Disassembling and installation method for tower crane attachment

A technology of tower cranes and tower caps, which is applied to cranes and other directions, can solve problems such as difficulty in installation and attachment, broken ropes of small hoisting wire ropes, and falling of hanging objects, so as to achieve high construction efficiency and ensure construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

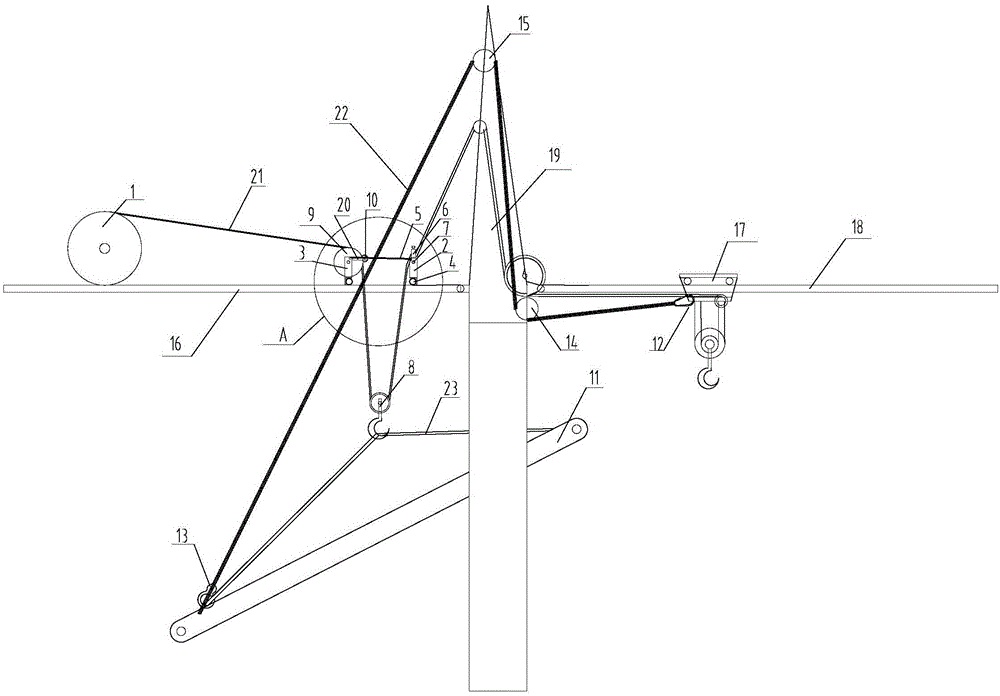

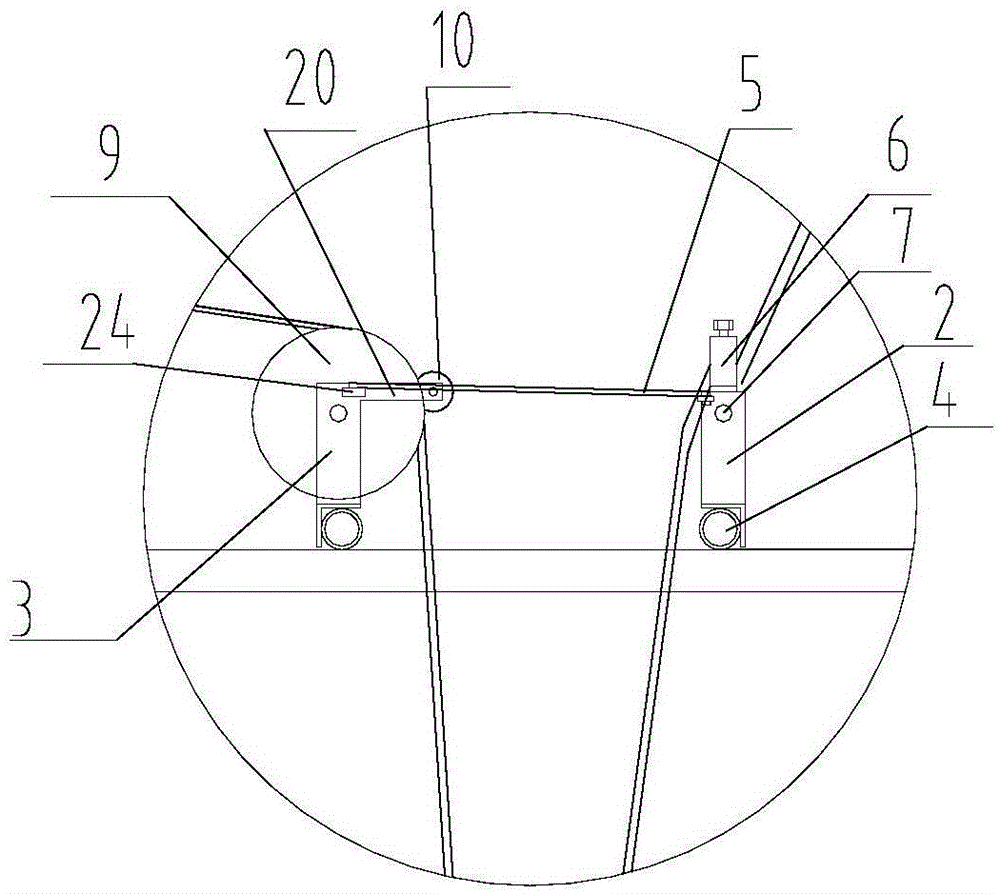

[0027] Such as Figure 1-Figure 2 As shown, a device for attachment, disassembly and installation of a tower crane includes a steel wire rope fixing frame, a fixed pulley device, a fixed pulley B14, a fixed pulley C15, and installation ropes on the balance arm of the tower crane. Between the lift 1 and the tower cap 19, the wire rope fixing frame and the fixed pulley device are fixed in turn, the wire rope fixing frame is installed on the side close to the tower cap 19, and the fixed pulley B14 is fixed at the joint between the boom 18 and the tower cap 19. At the lower end, the fixed pulley C15 is fixed on the upper end of the tower cap 19, a lasso wire rope 22 is installed to bypass the fixed pulley B14 and the fixed pulley C15, and the hook 12 at one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com