Execution method for feeding tiny tunnel into ultra heavy section tunnel transversally

A technology with super large section and construction method, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as hidden safety hazards, slow construction, long construction period, etc., and achieve the effect of safe construction method, convenient construction and powerful measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

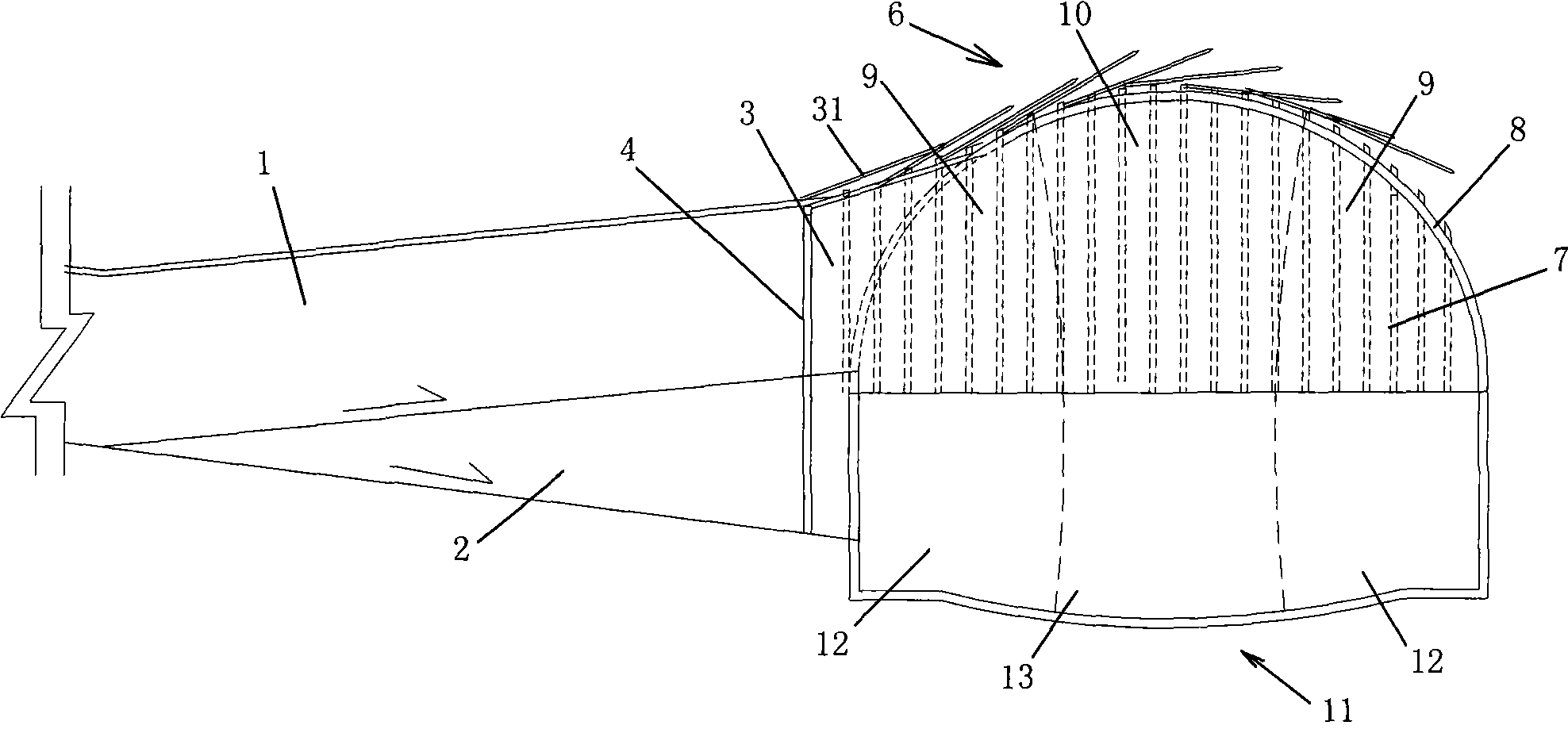

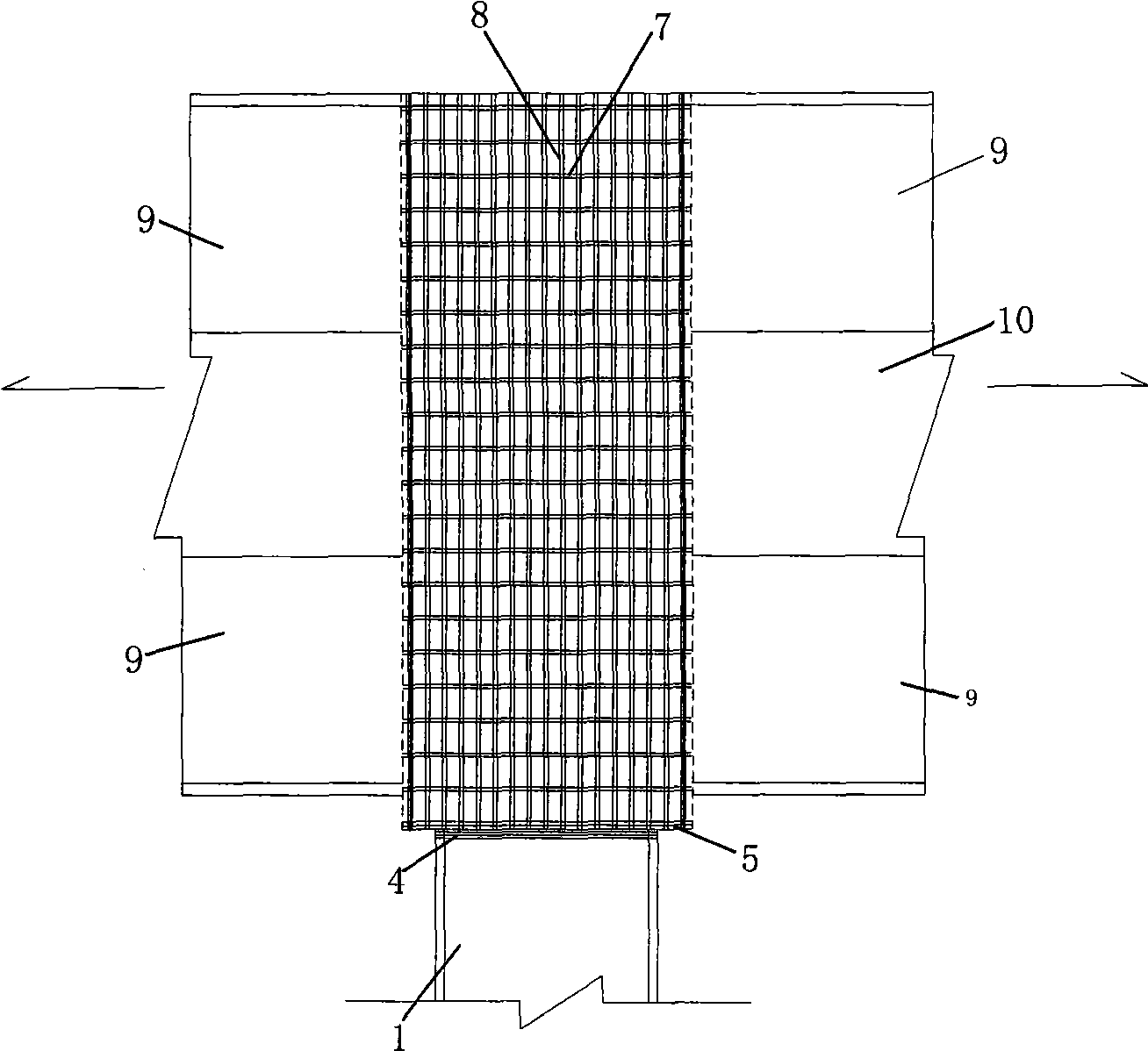

[0031] In this embodiment, the construction methods are formulated respectively according to the four parts of the small-section tunnel, the portal section, the opening section and the entrance into the large-section tunnel. The specific construction steps are as follows:

[0032] 1. Construction of small cross-section tunnels

[0033] figure 1 As shown, the upper area 1 of the small-section tunnel is excavated along the upper steps to prepare for entering the upper area of the large-section tunnel;

[0034] According to the site conditions, at the point where the small-section tunnel is 22m away from the large-section tunnel, start uphill with a slope of 10% to meet the requirements of entering the upper half of the large-section tunnel above the arch line. The small-section tunnel is excavated in two parts according to the upper and lower steps method. First, the upper part of the small-section tunnel is constructed according to the original section, and the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com