Patents

Literature

136results about How to "Won't fall into" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

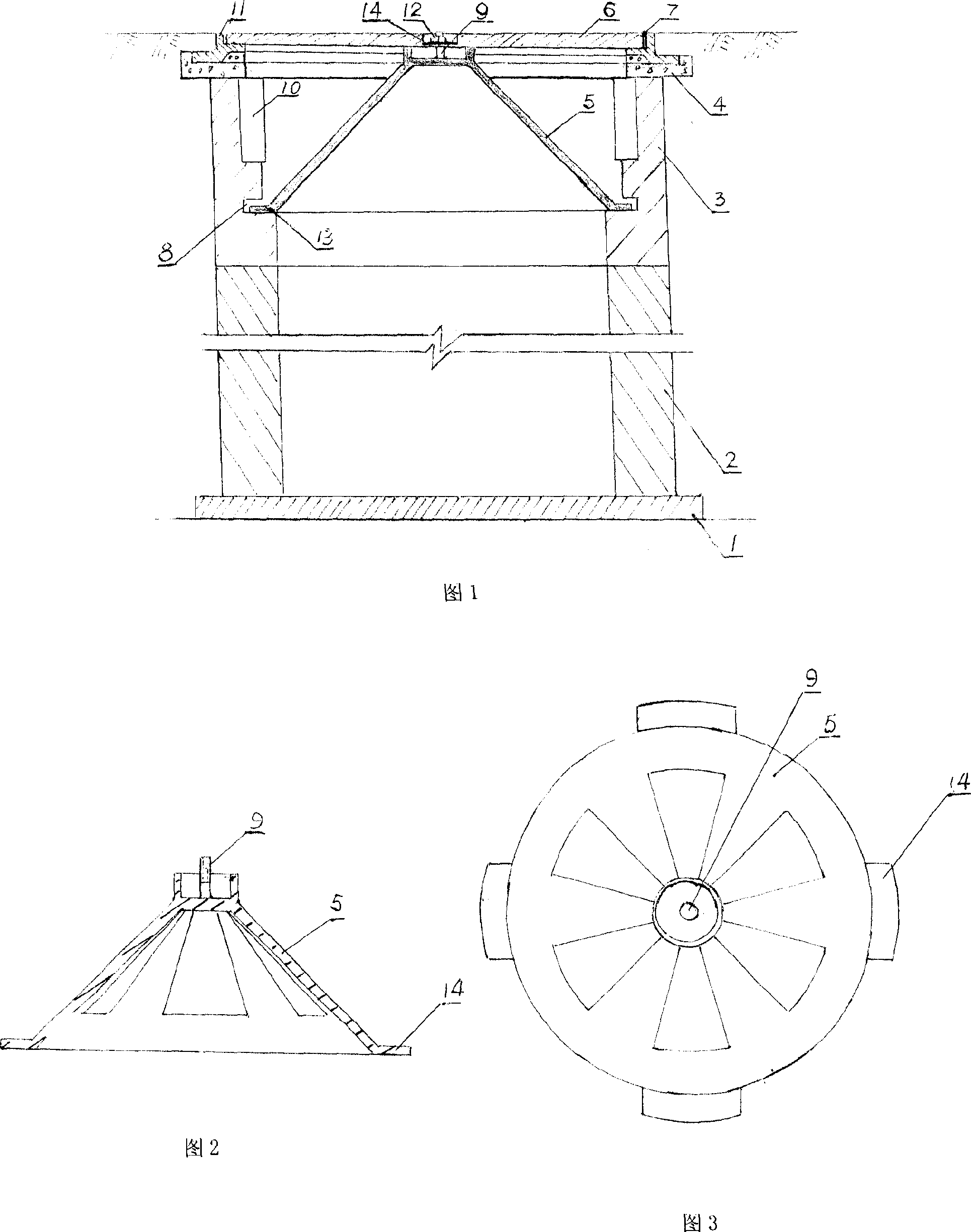

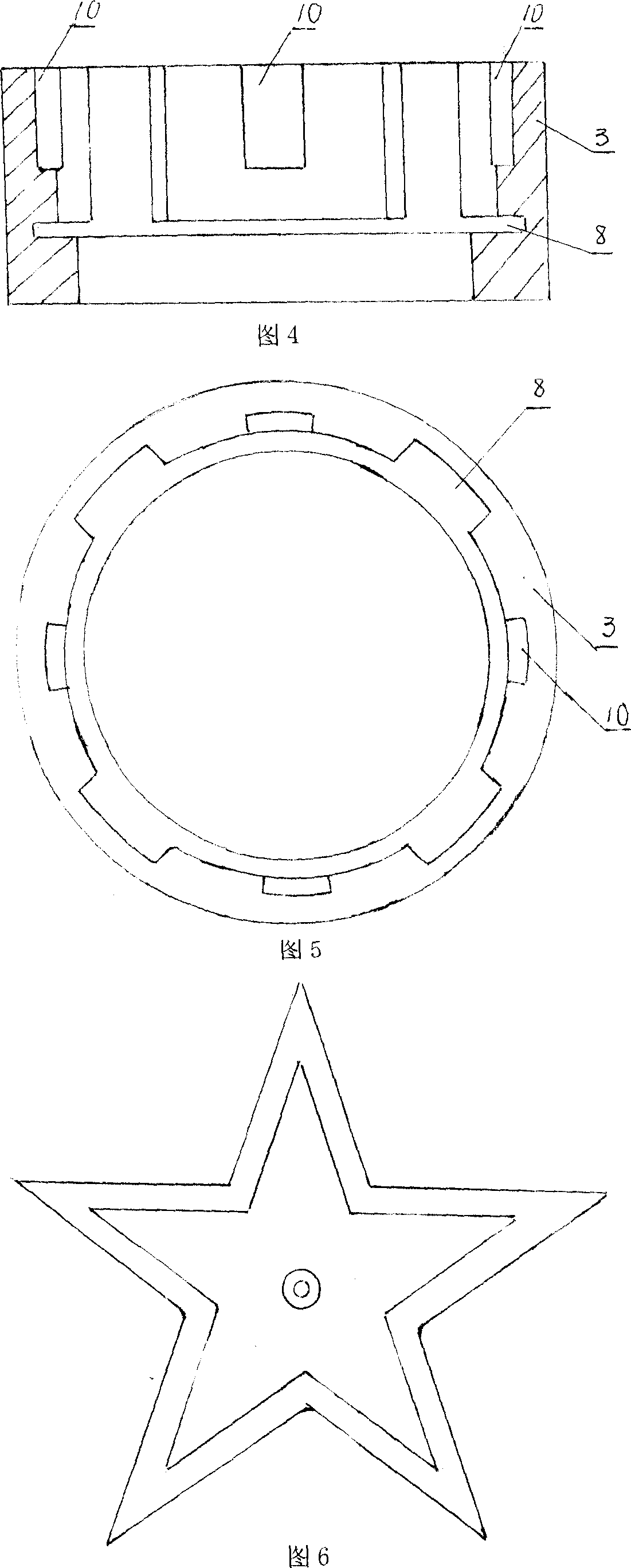

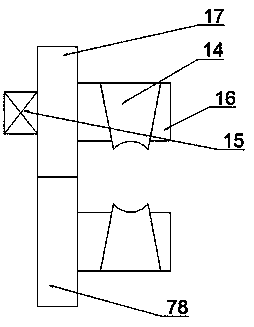

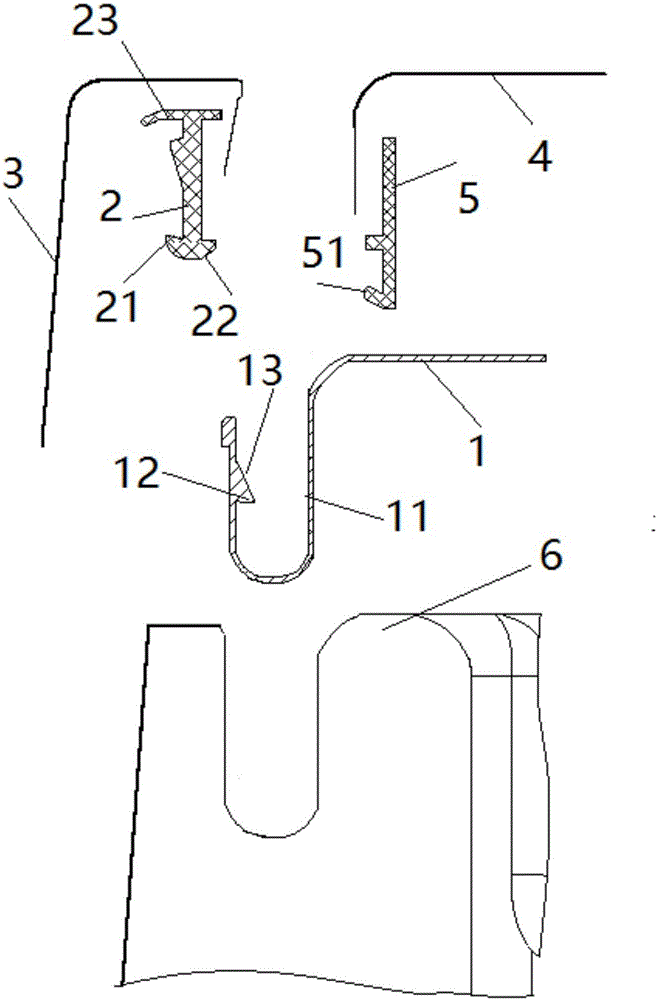

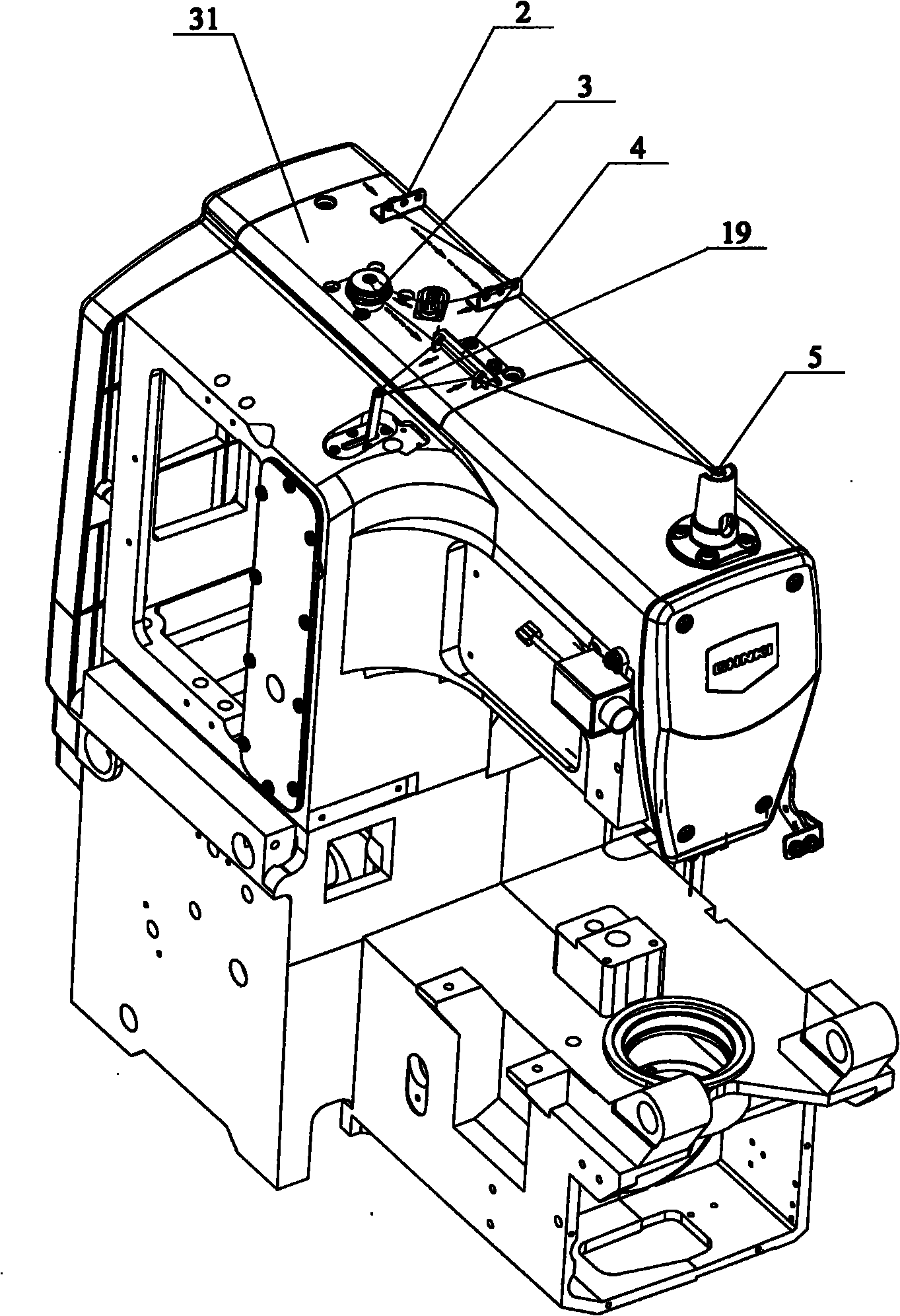

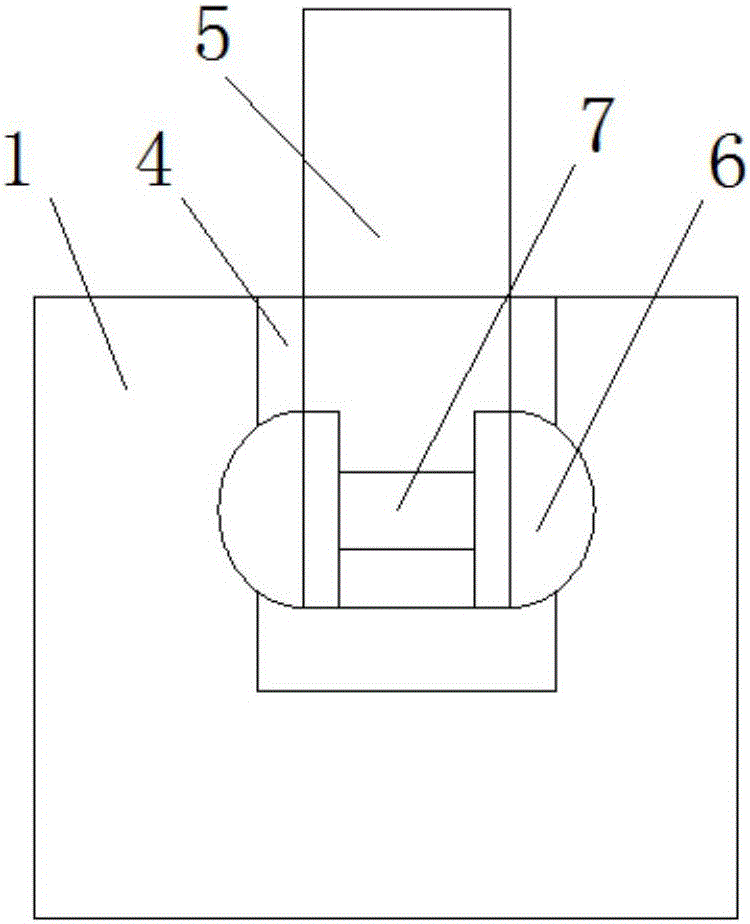

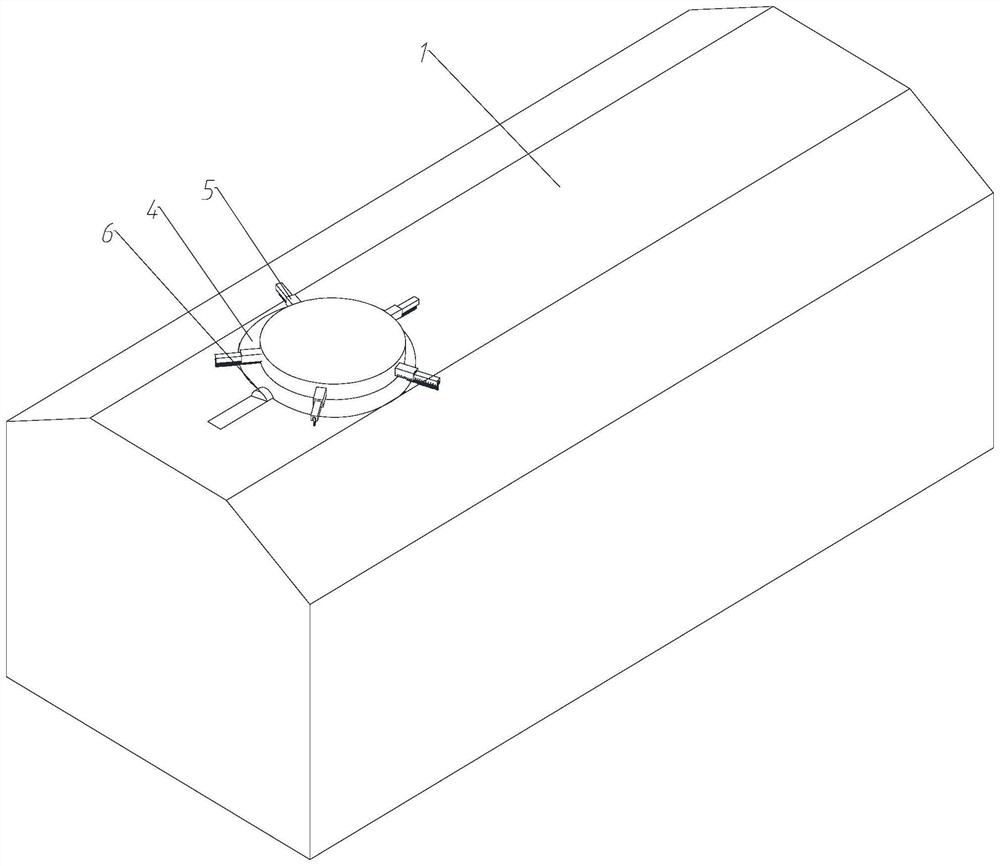

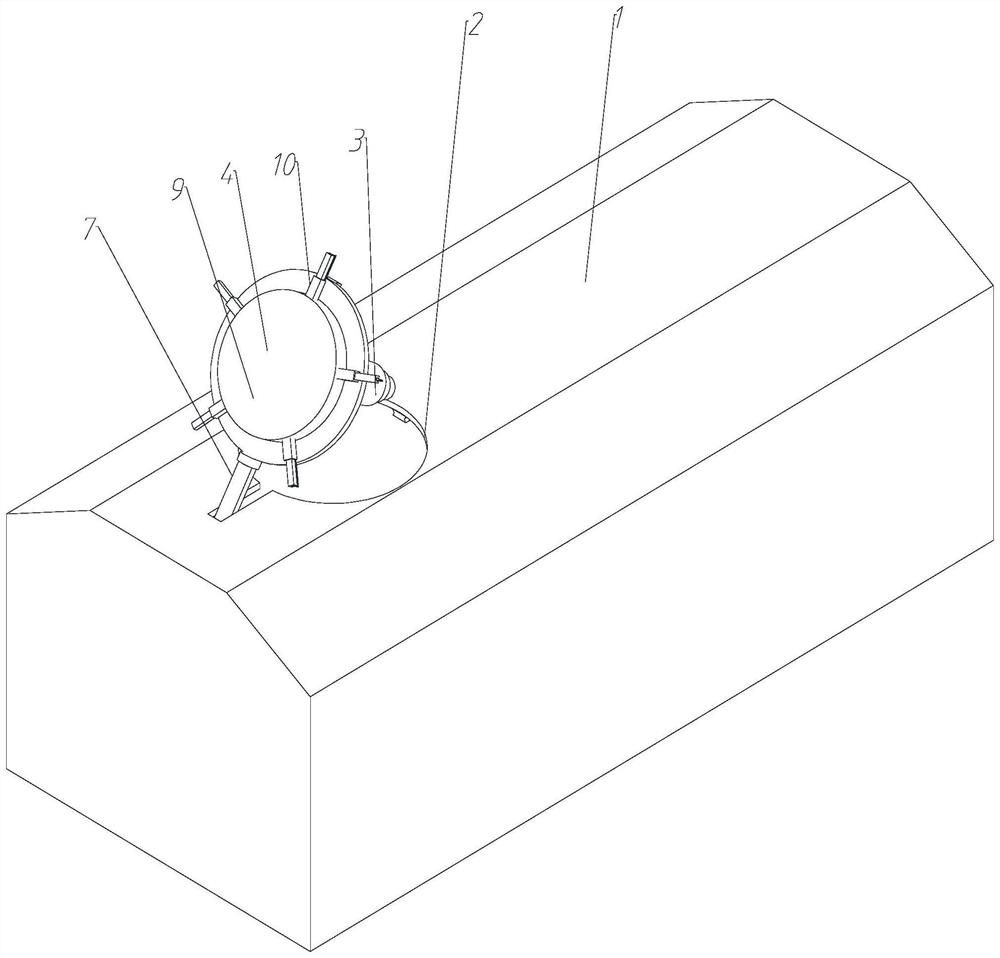

Bearing platform type safety manhole

InactiveCN1970899ASolve sinkingNot easy to pull outArtificial islandsUnderwater structuresTraffic accidentEngineering

The invention discloses a desk safety and inspection well, comprising well base (1) set at the bottom of inspection well, well cylinder, well seat (4) and well cover (6). Its well cylinder is divided into fixed well cylinder (2) and active well cylinder (3). The fixed well cylinder (2) is fixed on the well base (1) and presetting active well cylinder (3) is set on the fixed well cylinder (2) vertically. Pre-buried well ring (11) is set on the well seat (4), which is covered on the active well cylinder (3) flatly. Under the well cover (6) there is a desk (5), which covers on the active well seat (3). The well cover (6) is set in the well ring (11) of well seat (4). The well cover (6) and desk (5) are locked together by screw cap (3) and screw bar (9). The inspection well in the invention can solve the repairing problem when inspection well goes down or declines under pressure and the well cover is connected with the well seat by hinge so that it is opened freely and not easy to be stolen. Abnormal well cover is not easy to be turn out when it is extruded by wheel. If one well cover is lost, the reflectorized paint on the desk can take a caution to foot passenger or traveling crane so as to avoid the traffic accident.

