Antistatic and high-performance PA66 composite material and preparation method thereof

A technology of PA66 and composite materials, which is applied in the field of antistatic high-performance PA66 composite materials and its preparation, can solve the problems of PA66 antistatic performance and mechanical properties that cannot be adapted, achieve good dispersion, improve mechanical properties, and improve antistatic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

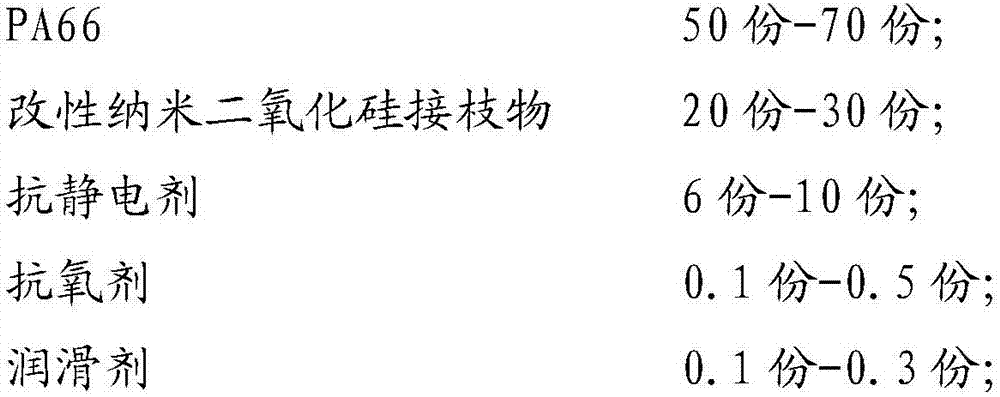

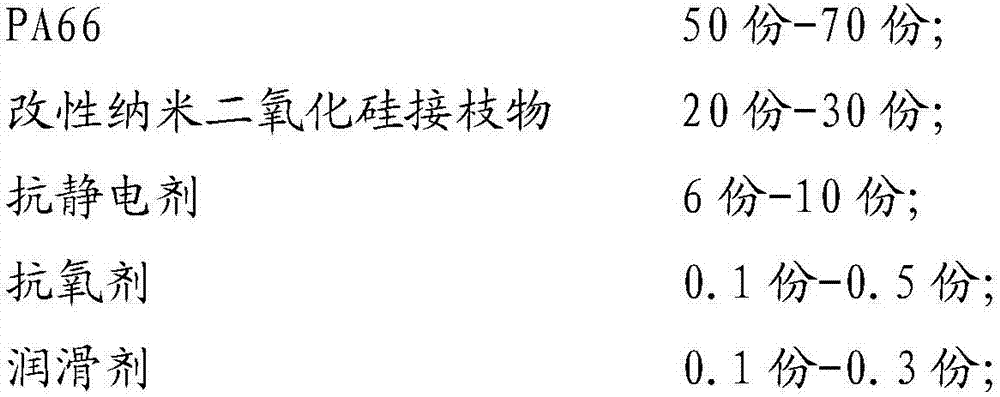

[0041] The preparation method of the antistatic high-performance PA66 composite material of any one of the above-mentioned, comprises the following steps:

[0042] 1) Weigh 50-70 parts of PA66, 20-30 parts of modified nano-SiO 2 The graft, 6-10 parts of antistatic agent, 0.1-0.5 parts of antioxidant, 0.1-0.3 parts of lubricant are mixed and stirred evenly to obtain a mixture;

[0043] 2) Extruding and granulating the mixture obtained in step 1), to obtain the PA66 composite material.

[0044] Described step 2) specifically is:

[0045] Put the mixture obtained in step 1) into the hopper of a twin-screw extruder for extrusion and granulation, wherein the twin-screw extruder includes six temperature zones arranged in sequence, and the temperature in the first zone is 240-270 ℃, the temperature in the second zone is 260~290℃, the temperature in the third zone is 260~290℃, the temperature in the fourth zone is 260~290℃, the temperature in the fifth zone is 260~290℃, the temperat...

preparation example 1

[0047] Described modified nano silicon dioxide graft, its preparation method is:

[0048] 1) Weigh a certain amount of absolute ethanol, nano-SiO 2 , KH550 mixed evenly, put into a three-necked flask, react at a constant temperature of 70°C for 3 hours, filter and dry to obtain the product KH550-g-SiO 2 ; The dehydrated alcohol, the nano-SiO 2 , The mass ratio of KH550 is 120:30:4.

[0049] 2) Weigh a certain amount of KH550-g-SiO in step 1) 2, Sodium lauryl sulfate, sodium bicarbonate, styrene and potassium persulfate were evenly mixed and put into a three-necked flask, reacted at a constant temperature of 80°C for 8 hours, filtered and dried to obtain the product modified nano-SiO 2 Graft; the KH550-g-SiO 2 , The mass ratio of the sodium lauryl sulfate, the sodium bicarbonate, the styrene and the potassium persulfate is 40:2:1:60:3.

preparation example 2

[0051] Described modified nano silicon dioxide graft, its preparation method is:

[0052] 1) Weigh a certain amount of absolute ethanol, nano-SiO 2 , KH550 were mixed evenly and put into a three-necked flask, reacted at a constant temperature of 90°C for 5 hours, filtered and dried to obtain the product KH550-g-SiO 2 ; The dehydrated alcohol, the nano-SiO 2 , The mass ratio of the KH550 is 160:40:6.

[0053] 2) Weigh a certain amount of KH550-g-SiO in step 1) 2 , Sodium lauryl sulfate, sodium bicarbonate, styrene and potassium persulfate are mixed evenly and put into a three-necked flask, reacted at a constant temperature of 120°C for 12 hours, filtered and dried to obtain the product modified nano-SiO 2 Graft; the KH550-g-SiO 2 , The mass ratio of the sodium lauryl sulfate, the sodium bicarbonate, the styrene and the potassium persulfate is 60:4:3:80:6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com