Rear concrete thermal curtain wall connecting piece and construction method

A construction method and concrete technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of violating the safety rules of building thermal insulation engineering, speeding up the damage of concrete formwork, hidden dangers of welding operation, etc., and achieving good connection and fixing effect, convenient construction, The effect of a high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

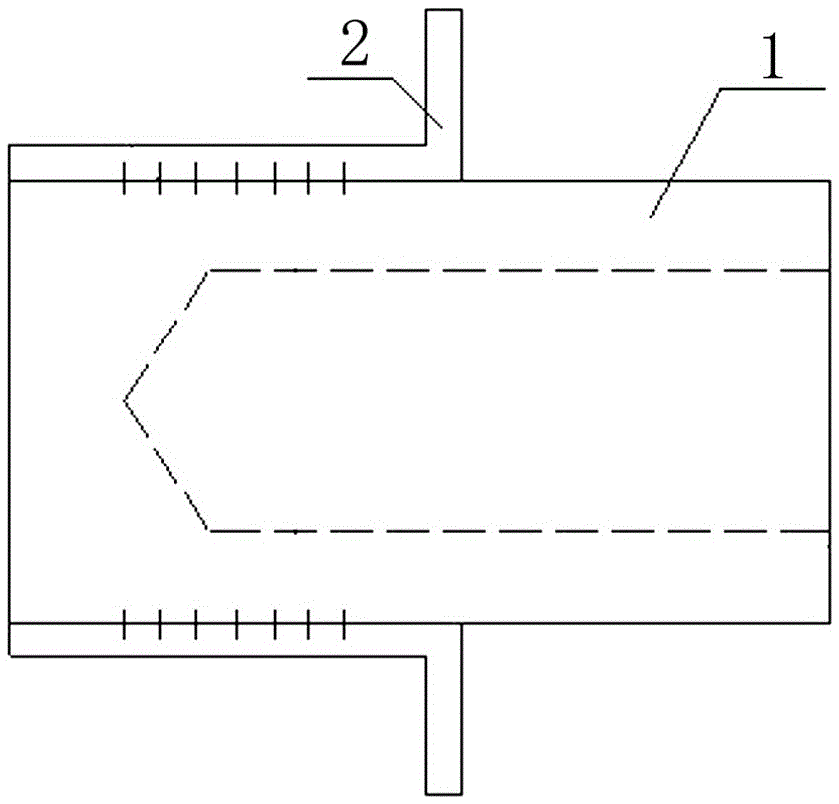

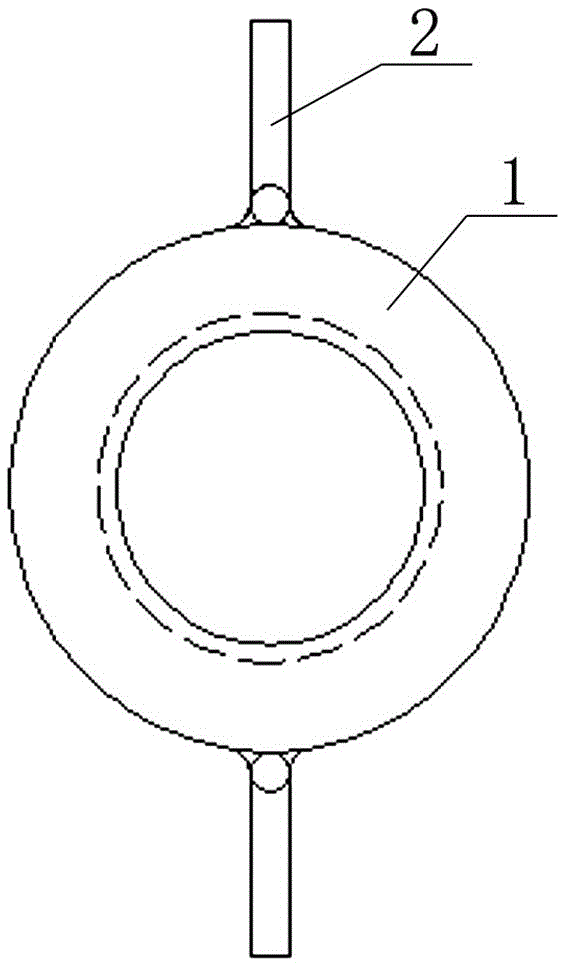

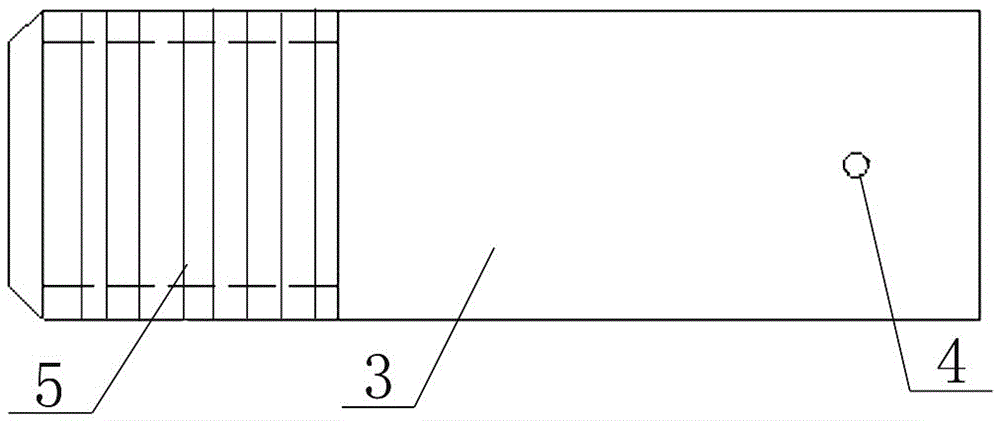

[0034] Embodiment 1: A rear concrete insulation curtain wall connector, see figure 1 , figure 2 , image 3 , including the embedded support and connecting rod 3, the embedded support includes a connector 1 and a connecting steel bar 2, the connecting device 1 is fixed on the surface steel bar 7 of the main concrete structure through the connecting steel bar 2; the connecting steel bar 2 is L Type, one end is fixed on the outer surface of the connector 1, and the other end is bound on the surface layer steel bar 7 of the main concrete structure. Wherein, there are two connecting steel bars 2 symmetrically arranged on both sides of the circumference of the outer wall of the connector 1 . The end of the connector 1 is a sealed and impermeable structure, which is pre-embedded in the main concrete structure 6, so as to prevent concrete from entering the connector from the end during the construction of the main structure. The open end of the connector 1 fits the inner surface o...

Embodiment 2

[0035] Embodiment 2: A post-mounted concrete thermal insulation curtain wall connector. The difference from Embodiment 1 is that there are four connecting steel bars 2, which are evenly distributed on the peripheral outer wall of the outer wall of the connector 1.

Embodiment 3

[0036] Embodiment 3: The construction method of the rear concrete thermal insulation curtain wall using the connector in Embodiment 1 includes the following steps:

[0037] (1) Install the embedded support: see Figure 4 , before the formwork 8 of the main concrete structure is sealed, the pre-embedded support is bound to the surface steel bar of the main concrete structure according to the design position, so that the end of the connector 1 is located inside the main structure, and the open end of the connector 1 Paste the sealing tape, and tighten the open end of the connector 1 against the inner surface of the formwork 8; then carry out the main body concrete construction. When the main structure is pouring concrete, it is necessary to avoid touching the surface steel bars and pre-embedded supports of the main concrete structure to prevent concrete grout from being poured into the connector of the pre-embedded supports.

[0038] Among them, the connector 1 of the pre-embed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com