Owner:姜静怡

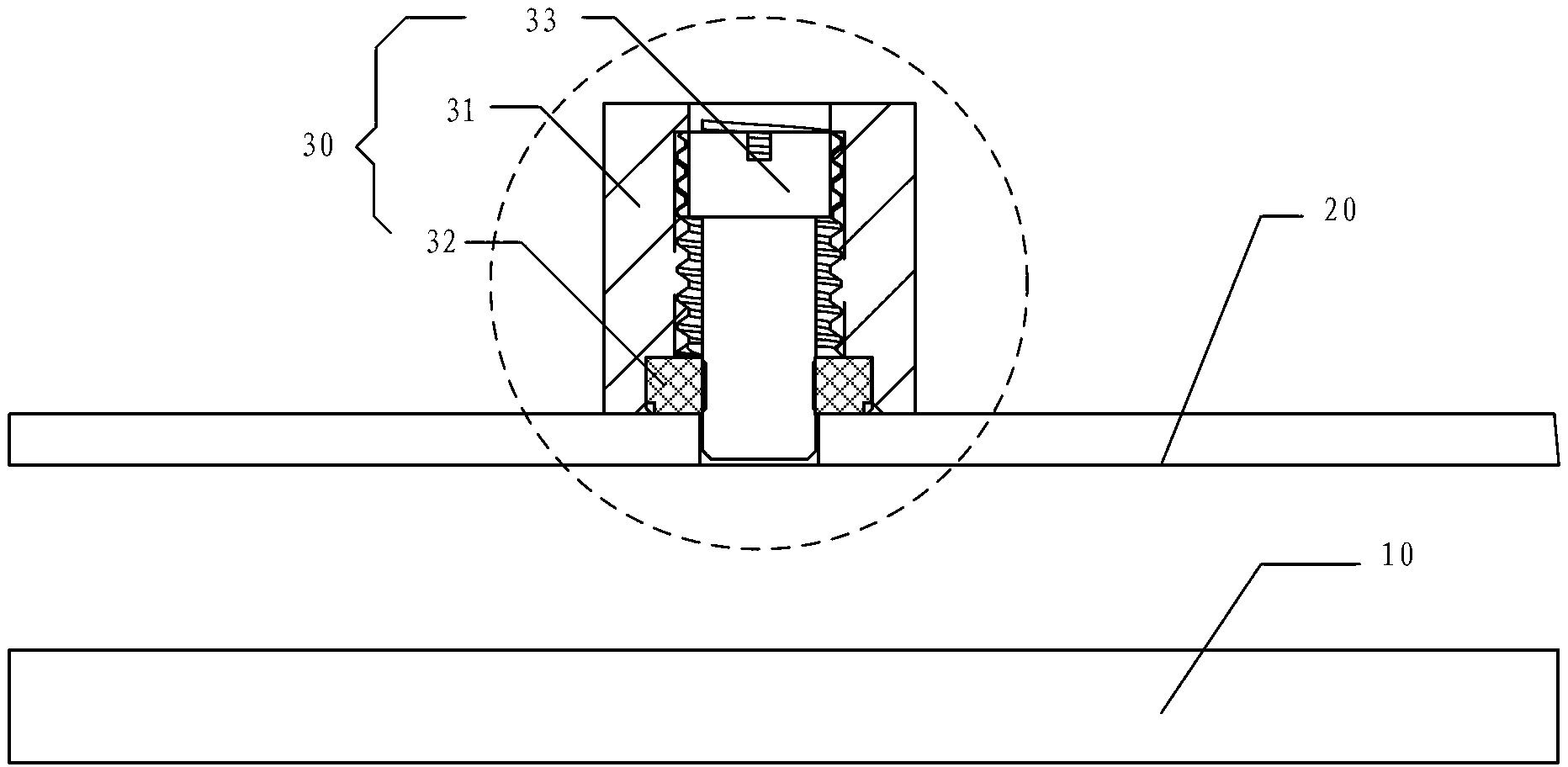

Coupling device, cavity filter and communication radio frequency equipment

ActiveCN103219573AWith limit functionShort circuit will not causeCoupling devicesInterference fitElectrical conductor

The invention discloses a coupling device, a cavity filter and communication radio frequency equipment. The coupling device comprises a signal transmission main rod and a coupling body which is used for acquiring a signal of the signal transmission main rod, wherein the coupling body is connected to a printed circuit board in parallel to the signal transmission main rod. The coupling device is characterized in that the coupling body comprises a coupling outer conductor which is connected to the printed circuit board, and a coupling inner conductor which is arranged in the coupling outer conductor, wherein one end of the coupling inner conductor is positioned in a through hole of the printed circuit board; the coupling inner conductor comprises a threaded part and is in threaded fit with the coupling outer conductor through the threaded part; an elastic fixing block is arranged between the coupling outer conductor and the coupling inner conductor; and the coupling inner conductor is in interference fit with the elastic fixing block and is fixed in the through hole of the coupling outer conductor. The coupling device can be conveniently installed, has limiting and self-locking functions, is free of short-circuit, and is high in safety.

