Patents

Literature

32results about How to "Appropriate method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

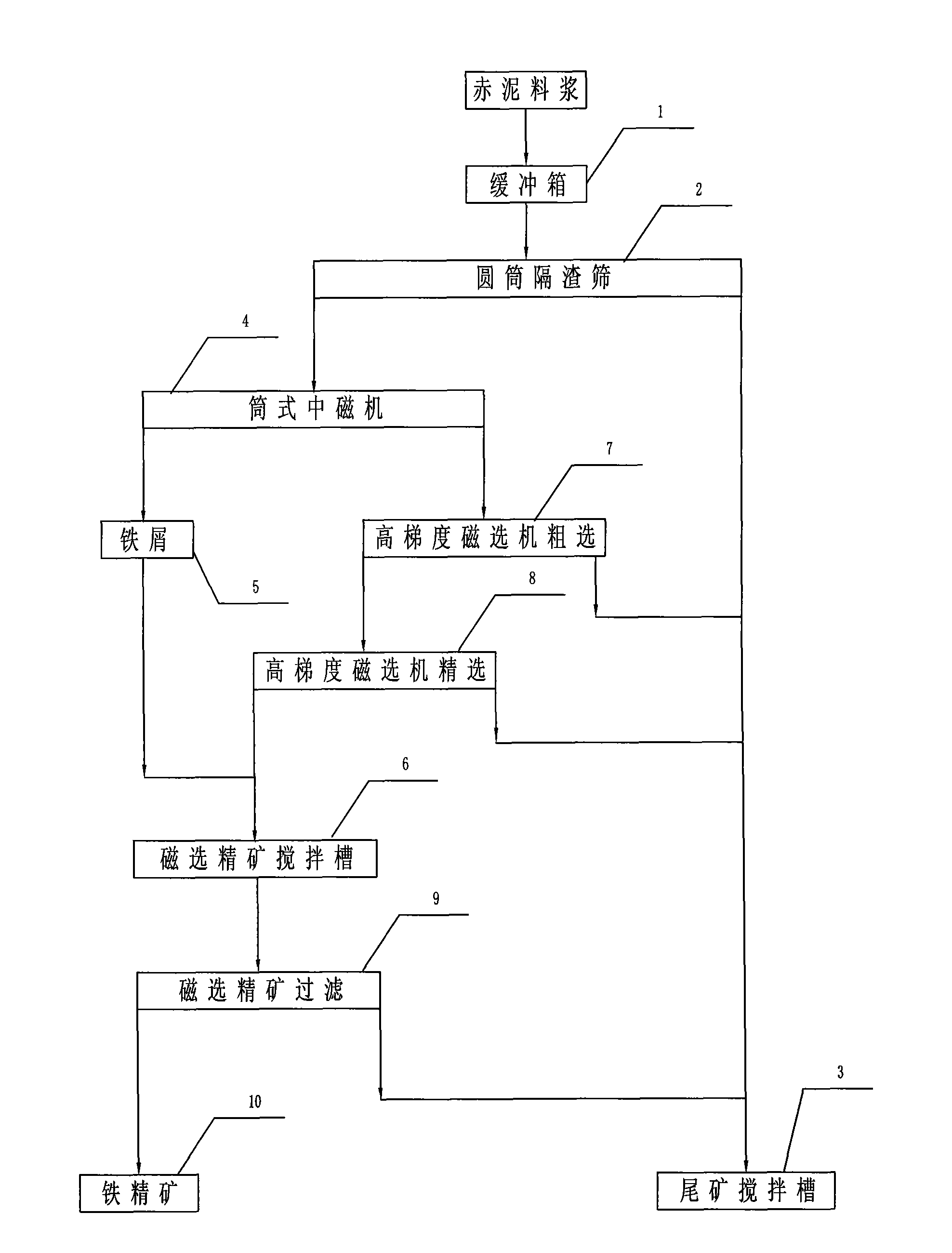

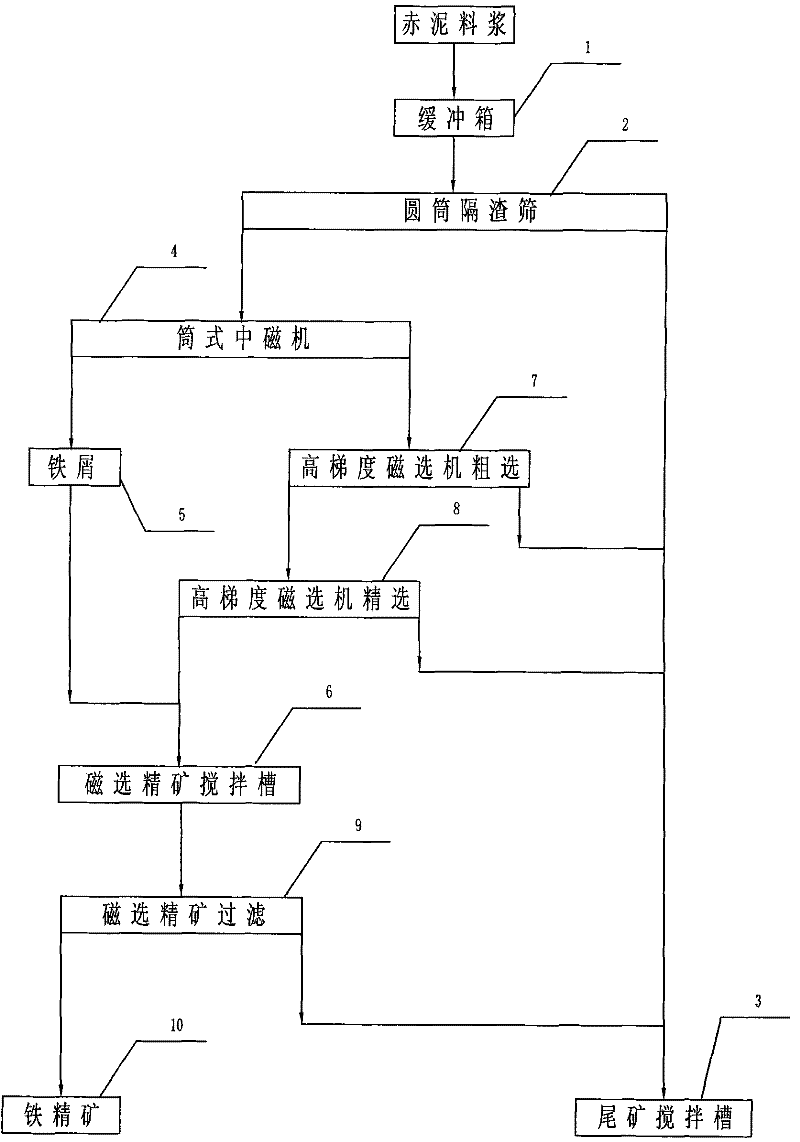

Method for recovering iron concentrates from alumina red mud

The invention provides a method for recovering iron concentrates from alumina red mud, adopting the following technical scheme: a medium-intensity magnetic separator is adopted to recover the stronglymagnetic iron concentrates after red mud tailings are subjected to slag separation, then the obtained tailings are subjected to open rough separating and refined separating by a high gradient magnetic separator to recover weakly magnetic iron concentrates, combining the strongly magnetic iron concentrates and the weakly magnetic iron concentrates and carrying out dehydrating to obtain the iron concentrates. An slon vertical ring pulsating high gradient magnetic separator is selected to replace the traditional high gradient magnetic separator, and the medium-intensity magnetic separator is adopted to recover the strongly magnetic iron concentrates before. The method provided by the invention can be used for efficiently recovering the iron concentrates from the alumina red mud, and the obtained iron concentrates have high grades and good recovery rate; therefore, the method increases the utilization ratio of the alumina red mud, reduces the environmental pollution and is suitable for large-scale application.

Owner:山西华兴铝业有限公司

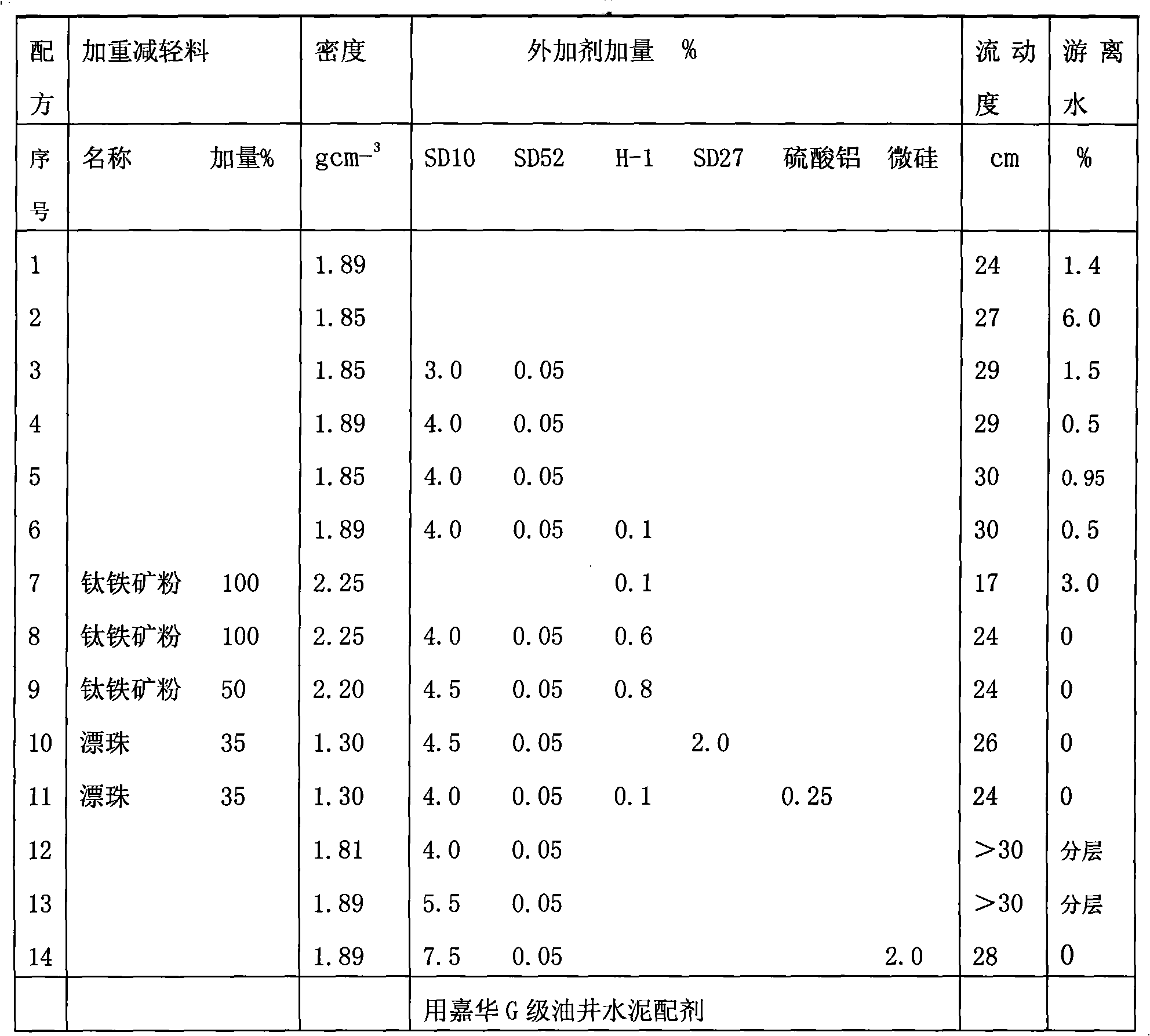

Method for preparing fluid loss additive for drilling fluid

ActiveCN101851491AEffective protectionImprove rheologyDrilling compositionHydroxyethyl cellulosePolyacrylamide

The invention provides a method for preparing a fluid loss additive for drilling fluid. The fluid loss additive is mainly prepared from the following raw materials in part by weight: 30 to 35 parts of humic acid sodium, 20 to 30 parts of etherified starch, 10 to 15 parts of hydroxyethyl cellulose, 5 to 10 parts of polyacrylamide and 5 to 10 parts of water soluble silicone oil, preferably 30 parts of humic acid sodium, 25 parts of etherified starch, 10 parts of hydroxyethyl cellulose, 7 parts of polyacrylamide and 6 parts of water soluble silicone oil. The preparation method comprises the following steps of: heating the raw materials to 120 DEG C under sealing and stirring conditions and under the pressure of 0.8 to 1.2MPa, keeping the temperature for 8 to 10 hours to obtain a semi-finished product; and drying the semi-finished product at the temperature of between 85 and 100 DEG C, and adding 5 to 10 parts of sulfonated asphalt into the semi-finished product to obtain the fluid loss additive, wherein at the step of synthesizing the etherified starch, 50 to 80 parts of starch are soaked into 50 to 80 parts of 10-percent sodium hydroxide solution for swelling for 24 to 48 hours, the mixed solution is dried at the temperature of between 75 and 85 DEG C, the obtained product is ground to obtain the semi-finished product, 30 to 50 parts of chloroactic acid are added into 30 to 50 parts of the semi-finished product, the mixed solution is sealed and stirred, the pressure is controlled to be 0.8 to 1.2MPa, the PH value is adjusted to 7 to 8, and the mixed solution is heated to 135 to 145 DEG C and then kept at the constant temperature for 15 to 17 hours to obtain the etherified starch. The fluid loss additive possesses high anti-salt, anti-calcium and anti-high temperature properties, and has the effects of carrying drill cuttings and making mud cakes dense.

