A construction method of water-stop curtain for pba construction method tunnel based on approach hole technology

A technology of water-stop curtain and construction method, which is applied in the direction of basic structure engineering, building, sheet pile wall, etc., can solve the problems of affecting the water-stop effect, the fine sand layer is easy to collapse holes, and waste time, so as to save labor costs and control The effect is good and the effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

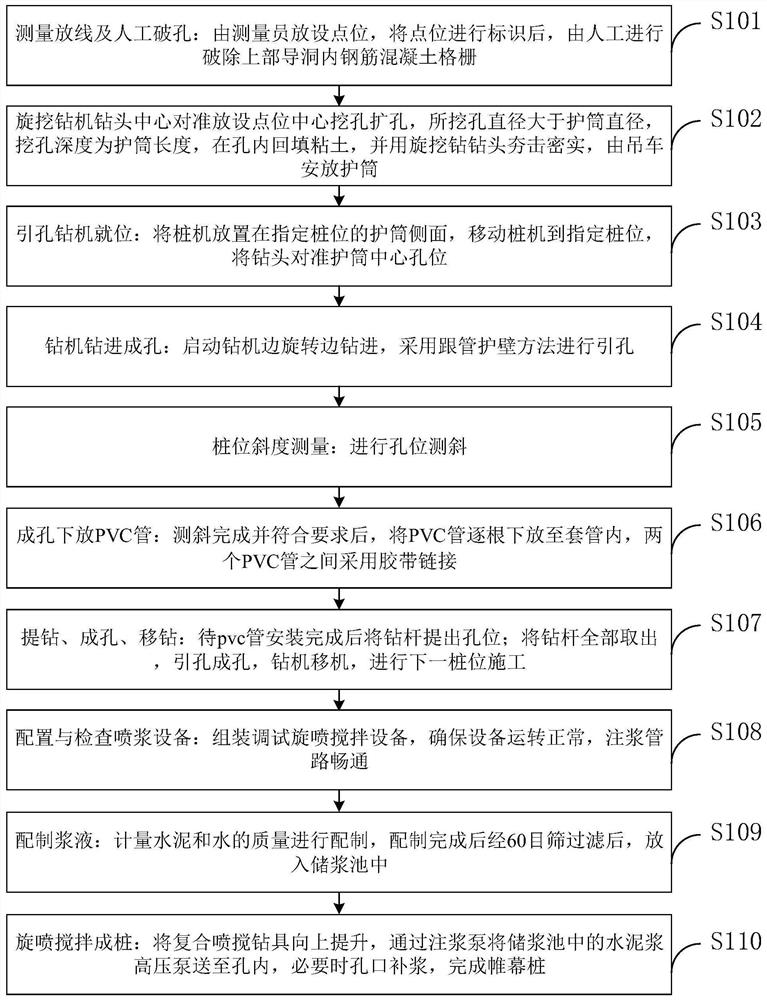

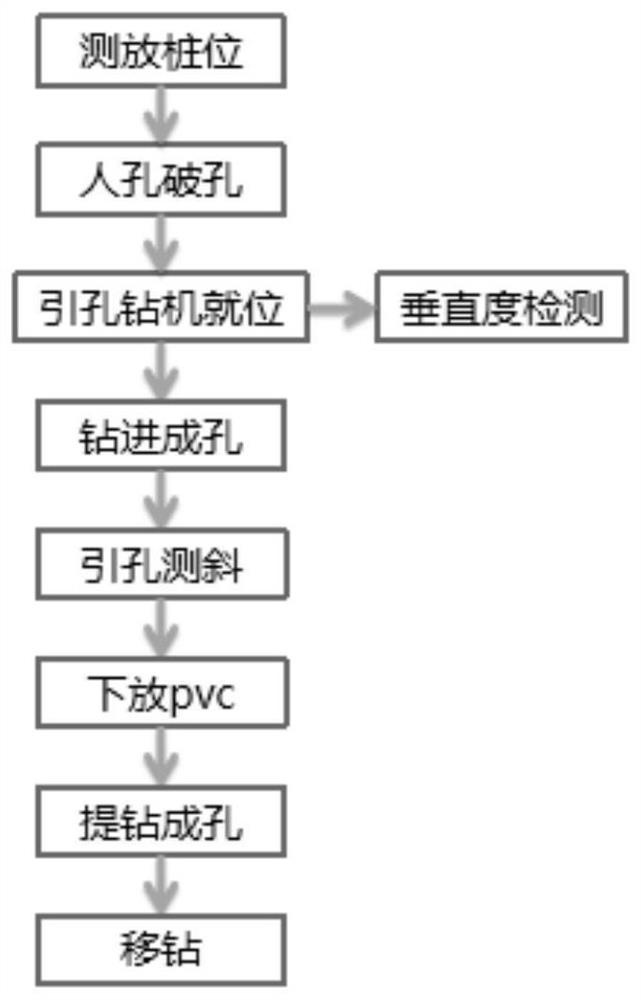

Method used

Image

Examples

Embodiment

[0064] 1. Project overview

[0065] 1.1 Geographic location

[0066] The originating shaft of the shield tunneling in the section from Guangximen Station to Xibahe Station is located in the green space in front of the