Owner:ANHUI TATFOOK TECH CO LTD

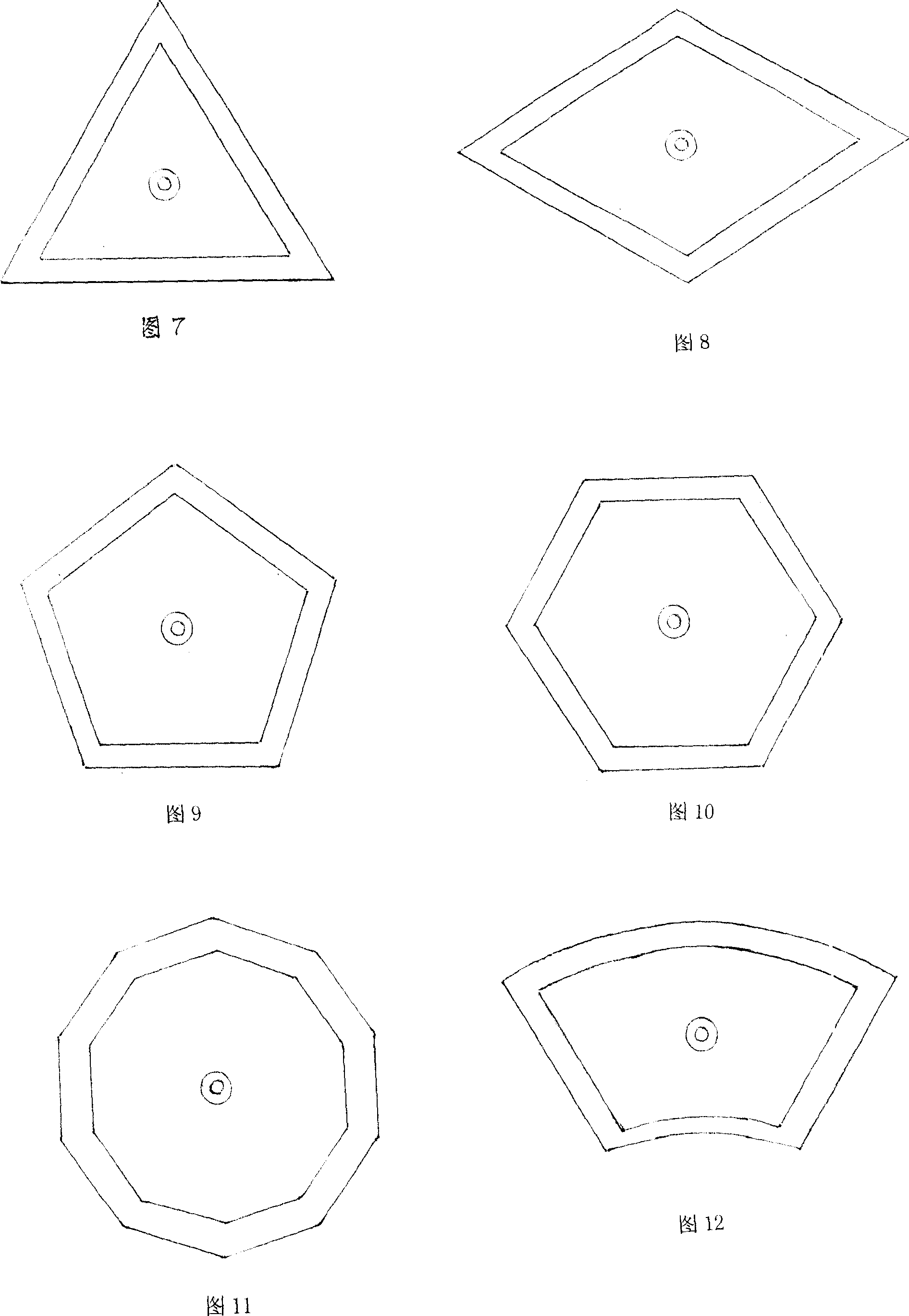

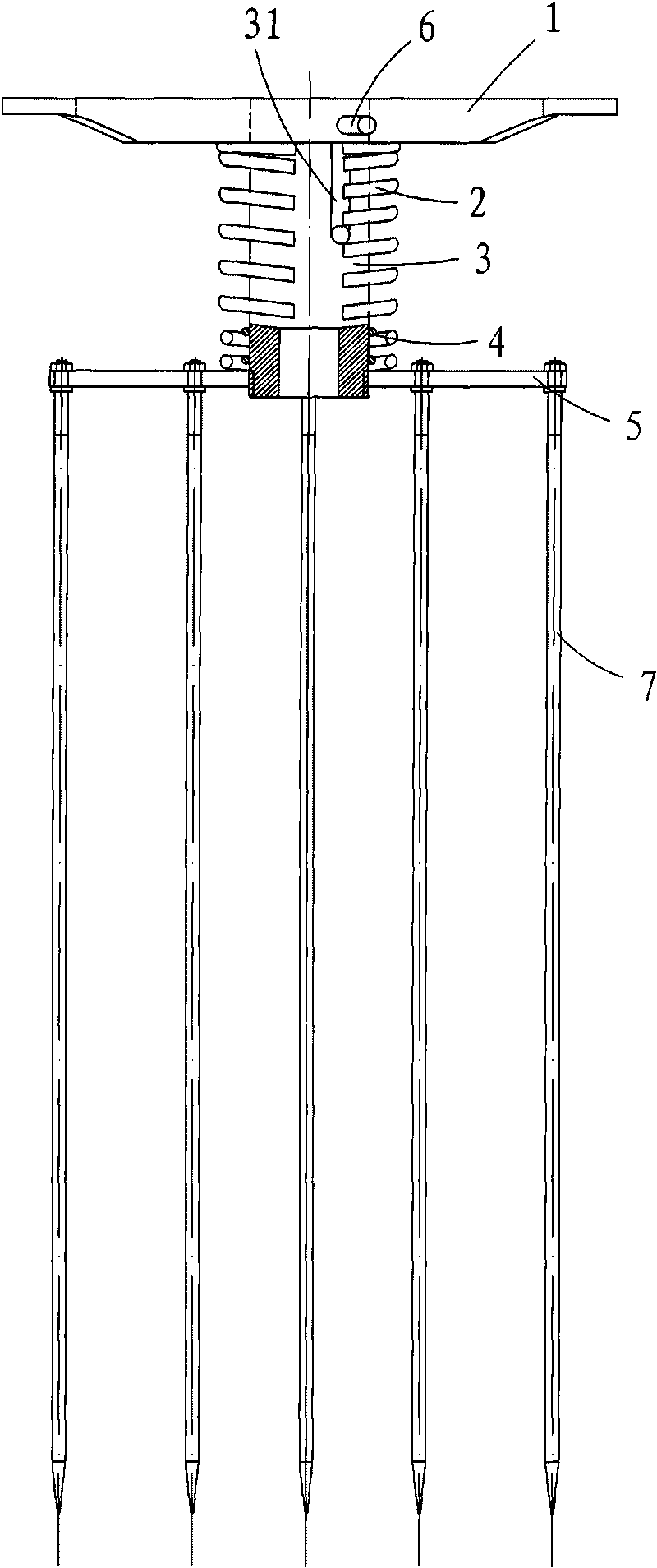

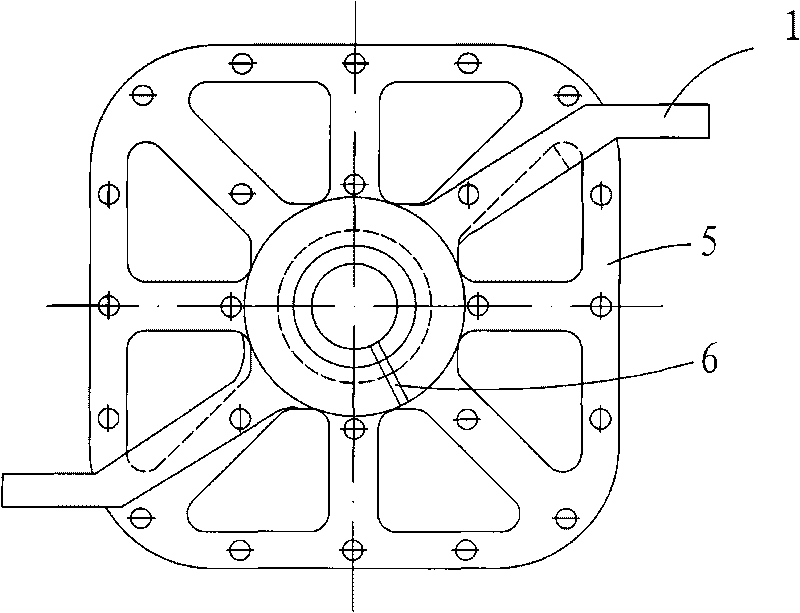

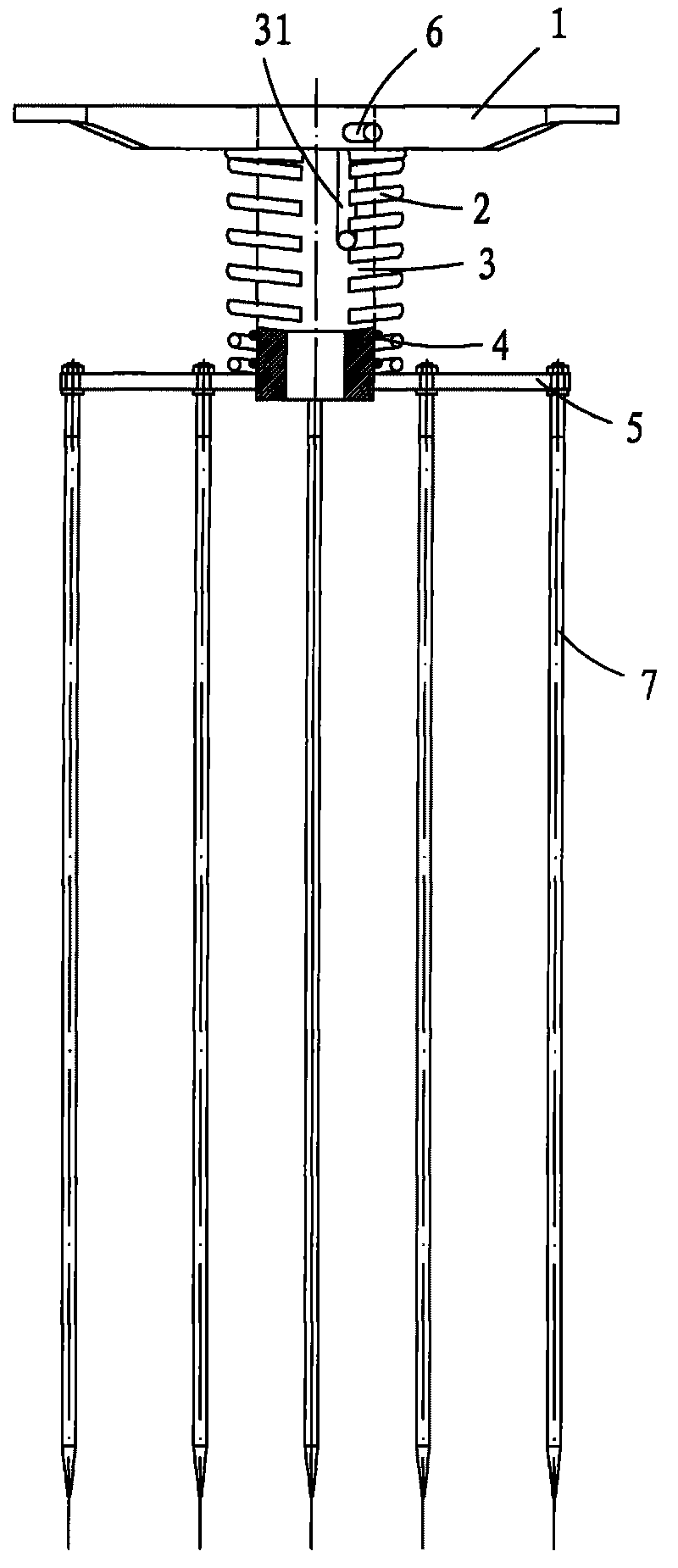

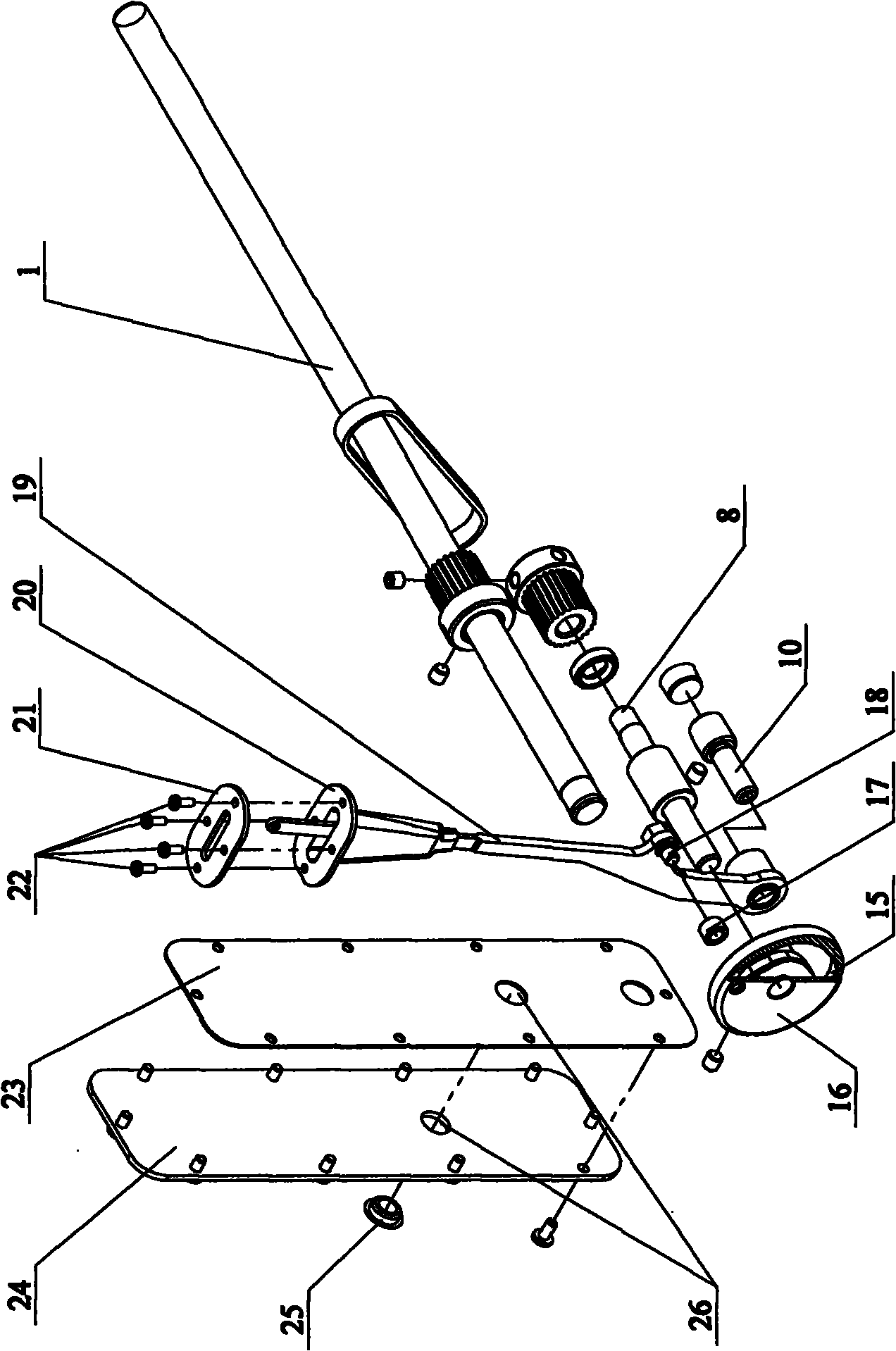

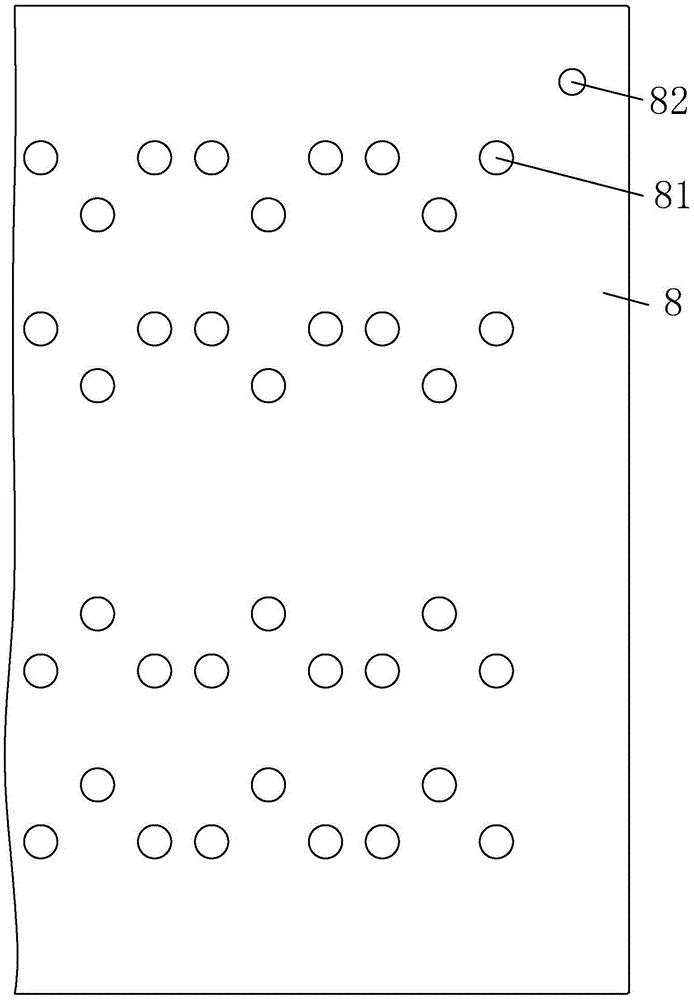

Processing method of burnable poison bar of nuclear power station and suspension frame for burnable poison bar

InactiveCN101710496AFor long-term storageReduce occupancyRadioactive decontaminationNuclear powerBorate glass

The invention provides a processing method for a burnable poison bar of a nuclear power station, which comprises the following steps: arranging the burnable poison bar on a suspension frame; then cutting and disintegrating the burnable poison bar by a cutting machine in a spent fuel canning tank; collecting and putting the cut burnable poison bar into a packing container; and finally, putting the packing container on a spent fuel grillage for storing. The suspension frame provided by the invention comprises a connecting plate and a yoke plate, wherein the connecting plate is connected with the yoke plate through a guide cylinder; and a plurality of connecting holes which can be connected with the burnable poison bar are uniformly distributed on the connecting plate. In the invention, the burnable poison bar is arranged on the suspension frame, then cut and disintegrated by the cutting machine in the spent fuel canning tank, put into the special packing container and stored in the spent fuel grillage, thus the disposition volume of the radioactive waste can be maximumly reduced, the fuel grillages occupied by the burnable poison bar can be greatly reduced, the container can be stored for a long time, and at the same time, when the burnable poison bar is cut, no crushed borate glass falls into a water tank.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

