Fuel cell stack seal structure and production method therefor

A fuel cell stack and sealing structure technology, which is applied to fuel cell components, fuel cells, solid electrolyte fuel cells, etc., can solve the problems of damage to the first sealing component, difficulty in the interval between single cells, shortening of fuel cells, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0085] First, a fuel cell stack and a fuel cell module according to a first embodiment of the present invention will be described in detail with reference to the drawings. In addition, for convenience of description, the dimensional ratios of the drawings cited in the following embodiments are exaggerated and may differ from actual ratios.

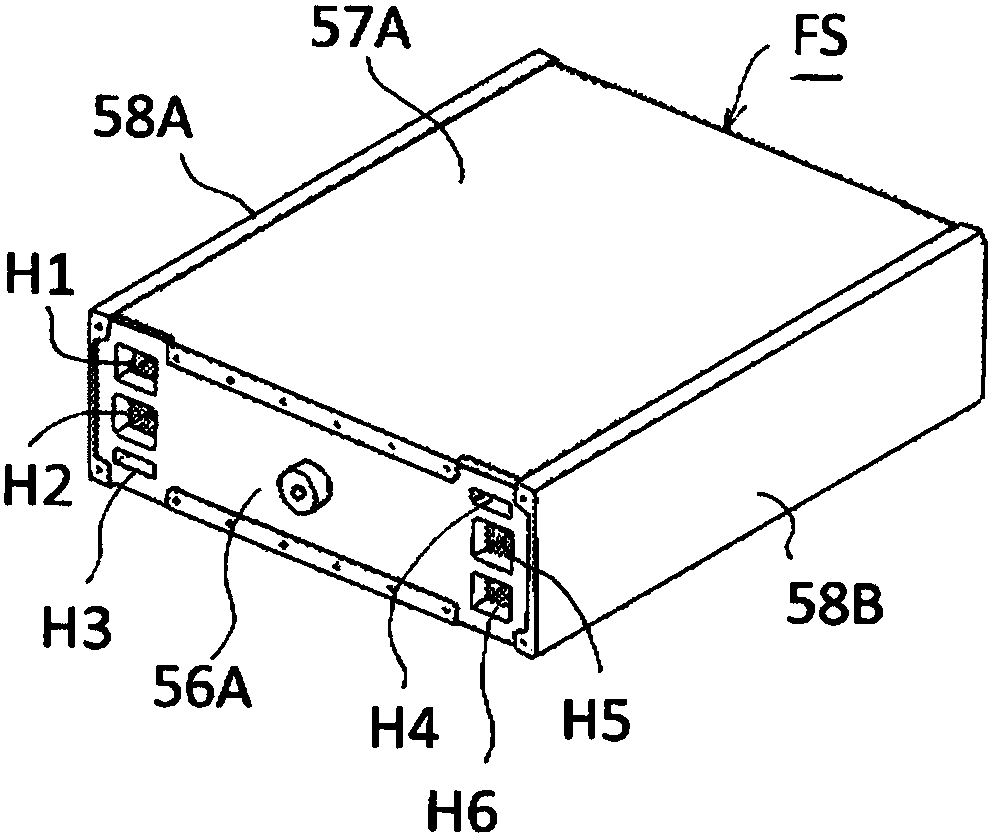

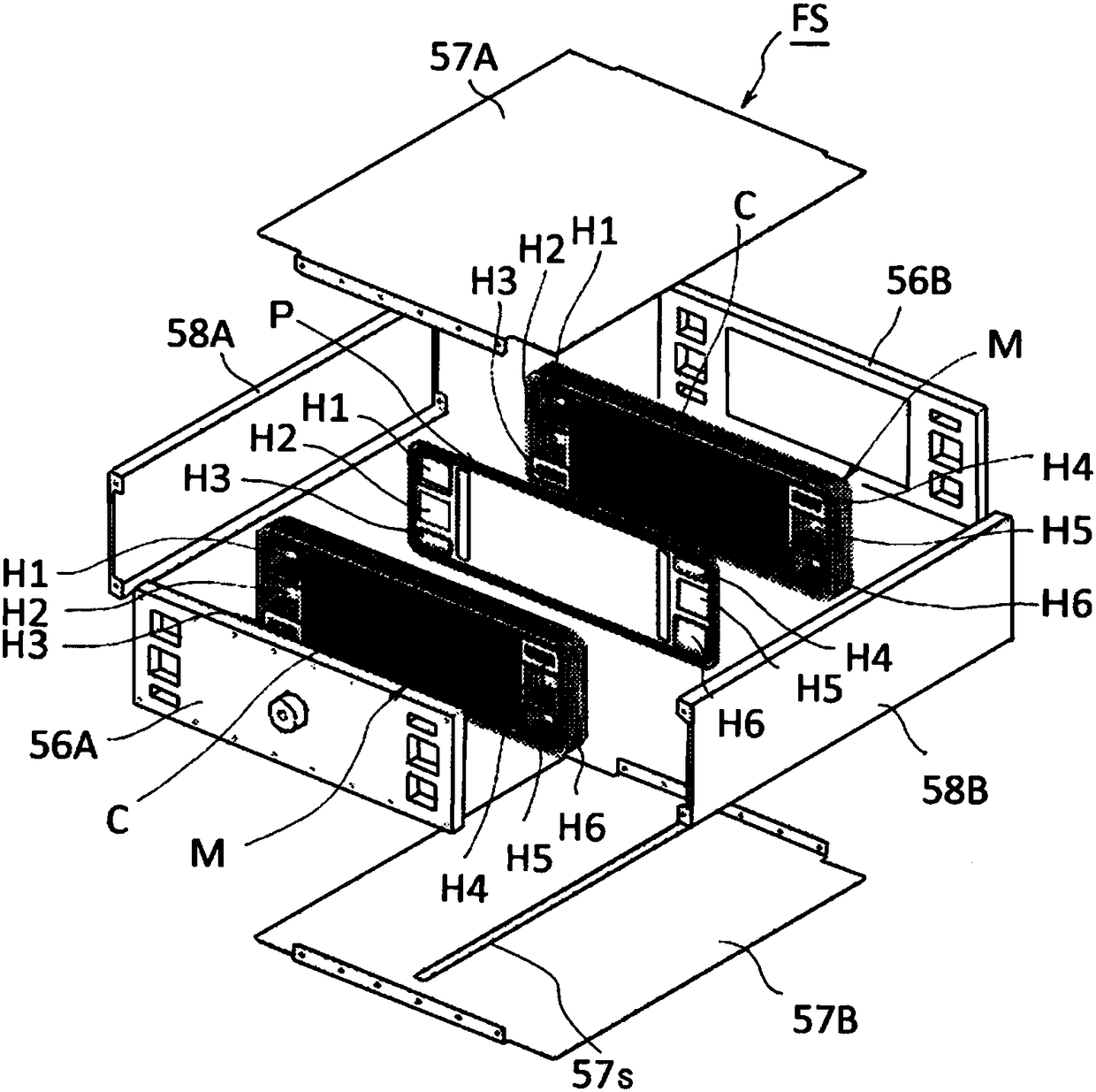

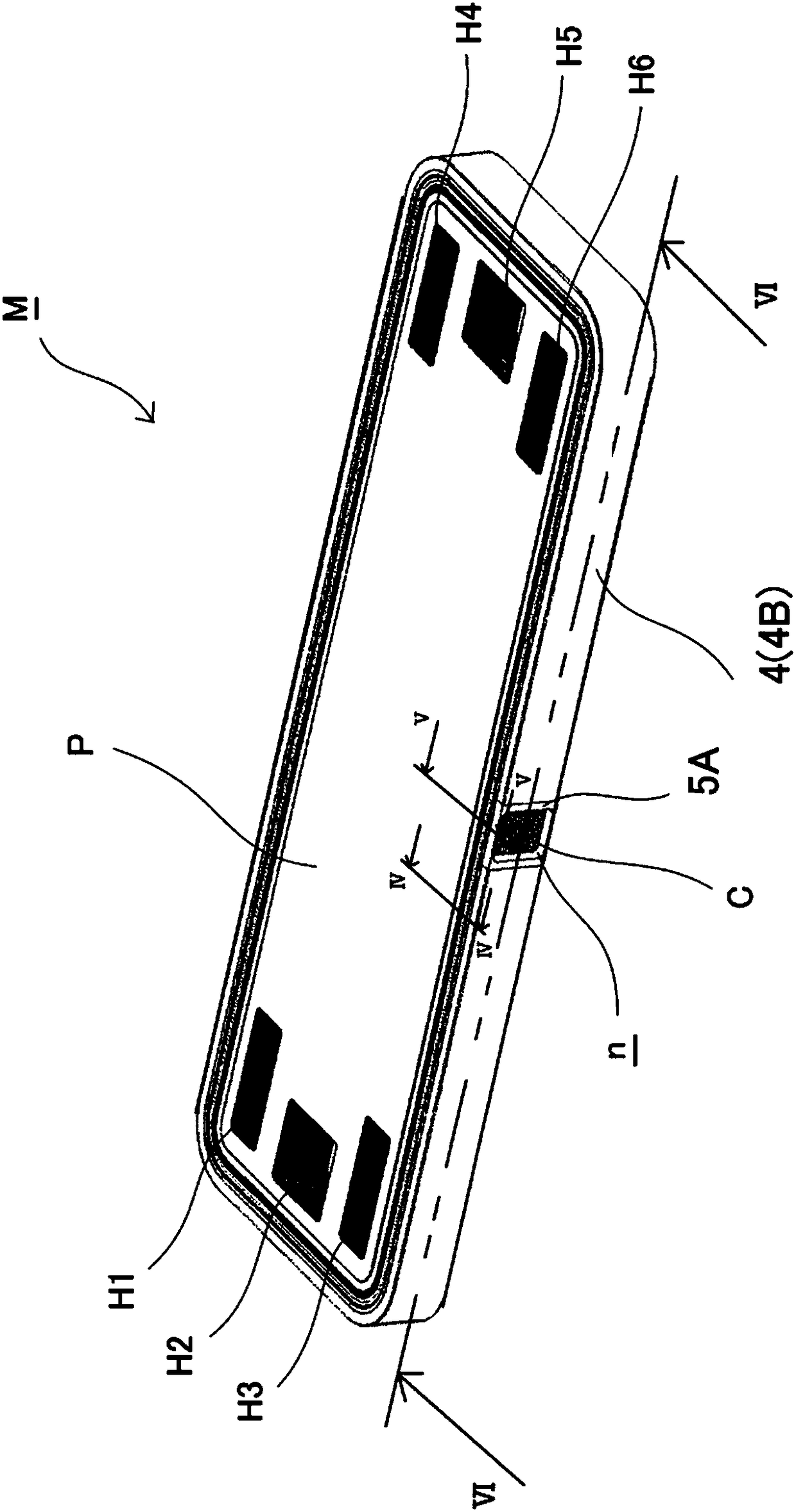

[0086] figure 1 It is a perspective view illustrating the fuel cell stack according to the first embodiment of the present invention. in addition, figure 2 It is a perspective view illustrating an exploded state of the fuel cell stack according to the first embodiment of the present invention. and, image 3 It is a