Ultra-shallow-buried rectangular large section four-step underground excavation construction method

A construction method and large-section technology, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems such as lack of dynamic load theory for vehicles, pedestrians, etc., large construction cost investment, and large construction interference, so as to reduce engineering costs , Fewer excavation steps, ensuring safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

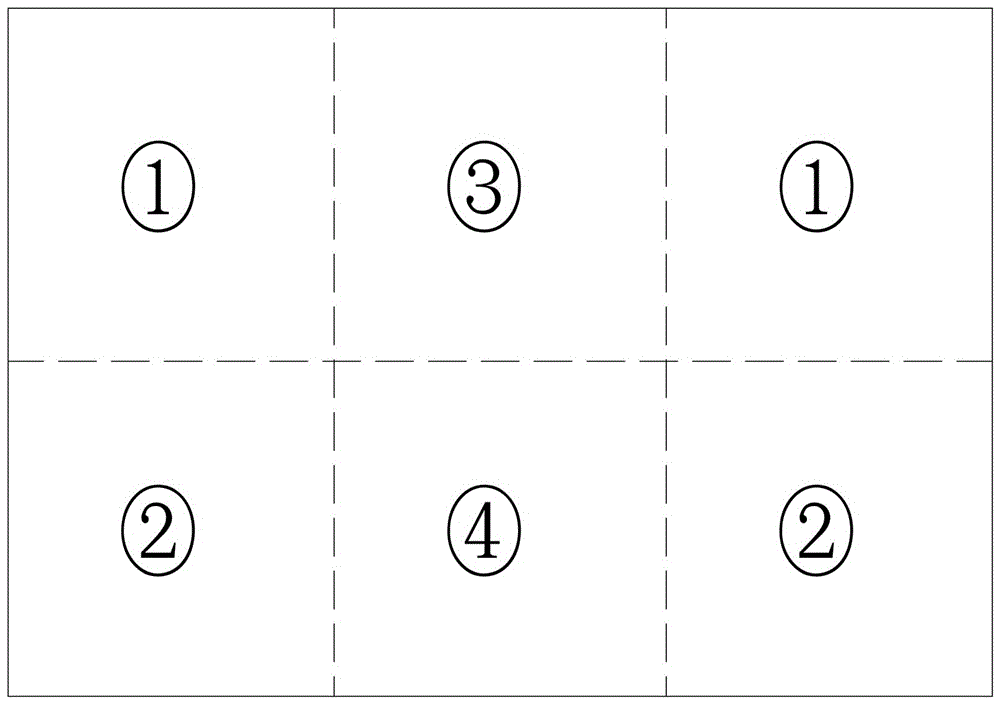

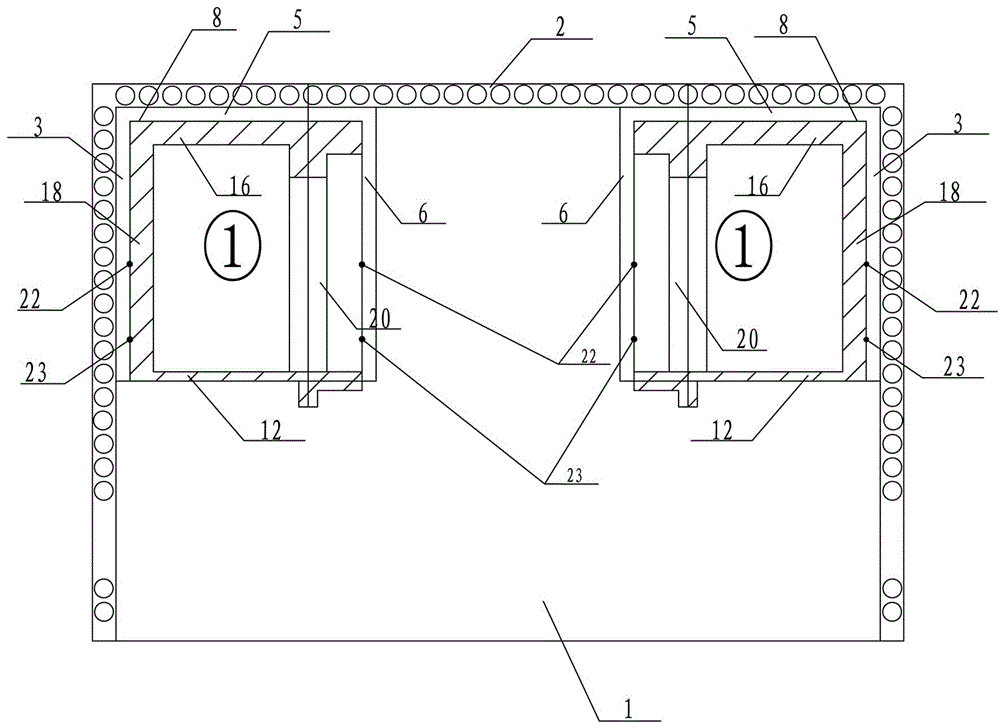

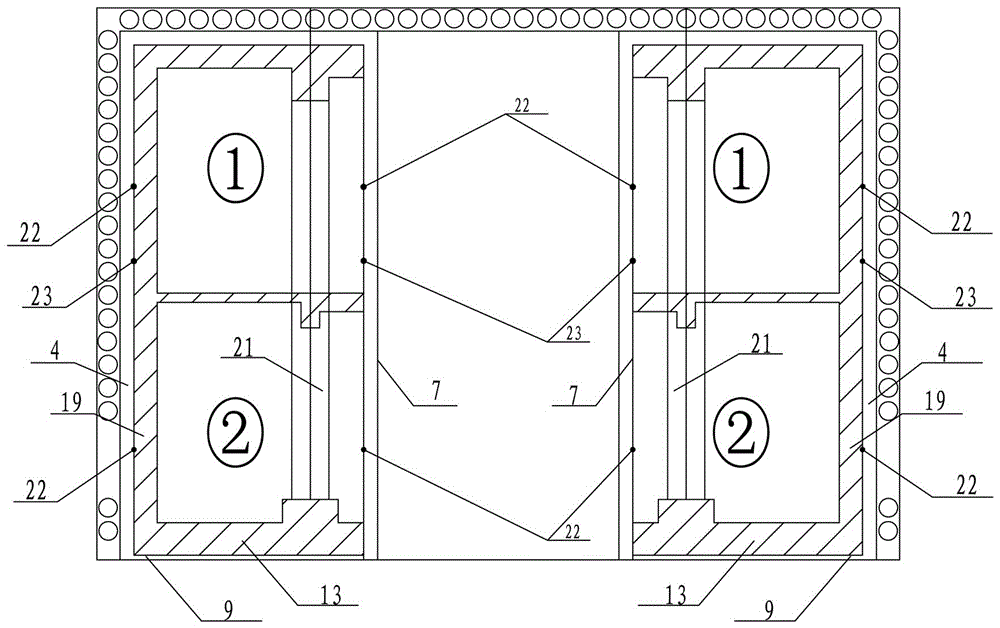

[0029] see figure 1 , the present embodiment divides the whole section into six blocks and four steps on the large rectangular section, and the six rectangular blocks are divided into upper and lower layers. According to the up and down and left, middle and right divisions, it is divided into the upper left and upper right area ① step, the upper middle area ③ step, the lower left area and the lower right area ② step, the lower middle area ④ step, the upper left and upper right area ① step, and the upper middle area ③ step On the negative floor, the lower left area and the lower right area ② steps, and the lower middle area ④ steps are located on the negative second floor.

[0030] Firstly, advance support 2 for the long pipe shed on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com