Owner:XINJIANG DELAND

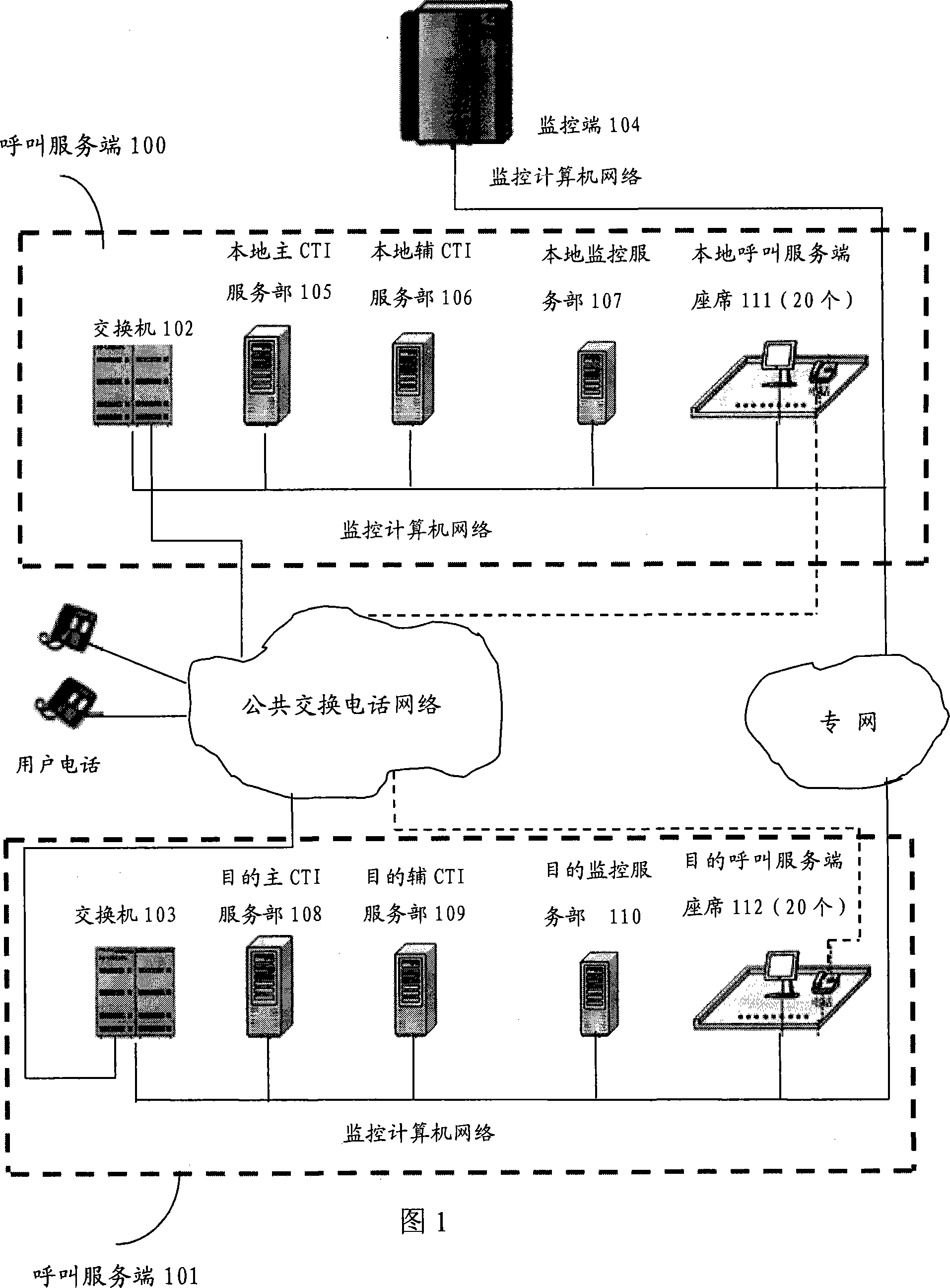

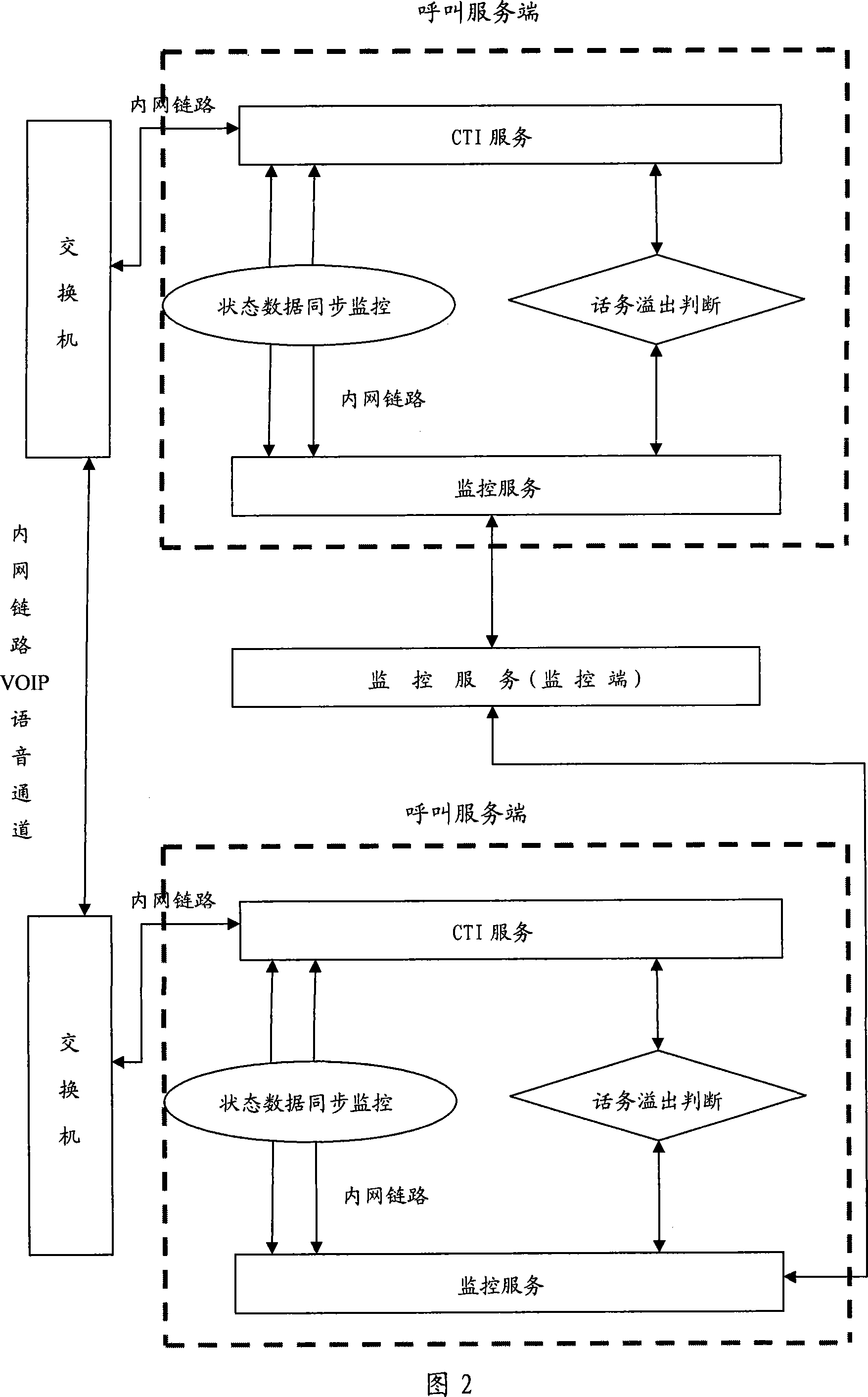

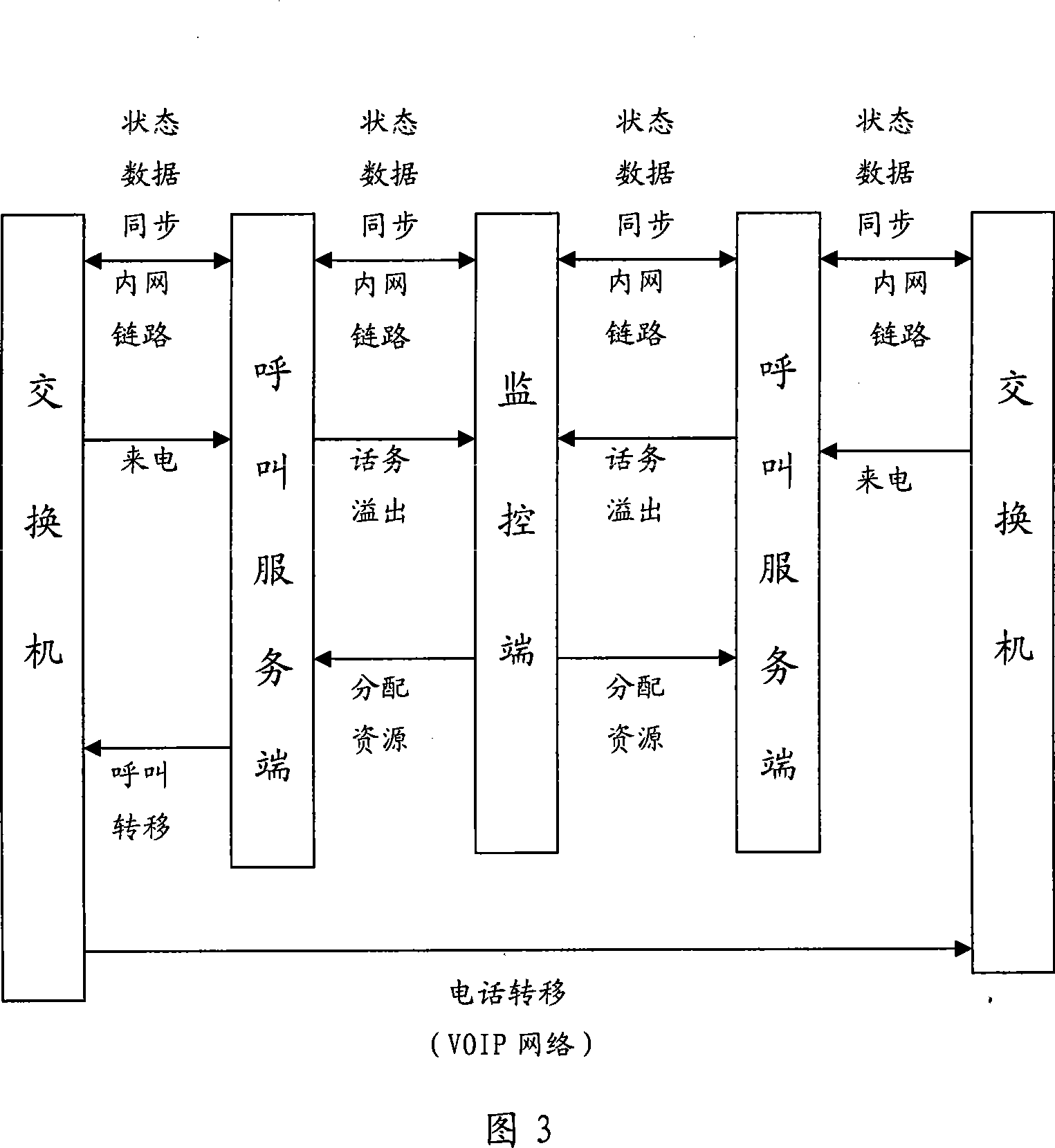

Distributed call centre system and traffic distributed transferring method

InactiveCN101227632ASimple structureReasonable designSpecial service for subscribersSelection arrangementsEngineeringService department

The invention relates to a distributed call center system which conducts the management by using regions as units, and a method which conducts the traffic distributed transfer through using the system. The system comprises a calling service terminal which is set according to regions, a switch and a monitor terminal which controls the traffic distributed transfer of the calling service terminal. The traffic distributed transfer comprises the following steps firstly detecting the local seated condition by the local monitor service department, secondly, sending the application of the seat spillover traffic to the local CTI service department by the local monitor service department, thirdly, sending the application of the seat spillover traffic to the monitor terminal by the local CTI service department, distributing the traffic resource by the monitor terminal, and finally transferring the application of the traffic to the calling terminal which set by a empty region by the local CTI service department according to the distributed information of the traffic resource which is sent by the monitor terminal through the switch. The distributed call center system of the invention has a simple structure, a reasonable design and a proper method, which has a high practical value.

Owner:SHENZHEN CLOU ELECTRONICS

Oral medical composition for preventing and/or treating cold and application thereof

InactiveCN103212079AReduce stimulationEffective controlPill deliveryPharmaceutical non-active ingredientsOral medicationMouth mucosa

The invention provides an oral medical composition for preventing and / or treating cold and application thereof. The oral medical composition comprises effective components for preventing and / or treating cold or early cold complication trend, and medically acceptable auxiliary materials, or further comprises assistant components, wherein the effective components for preventing and / or treating cold or early cold complication trend comprise medical components which are not suitable for being orally taken directly, such as components which are greatly irritating to mouth mucosa or bitter, or smelly; and the proportion of the medically acceptable auxiliary materials in the oral medical composition is greater than that of the auxiliary materials in the conventional oral medical composition for preventing and / or treating cold. By means of the technology provided by the invention, medicines which are not accepted and are not directly used or inhibited from oral administration are prepared to efficient medical preparations which can be safely taken and welcomed by patients, and have the remarkable effect of preventing and / or treating cold in early stage.

Owner:陆媛

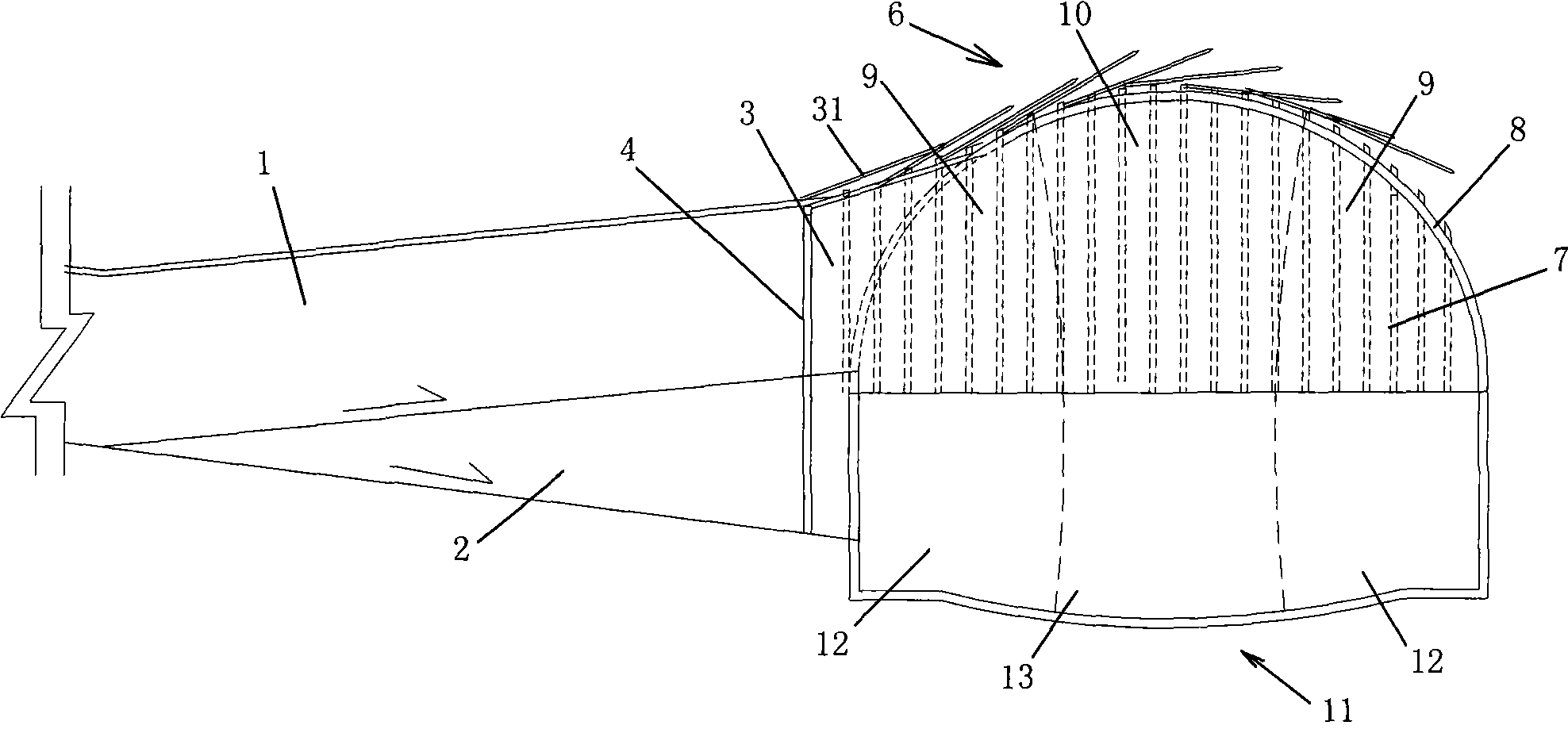

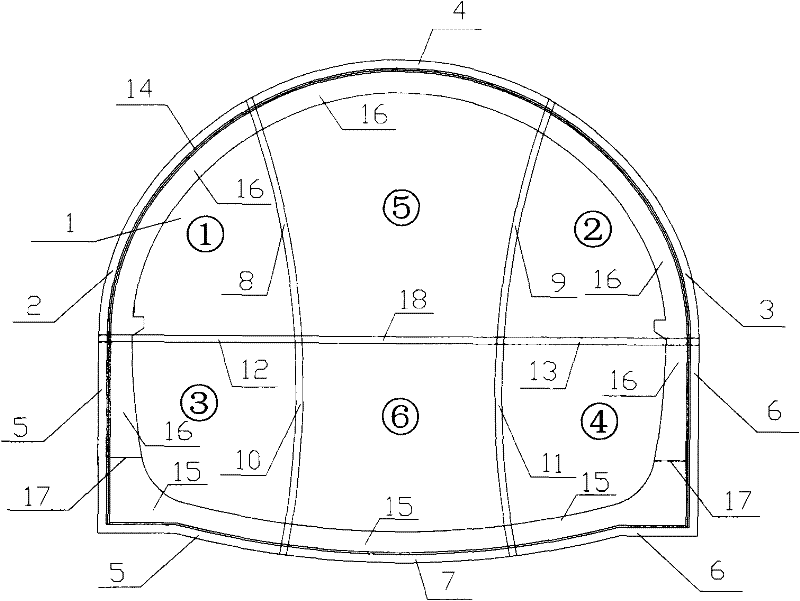

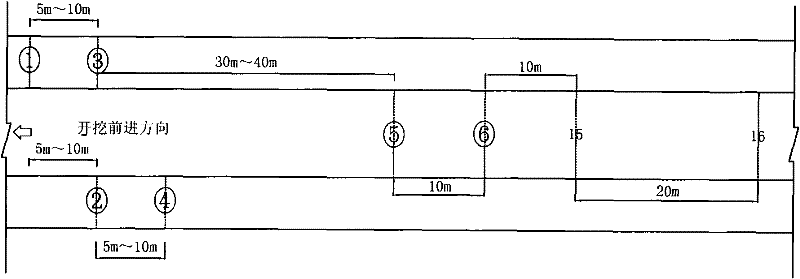

Execution method for feeding tiny tunnel into ultra heavy section tunnel transversally

InactiveCN101545376AConstruction method safetyImprove construction progressTunnelsLower zoneBuilding construction

