Mechanical suture type artificial heart valve and suture method thereof

A technology of artificial heart and mechanical valve, applied in the direction of heart valve, etc., can solve the problems of uneven needle distance and edge distance of manual suture, increase of patient pain and economic burden, irregular heart valve resection, etc., and achieve small surgical wound and shorten The effect of operation time and ease of popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

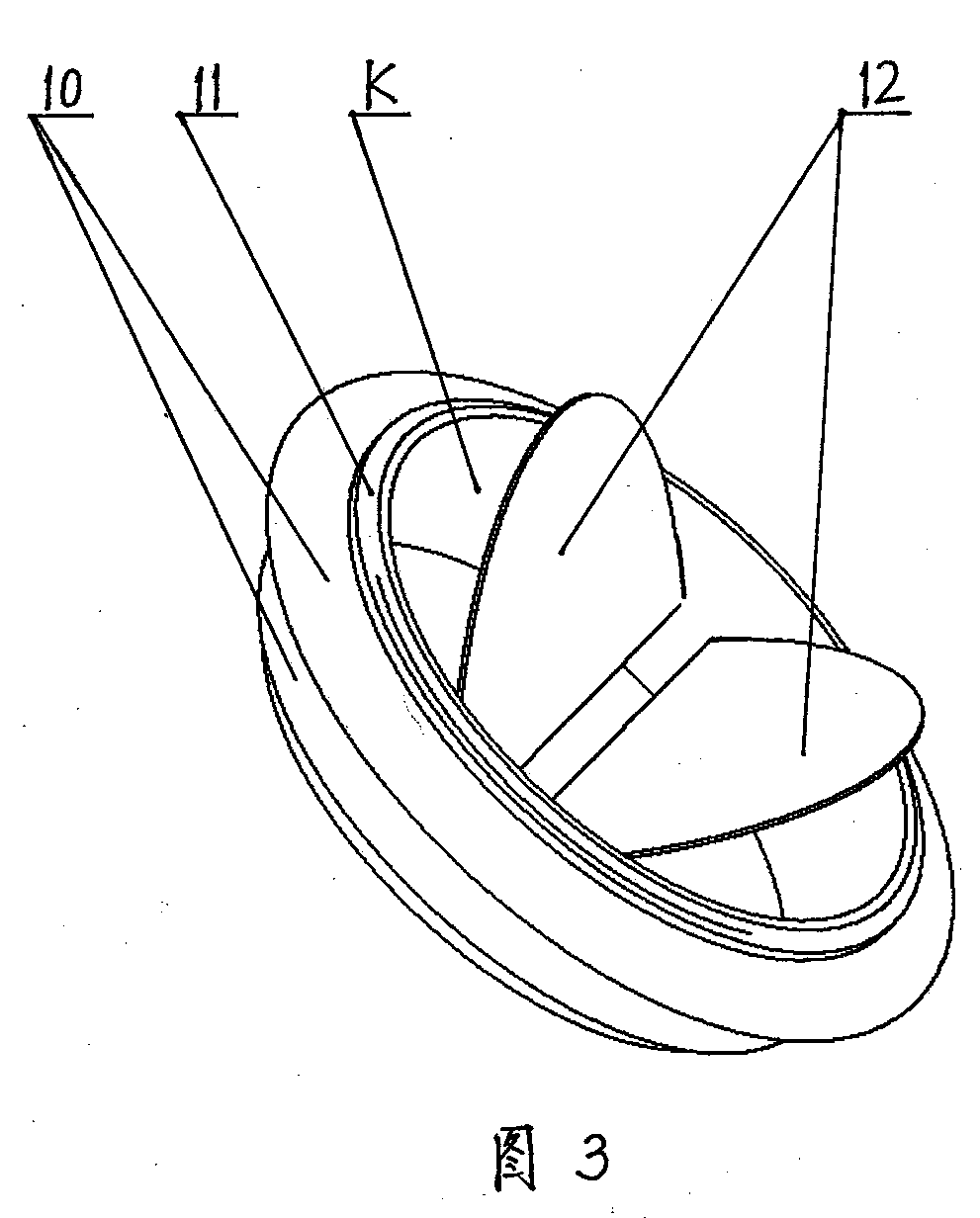

[0019] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

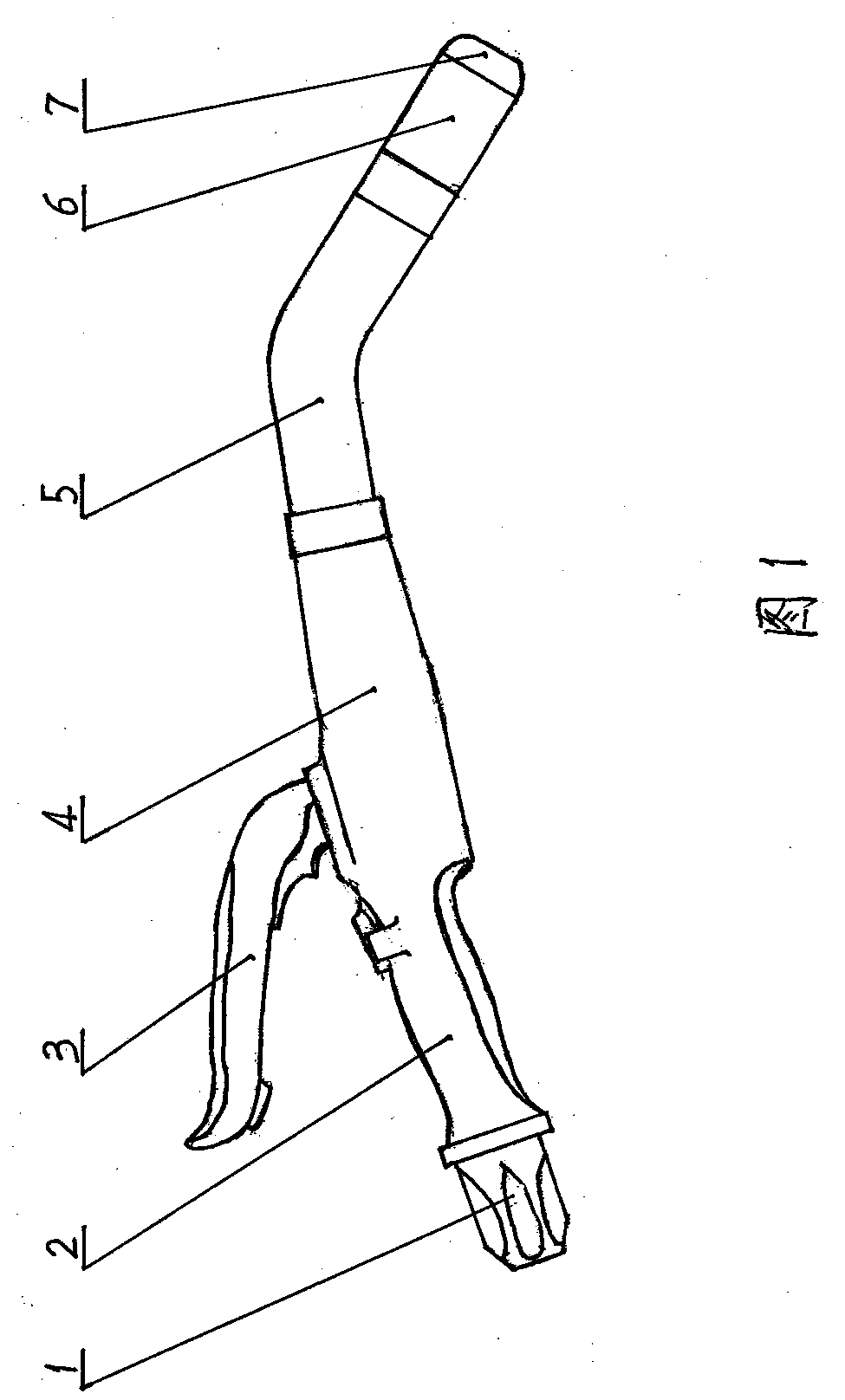

[0020] refer to figure 1 , the mechanical suturing device of the present invention is used in conjunction with the existing tubular stapler 4 for suturing stomach wounds. The main part of the tubular stapler 4 is connected to the needle and nail warehouse connecting pipe 6 at the front end through the elbow 5, equipped with the needle and nail warehouse 8, and the combined disc bottom anvil support 7 can be installed at the front end. The rear end of the tubular stapler 4 is a knob 1, which is installed on a fixed handle 2, and the upper part is a movable handle 3. The anvil support 7 at the bottom of the combined disc and other needle nail bin components are matched with the nail nail bin 8.