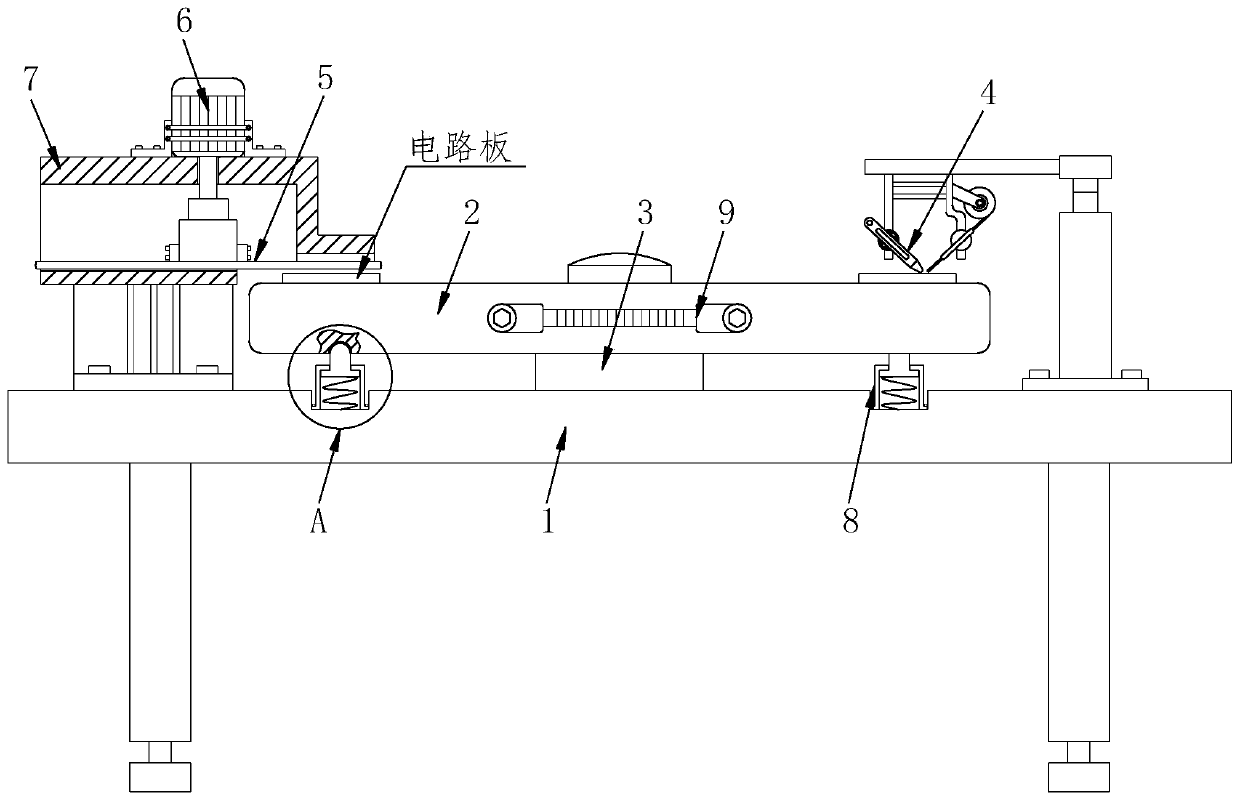

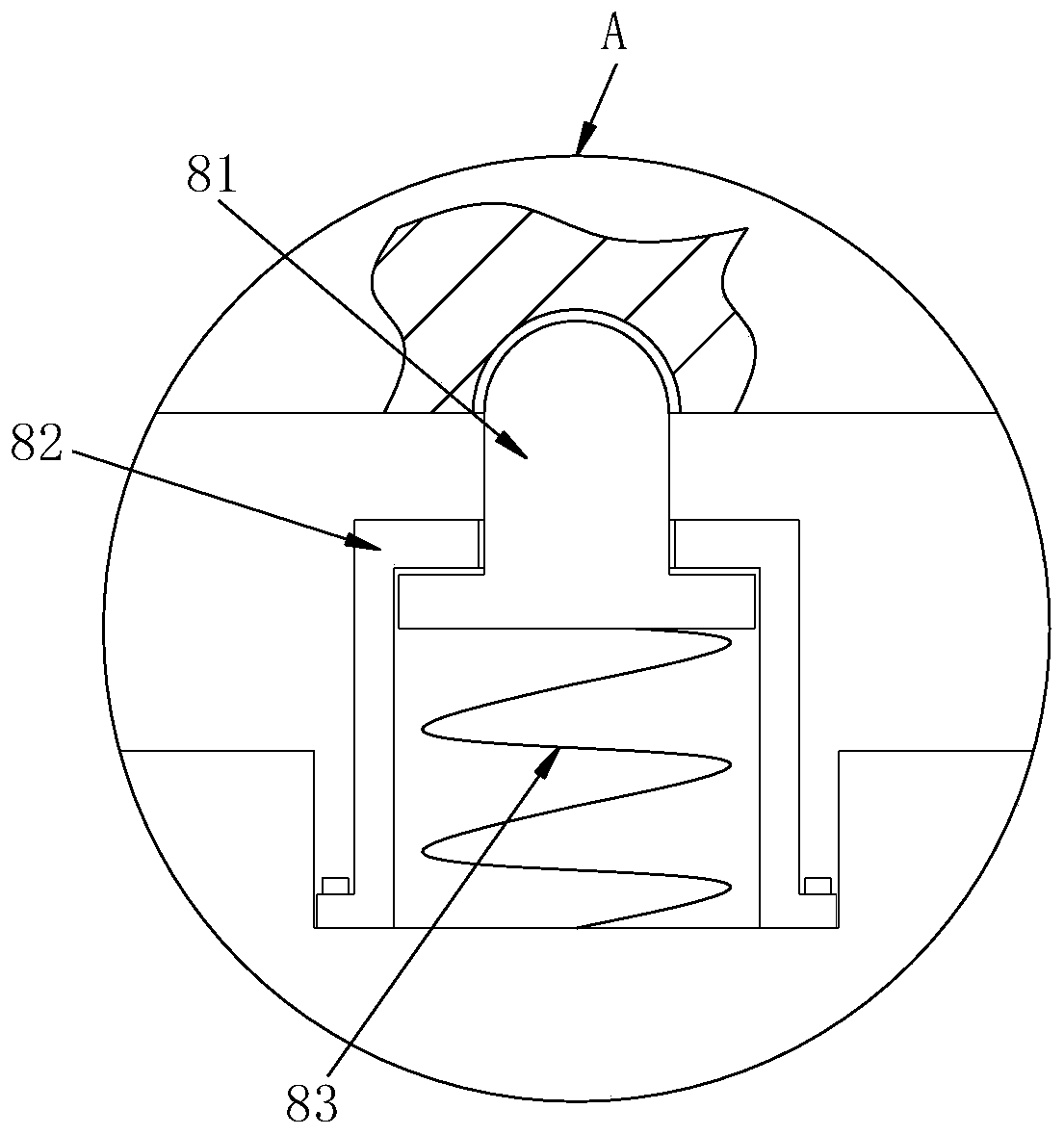

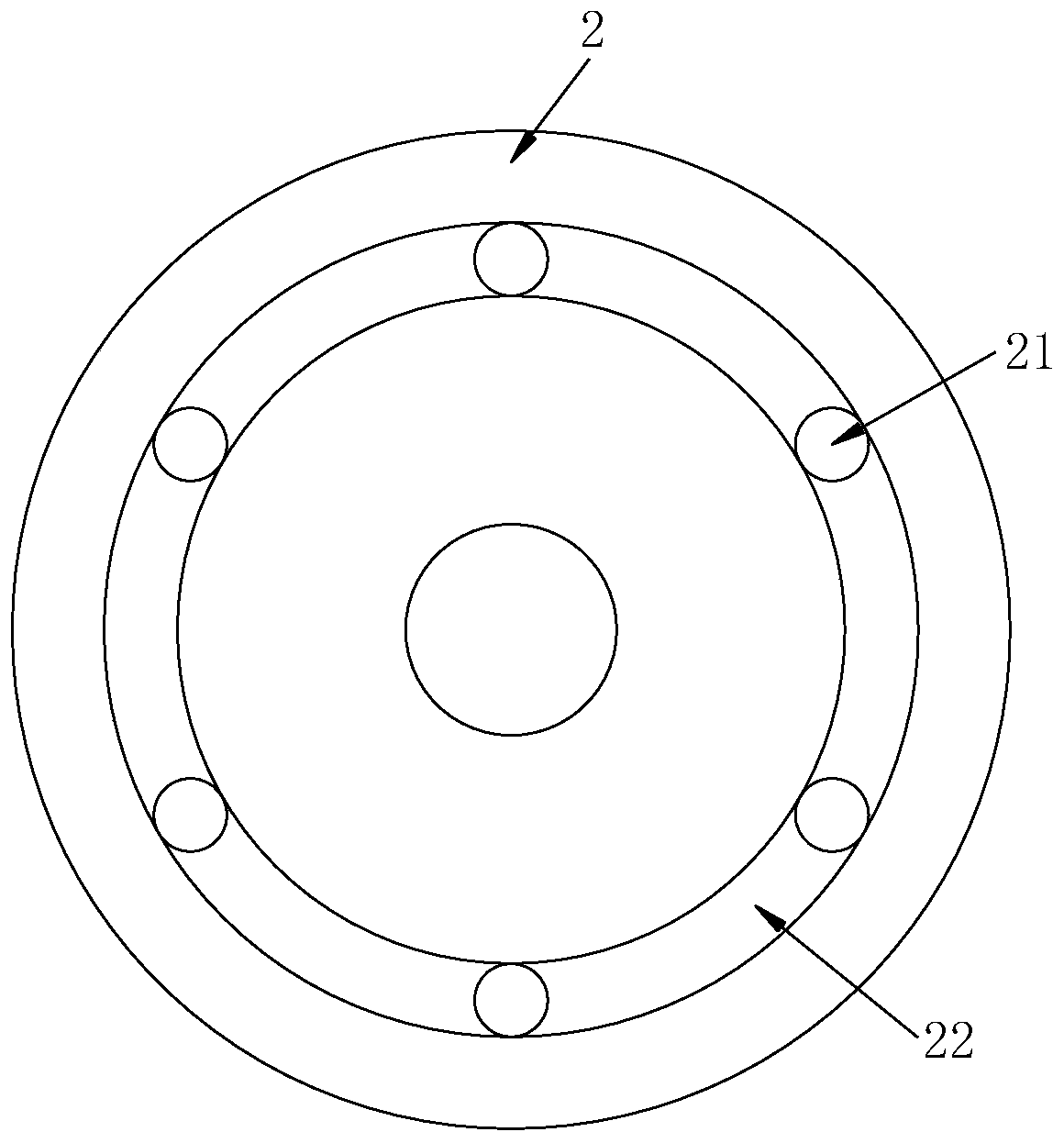

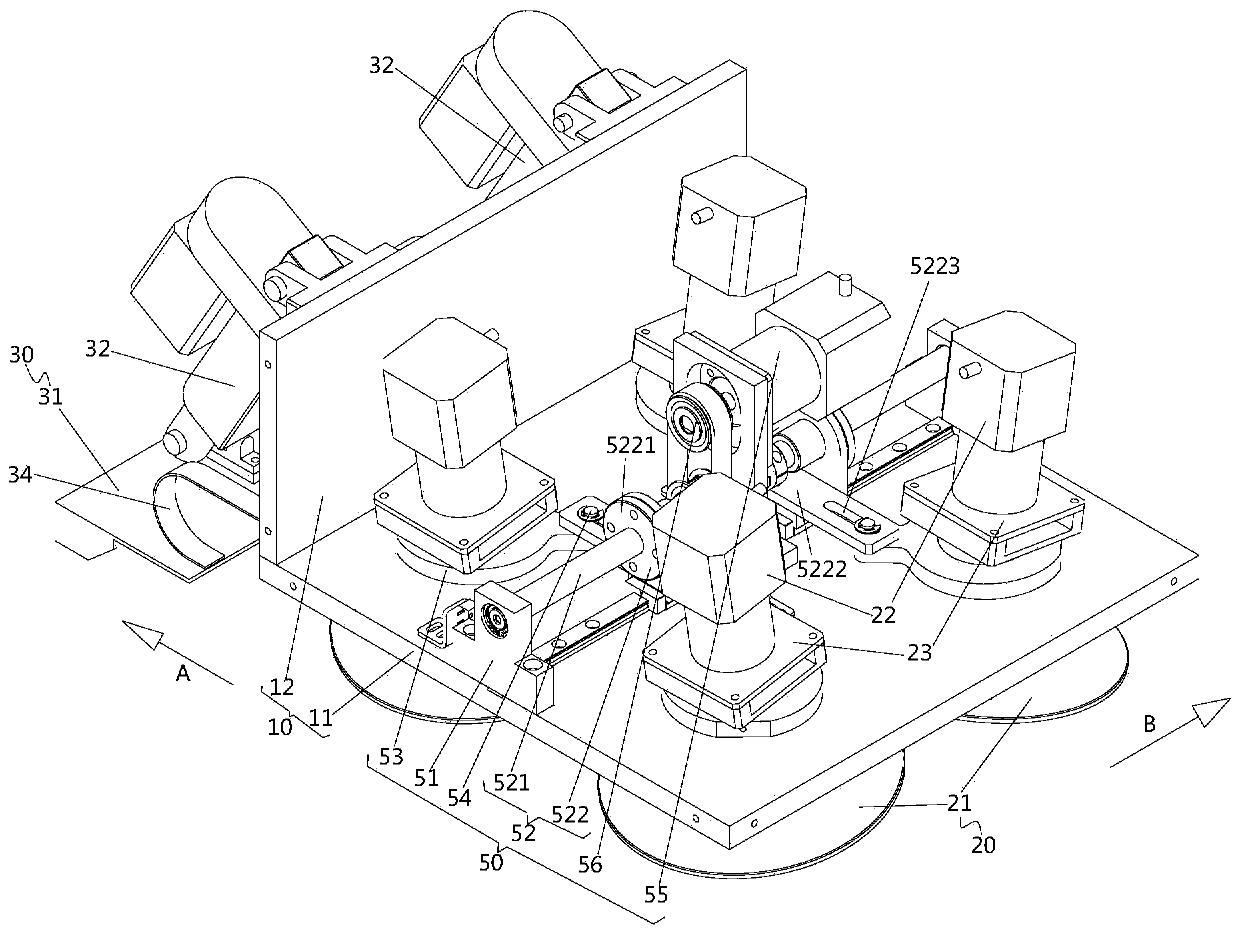

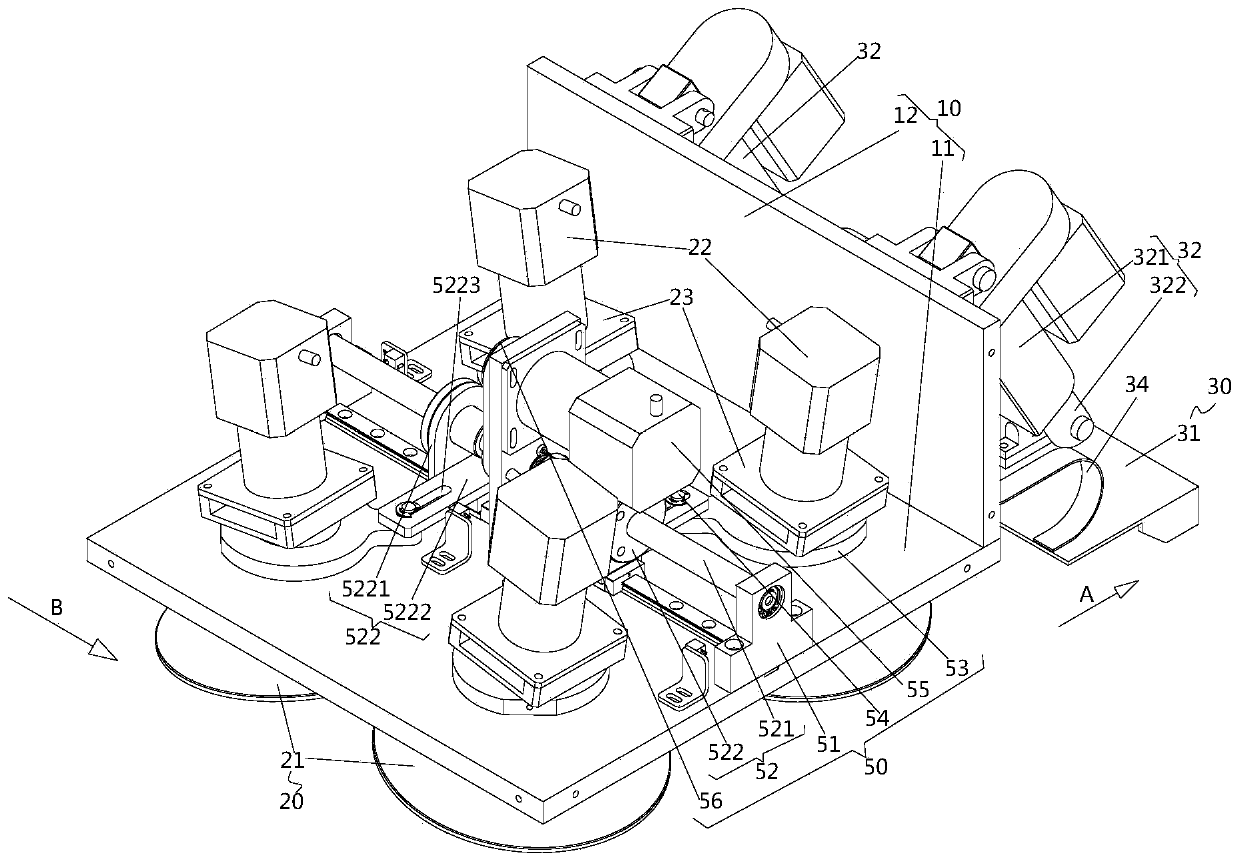

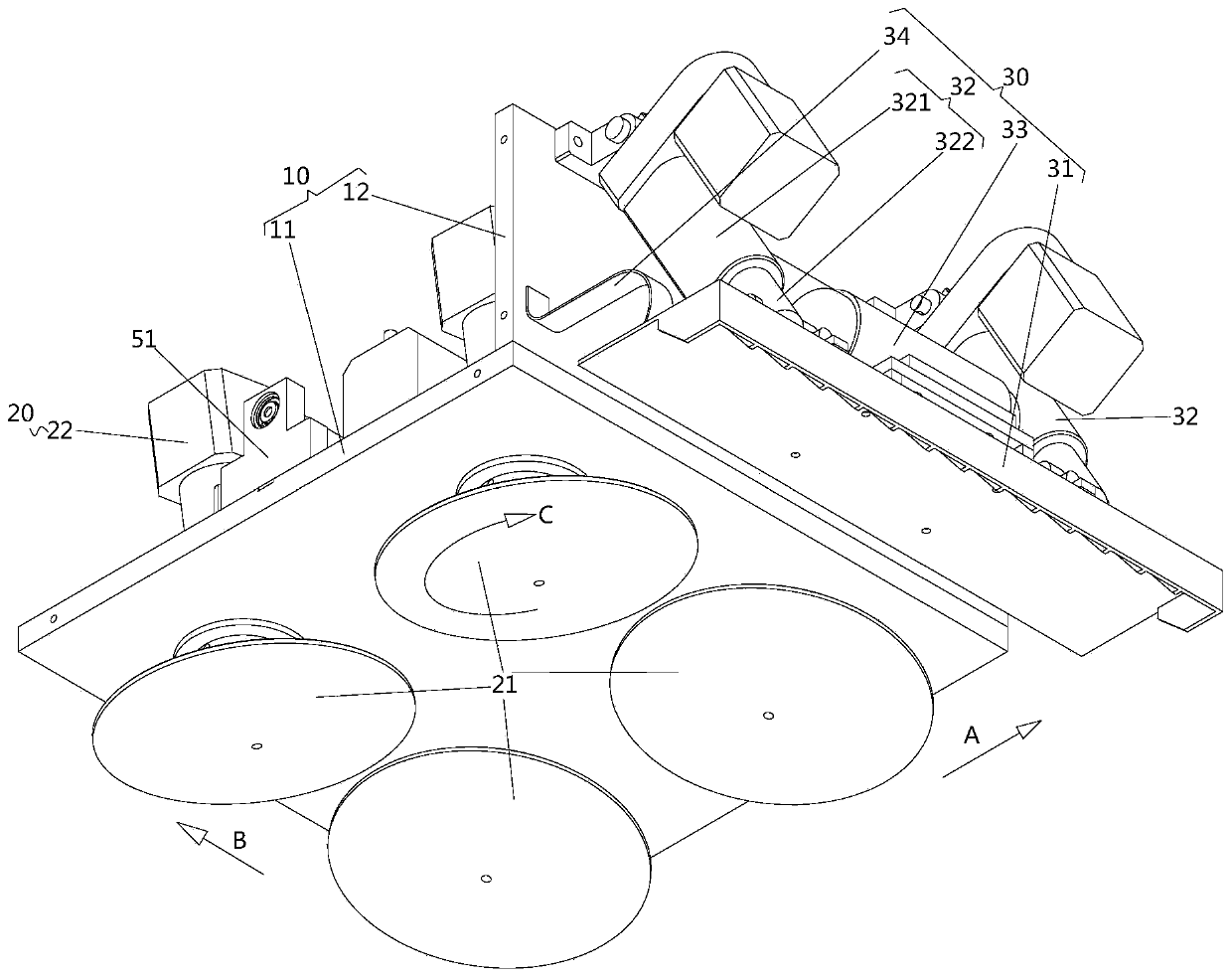

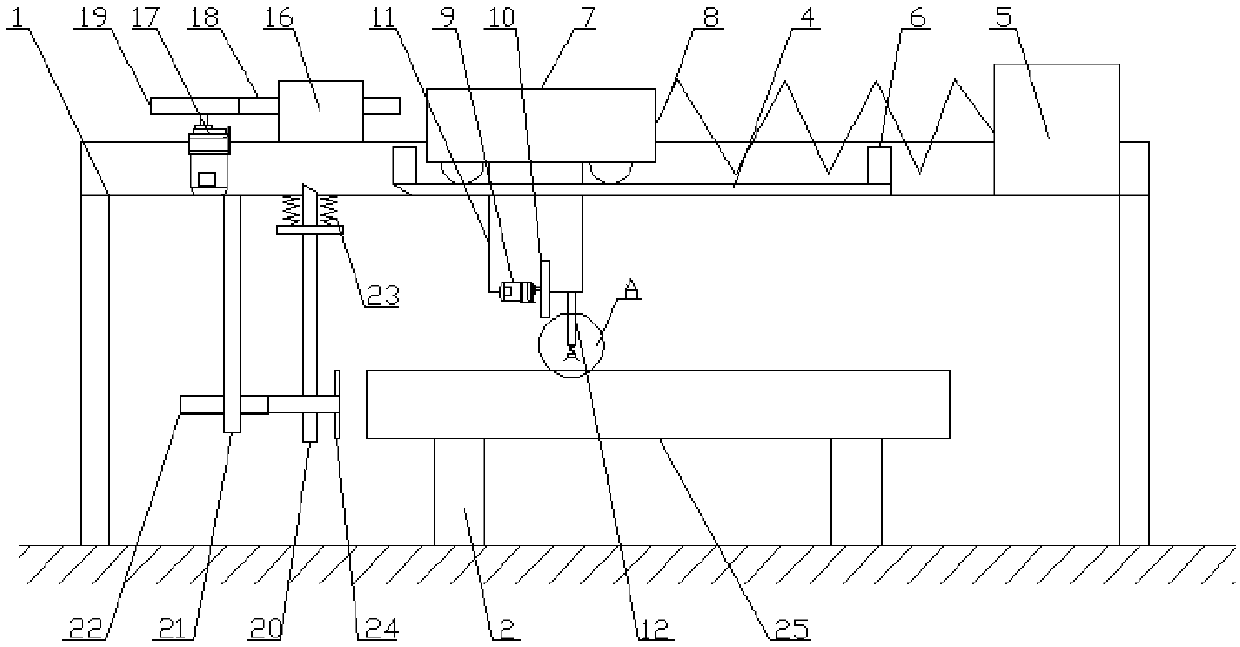

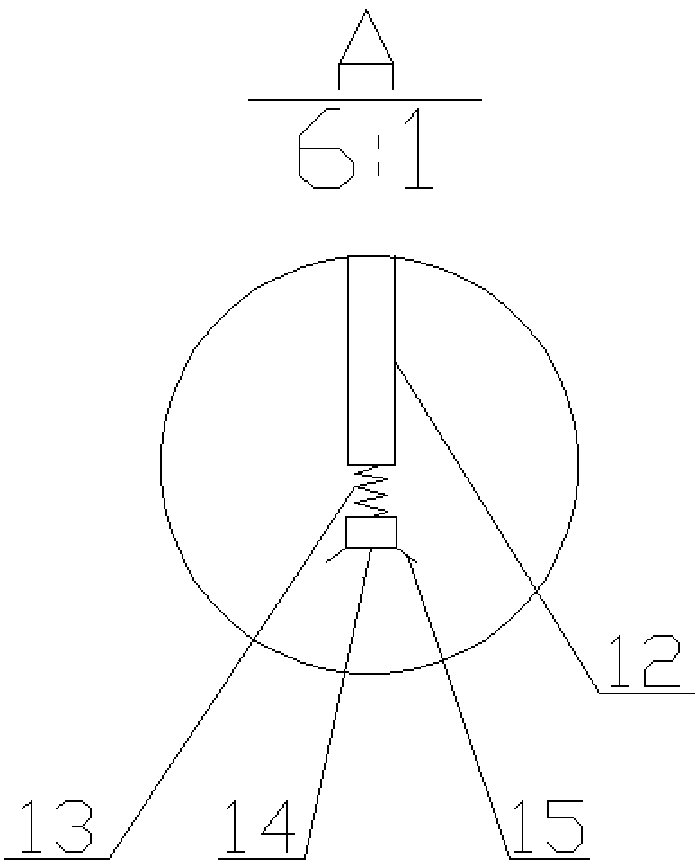

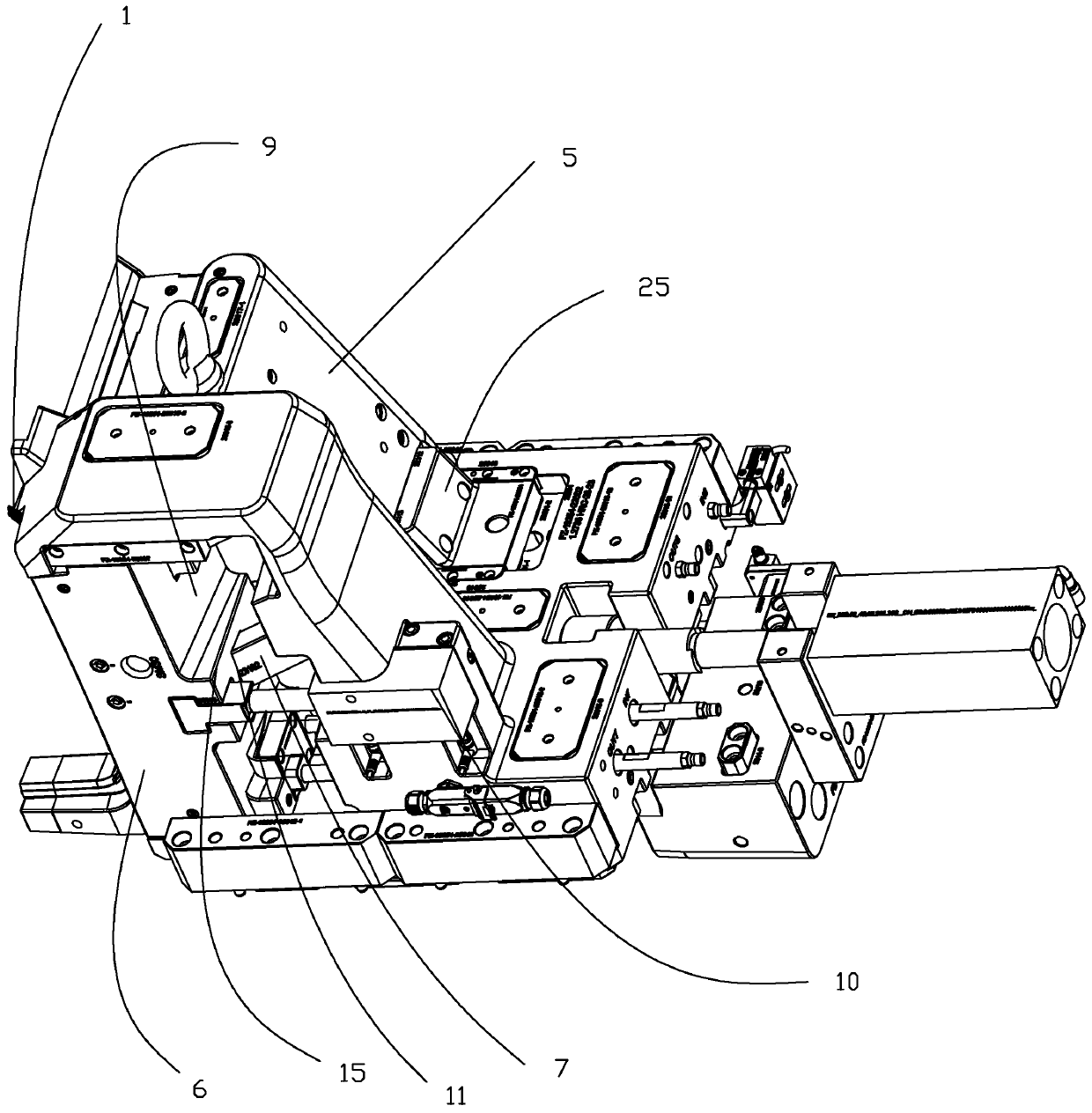

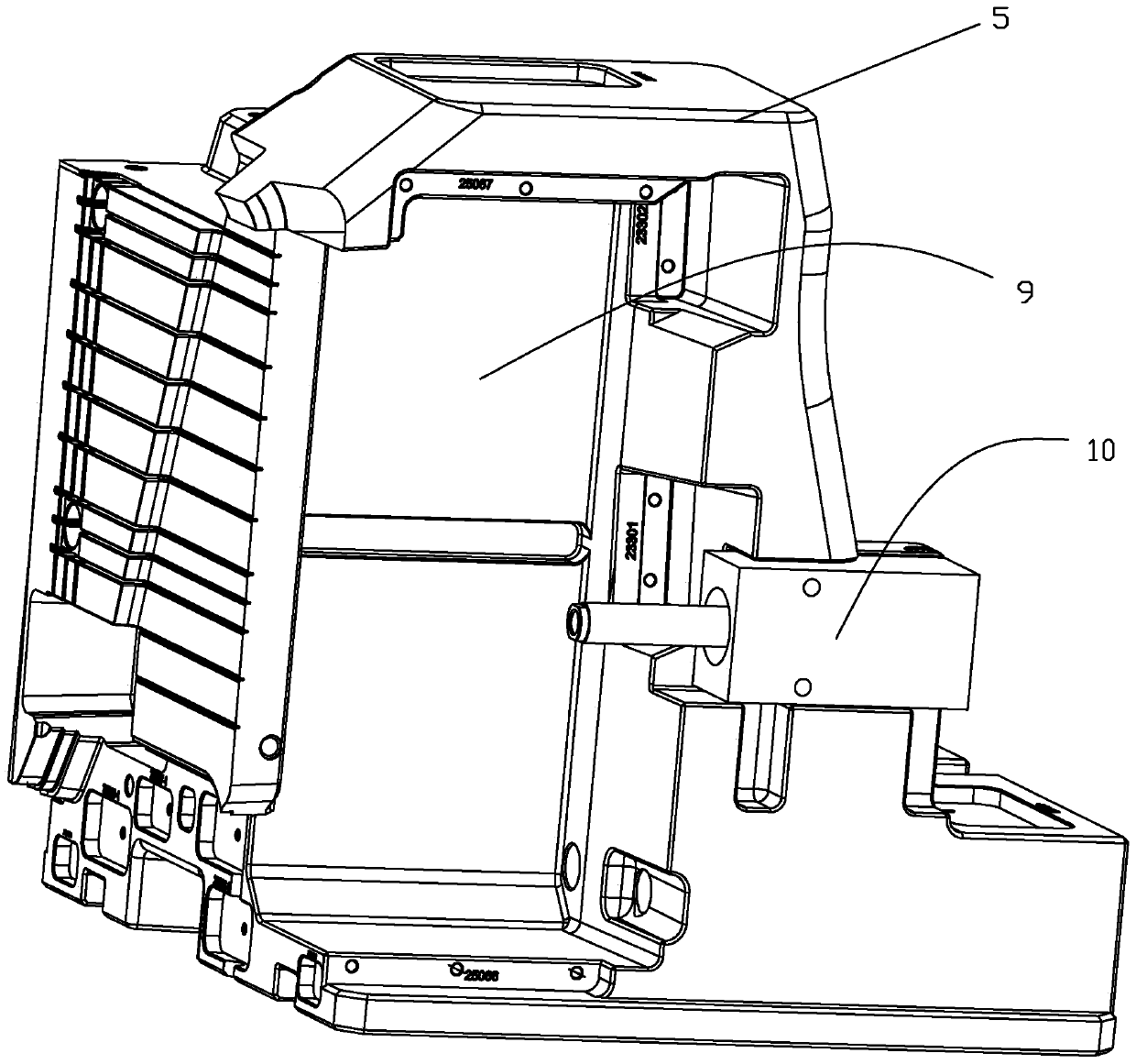

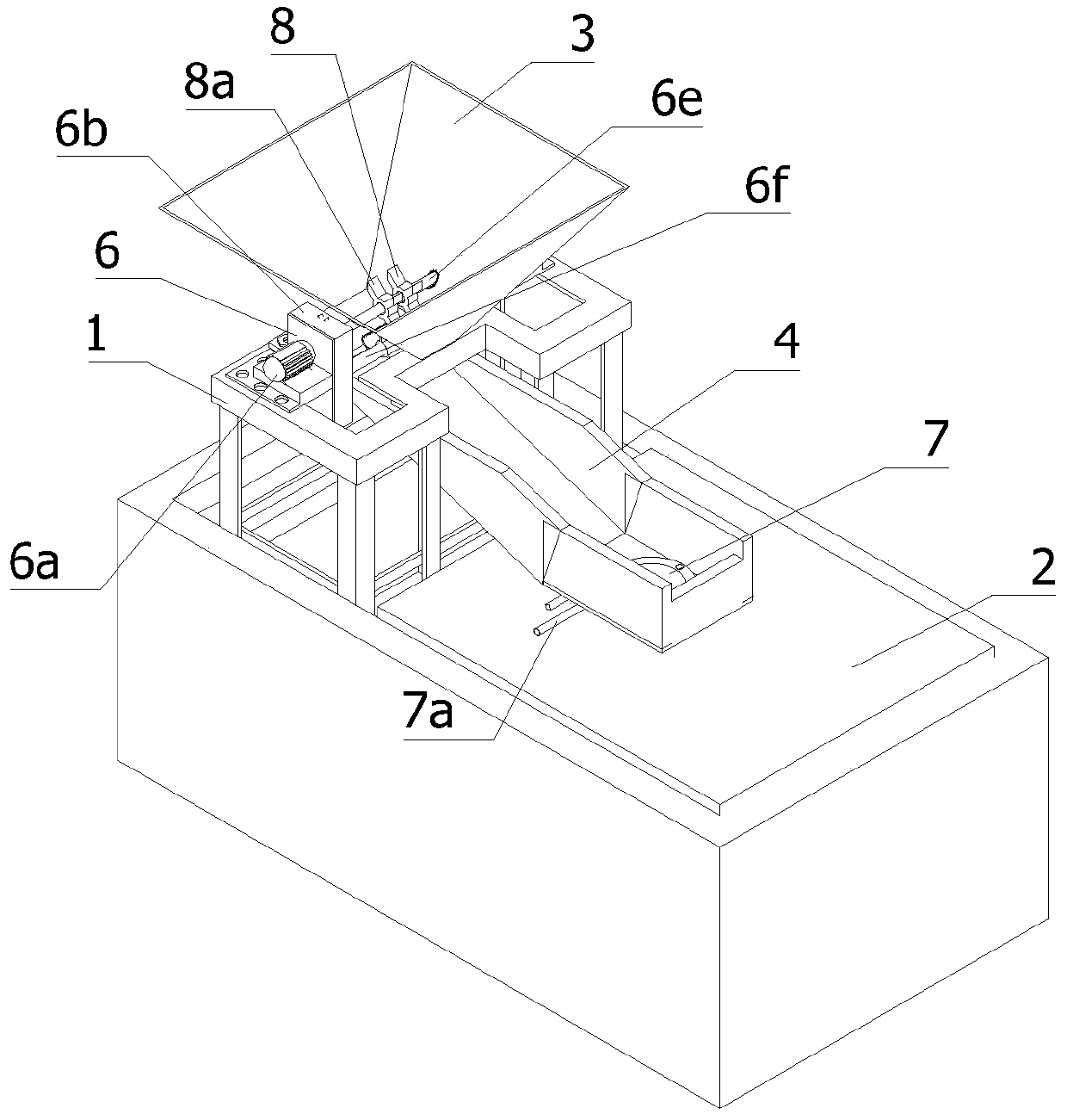

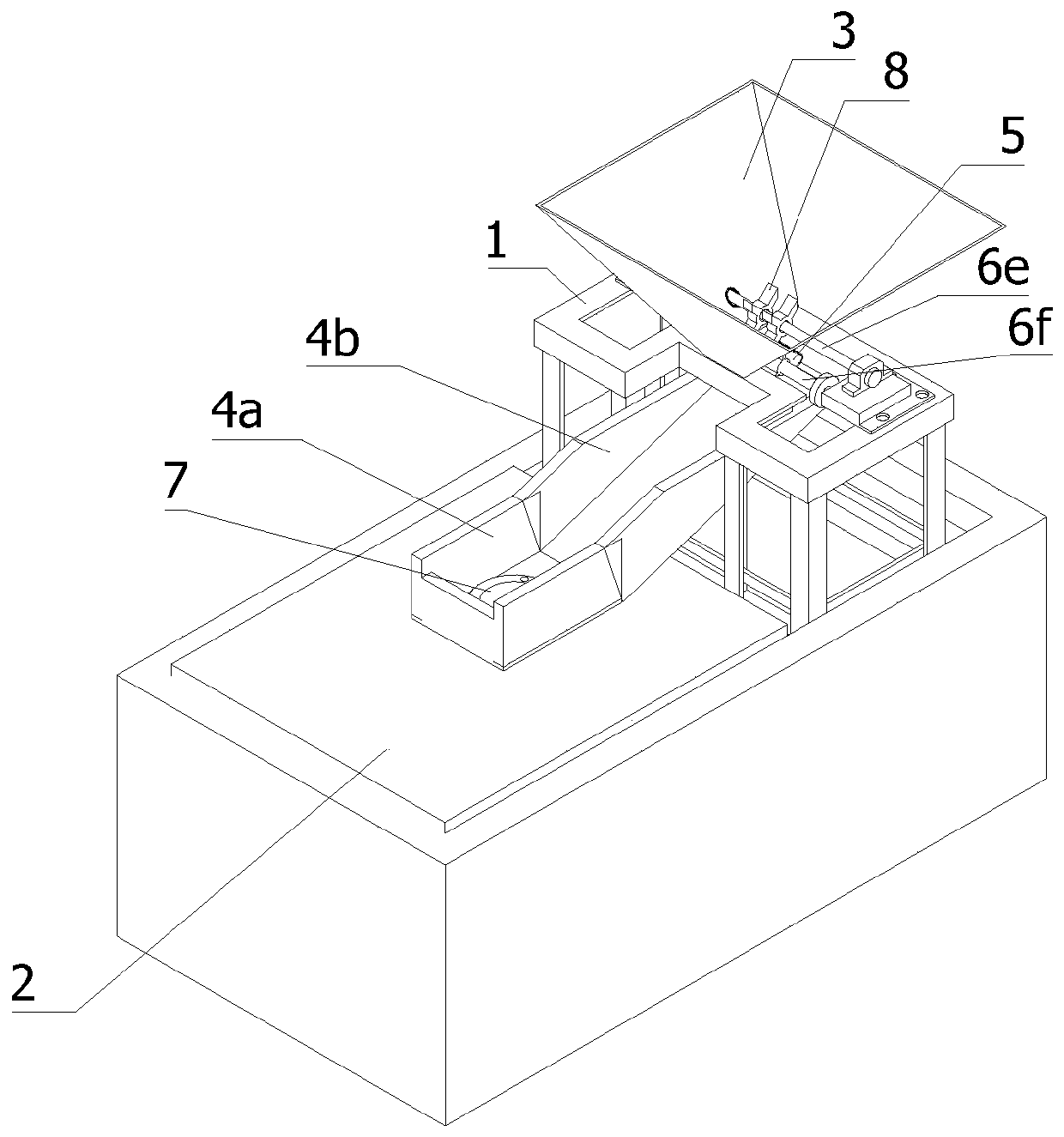

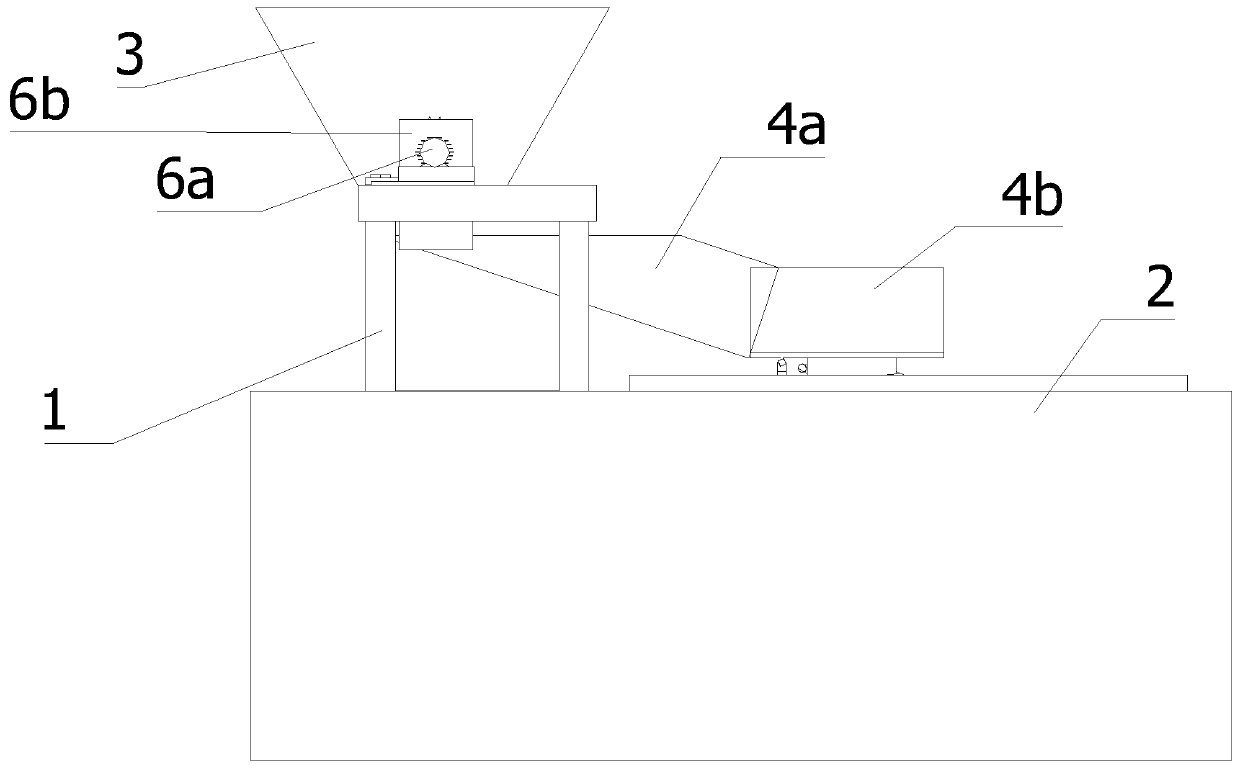

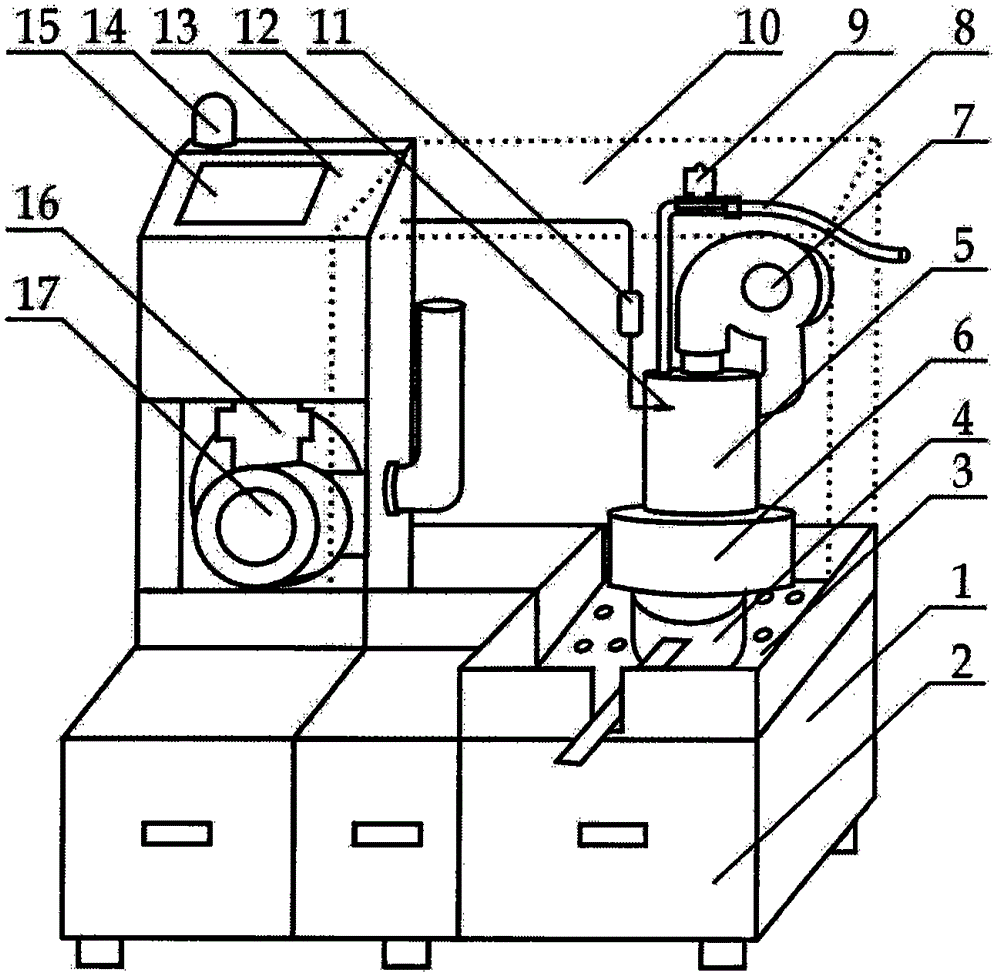

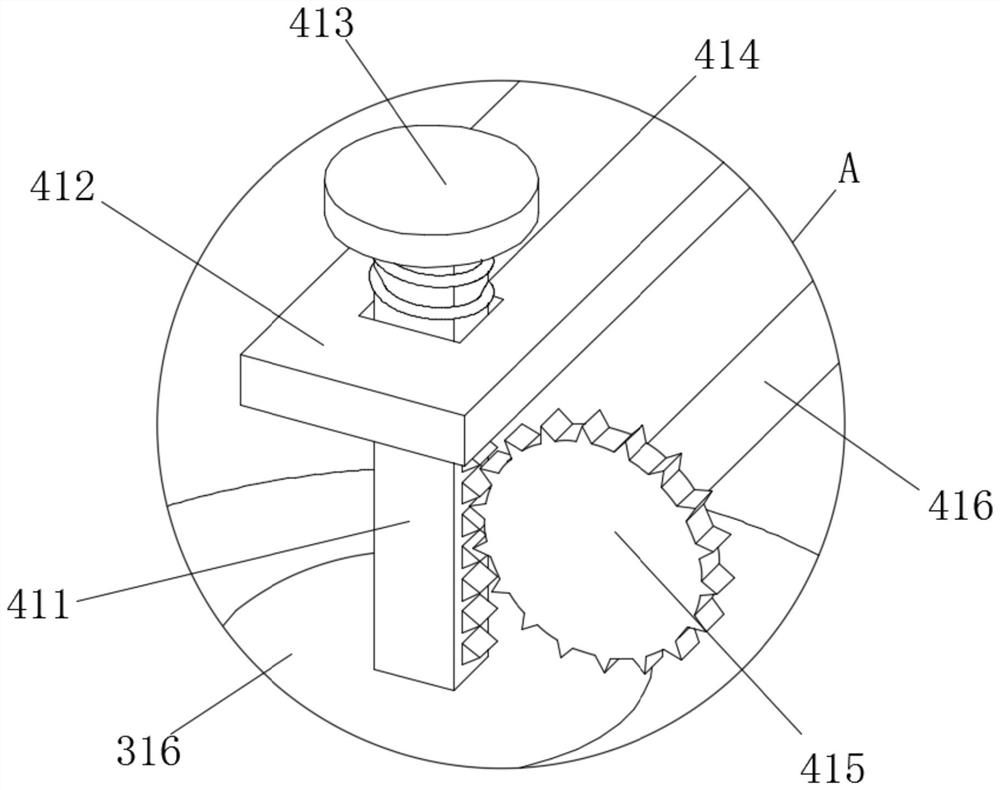

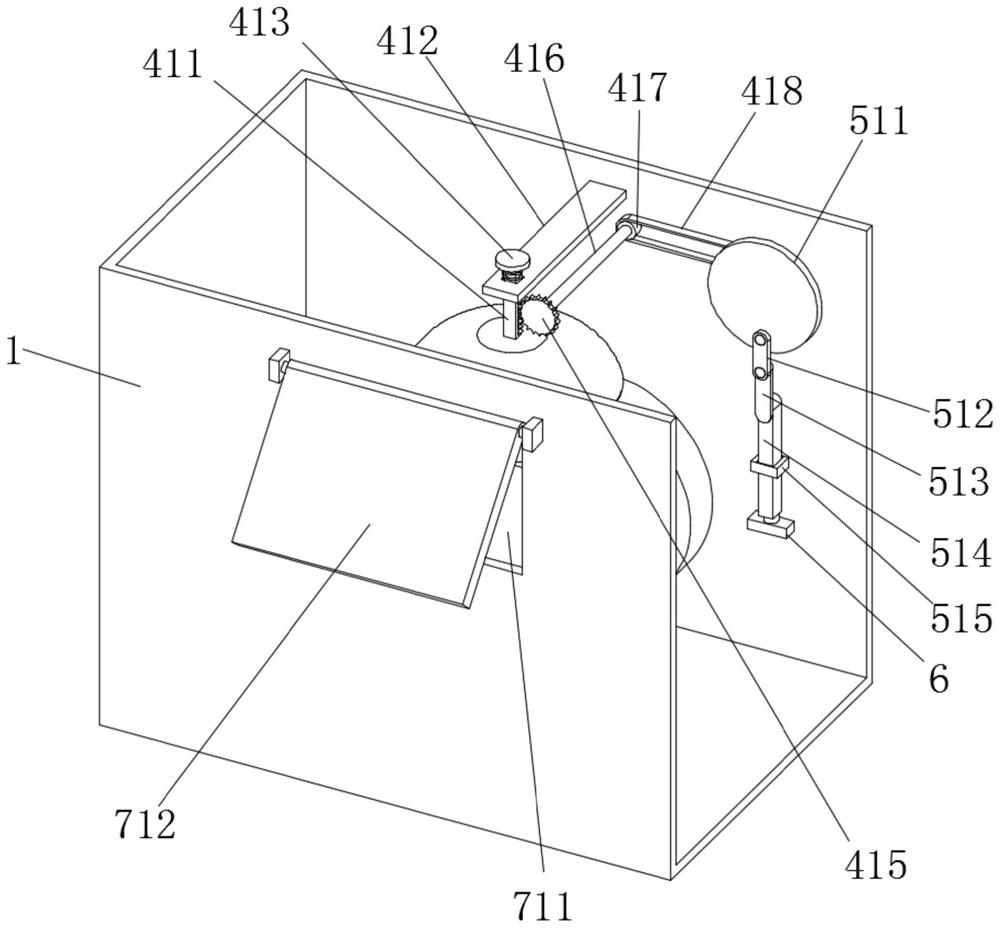

Location-welding all-in-one machine for electrical apparatus element pins of assembled circuit board

ActiveCN110899892AWon't fall intoPrevent fallingMetal working apparatusSoldering auxillary devicesElectric machineCoupling

The invention relates to a location-welding all-in-one machine for electrical apparatus element pins of an assembled circuit board. The location-welding all-in-one machine for the electrical apparatuselement pins of the assembled circuit board comprises a workbench