Lead belt production line for anodes and cathodes of storage batteries

A technology for positive and negative electrodes and storage batteries, which is applied in the field of lead belt production lines for battery positive and negative electrodes, can solve problems such as poor working conditions, reduce the working efficiency of casting machines and rolling mills, and hinder the cleaning of residual liquid, so as to improve the working environment and labor efficiency. Conditions and working environment, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

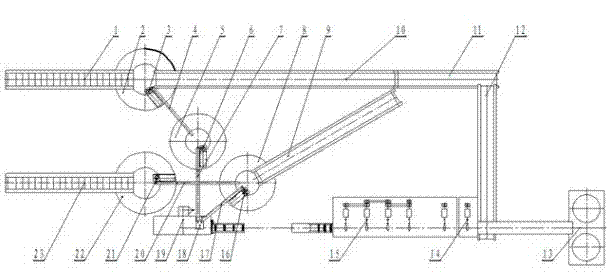

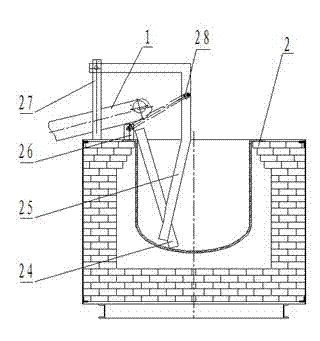

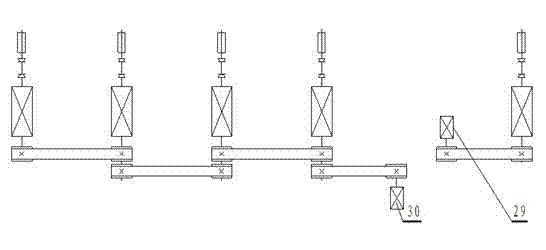

[0046] A lead belt production line for battery positive and negative poles, such as figure 1 As shown, the lead strip production line for battery positive and negative poles comprises the first lead melting furnace 2, the first holding furnace 5, the second lead melting furnace 22, the second holding furnace 8, continuous casting machine 19, continuous rolling unit 15, longitudinal Cutting and scrapping device 14 and coiler 13.

[0047] First lead-melting furnace 2 and the furnace mouth side of the second lead-melting furnace 22 are correspondingly provided with the first chain conveyor 1 and the second chain conveyor 23, the first lead-melting furnace 2 and the first holding furnace 5 A first lead delivery pipe 4 is provided between the furnace mouths, a second lead delivery pipe 20 is provided between the furnace mouths of the second lead-melting furnace 22 and the second holding furnace 8, and the furnace mouth of the first holding furnace 5 and the continuous casting tundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com