Construction method for prefabricating directly-buried uncompensated centralized heat supply pipeline by electrically preheating

A heat supply pipeline and central heating technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems affecting system elongation, large site requirements, changing processes, etc., to achieve operation Safe and reliable, fewer construction workers, uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

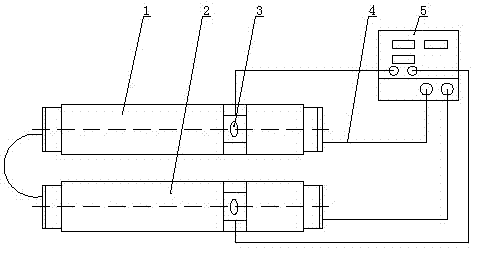

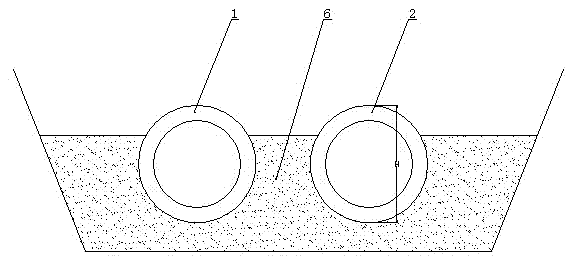

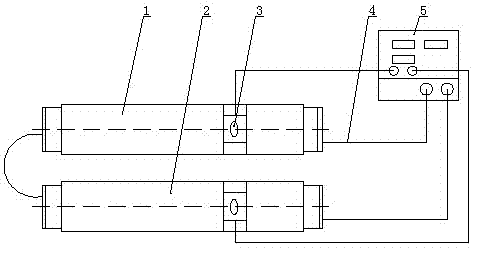

[0028] A construction method of electric preheating prefabricated direct buried non-compensated central heating pipelines, the construction method steps are: (1) Laying pairs of water supply and heating pipelines 1 and return water heating pipelines 2 after slotting, adjusting the coordinates of the heating pipelines and Elevation, and calculate the preheating temperature and the design elongation of the water supply heating pipeline and the design elongation of the return water heating pipeline;

[0029] The formula for calculating the preheating temperature:

[0030] t y =t max - [〔σ〕+ν·σ tan ] / E·α (°C)

[0031] In the formula: t y ——preheating temperature (°C)

[0032] 〔σ〕——Basic allowable stress of the steel at the calculated tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com