Parkson shopping mall. It is the translation and split origination of two earth pressure balance shield machines with a diameter of 6680mm in this tender section, and the disintegration and return of the 11th bid and the 14th bid section. The shield machine arrives at the receiving and hoisting site.

[0067] 1.2 Design overview

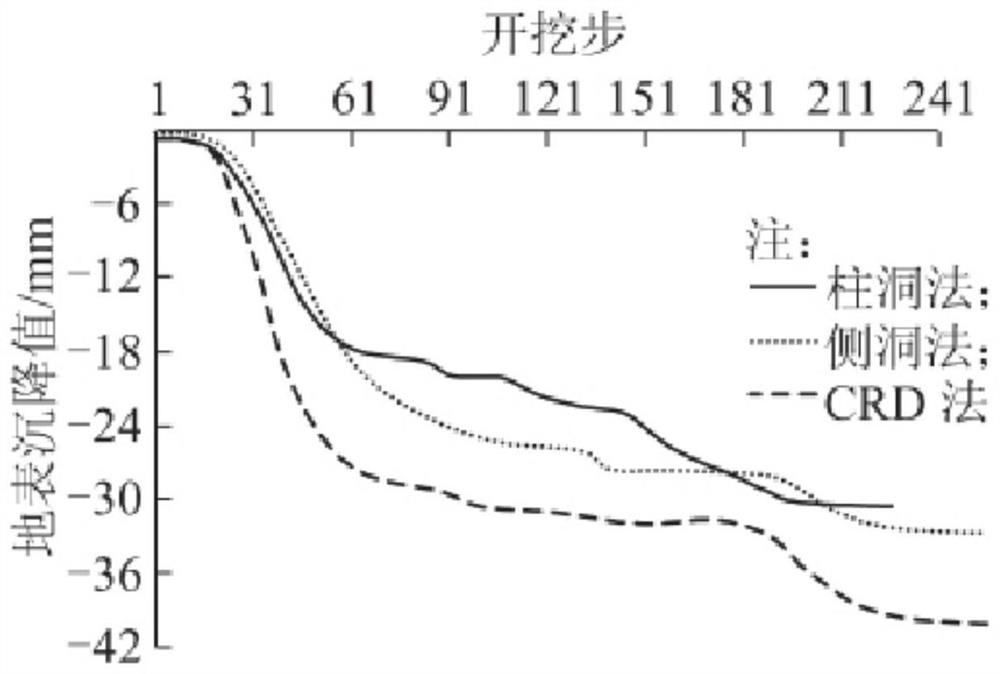

[0068] The main structure of the channel is an underground two-story single-span structure, and the thickness of the vaulted roof is about 16m. The net height of the structure is 14.74m, and the net width is 10m. The main structure adopts the PBA construction method of underground excavation and reverse construction. The top arch of the structure is composed of steel grid + shotcrete primary support and secondary lining of molded rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com