Horizontal-type dust collector with damping connecting device

A connecting device and vacuum cleaner technology, which is applied in the direction of vacuum cleaners, household appliances, cleaning equipment, etc., can solve the problems of easy damage to the vacuum cleaner body, enlarge the vibration of the whole machine, and large vibration noise, so as to reduce the outward transmission of vibration, improve vibration noise, The effect of reducing vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The horizontal vacuum cleaner with the shock-absorbing connection device of the present invention will be described in detail below with reference to the accompanying drawings and embodiments. In the drawings of the present invention, the same components as those in the prior art use the same symbols.

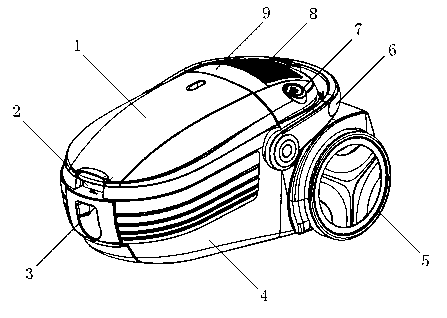

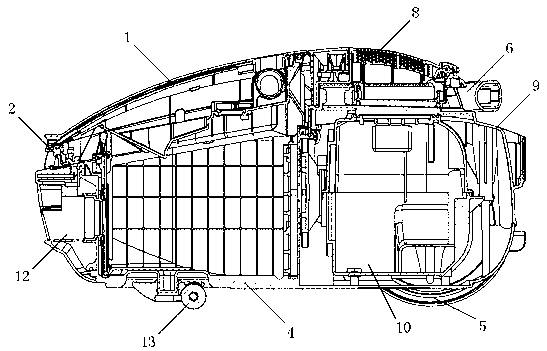

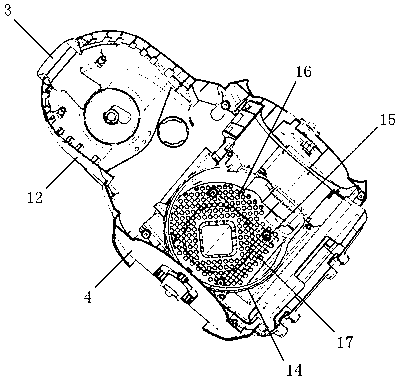

[0050] Figure 5 It is a top view of the vacuum cleaner bottom shell and part of the internal structure of the present invention. Such as figure 1 , figure 2 and Figure 5 As shown, the body of the horizontal vacuum cleaner with the shock-absorbing connection device of the present invention includes a front cover 1 , a rear cover 9 , a bottom case 4 and the like. The front end of the bottom case head 12 of the bottom case 4 is provided with a hose connector 3 , and the lower part of the front part of the bottom case 4 is provided with casters 13 which are convenient for changing directions. The front cover 1 is connected to the bottom case 4 through the connecting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com