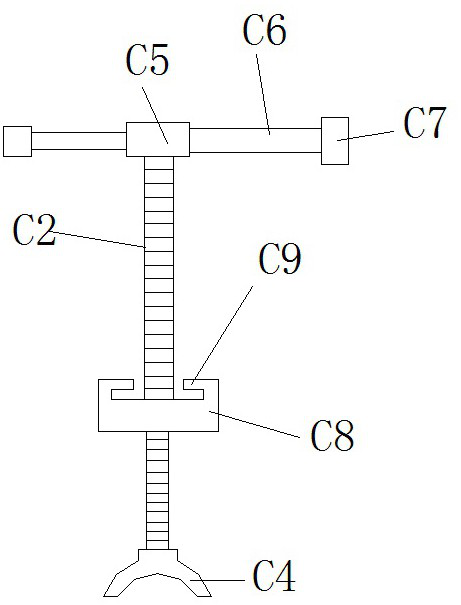

[0036] Example: such as Figure 1~12 As shown, in this embodiment, a method for fixing wires with compression-type tension clamps is provided, including a wire trimming mechanism B for trimming the ends of power transmission wires, and a rapid The pipe threading mechanism A and the bending correction mechanism C used for crimping and correcting the threaded transmission wire and the aluminum pipe.

[0037] The bending correction mechanism includes a support part C1, a screw C2 is provided in the middle of the support part, and a fixed hook C3 for supporting the tension clamp is provided under both sides of the support part, and an arc-shaped indenter is provided at the lower end of the screw rod C4, use the lower pressure to realize the correction of the strain clamp.

[0038] The crimping surface of the arc-shaped indenter can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com