Construction method for ceiling radiant heating/cooling coil

A technology of radiant heating and construction method, which is applied in the direction of pipeline layout, construction, building structure, etc., can solve the problems of easy damage, cumbersome, ceiling radiant heating/coil construction and installation, and achieve the effect of overcoming the complicated and cumbersome installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

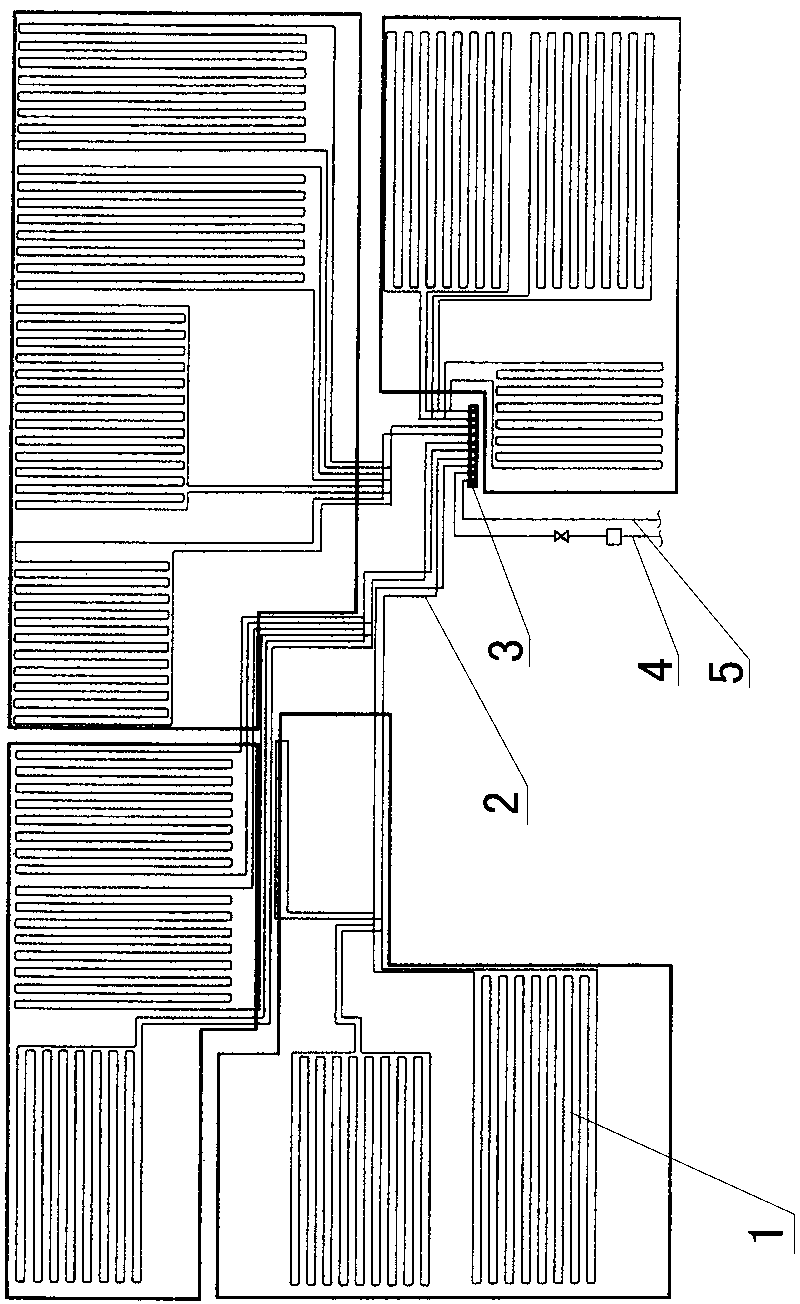

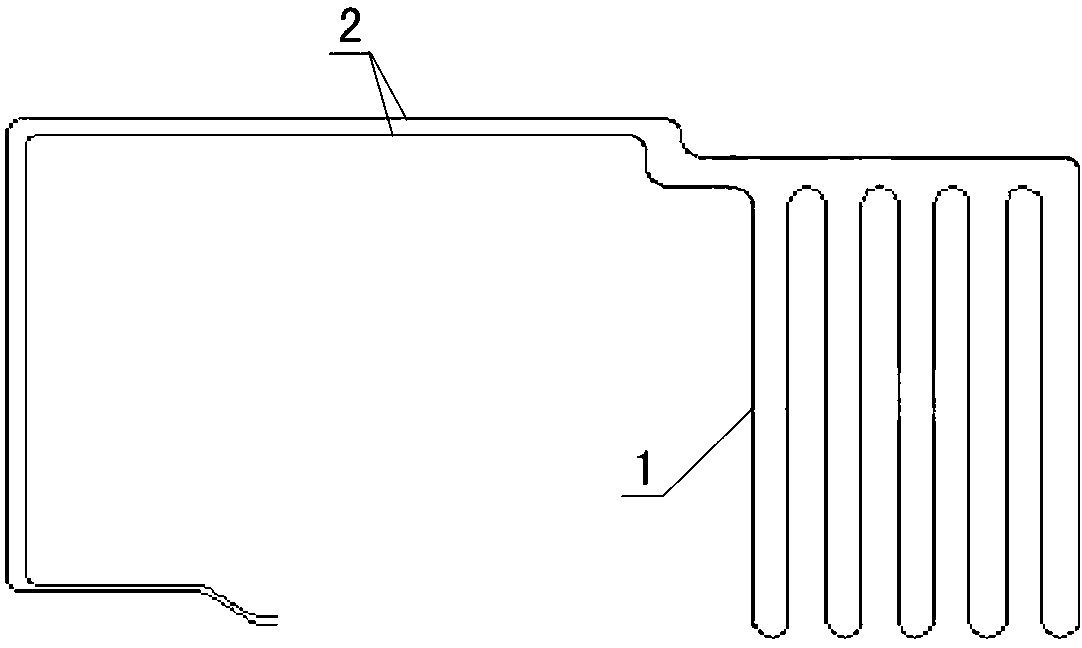

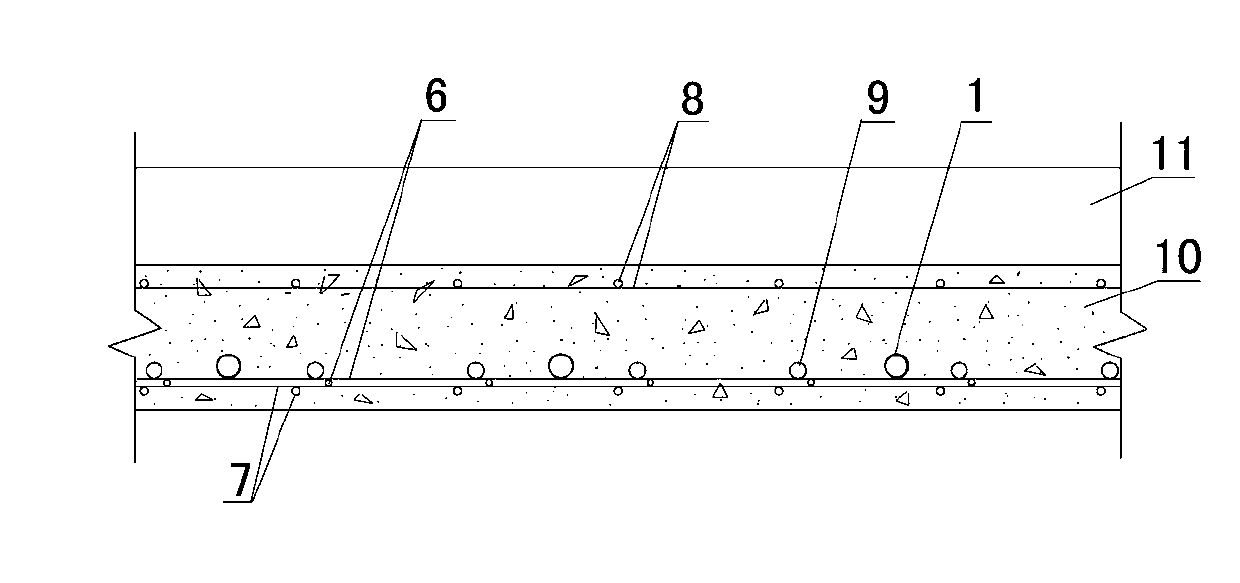

[0029] Examples see Figure 1-3 As shown, the ceiling radiant heating / cooling coil construction method has the following construction steps.

[0030] Step 1. In order to speed up the construction progress and ensure the construction quality of the ceiling tube, the steel mesh rack 6 and the ceiling radiant heating / cooling coil 1 are bound in an open place, that is, the size and size of the steel mesh rack are first determined according to the data provided by the design drawings , and then processed into a steel racket with round steel, and the ceiling radiant heating / cooling coil (referred to as the ceiling tube) is tied to the steel racket with non-metallic binding wires (such as plastic binding wires) according to the designed spacing. The radiant heating / cooling coils of the ceiling shall be bound according to the direction and size required by the design drawings, and the swing pipe 2 used to connect the sub-collector outside the steel racket shall be reserved (the swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com