Owner:THE FOURTH ENG CO LTD OF CTCE GRP

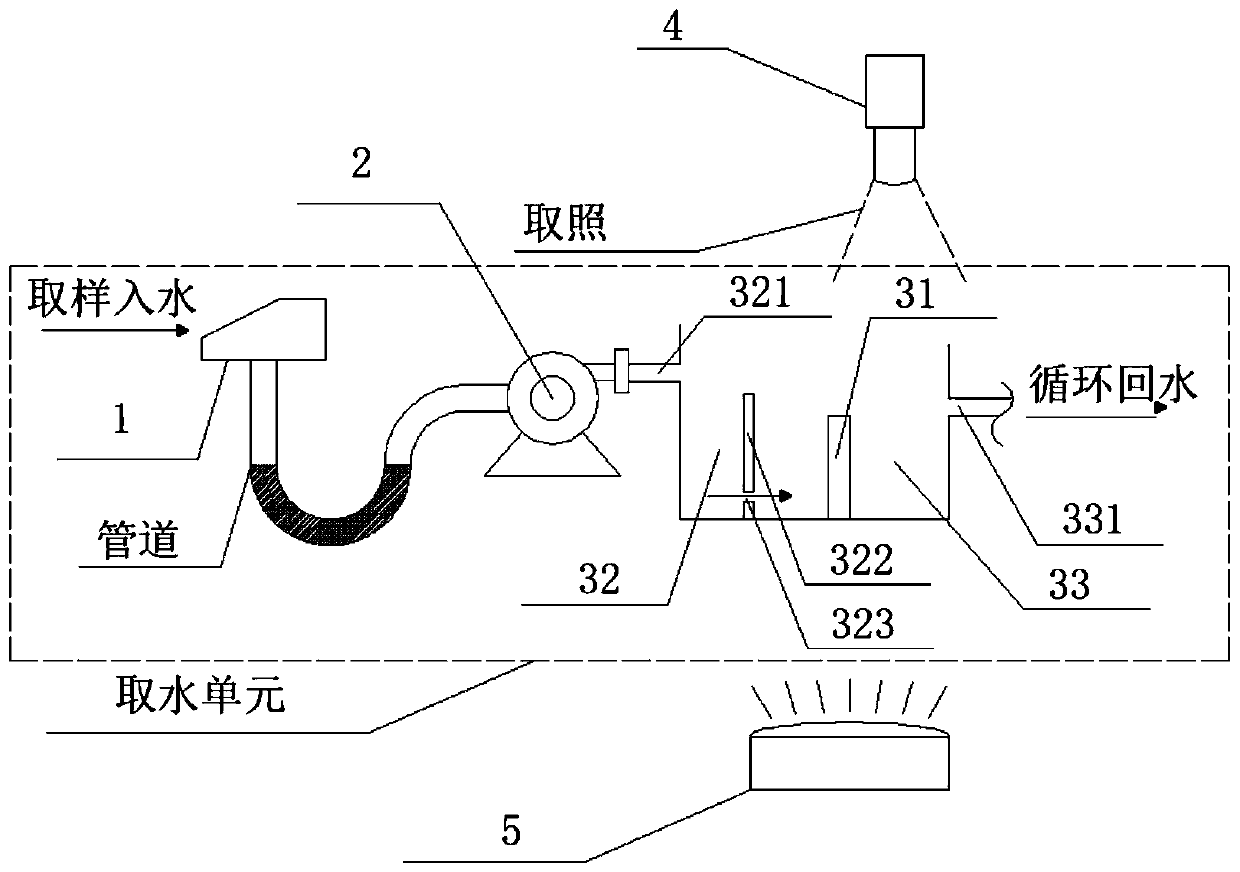

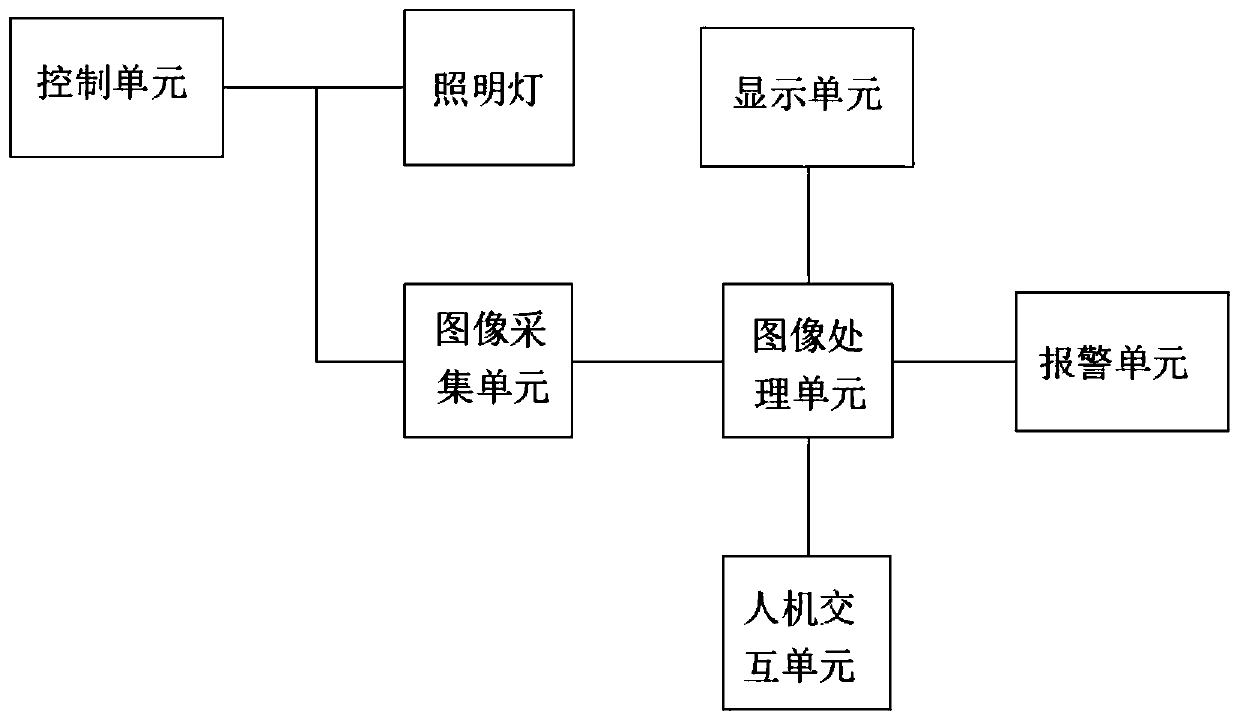

Water quality monitoring system and method based on image identification

ActiveCN110687050AGuaranteed accuracyGuaranteed real-timeMethod using image detector and image signal processingGeneral water supply conservationMonitoring systemWater quality

The invention discloses a water quality monitoring system and method based on image identification. The system comprises a water taking unit and a water quality monitoring unit. The water taking unitcomprises a floating type water taking device, a water suction pump and a water tank which are connected in sequence. An overflow plate is arranged in the water tank and divides the water tank into abuffer bin and an illumination taking bin, and the buffer bin is located on an upstream of the illumination taking bin. Due to adoption of the technical scheme, compared with the prior art, by using the system and the method of the invention, the overflow plate is arranged to inhibit fluctuations of a surface of a monitored water body so that definition of a water body image and accuracy of a detection result are improved, automation of water body surface pollution identification is realized, and identification work efficiency is higher, safer and reliable.

Owner:CINF ENG CO LTD

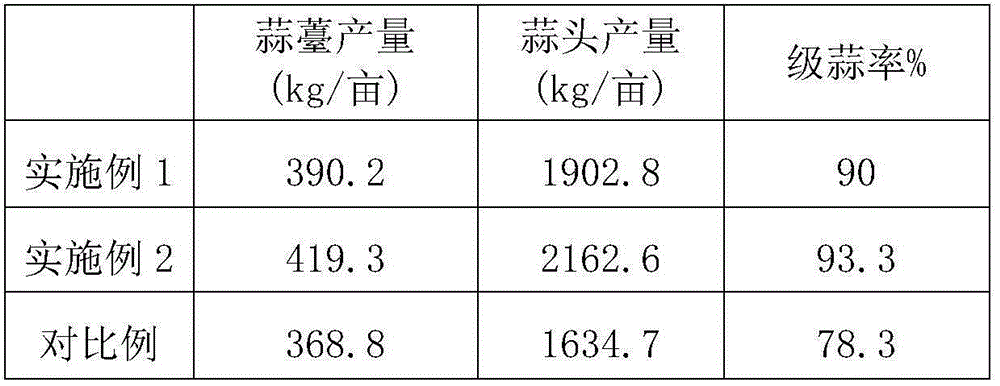

High-yield cultivation method for Jinxiang garlic

InactiveCN105340549AMeet nutritional needs for growthGuaranteed qualityPlant cultivationCultivating equipmentsSoil treatmentShoot

The invention discloses a high-yield cultivation method for Jinxiang garlic. The high-yield cultivation method mainly comprises the steps of seed reservation, base fertilizer applying, soil treatment, soil preparation, seed dressing, planting, watering, film mulching and field management. According to the high-yield cultivation method for the Jinxiang garlic, plant diseases and insect pests are reduced, the quality of the garlic is improved, and compared with that of a conventional cultivation and management mode, the yield of young garlic shoots is improved by 5.8% to 13.7%, and the yield of garlic bulbs is improved by 16.4% to 32.3%.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

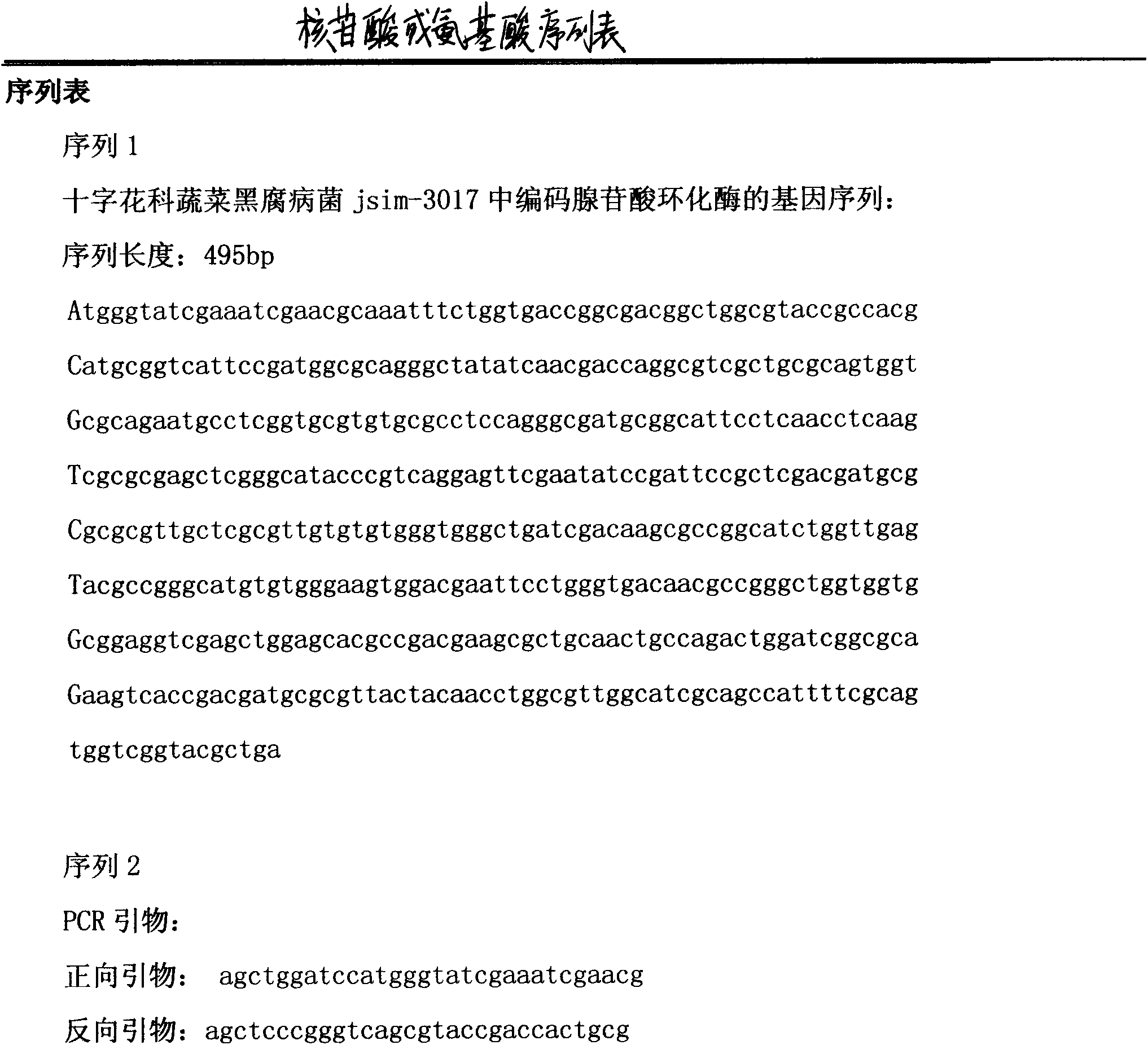

Method utilizing bacillus subtilis to produce adenosine cyclophosphate

InactiveCN104342468AAppropriate methodGood effectMicroorganism based processesFermentationAdenosineMicrobiology

The invention discloses an industrial method to produce adenosine cyclophosphate, which is used as a medicine and biochemical reagent. The invention further discloses a gene which codes a protein with adenylate cyclase activity and can be applied to the production method mentioned above, a recombinant DNA containing the gene, a novel bacterium strain containing the recombinant DNA, and a method utilizing the novel bacterium strain to produce adenosine cyclophosphate.

Owner:JIANSGU INST OF MICROBIOLOGY

Pharyngitis treating Chinese medicine plaster

InactiveCN1349821ASatisfied with the effectSymptoms disappear quicklyHydroxy compound active ingredientsAerosol deliveryDiseaseSide effect

The Chinese medicine plaster for external application for curing pharyngitis, tonsillitis, laryngitis and parotitis is made up by using 18 Chinese medicinal materials of ledebouriella root, lonicera flower, forsythia fruit, dried / fresh rehmannia root, scrophularia root, ophiopogon tuber and others through a certain preparation process. Said medicine plaster possesses the functions of expelling wind, clearing heat, removing toxic substances, relieving sore-throat, reflenishing yin essence and moisturizing the viscera, reducing phlegm and resolving masses, and is non-toxic, and has no any side effects. On every plaster carrier 0.1-0.6g of the medicine powder is applied to obtain the invented product.

Owner:赵健忠

Method for increasing production and improving quality of bee products

InactiveCN103109780AIncrease productionHigh organic contentAnimal husbandryBee productsOrganic content

The invention provides a method for increasing production and improving quality of bee product. The method mainly includes the steps of (1) confirming planned breeding quantity of male bees; (2) formulating reasonable male bee breeding time; (3) utilizing male bee combs to breed the male bees; (4) providing suitable temperature and humidity conditions; (5) feeding sufficient honey powder feed; (6) increasing male bee combs; and (7) cross breeding in groups. Via reasonable male bee breeding time and proportion, sufficient honey powder feed, suitable temperature and humidity conditions, a scientific breeding method and a group cross-breeding method, yield of the bee product of each comb is increased by 167%, and organic content (baume degree) in the bee product is increased by 8%.