perspective view showing the fuel cell module according to the first embodiment of the present invention. in addition, Figure 4 is along image 3 A schematic cross-sectional view of line IV-IV of the fuel cell module shown. and, Figure 5 is along image 3 A schematic cross-sectional view of the V-V line of the fuel c...

no. 2 approach

[0185] Next, a fuel cell module according to a second embodiment of the present invention will be described in detail with reference to the drawings. In addition, the fuel cell modules equivalent to the fuel cell modules described in the above-mentioned embodiments are denoted by the same reference numerals, and description thereof will be omitted.

[0186] Figure 10 (A) is a perspective view showing a fuel cell module according to a second embodiment of the present invention, Figure 10 (B) was Figure 10 (A) An enlarged view of a portion surrounded by line B of the fuel cell module shown in (A). Such as Figure 10 As shown, the difference between the fuel cell module M2 of this embodiment and the fuel cell module of the above-mentioned first embodiment is that the notch forming member 5A is covered by the outer peripheral sealing member 4 ( 4B).

[0187] In this embodiment, in addition to the effects obtained in the first embodiment described above, since the notch form...

no. 3 approach

[0189] Next, a fuel cell module according to a third embodiment of the present invention will be described in detail with reference to the drawings. In addition, the fuel cell modules equivalent to the fuel cell modules described in the above-mentioned embodiments are denoted by the same reference numerals, and description thereof will be omitted.

[0190] Figure 11 It is a perspective view showing a fuel cell module according to a third embodiment of the present invention. Such as Figure 11 As shown, the difference between the fuel cell module M3 of this embodiment and the fuel cell module of the above-mentioned first embodiment is that the outer peripheral sealing member 4 ( 4B) has a pair of plate-shaped notch forming members in the notch n 5B, the spacer has a protruding measurement terminal 23 extending along its planar direction, and the measurement terminal 23 is exposed at the notch n.

[0191] In this embodiment, in addition to the effects obtained in the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com