Method and device for producing grip ring of pipe joint and grip ring for pipe joint

A technology for manufacturing devices and pipe joints, which is applied in the field of hoops, can solve the problems of decreased effective utilization rate of materials, decreased added value of products, and deterioration of surface properties, and achieves the elimination of winding defects, high effective utilization rate, and good surface properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Embodiments of the present invention will be described below with reference to the drawings. However, the present invention is not limited to the following examples, and can be appropriately modified and implemented.

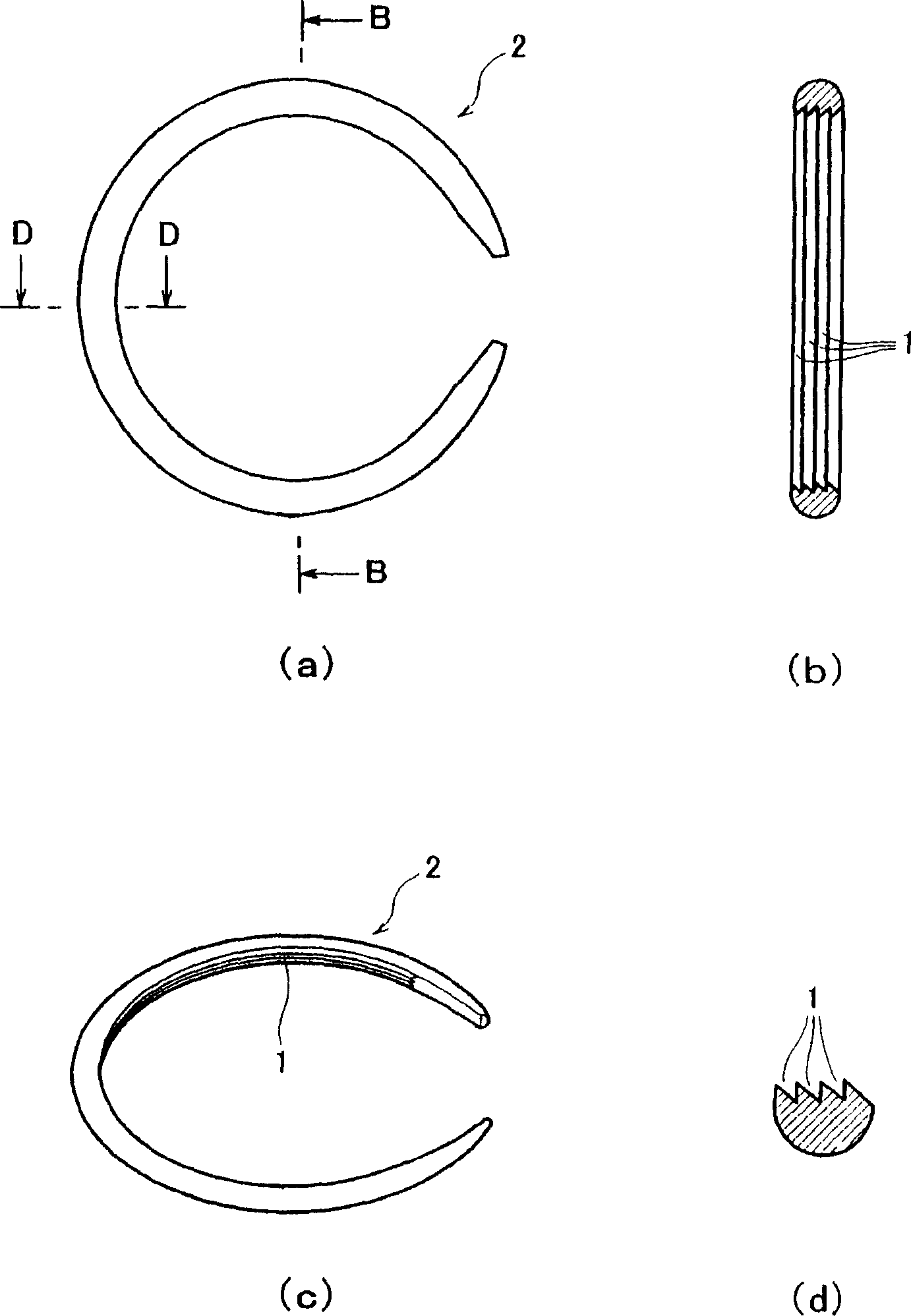

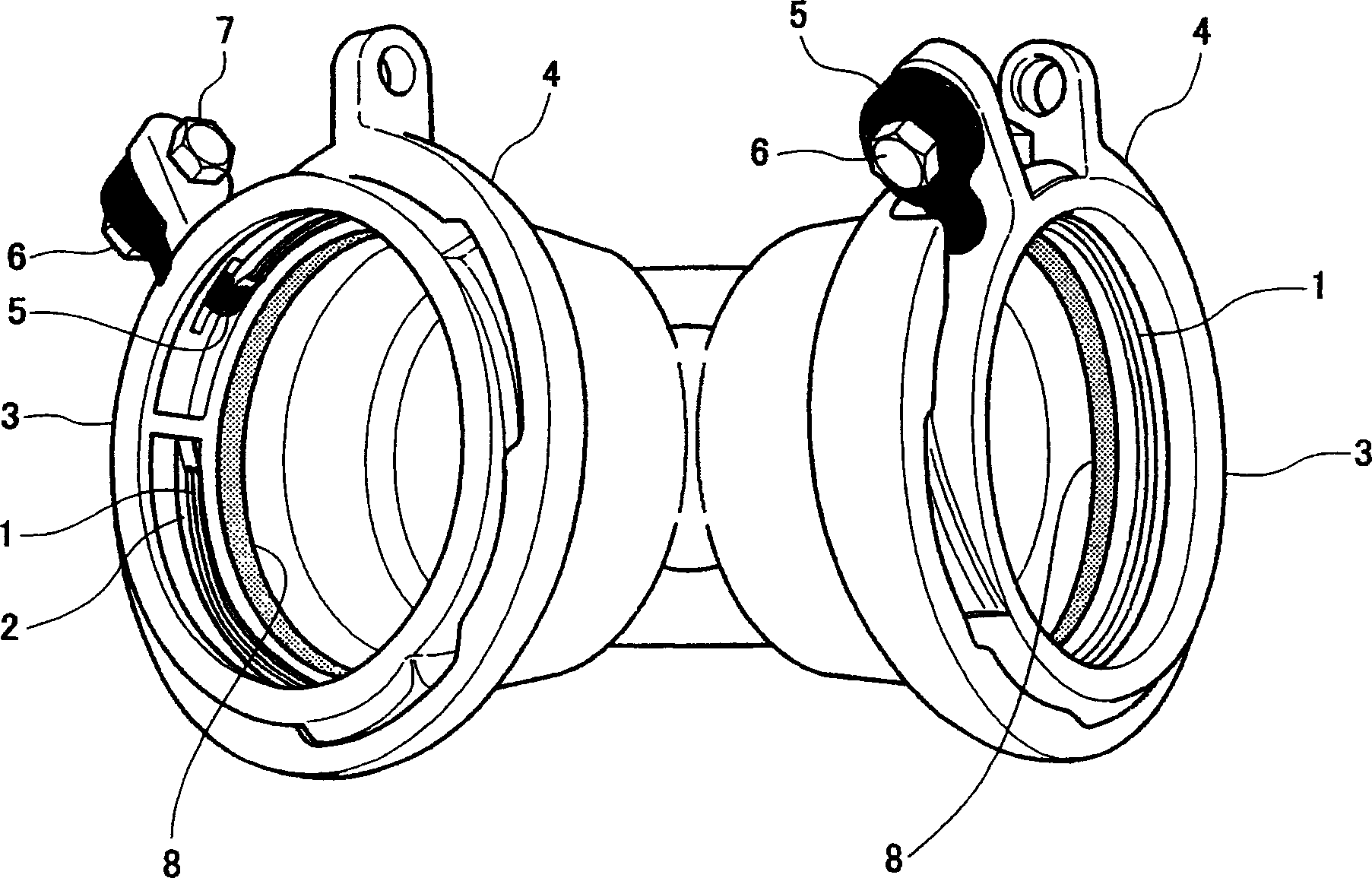

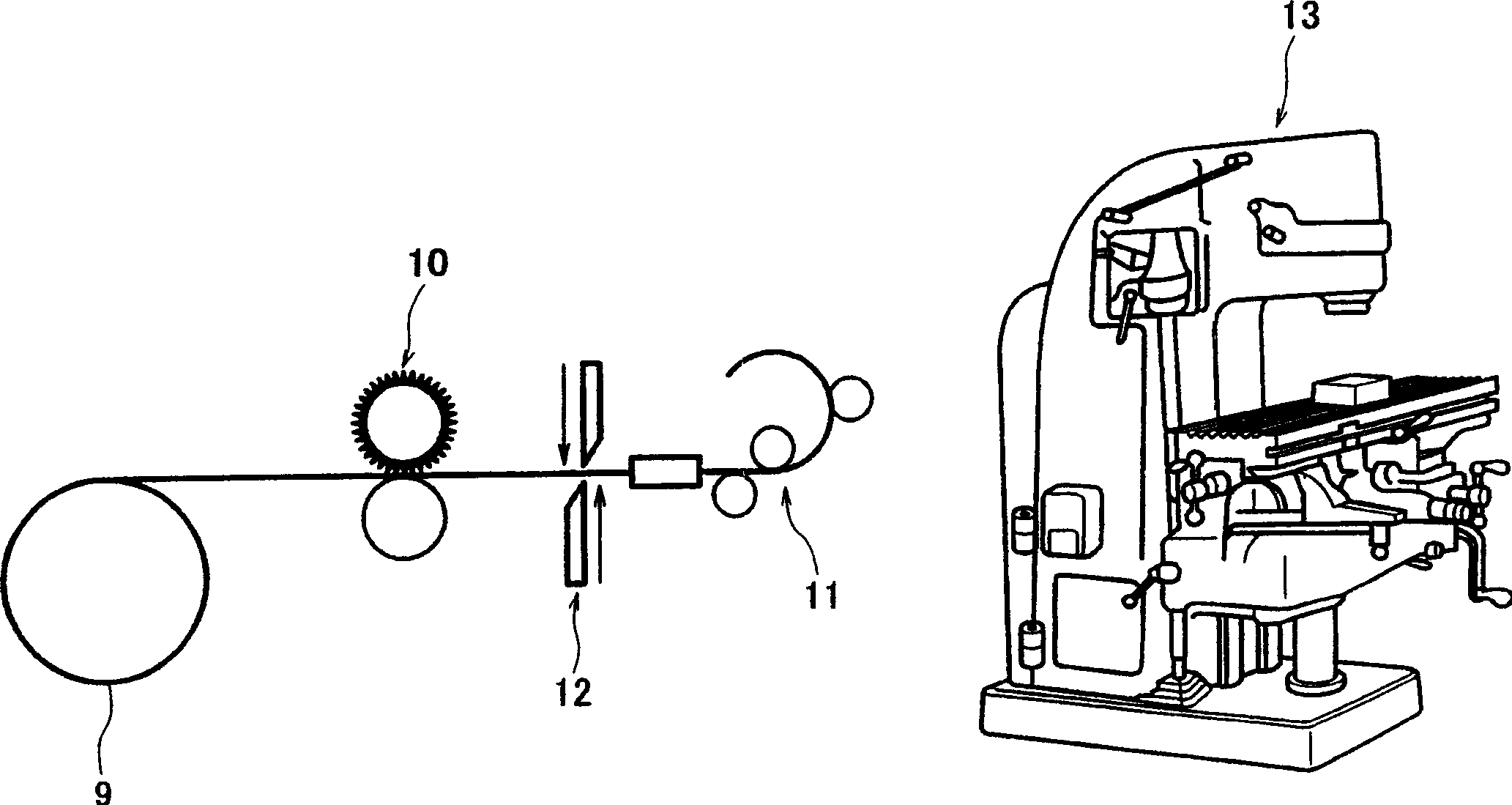

[0041] exist image 3 Among them, the metal wire 9: it is wound into a coil shape; the cutting device 10 (metal wire manufacturing device for a hoop): it rewinds the coil-shaped metal wire, and performs continuous wedge-shaped groove processing on the metal wire; Processing device 11: It processes the metal wire rod processed into a wedge-shaped groove into a ring shape; Cutting device 12: It cuts the ring-shaped metal wire rod processed into a ring shape into a ring piece of a specified length, which is included in the ring processing device 11 Middle; a cutting device 13 (such as a milling machine), which is used to perform cutting on the two end faces of the ring piece of a predetermined length. The details of cutting processing device 10 are in Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com