Owner:ANSHUN CITY XIXIU DISTRICT GUOXING APICULTURE SPECIALIZED COOP

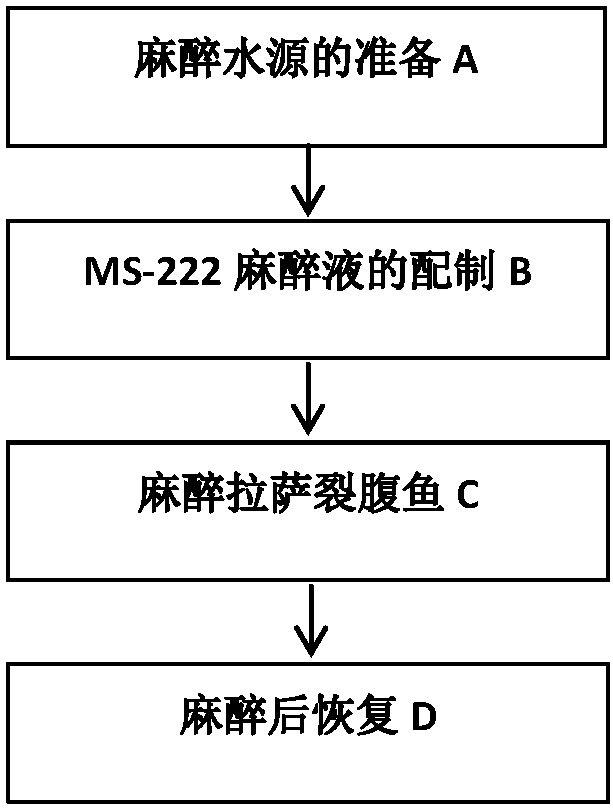

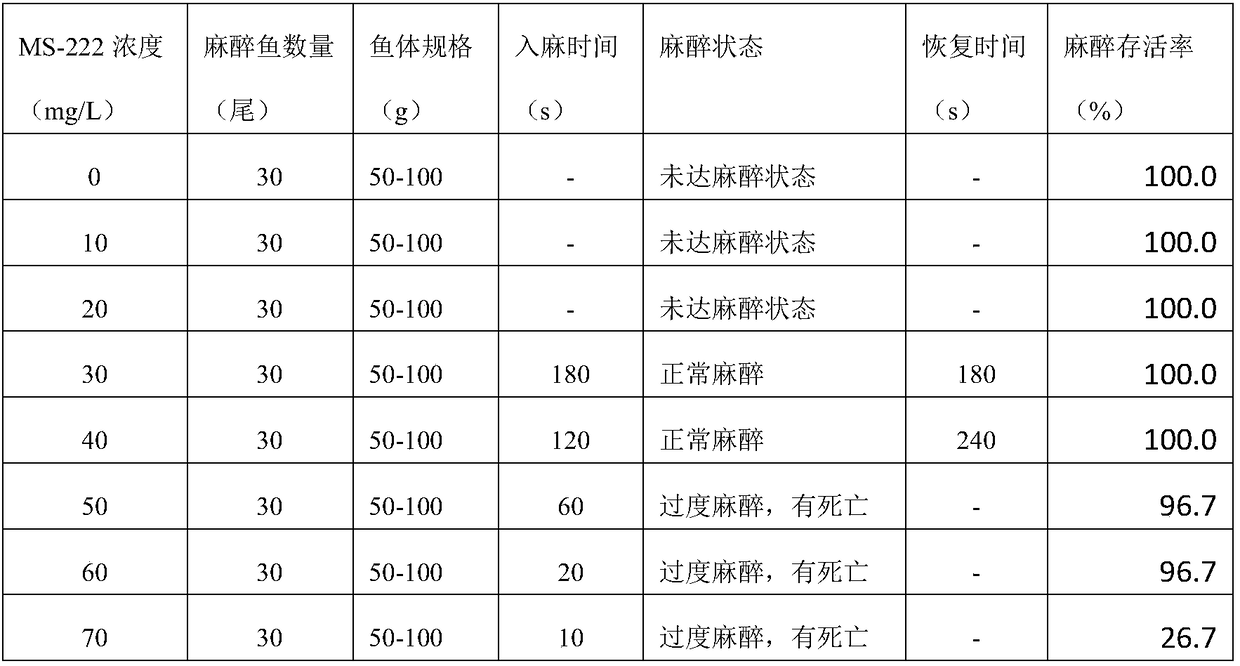

Schizothorax waltoni anesthesia method

InactiveCN108324708AFix the injurySolve the technical problems of sickness and even deathOrganic active ingredientsClimate change adaptationDiseaseWater source

The invention discloses a schizothorax waltoni anesthesia method and relates to application of the method in schizothorax waltoni long-distance transport and short-time water-leaving practice of schizothorax waltoni. The method includes steps: 1) anesthesia water source preparation A, to be more specific, adding a water source at the same temperature with water in a schizothorax waltoni aquaculture pond into an anesthesia container, wherein the temperature is 15-20 DEG C, and dissolved oxygen content is larger than or equal to 5mg / L; 2) MS-222 anesthesia liquid preparation B, to be more specific, adding MS-222 powder into the water source obtained in the step 1) to prepare anesthesia liquid; 3) schizothorax waltoni anesthesia C, to be more specific, subjecting schizothorax waltoni to anesthesia in the anesthesia liquid; 4) after-anesthesia recovery, to be more specific, enabling schizothorax waltoni to recover to normally swim for 3-6min in clear water after anesthesia. The method is feasible, simple and convenient to operate and effective in anesthesia effect, and problems of disease resistance decline and low survival rate due to stress reaction of schizothorax waltoni in transport and water-leaving process are solved.

Owner:YANGTZE RIVER FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

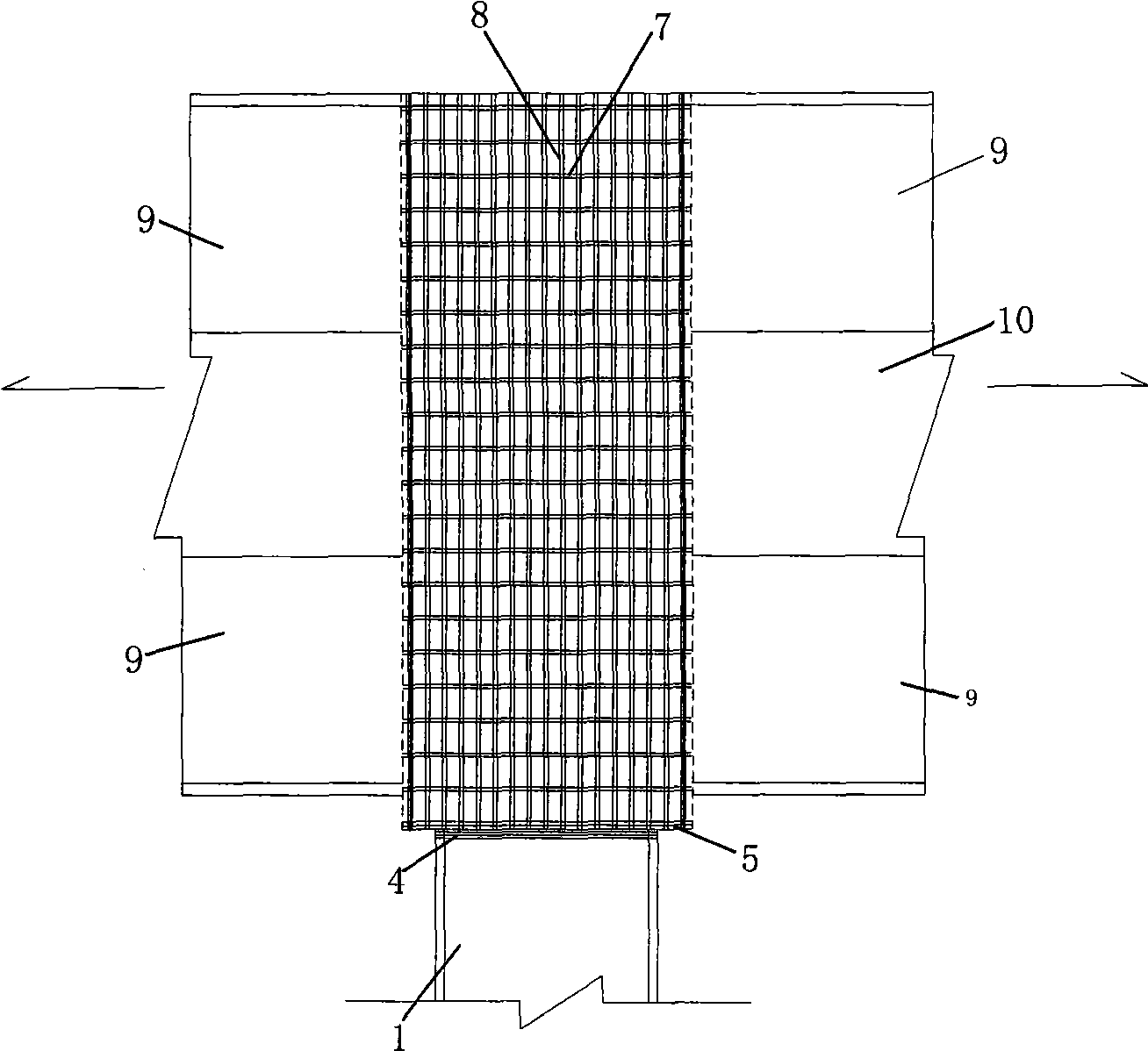

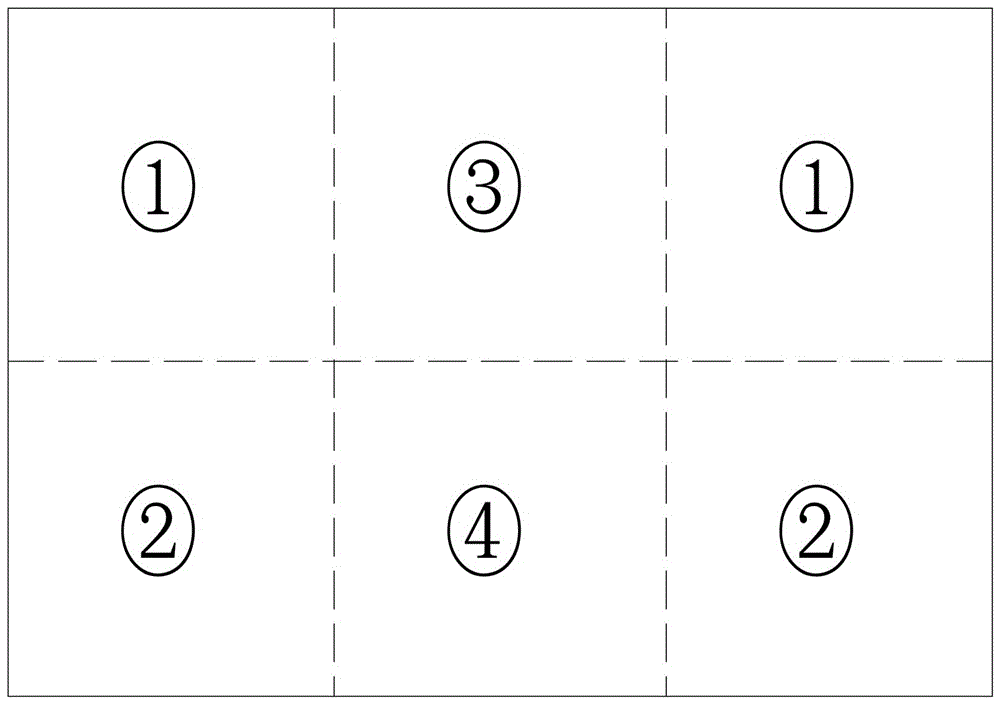

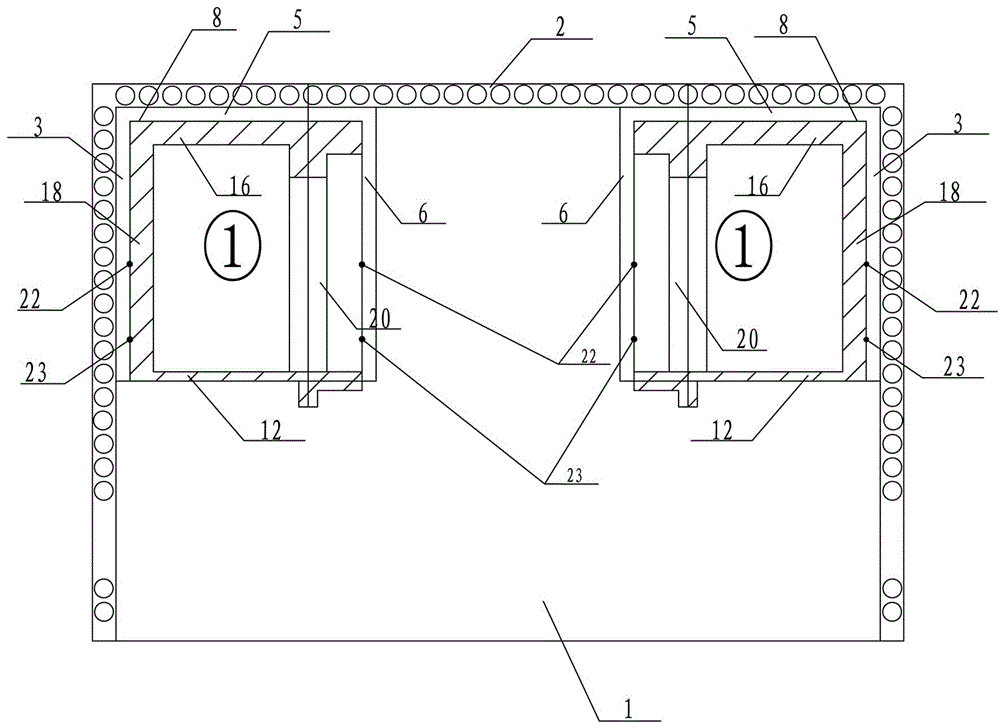

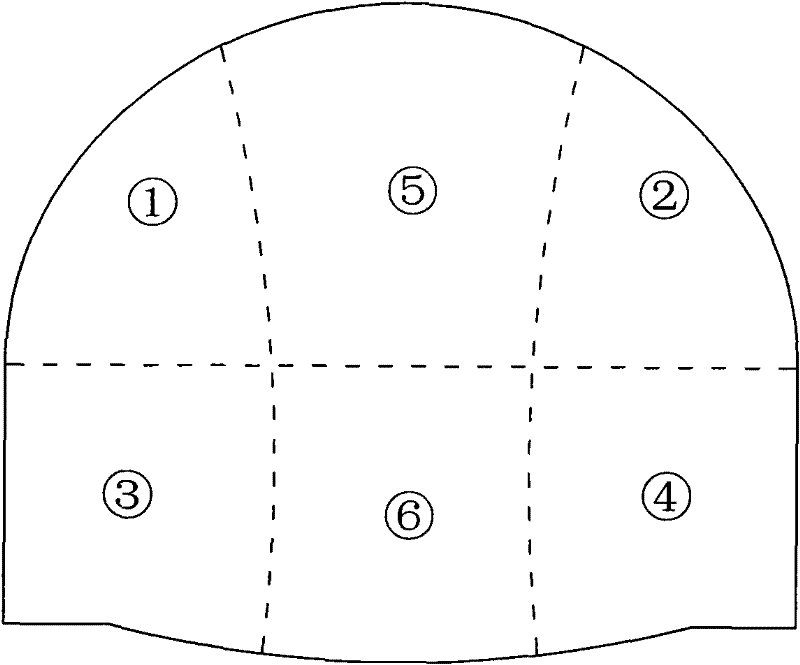

Ultra-shallow-buried rectangular large section four-step underground excavation construction method

InactiveCN106368711AFewer excavation stepsLess temporary supportUnderground chambersTunnel liningEngineeringBuilding construction

The invention relates to an ultra-shallow-buried rectangular large section four-step underground excavation construction method. The method is characterized in that a whole section is divided into six blocks on a rectangular large section, the six blocks are constructed in four steps according to up-down division and left-middle-right division, specifically, the upper left area and the upper right area are constructed in the step 1, the upper middle area is constructed in the step 3, the lower left area and the lower right area are constructed in the step 2, and the lower middle area is constructed in the step 4; and the whole section is separated into two layers, and all steps of construction are conducted orderly through a step underground excavation method. According to the ultra-shallow-buried rectangular large section four-step underground excavation construction method, the number of the excavation steps and the number of temporary supports are small, the structure is stable and safe, and the efficiency is high; and the construction progress can be effectively accelerated, and cost investment can be effectively reduced.

Owner:THE SIXTH COMPANY OF CHINA CONSTR FIRST GRP +1

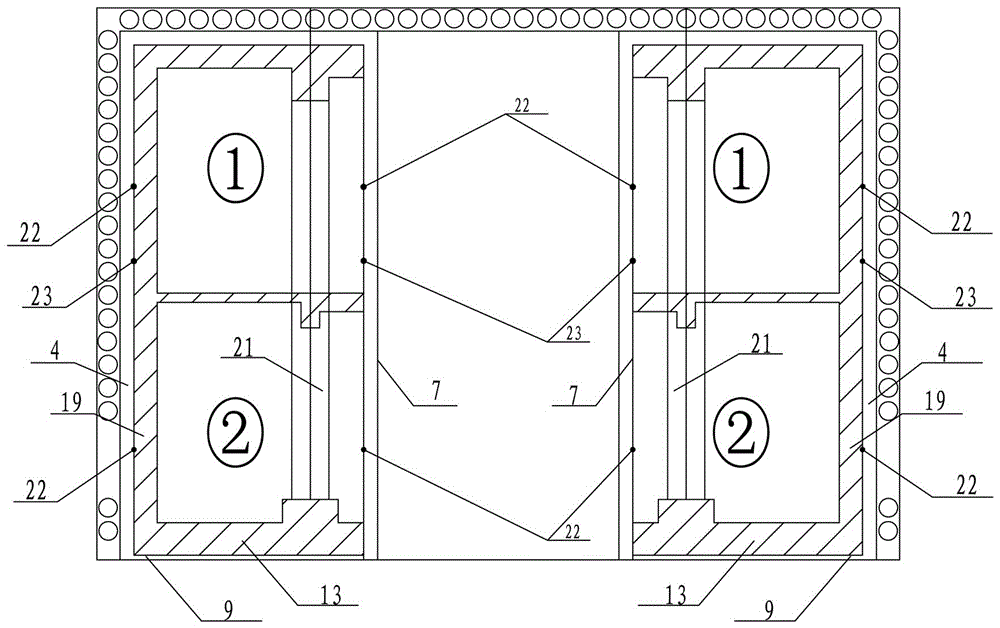

Construction method of six-zone digging of super cross section tunnel

ActiveCN101666232BFewer excavation stepsStable structureUnderground chambersTunnel liningMiddle zoneBuilding construction