surface, a placement rotary disc, a rotary shaft, a welding gun, a cutting assembly, a drive motor, a fixed frame, a location assembly and rotary handles, wherein the rotary shaft is installed at the central position of the top of the workbench surface; the placement rotary disc is installed at the upper end of the rotary shaft; the rotary handles are equidistantly arranged on the sidewall of the placement rotary disc; the location assembly is arranged at the top of the workbench surface and in an area on the lower end surfaceof the placement rotary disc; the welding gun is installed at one end of the placement rotary disc; the fixed frame is installed at the other end of the placement rotary disc; the drive motor is installed at the central position of the top of the fixed frame; the cutting assembly is connected to the bottom of the drive motor through a shaft coupling; and a circular rail is formed at the bottom ofthe placement rotary disc. According to the location-welding all-in-one machine for the electrical apparatus element pins of the assembled circuit board, the electrical apparatus element pins can be rapidly inserted into metal through holes; and moreover, the location-welding all-in-one machine for the electrical apparatus element pins of the assembled circuit board is appliable to different typesof circuit boards, and capable of rapidly and effectively cutting redundant pins.

Owner:东莞市硕动自动化设备有限公司

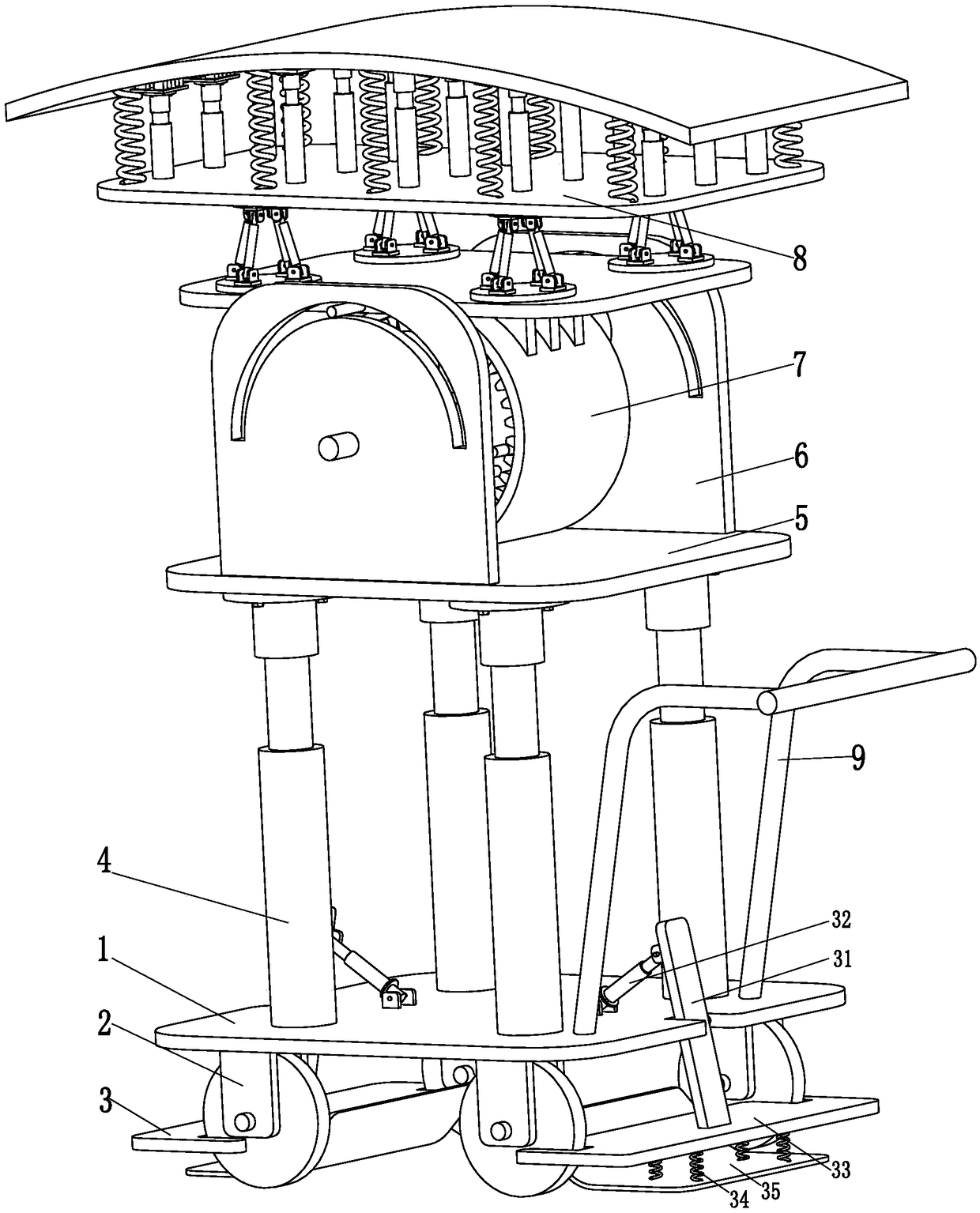

Tunnel bridge construction temporary support equipment

ActiveCN109356632ARealize the function of automatic adjustment of temporary supportEasy to operateBridge erection/assemblyMine roof supportsHydraulic cylinderArchitectural engineering

The invention relates to tunnel bridge construction temporary support equipment comprising a bottom plate. Two fixing devices capable of realizing limiting are symmetrically mounted at the front end and the rear end of the bottom plate, lifting hydraulic cylinders are symmetrically mounted at the upper end of the bottom plate, and the top ends of the lifting hydraulic cylinders are mounted on a positioning plate through flanges; two adjusting devices are symmetrically mounted at the upper end of the positioning plate, an adjusting column is mounted between the two adjusting devices, and a