Rubber vibration reduction device for noise reduction of elevator machine room

A kind of rubber shock absorption, elevator machine room technology, applied in elevators, transportation and packaging, sounding equipment and other directions in buildings, can solve the problem of damping effect attenuation and other problems, to reduce vibration noise, the main engine runs smoothly, and prevent the nut from falling off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

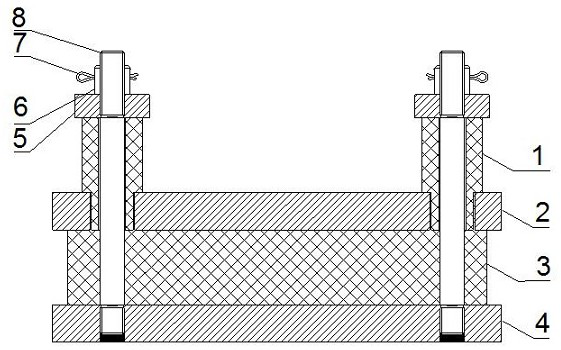

[0016] refer to figure 1 , a rubber damping device for noise reduction in an elevator machine room, comprising a rubber sound insulation pad 1, an upper support plate 2, a rubber damping pad 3, a lower support plate 4, a gasket 5, a cotter nut 6, a cotter pin 7 and a double-ended screw 8. It has the advantages of good shock absorption effect and long service life.

[0017] Specifically, in the embodiment of the present invention, such as figure 1 As shown, the double-ended screw rod 8 and the lower support plate 4 are tightened and welded so that the verticality is less than or equal to 0.5 mm;

[0018] The lower support plate 4 is placed on the pre-embedded iron i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com