Automatic edge curling device for steel door panels

A technology of curling device and door panel, which is applied in the direction of feeding device, stripping device, positioning device, etc., can solve the problems of reducing the service life of the equipment, labor, and increasing the cost of the enterprise, so as to save processing costs, ensure the quality of curling, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

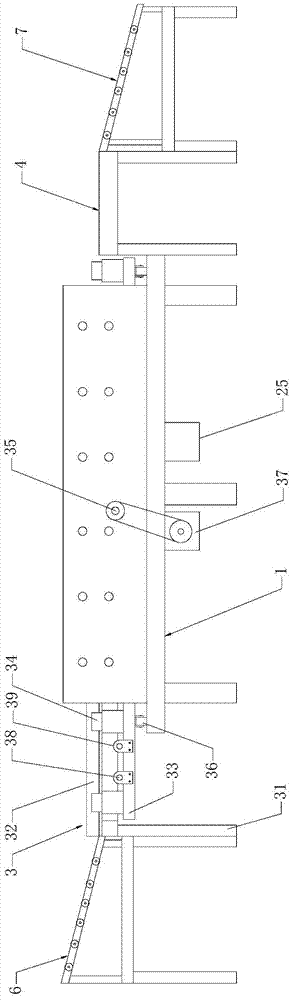

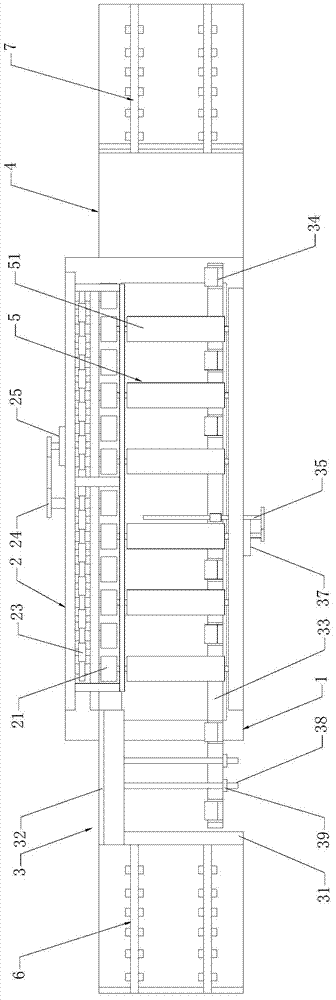

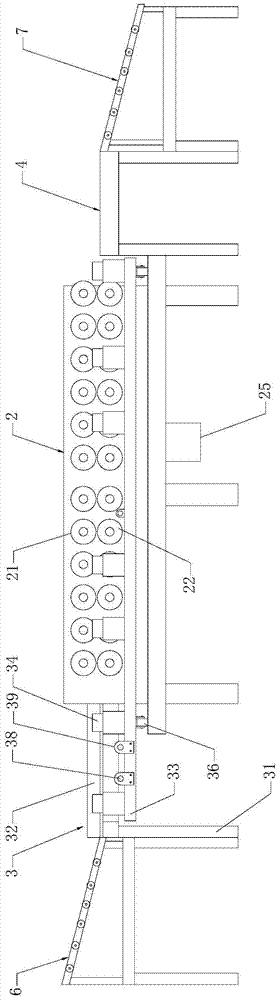

[0019] see Figure 1 to Figure 6 , the present invention includes a frame 1, a roller group 2 installed on one side of the frame 1 and used for one-sided curling of panels, a loading platform 3 installed at one end of the frame 1, and a lower panel installed at the other end of the frame 1. Material platform4.

[0020] The feeding platform 3 includes a frame body 31, a fixed baffle 32, a movable crossbeam 33 and a plurality of movable blocks 34. The fixed baffle 32 is installed on the upper end of the frame body 31 and is close to the side of the roller group 2. The moving The crossbeam 33 is movably installed on the upper end of the frame body 31 by a lead screw 35 and is positioned on the opposite side of the roller group 2. A roller 36 is arranged between the movable crossbeam 33 and the longitudinal bar of the frame 1, and the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com