Construction method and system for hole cleaning and sediment thickness reducing of inclined steel pipe pile

A technology of sediment thickness and construction method, which is applied in the direction of drill pipe, casing, earthwork drilling, etc., can solve the problems that the hole cleaning process is difficult to meet the construction requirements, and the hole cleaning is not easy to be completely removed, so as to achieve clean and thorough hole cleaning. High construction efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

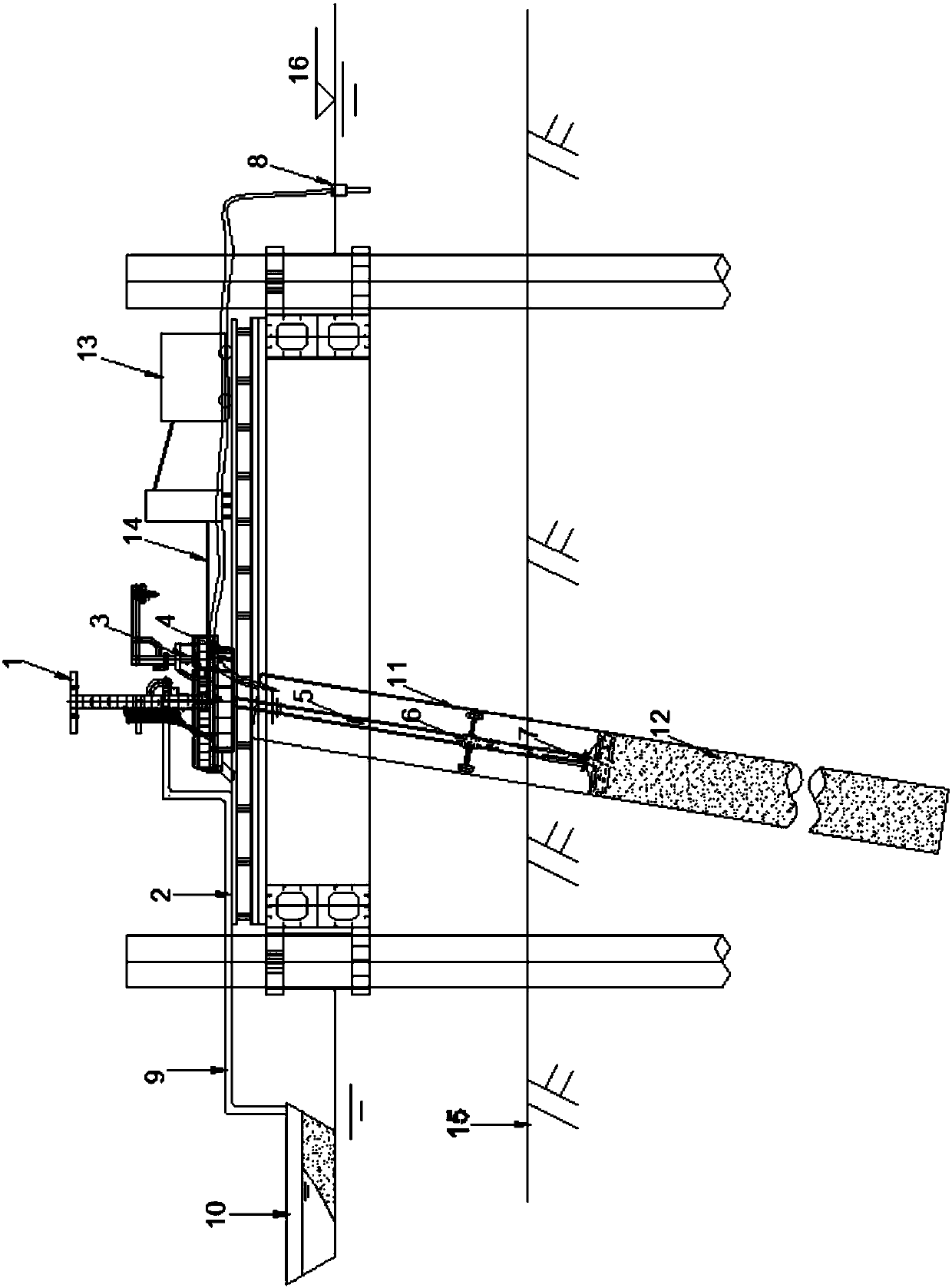

[0037] see figure 1 As shown, the embodiment of the present invention provides a construction method for clearing holes of inclined steel pipe piles and reducing the thickness of sediment. The method includes the following steps:

[0038] S1. Use a reverse circulation drilling rig to drill holes, lift the drill bit after completion, and start the gas lift reverse circulation system to remove slag;

[0039] Specifically, step S1 can be divided into the following steps:

[0040] S101. Place the reverse circulation drilling rig, strengthen the anchor point between the reverse circulation drilling rig 1 and the construction platform 2, check the inclination of the operation platform 4, measure the elevation of the construction platform 2 and the elevation of the reference point of the operation platform 4, and then install and lower the flat bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com