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

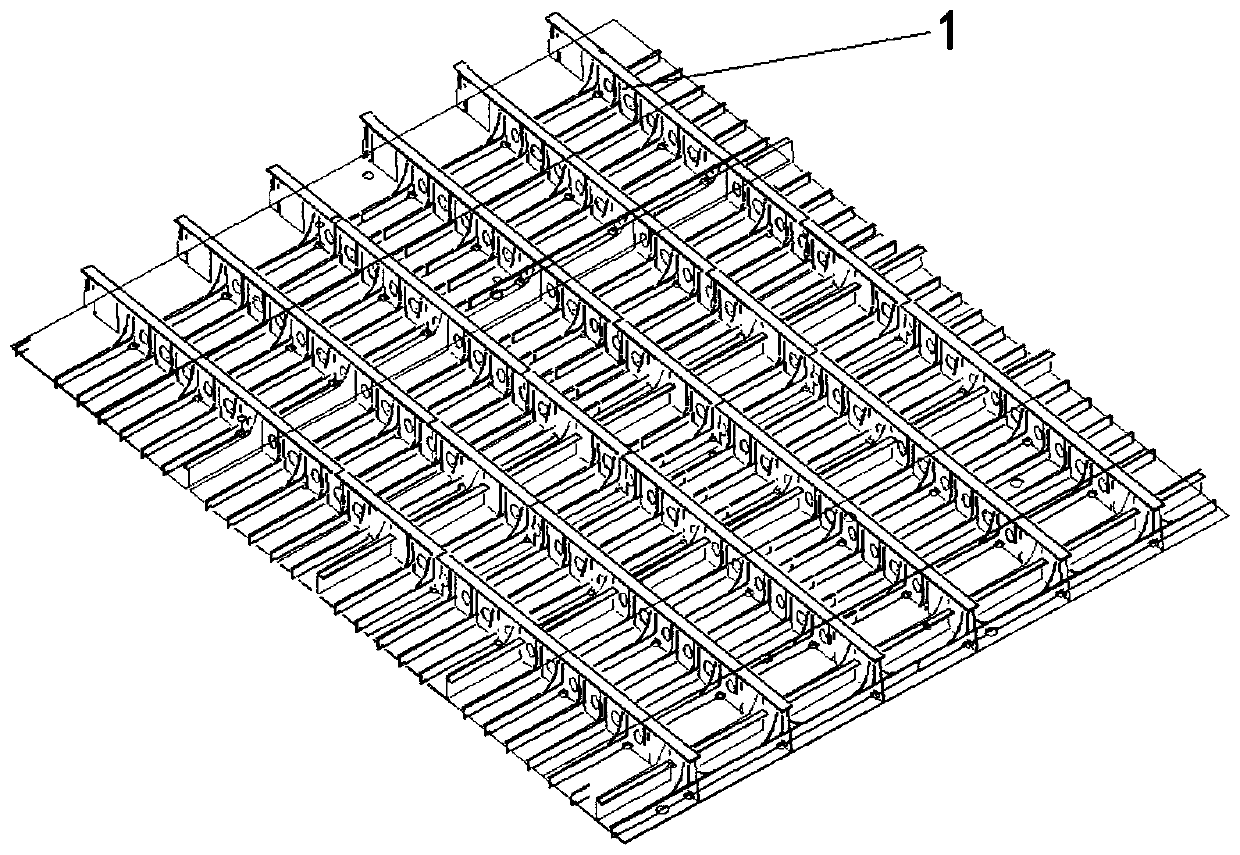

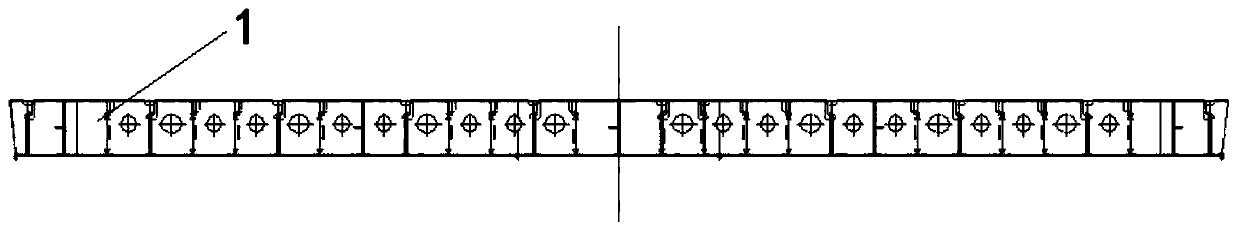

Flatness control process for large-span deck

The invention relates to a flatness control process for a large-span deck, and relates to the technical field of shipbuilding. The process comprises a sectional structure form, a construction process,a precision control method and a deformation correction measure. The process solves the problem of precision control of a ship deck section with a large main size from the perspective of a construction process, is suitable for flatness and precision control of ship section construction with a large main size, and is clear in process, clear in key point, proper in method and high in construction efficiency.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Cat food with digestion-helping and appetite-stimulating effects

InactiveCN108783056AEnsure balanceStimulate the immune systemFood processingAnimal feeding stuffFruit juiceVegetable oil

The present invention discloses cat food with digestion-helping and appetite-stimulating effects. The cat food comprises the following raw materials in parts by weight: 80-120 parts of wheat flour, 20-50 parts of corn flour, 3-6 parts of apple juice, 3-6 parts of malt, 3-6 parts of probiotics, 5-11 parts of Chinese yam powder, 5-11 parts of sweet wormwood herb, 3-5 parts of poria cocos, 3-5 partsof chicken's gizzard-membrane, 10-15 parts of bananas, 1-3 parts of taurine, 3-5 parts of licorice, 3-5 parts of apricot kernels, 5-9 parts of kelp, 4-8 parts of dried tangerine peels, 5-9 parts of haws, 3-7 parts of nostoc flagelliforme, 2-6 parts of tea polyphenols, 3-7 parts of hazelnut kernels, 4-8 parts of hedychium spicatum seeds, 2-6 parts of thunbergia fragrans stem leaves, 5-8 parts of vegetable oil, 1-4 parts of edible salt and 3-6 parts of honey. The cat food is reasonable in design, proper in method, good in the appetite-stimulating effect and suitable for promotion.

Owner:邢台市伊萨宠物食品有限公司

Low-cost synthesis method of rosin modified phenolic resin

The invention discloses a low-cost synthesis method of rosin modified phenolic resin. The low-cost synthesis method comprises the following steps: weighing rosin and heating until the rosin is melted;then adding grade-A phenolic resin prepared by S1; reacting at 230 to 260 DEG C for 6 to 9 h; weighing vegetable oil and heating until the vegetable oil is melted; then adding the vegetable oil intoS2 and reacting at 230 to 260 DEG C for 6 to 9 h; adding polyol into a mixture obtained by S2, wherein the adding amount of the polyol is 4 to 6 percent of the weight of the rosin in S2; carrying outesterification reaction at the temperature of 260 to 340 DEG C, wherein the reaction time is 11 to 20 h; then removing a low-boiling-point small molecular substance in vacuum to obtain the rosin modified phenolic resin. The low-cost synthesis method disclosed by the invention has the advantages of reasonable design, proper method, low cost, good quality and high purity and is suitable for being popularized.

Owner:新洲(武平)林化有限公司

Method for preparing fluid loss additive for drilling fluid

ActiveCN101851491BAppropriate methodSignificant technological progressDrilling compositionHydroxyethyl cellulosePolyacrylamide

Owner:XINJIANG DELAND

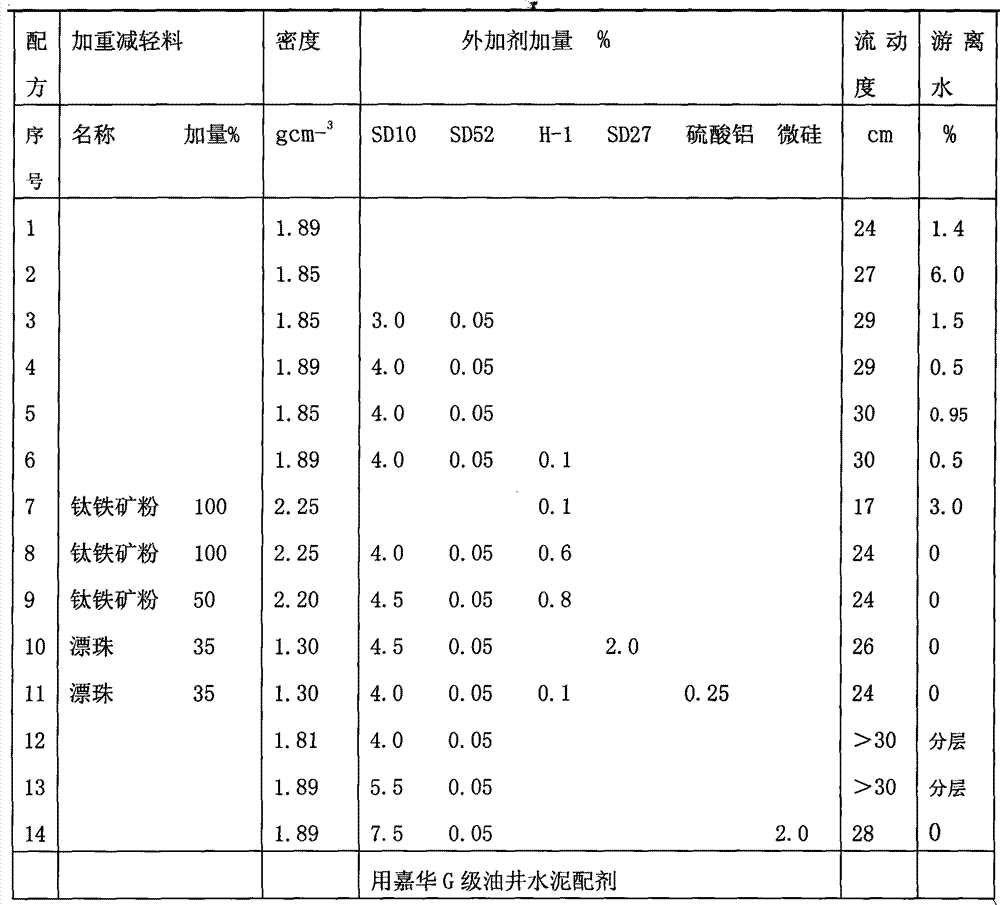

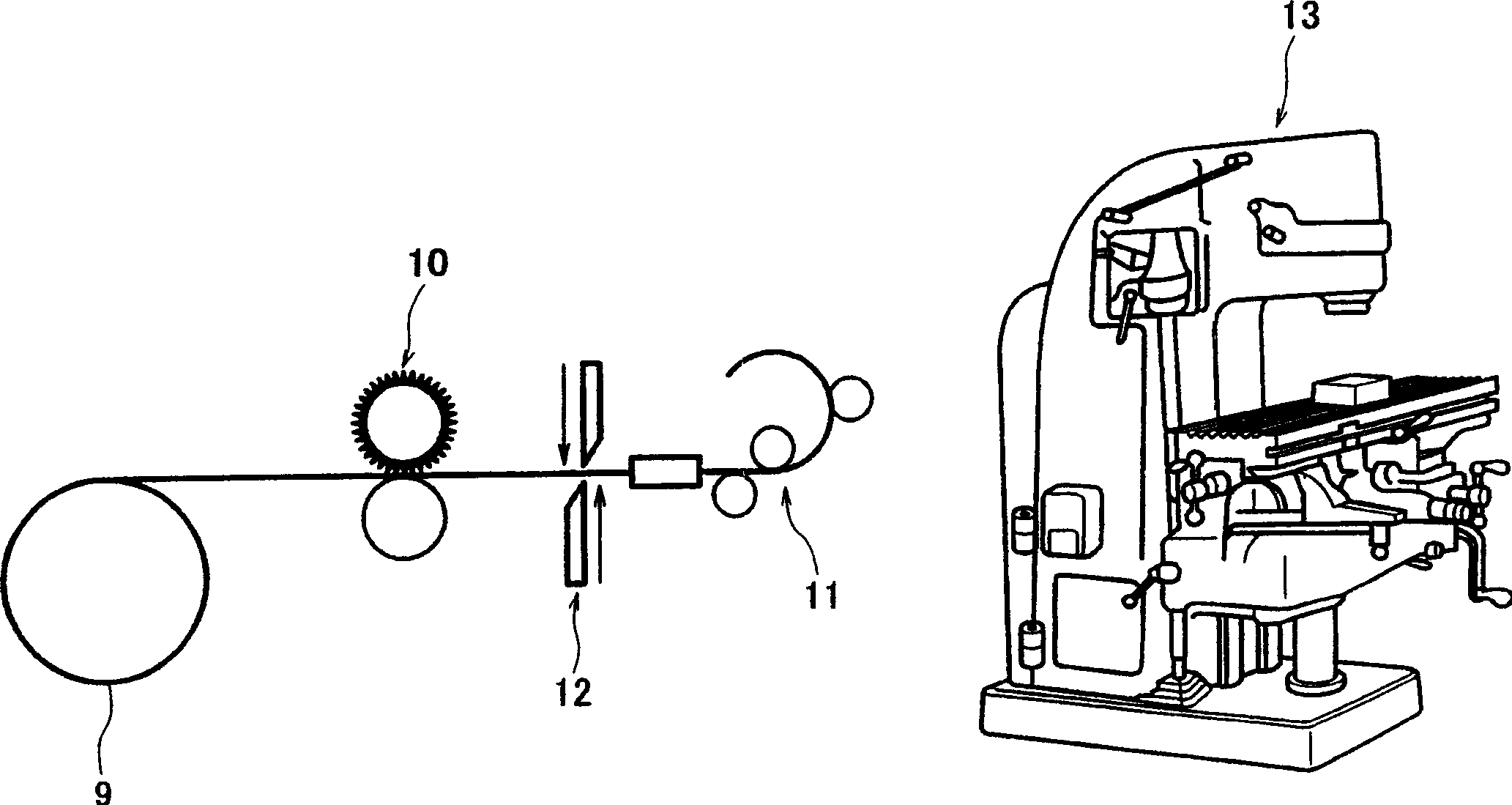

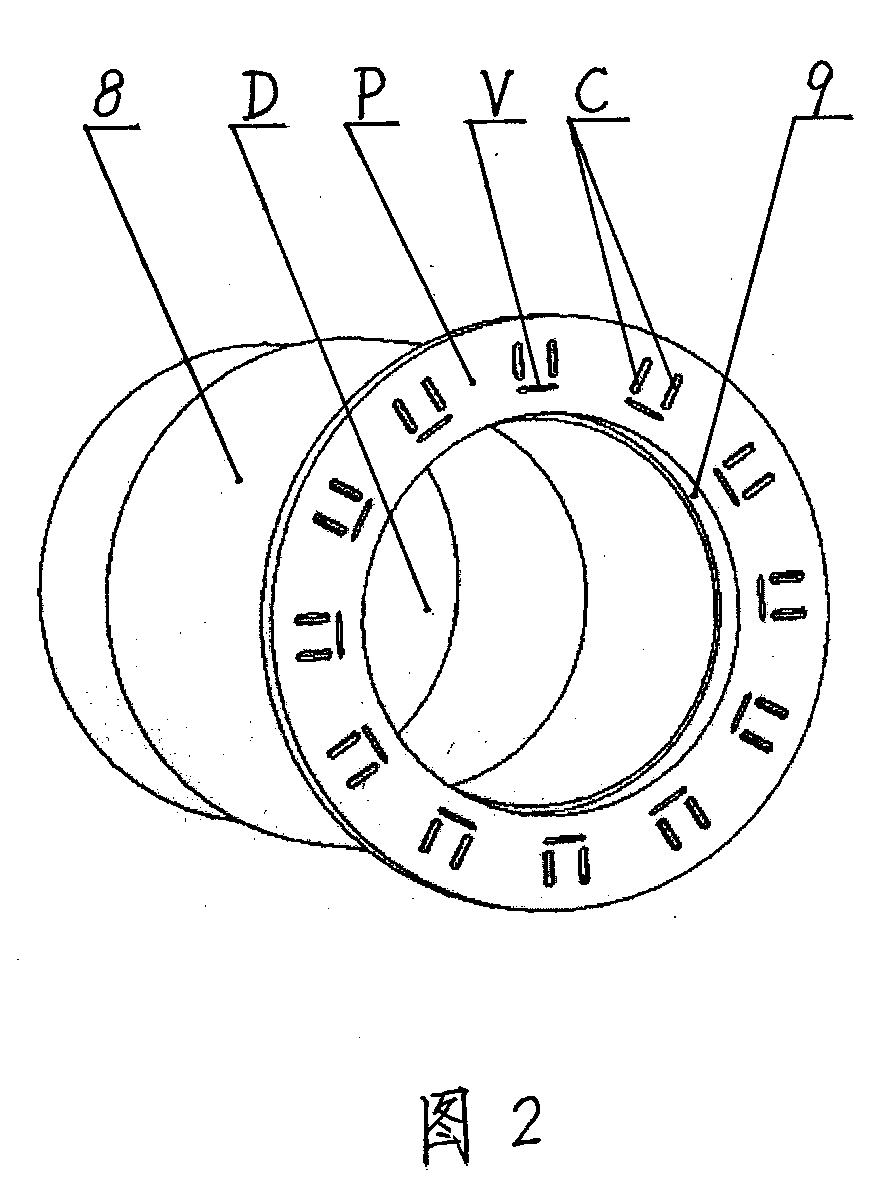

Method and device for producing grip ring of pipe joint and grip ring for pipe joint

A metal wire material suitable for use as a grip ring material, having good surface properties and produced at low cost; a producing method therefor; and a producing device therefor. For this purpose, a metal wire material (34) is passed through a shape correction unit (14) to have its coil-like winding-produced deformation removed. Further, while preventing the downward or upward turn of the metal wire material (34) by upper and lower hold rollers (19, 20, and 26, 27), a continuous wedge-like groove is formed in the metal wire material (34) by a first cutting roller (21) and a second cutting roller (23).