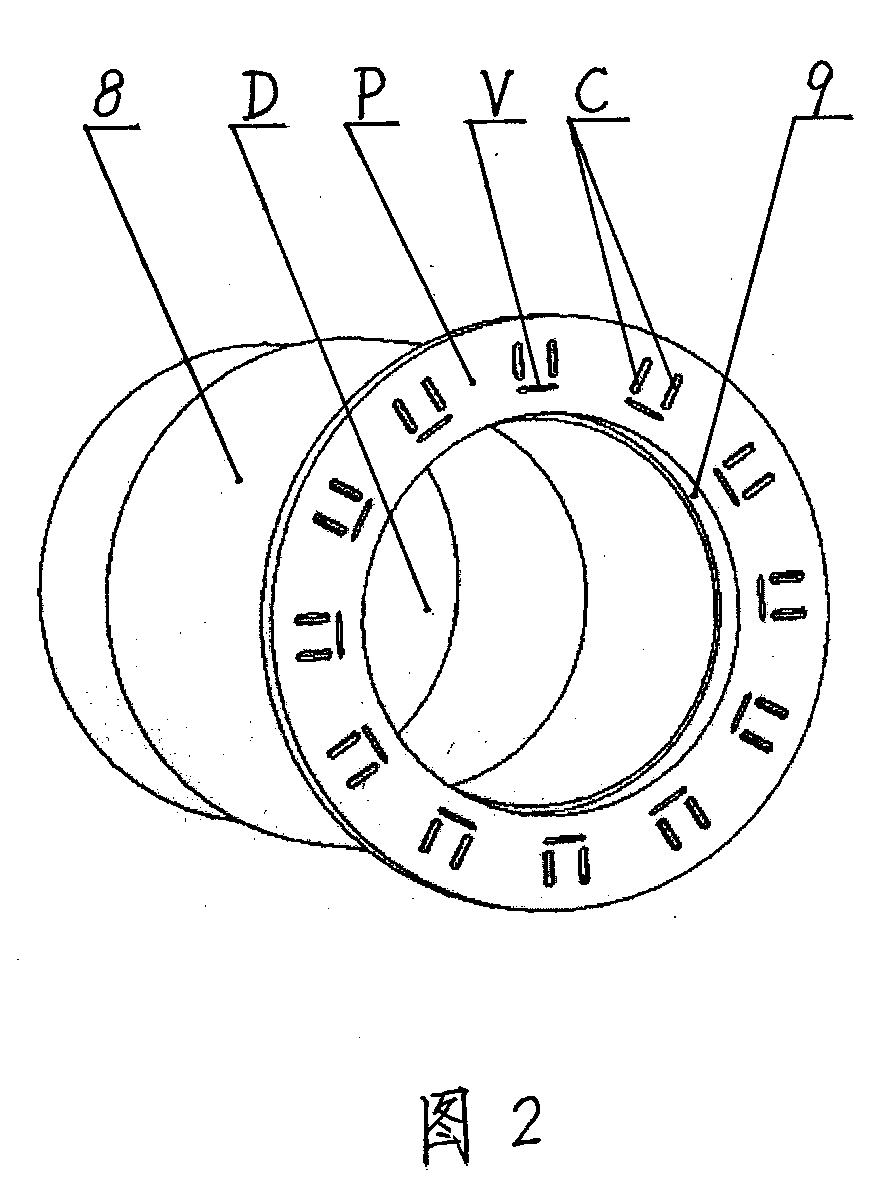

[0021] refer to figure 2, the needle nail bin 8 is a double-layer cylindrical container, the front end face is an end face nail anvil P, the ring barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com