Production process for improving weather resistance of PE solid-wall pipe

A production process and solid-wall pipe technology, which is applied in the direction of tubular objects, applications, household appliances, etc., can solve the problems of poor mold matching between the protective layer and the PE solid wall, no improvement in the performance of the PE pipe, and poor weather resistance of the PE solid wall. , to achieve good clamping effect, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

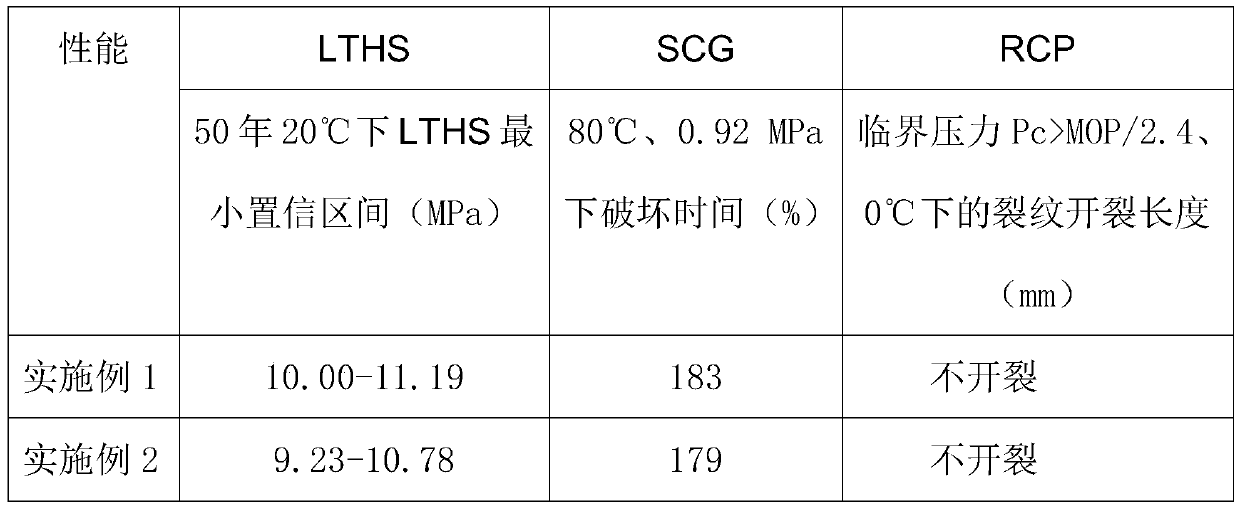

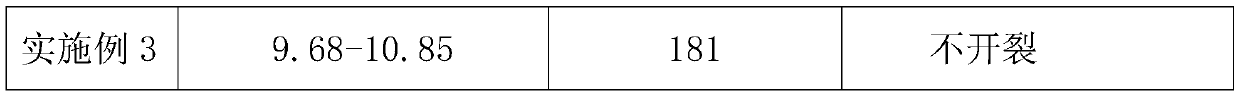

Embodiment 1

[0047] Conduct a comprehensive and detailed inspection of all equipment in the production line to confirm that there is no abnormality in the equipment, and install the corresponding molds and adjust the equipment according to the specifications and models;

[0048] Prepare the special pipe material for PE solid wall pipe. The special pipe material is composed of the following components in parts by mass: PE resin: 50 parts; antibacterial agent 5 parts; organic montmorillonite: 7 parts; peroxidized Dicumyl: 0.5 parts; calcium-zinc composite stabilizer: 3 parts; MB antioxidant: 2 parts; maleic anhydride: 8 parts; titanium dioxide loaded with antibacterial agent: 20 parts; carbon black: 0.5 parts; polyolefin elastomer : 5 parts; vinyl triethoxysilane: 1 part; polyethylene wax: 0.5 parts; color masterbatch: 1.5 parts. The preparation process of the special pipe material includes the following steps: (1) preparing PE resin / antibacterial agent blend: blending the PE resin and antib...

Embodiment 2

[0054] Conduct a comprehensive and detailed inspection of all equipment in the production line to confirm that there is no abnormality in the equipment, and install the corresponding molds and adjust the equipment according to the specifications and models;

[0055] Prepare the special pipe material for PE solid-wall pipe. The special pipe material is composed of the following components in parts by mass: PE resin: 55 parts; antibacterial agent 5 parts; organic montmorillonite: 7 parts; peroxidized Dicumyl: 0.5 parts; calcium-zinc composite stabilizer: 3 parts; MB antioxidant: 2 parts; maleic anhydride: 10 parts; titanium dioxide loaded with antibacterial agent: 20 parts; carbon black: 0.5 parts; polyolefin elastomer : 5 parts; vinyl tris (β-methoxyethoxy) silane): 1 part; polyethylene wax: 0.5 parts; color masterbatch: 1.5 parts. The preparation process of the special pipe material includes the following steps: (1) preparing PE resin / antibacterial agent blend: blending the PE...

Embodiment 3

[0061]Conduct a comprehensive and detailed inspection of all equipment in the production line to confirm that there is no abnormality in the equipment, and install the corresponding molds and adjust the equipment according to the specifications and models;

[0062] Prepare the special pipe material for PE solid-wall pipe. The special pipe material is composed of the following components in parts by mass: PE resin: 50 parts; antibacterial agent 7 parts; organic montmorillonite: 8 parts; peroxidized Dicumyl: 0.5 parts; calcium-zinc composite stabilizer: 3 parts; MB antioxidant: 2 parts; maleic anhydride: 10 parts; titanium dioxide loaded with antibacterial agent: 20 parts; carbon black: 0.5 parts; polyolefin elastomer : 5 parts; vinyl trimethoxysilane: 1 part; polyethylene wax: 0.5 parts; color masterbatch: 1.5 parts. The preparation process of the special pipe material includes the following steps: (1) preparing a PE resin / antibacterial agent blend: blending the PE resin and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com