Owner:金井宏彰

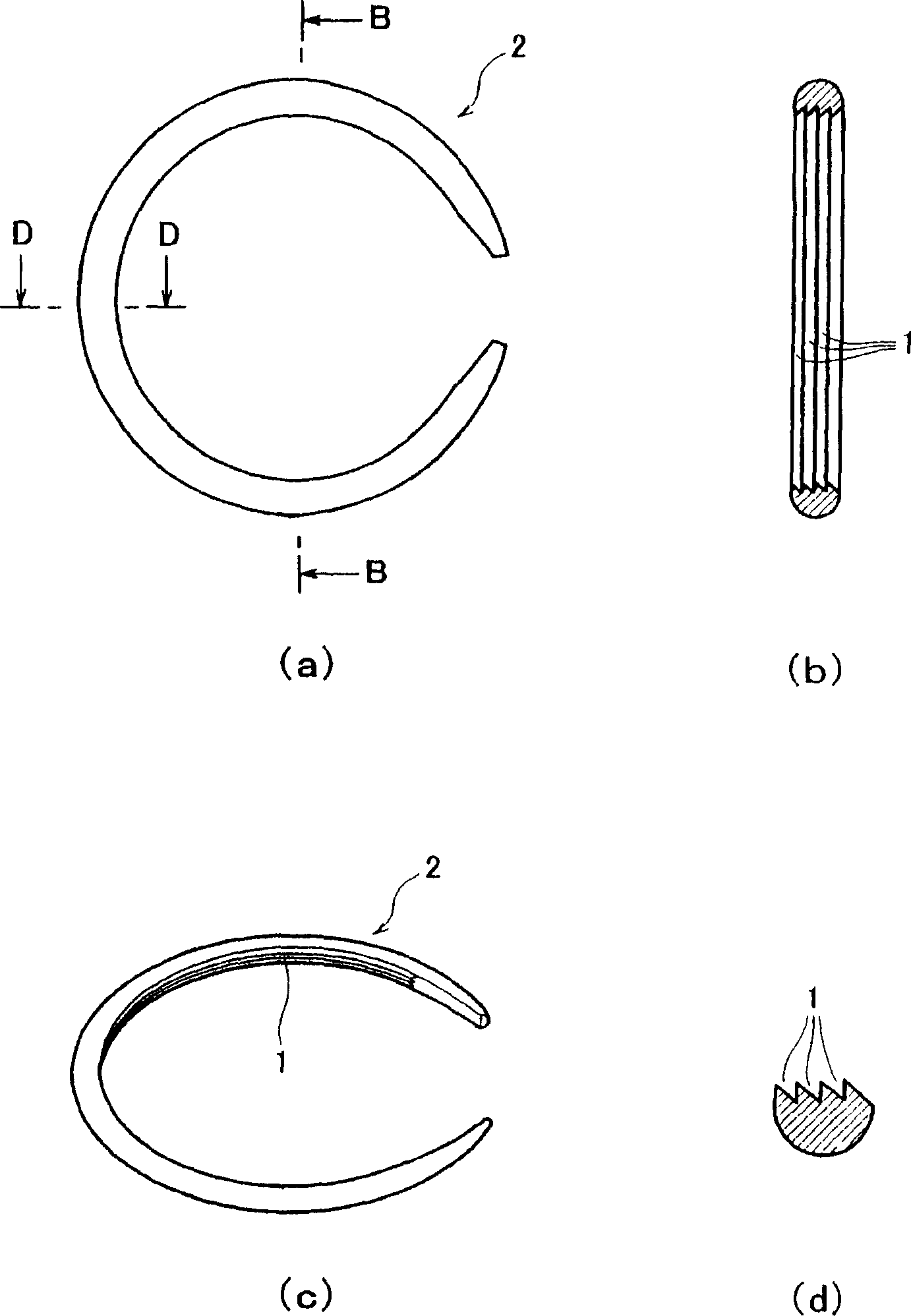

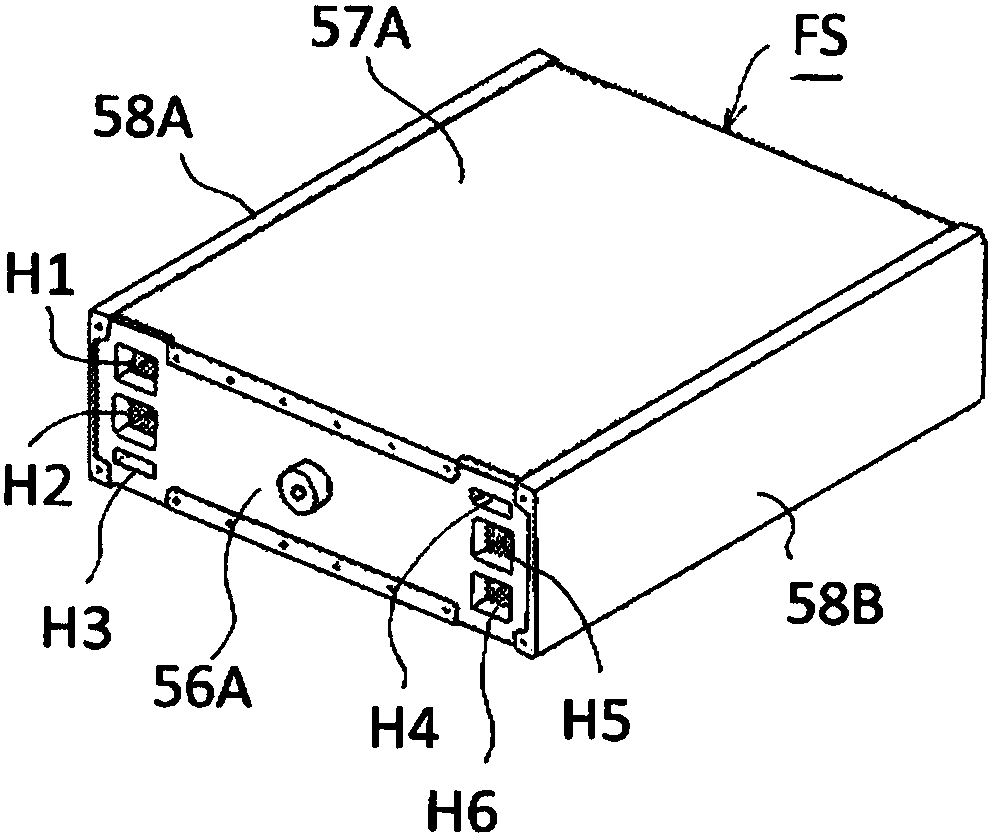

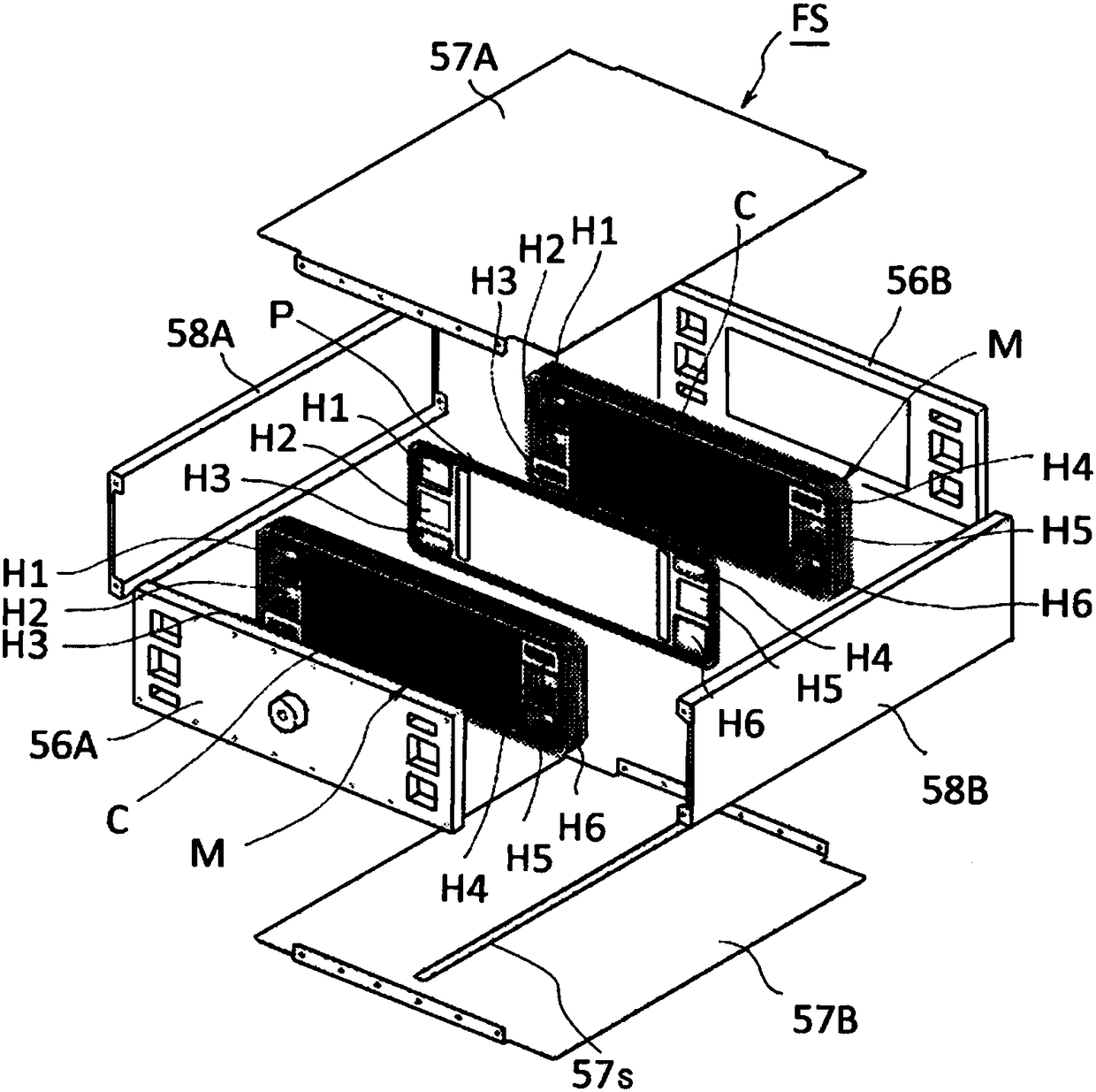

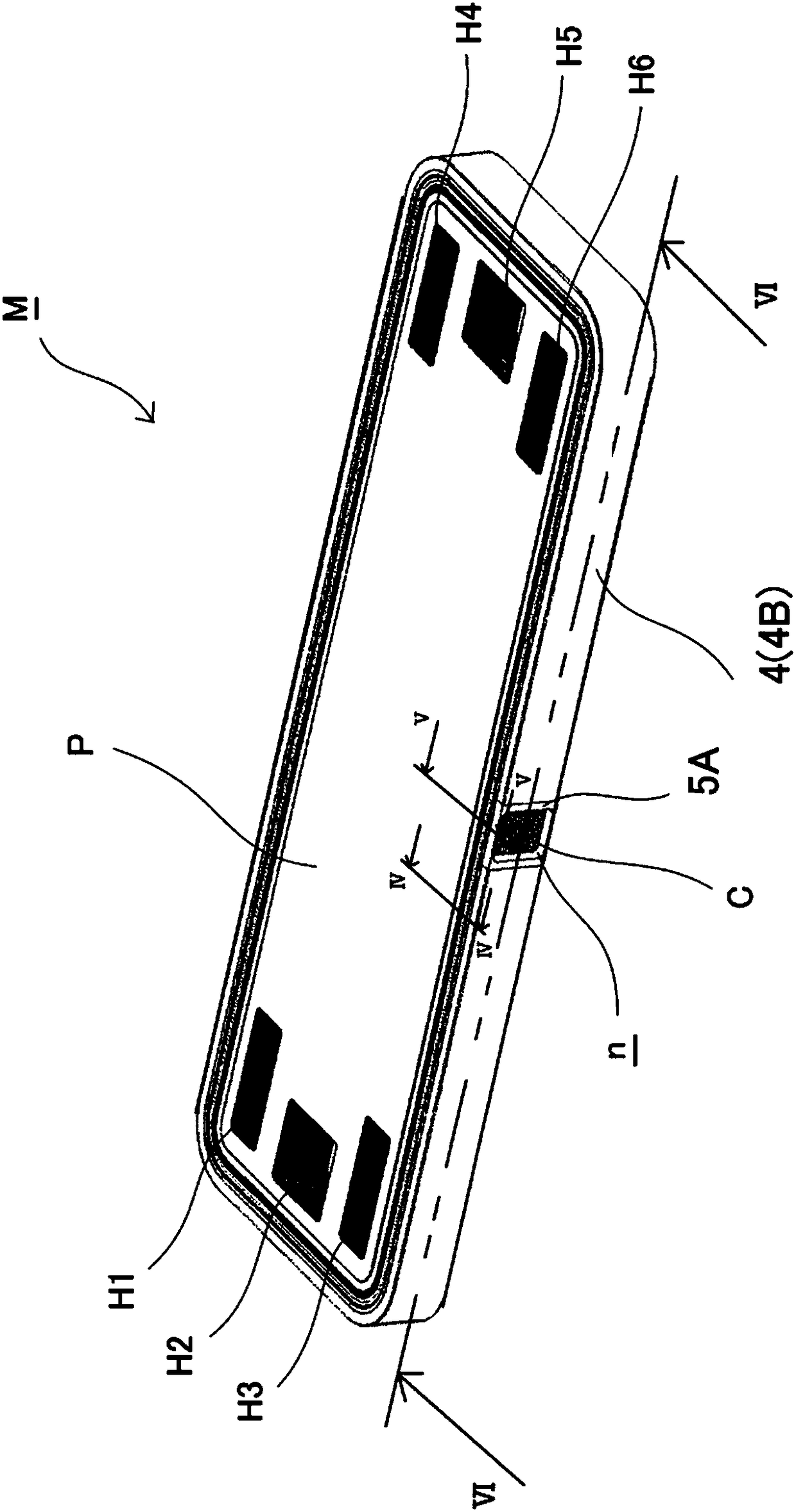

Fuel cell stack seal structure and production method therefor

ActiveCN108370044AAvoid damageProper tightnessElectrolyte moving arrangementsFinal product manufactureFuel cellsPeripheral

In the present invention, a fuel cell stack is configured by layering a plurality of fuel cell single cells, each having a membrane electrode joined body and a pair of separators sandwiching the membrane electrode joined body. This fuel cell stack seal structure comprises: an inner peripheral seal member plugging a gap between inner peripheral ribs, each protruding at least on the facing surface side of the pair of separators, at the peripheral edge portion of each of the separators; and an outer peripheral seal member plugging a gap between outer peripheral ribs, each protruding at least on the facing surface side of the pair of separators, at the outer peripheral side of the inner peripheral ribs. The inner peripheral seal member and the outer peripheral seal member form a first closed space between the inner peripheral seal member and the outer peripheral seal member. The outer peripheral seal member has a cut-out portion wherethrough the first closed space is in communication withthe exterior.

Owner:NISSAN MOTOR CO LTD

Pharyngitis treating Chinese medicine plaster

InactiveCN1133455CSatisfied with the effectSymptoms disappear quicklyHydroxy compound active ingredientsAerosol deliveryDiseaseSide effect

The Chinese medicine plaster for external application for curing pharyngitis, tonsillitis, laryngitis and parotitis is made up by using 18 Chinese medicinal materials of ledebouriella root, lonicera flower, forsythia fruit, dried / fresh rehmannia root, scrophularia root, ophiopogon tuber and others through a certain preparation process. Said medicine plaster possesses the functions of expelling wind, clearing heat, removing toxic substances, relieving sore-throat, reflenishing yin essence and moisturizing the viscera, reducing phlegm and resolving masses, and is non-toxic, and has no any side effects. On every plaster carrier 0.1-0.6g of the medicine powder is applied to obtain the invented product.

