Nano-superconducting composite material and preparation method thereof

A composite material and superconducting technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor processing performance, mechanical performance and environmental stress cracking resistance, and achieve physical performance Good, strong conductivity, ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

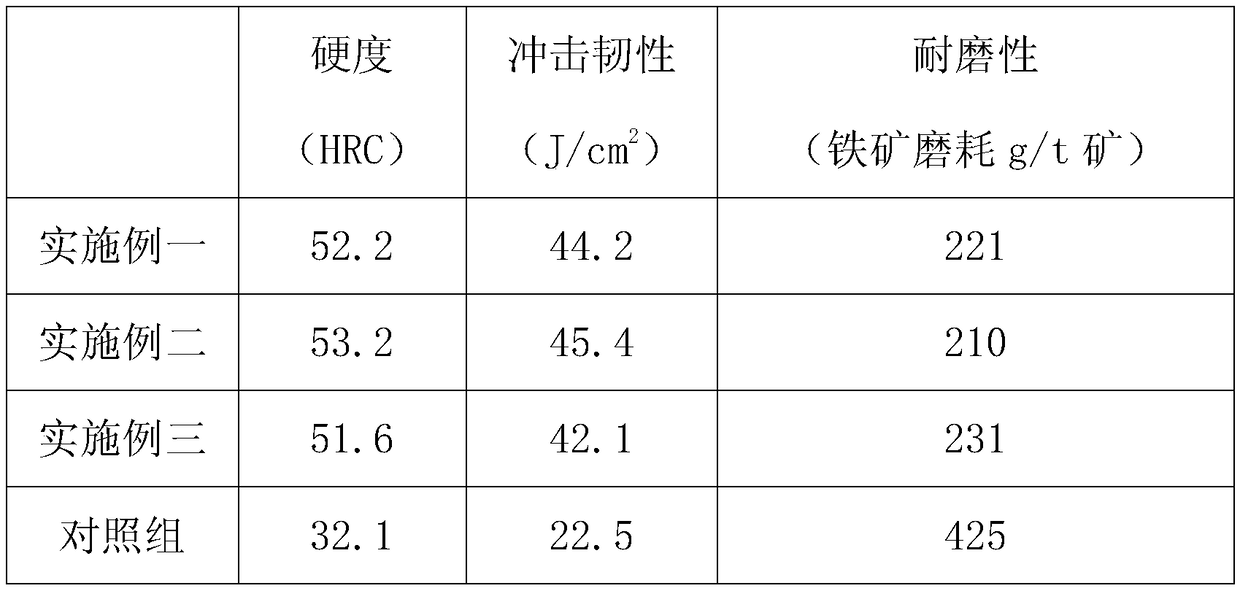

Examples

Embodiment 1

[0027] A nano-superconducting composite material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of graphene, 40 parts of yttrium powder, 40 parts of niobium powder, 25 parts of sodium fluoride, 13.5 parts of metal catalyst, 25 parts of silver powder, 240 parts of Parts of isopropanol, 17.5 parts of calcium carbonate, 27.5 parts of methyl cellulose, 12.5 parts of sodium borate, 12.5 parts of benzoic acid, 12.5 parts of calcium nitrate, 12.5 parts of barium sulfate, 7.5 parts of dispersant, 7.5 parts of polyphenylene sulfide, 15 parts Parts of PPS resin, 4 parts of single-walled carbon nanotubes, 22.5 parts of superconducting carbon black, 7.5 parts of conductive metal mixture, 7.5 parts of carbon nanotube dispersion, 3 parts of rheological agent, and 4 parts of antioxidant.

[0028] The preparation method of a kind of nano superconducting composite material that the present invention proposes, comprises the following steps, ...

Embodiment 2

[0037] A nano-superconducting composite material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of graphene, 40 parts of yttrium powder, 40 parts of niobium powder, 25 parts of sodium fluoride, 13.5 parts of metal catalyst, 25 parts of silver powder, 240 parts of Parts of isopropanol, 17.5 parts of calcium carbonate, 27.5 parts of methyl cellulose, 12.5 parts of sodium borate, 12.5 parts of benzoic acid, 12.5 parts of calcium nitrate, 12.5 parts of barium sulfate, 7.5 parts of dispersant, 7.5 parts of polyphenylene sulfide, 15 parts Parts of PPS resin, 4 parts of single-walled carbon nanotubes, 22.5 parts of superconducting carbon black, 7.5 parts of conductive metal mixture, 7.5 parts of carbon nanotube dispersion, 3 parts of rheological agent, and 4 parts of antioxidant.

[0038] The preparation method of a kind of nano superconducting composite material that the present invention proposes, comprises the following steps, ...

Embodiment 3

[0047] A nano-superconducting composite material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of graphene, 40 parts of yttrium powder, 40 parts of niobium powder, 25 parts of sodium fluoride, 13.5 parts of metal catalyst, 25 parts of silver powder, 240 parts of Parts of isopropanol, 17.5 parts of calcium carbonate, 27.5 parts of methyl cellulose, 12.5 parts of sodium borate, 12.5 parts of benzoic acid, 12.5 parts of calcium nitrate, 12.5 parts of barium sulfate, 7.5 parts of dispersant, 7.5 parts of polyphenylene sulfide, 15 parts Parts of PPS resin, 4 parts of single-walled carbon nanotubes, 22.5 parts of superconducting carbon black, 7.5 parts of conductive metal mixture, 7.5 parts of carbon nanotube dispersion, 3 parts of rheological agent, and 4 parts of antioxidant.

[0048] The preparation method of a kind of nano superconducting composite material that the present invention proposes, comprises the following steps, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com