Construction method of double arch tunnel auxiliary middle wall without middle pilot tunnel

A construction method, the technology of multi-arch tunnels, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as difficulty, inconvenient slag discharge, and complicated construction techniques, so as to improve construction efficiency, reduce construction period, and ensure construction safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

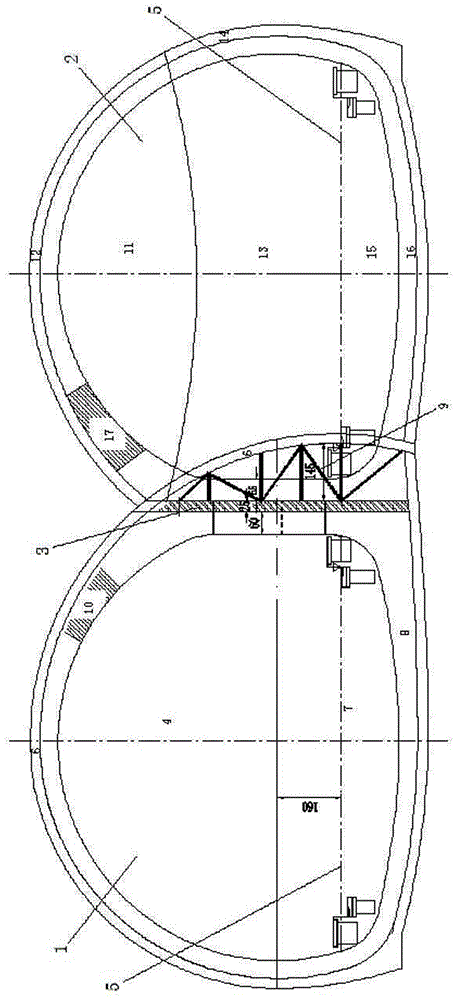

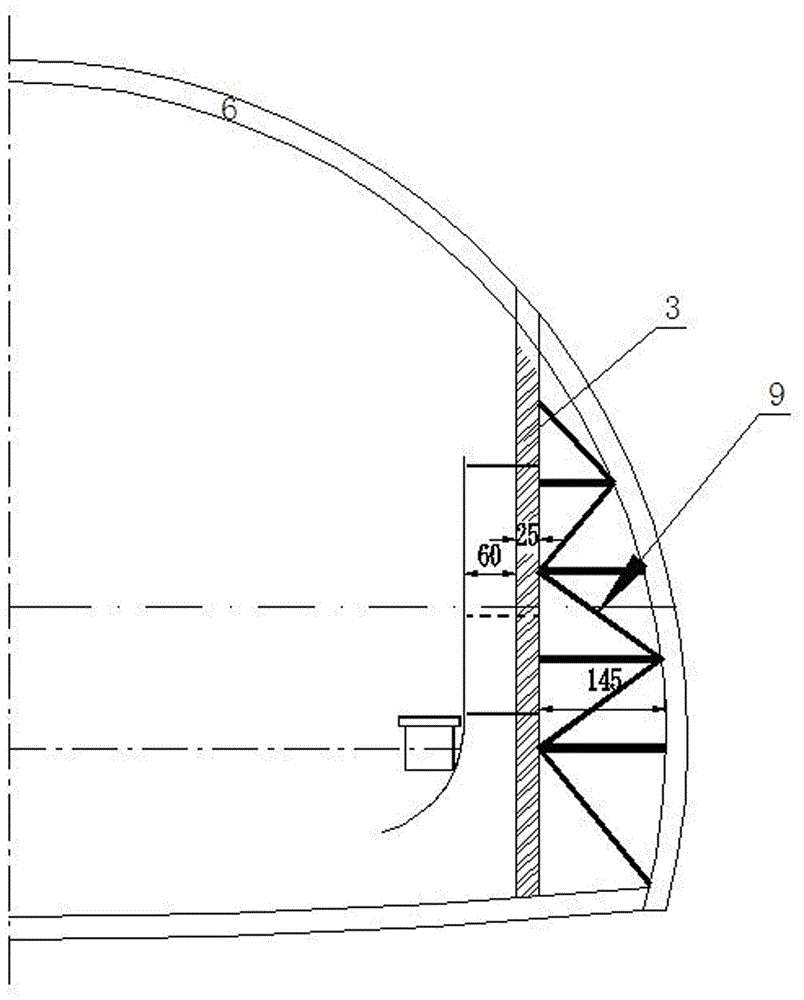

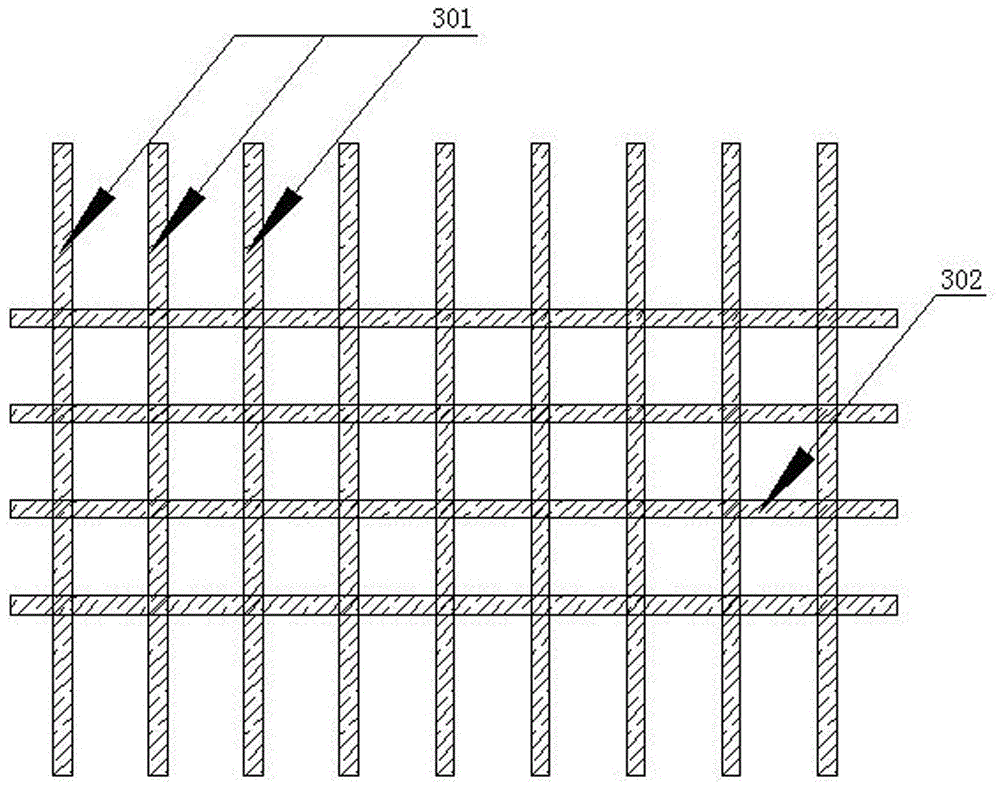

[0020] see Figure 1 to Figure 6 , the left tunnel 1 in the figure is the first tunnel, the right tunnel 2 is the rear tunnel, and the third is the auxiliary middle wall. The dimensions in the figure are in cm.

[0021] In this embodiment, the construction steps of the auxiliary middle wall of the multi-arch tunnel without the middle pilot tunnel are as follows:

[0022] Excavate the left tunnel 1 first, and the construction sequence of the left tunnel 1 is: first construct the upper step 4 (the upper step 4 is the area above 1.6 meters above the design datum line 5), adopt conventional construction methods; then construct the initial support 6 , note that in the position of the auxiliary middle wall 3 in the design, it is necessary to embed embedded parts on the initial support 6 to facilitate the connection in later construction; after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com