Owner:赵健忠

Nano-superconducting composite material and preparation method thereof

InactiveCN108687342AImprove conductivityGood physical propertiesMaterial nanotechnologyTransportation and packagingFiberNiobium

The invention discloses a nano-superconducting composite material and a preparation method thereof. The nano-superconducting composite material comprises the following raw materials of, by weight, 80-120 parts of graphene, 30-50 parts of yttrium powder, 30-50 parts of niobium powder, 20-30 parts of sodium fluoride, 10-20 parts of PPS resin, 3-5 parts of single-walled carbon nano tubes, 20-25 partsof superconducting carbon black, 5-10 parts of conductive metal mixtures, 5-10 parts of carbon nano tube dispersion solutions, 1-5 parts of rheological agents, and 3-5 parts of antioxidants. A quartzboat is put into a tubular furnace, in protection of mixed gas of 5-7% of hydrogen and 96-98% of nitrogen, the furnace is heated up to the temperature being 1050-1450 DEG C, heat preservation is conducted for 7-9 hours for a sintering reaction, then the furnace is quickly cooled to the room temperature, and thus the nano carbon conductive fiber yttrium-niobium-silver superconducting material is prepared. The nano-superconducting composite material is ingenious in design, reasonable in composition and proper in method, and the obtained superconducting composite material is good in physical property and suitable for popularization.

Owner:ZHEJIANG ZHONGPING POWDER METALLURGY

Liniment for treating acnes and preparation method thereof

InactiveCN108159167AImprove stabilityAvoid affecting the curative effectOrganic active ingredientsInorganic boron active ingredientsVitamin CAntioxidant

The invention discloses a liniment for treating acnes. The liniment comprises the following components in parts by weight: 23.8 parts of a calamine powder, 7.1 parts of a boric acid powder, 3.5 partsof a resorcinol powder, 1.2 parts of a vitamin C powder, 23.8 parts of a zinc oxide powder, 5.9 parts of a sulfur deposit powder, 0.9 part of a chloramphenicol powder, 2.8 parts of a dried alum powder, 0.7 part of coptis chinensis, 0.7 part of phellodendron amurense and 29.6 of glycerin. In a preparation method of the liniment for treating acnes, the vitamin C is added as an antioxidant, so that the therapeutic effect is prevented from being affected by reduction in the overall stability of a suspended liquid preparation due to poor chemical stability of the resorcinol powder in the liniment;the components in a formula are separately prepared; the method is appropriate; the stability of the acne treating liniment is improved.

Owner:ANHUI AIKEER PHARMA CO LTD

Method for recovering iron concentrates from alumina red mud

The invention provides a method for recovering iron concentrates from alumina red mud, adopting the following technical scheme: a medium-intensity magnetic separator is adopted to recover the strongly magnetic iron concentrates after red mud tailings are subjected to slag separation, then the obtained tailings are subjected to open rough separating and refined separating by a high gradient magnetic separator to recover weakly magnetic iron concentrates, combining the strongly magnetic iron concentrates and the weakly magnetic iron concentrates and carrying out dehydrating to obtain the iron concentrates. An slon vertical ring pulsating high gradient magnetic separator is selected to replace the traditional high gradient magnetic separator, and the medium-intensity magnetic separator is adopted to recover the strongly magnetic iron concentrates before. The method provided by the invention can be used for efficiently recovering the iron concentrates from the alumina red mud, and the obtained iron concentrates have high grades and good recovery rate; therefore, the method increases the utilization ratio of the alumina red mud, reduces the environmental pollution and is suitable for large-scale application.

Owner:山西华兴铝业有限公司

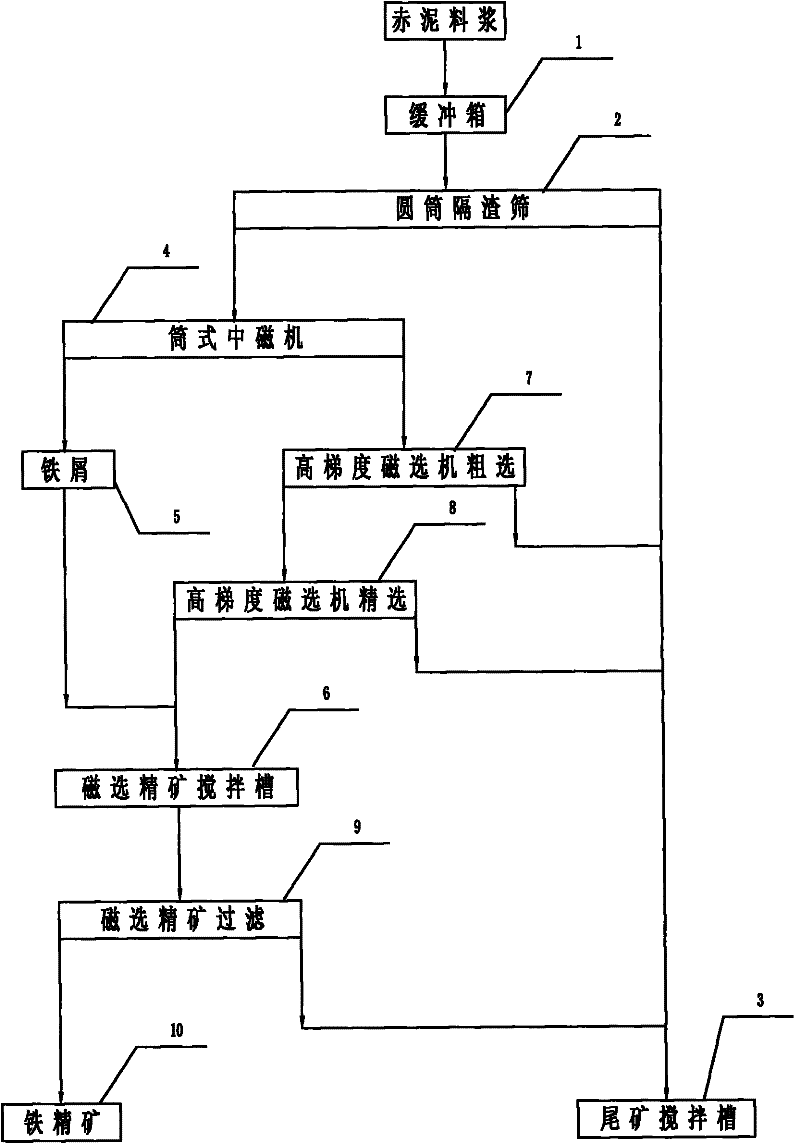

Abnormality determining device and abnormality determining method, and recording medium

InactiveCN109905695AProper detectionAppropriate Abnormal Judgment DeviceImage enhancementImage analysisRadiologyNuclear medicine

Provided is an abnormality determining device capable of appropriately detecting presence or absence of an abnormality in an image capturing device. An abnormality determining device (1) which determines, in accordance with imaging data on a subject (light source 3) having uniform brightness, whether or not an image capturing device (2) has an abnormality includes: a smoothing processing section (11) which generates smoothed image data by using a smoothing filter for each given range of divided data while moving a position of the smoothing filter by a range smaller than the each given range, the divided data being data obtained by dividing, into a plurality of regions, brightness data which is obtained by extracting brightness information from the imaging data; and an abnormality determining section (12) which compares the smoothed image data with the divided data and determines whether or not the image capturing device has an abnormality.

Owner:SHARP KK

A kind of elastic thermal transfer lettering film and its production method

ActiveCN107443945BSimple and fast productionShorten the production cycleInksCoatingsAcrylic resinEngineering

An elastic heat transfer printing lettering film comprises a bearing bottom material, protection layer back coating liquid, a release layer pressure-sensitive adhesive, color layer printing ink and a bonding layer hot melt adhesive. The formula of the protection layer back coating liquid comprises 14 parts of amino resin, 4 parts of acrylic resin, 3 parts of silicon dioxide, 1 part of an amino resin cross-linking agent and 78 parts of a mixing solvent. The formula of the release layer pressure-sensitive adhesive comprises 10 parts of organosilicone pressure-sensitive adhesive, 15 parts of silica gel, 2 parts of a platinum catalyst and 73 parts of a 120# solvent. The formula of the color layer printing ink comprises 25 parts of high-elasticity high-temperature-resisting TPU resin, 10 parts of toner, 3 parts of a wetting dispersing leveling assistant and 62 parts of the mixing solvent. The formula of the bonding layer hot melt adhesive comprises 65 parts of high-elasticity and low-temperature type TPU resin, 30 parts of high-melting-index low-temperature type TPU resin and 5 parts of a TPU opening agent. According to the elastic heat transfer printing film, the same-batch same-color difference delta E is smaller than or equal to 4, the thermoprint layer abrasion resistance is larger than or equal to 90%, the release force is equal to (0.10-3.00)N / 25 mm, washing resistance is achieved, the washing color fading rate is smaller than or equal to 10%, and the basic safety technology requirement conforms to the B type in the GB18401.

Owner:青艺(福建)烫画科技有限公司

Method for breeding Ningqiang spicy and hot raw chickens

InactiveCN109006660AConsistent growth rateAdequate pest controlAnimal husbandryDiseaseIntestinal tract diseases

The invention discloses a method for breeding Ningqiang spicy and hot raw chickens. According to the method, laying hen eggs or local chicken eggs are selected to be incubated according to a conventional method, and then the feeding management is carried out in three stages. The first stage is from 0 day to 30 days and the medicine prevention of chick intestinal tract diseases, respiratory diseases and epidemic diseases is completed in a unified mode in a brooding room. The second stage is from 30 days to 90 days and the third stage is from 90 days to the full-grown and ready-for-slaughter period. The second stage and the third stage are completed in an open-air chicken farm. During the second and third stages, chickens are fed with corns, broiler chicken midterm concentrated feeds and green grass mixed materials. The feeding amount of mixed materials for each chicken every day is different, wherein the feeding amount is about 100-125g during the second stage, the feeding amount is about 150g during the early period of the third stage and the feeding amount is about 100-125g during the later period of the third stage. No more than 8 chickens are fed in each henhouse every square meter. The activity range of each chicken outside the henhouse reaches more than 5 square meters. The method has the advantages of standard management, appropriate method, and easy operation. Slaughtered raw materials are free of fat under chicken skins. Meanwhile, obtained Ningqiang spicy and hot chickens are tough and chewy in meat quality, and delicious in taste. The qualities of raw chicken materials in different batches are basically consistent, and the qualities of chickens are stable.

Owner:李勇

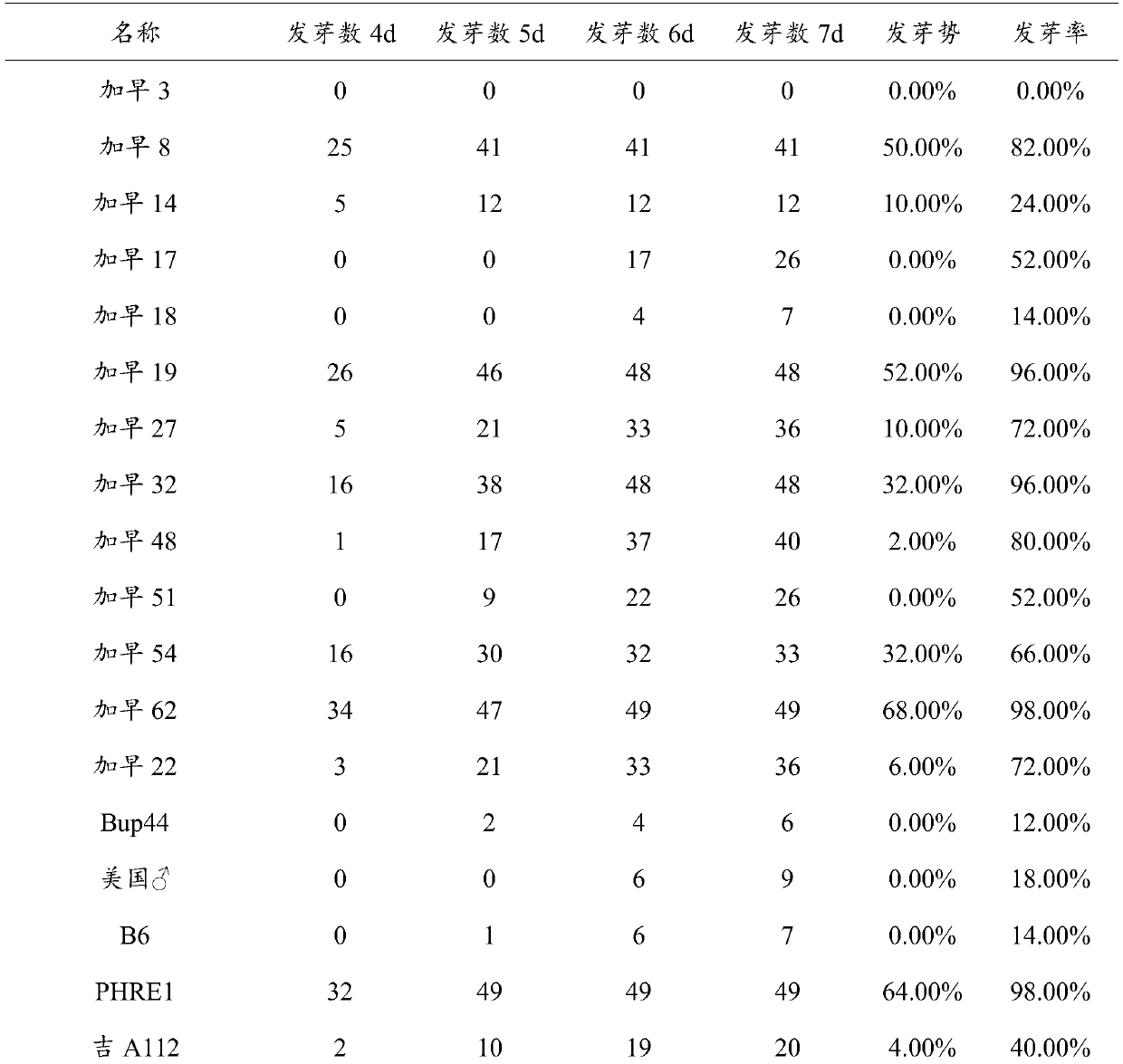

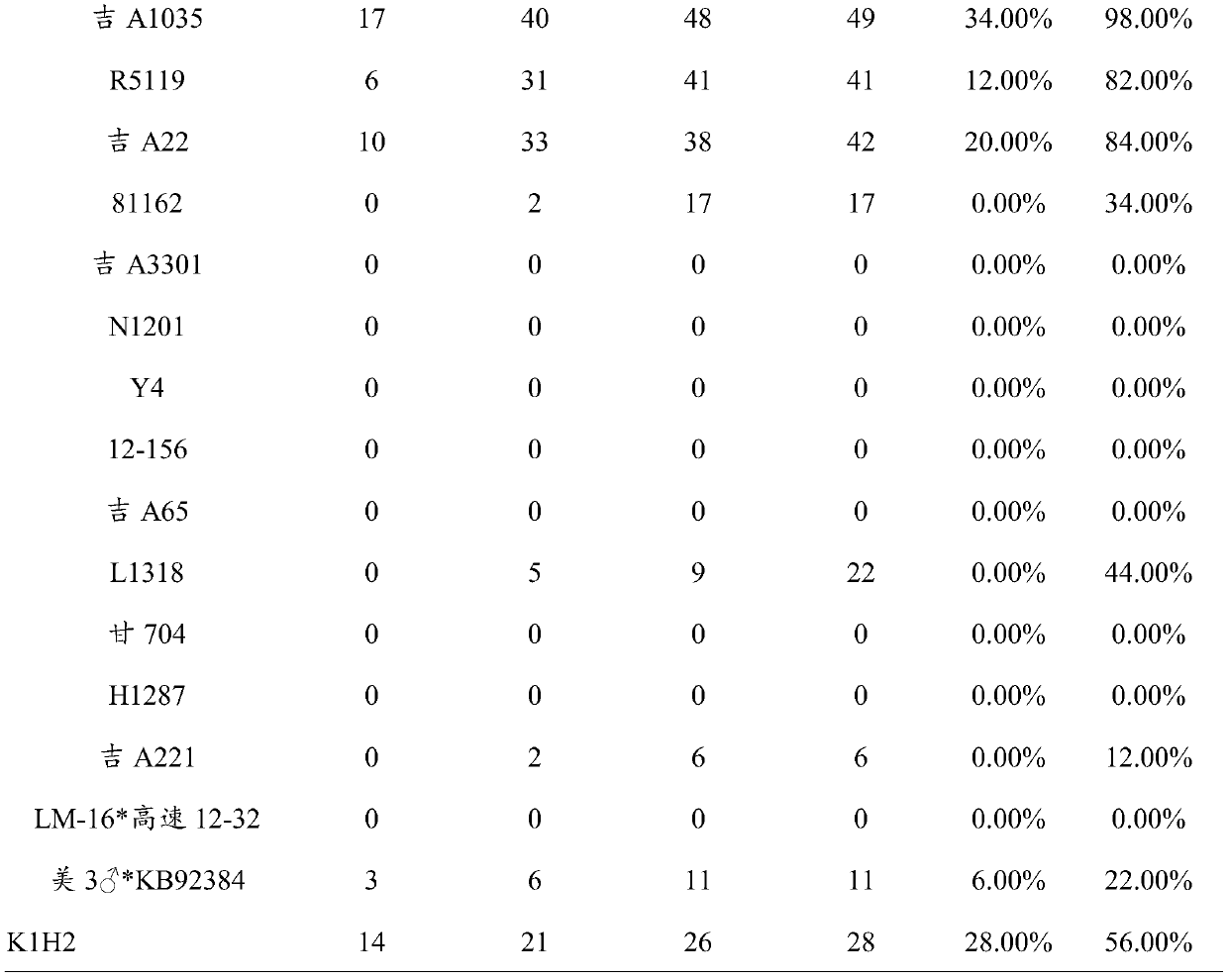

Method for detecting corn storability

PendingCN111492745AThe experimental operation is simple and clearAppropriate methodGrowth substratesCulture mediaGerminationEnvironmental geology

The invention provides a method for detecting corn storability, and relates to the technical field of storability detection. When a high-temperature and high-humidity method is used for testing the storage resistance of corn seeds, the temperature is controlled to be 48-53 DEG C, the humidity is controlled to be 95-100%, and the germination potential and the germination rate of the aged seeds aremeasured, so that the storage resistance of the corn seeds is judged. According to the method, temperature and humidity control can be used as a standard for identifying the storage resistance of theseeds of the northeast corn self-bred line, the experimental operation is simple and clear, and the method is suitable for popularization.

Owner:JILIN ACAD OF AGRI SCI

Preparing method of biliary-tract carriage carrying about medicine

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

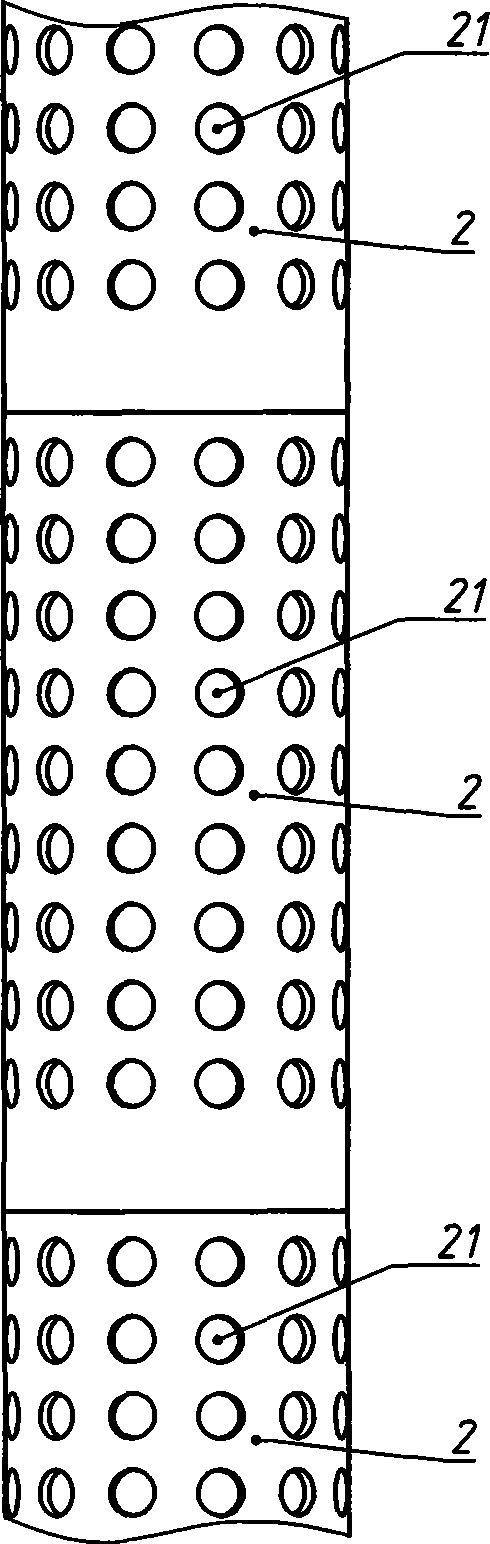

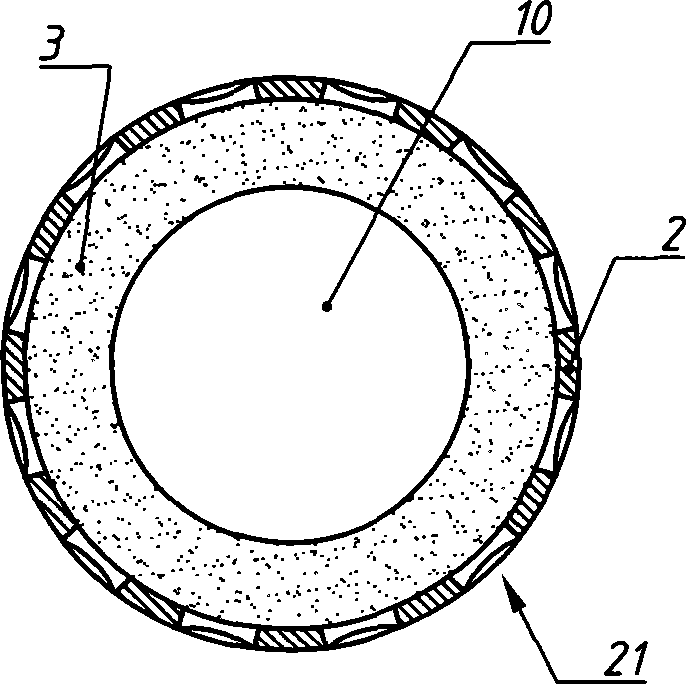

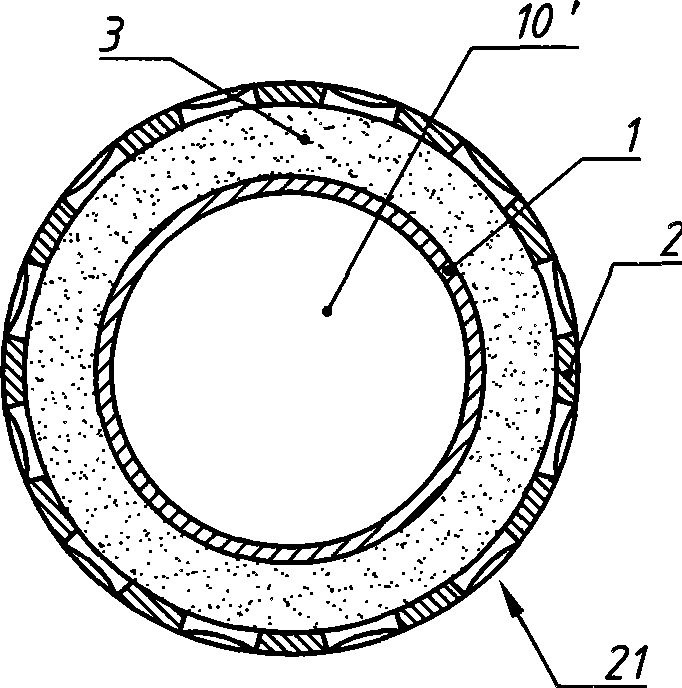

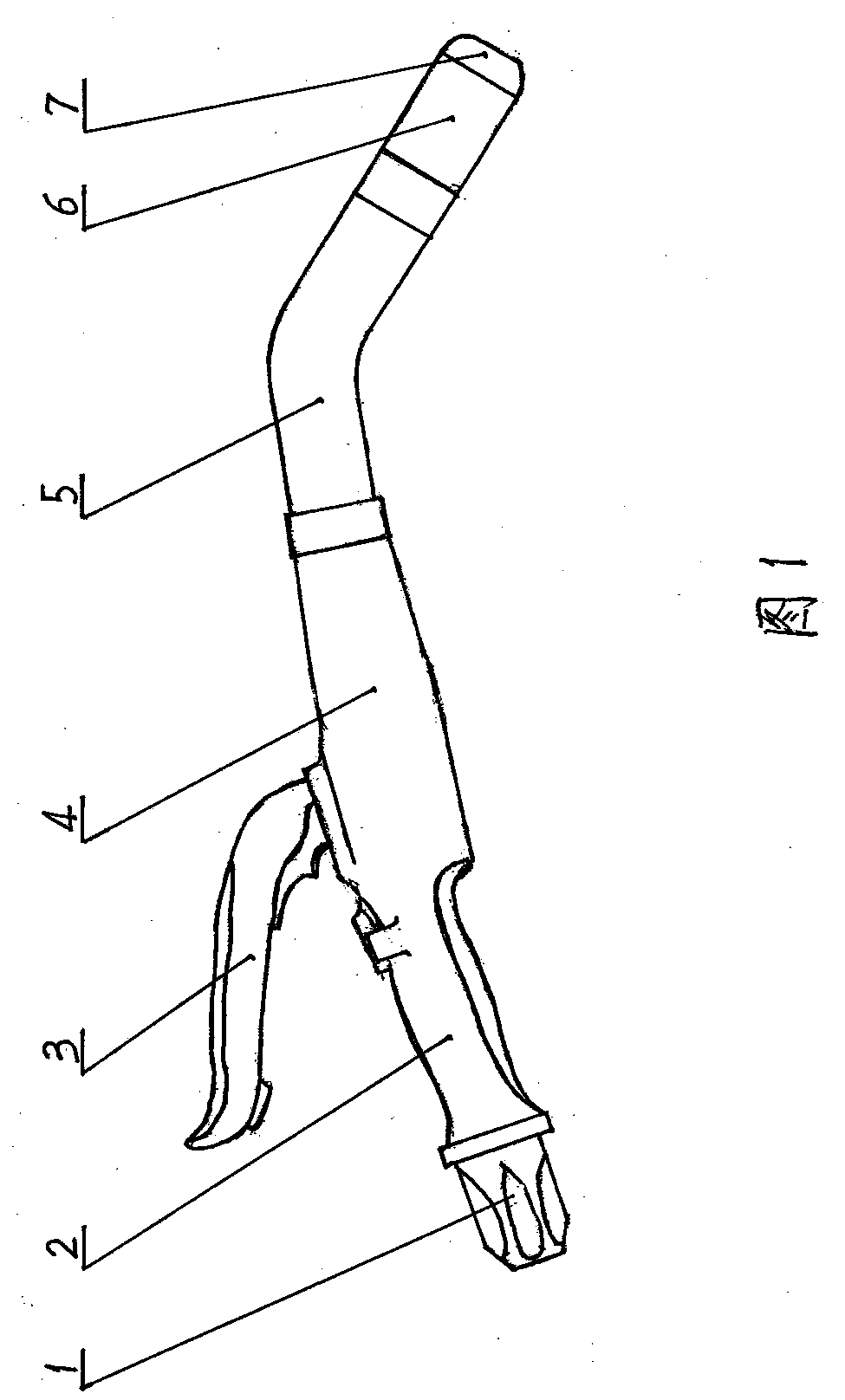

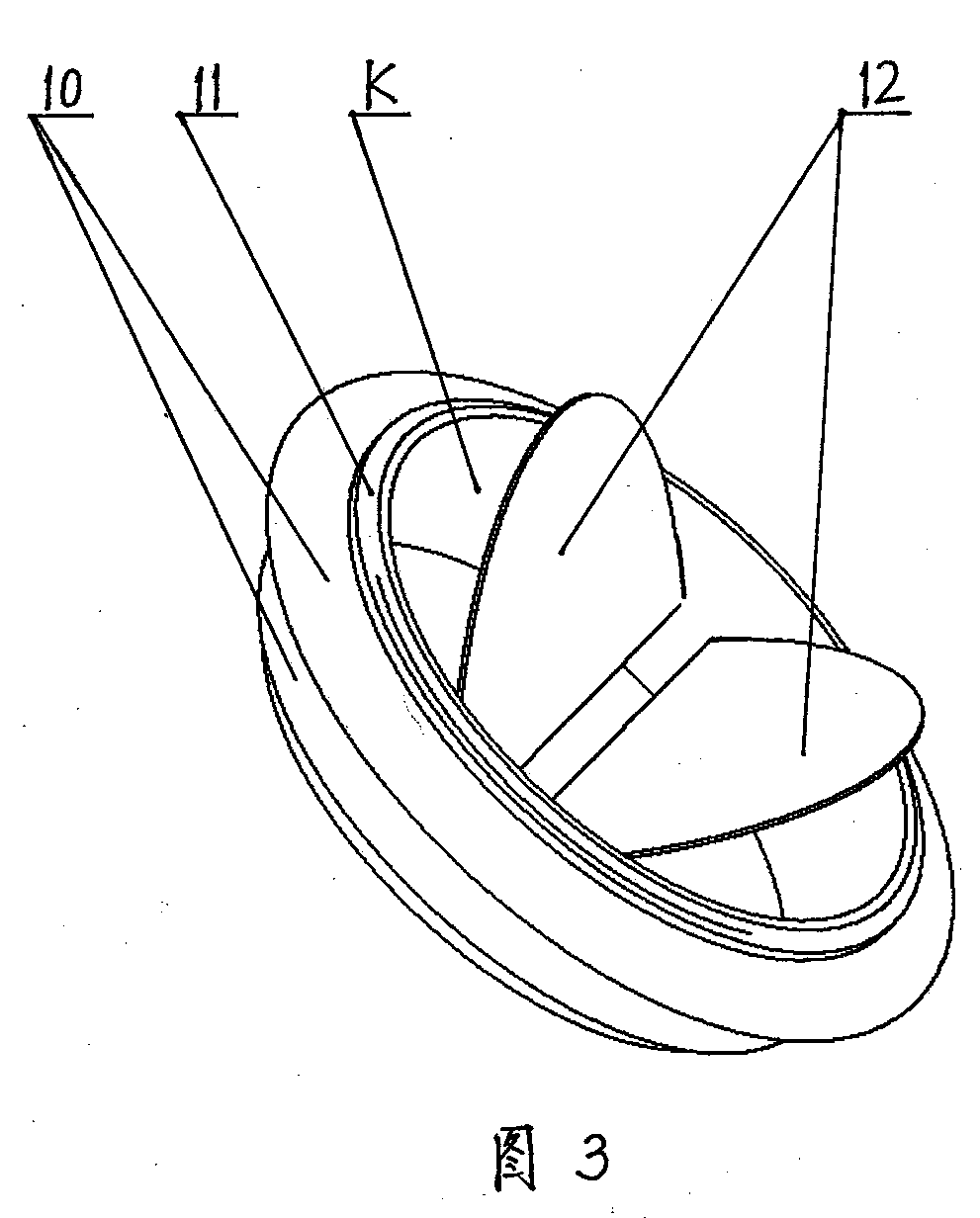

Mechanical suture type artificial heart valve and suture method thereof

The invention discloses a mechanical suture type artificial heart valve and a suture method thereof. A suture valve ring (10) of an artificial heart valve takes a plastic valve ring (13) as a bracket; a concave-convex lantern ring (14) is sleeved on the plastic valve ring (13); an outer edge of the concave-convex lantern ring (14) is wrapped by a polyester ring sleeve (15); and a metal valve leaflet (12) is erected in an inner hole (K) of a metal valve ring (11) of a mechanical valve. A mechanical suture device is arranged at the front end of a tube-shaped anastomat (4); the suture valve ring (10) is arranged on the outer edge of a disk of a combined disk bottom anvil support (7); and the plastic valve ring (13) and the polyester ring sleeve (15) are sleeved on the inner edge of the disk. The preliminary suture is carried out after the combined disk bottom anvil support (7) is placed. A cutting and positioning suture method comprises the following steps of: pushing an annular tube cutter (9) to cut off a pathological mitral valve (Q) sleeved on an inner ring of the suture valve ring (10); suturing the suture valve ring (10) with a heart chamber (R) by a staple (17); taking out the combined disk bottom anvil support (7); and then sheathing the mechanical valve with the suture valve ring (10). The mechanical suture type artificial heart valve disclosed by the invention has the advantages of accuracy in positioning, favorable suture quality, high efficiency and success rate of an operation. The pains of patients are alleviated.

Owner:马增山

Control method suitable for rotation of parallel equipment

InactiveCN111174367AGuaranteed uptimeRun continuouslyMechanical apparatusSpace heating and ventilation safety systemsCooling towerControl system

The invention discloses a control method suitable for rotation of parallel equipment and relates to the technical field of air conditioning equipment. The control method comprises the steps of 1) determining enabling states of the equipment; 2) when a valve is in states of fault, in-situ, remote manual operation and opening action overtime and the valve is in a state of being opened in position, marking the valve as being preferably used; 3) when a water pump body is in the states, marking the water pump as being prohibited to use; 4) when a cooling machine body is in the states, marking a cooling machine as being prohibited to use; 5) when a cooling tower body is in the states, marking a cooling tower as being prohibited to use; 6) when the equipment is used normally, recording the sequencing time as an accumulated operation time; 7) when it is needed to sequence an equipment group again, carrying out sequencing according to the sequencing time; 8) determining a relationship as follows: preferably used number is smaller than or equal to the lower limit of the number, the lower limit of the number is smaller than or equal to the set operating number, the set operating number is smaller than or equal to the upper limit of the number, and the upper limit of the number is smaller than or equal to the available number; and 9) when the actual operating number is equal to the set operating number, maintaining unchanged control. When the equipment is in abnormal states, various abnormal states are handled comprehensively and timely, so that a self-control system can be operated continuously and efficiently.

Owner:同方泰德国际科技(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com