supporting device is mounted at the upper end of the adjusting column; and a technology for tunnel bridge temporary support is completed through mutual cooperation of the fixing devices, the adjusting devices, the adjusting column and the supporting device. According to the tunnel bridge construction temporary support equipment, the difficult problems that in the existing tunnel bridge construction temporary support building process, materials such as concrete and steel frames need to be manually processed into temporary supports, the consumed time is long, the project progress is affected, the corresponding temporary supports need to be constructed according to construction faces of different structures, the labor intensity is high, operation is complex, sources are wasted, and the working efficiency is low can be solved, and the function of automatically adjusting the temporary supports can be achieved.

Owner:江苏锡沂钢模有限公司

Device for recycling waste cables

ActiveCN111145965AFacilitate strippingQuick peelBasic electric elementsElectronic waste recyclingInsulation layerProcess engineering

The invention discloses a device for recycling waste cables. The device comprises a housing, and a delivery cavity with an opening in the left side is formed in the upper left portion of the shell. Adelivery mechanism for delivering a cable rightwards is arranged in the delivery cavity; the right side of the delivery cavity is provided with a heating pipe used for heating and softening a cable insulation layer. A heating cavity which is through left and right is formed in the heating pipe; the right side of the heating cavity is communicated with a peeling cavity; a scraper for stripping theinsulating layer is arranged in the peeling cavity. According to the invention, a cable is clamped and conveyed through the concave wheels on the upper side and the lower side; meanwhile, the cable insulation layer is heated and softened through a heating device, so that a scraper can perform stripping conveniently, separates metal and nonmetal, and performs an extrusion operation on the nonmetal;the metal is cut into particles through a cutting knife, and then magnetic metal and non-magnetic metal are separately recycled through a sorting mechanism.

Owner:绍兴阔源机械科技有限公司

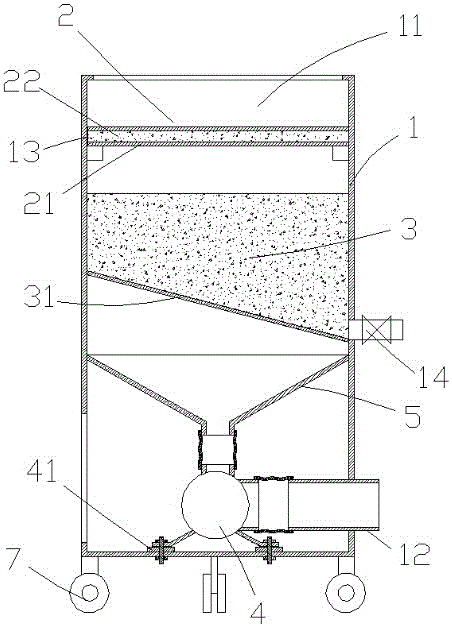

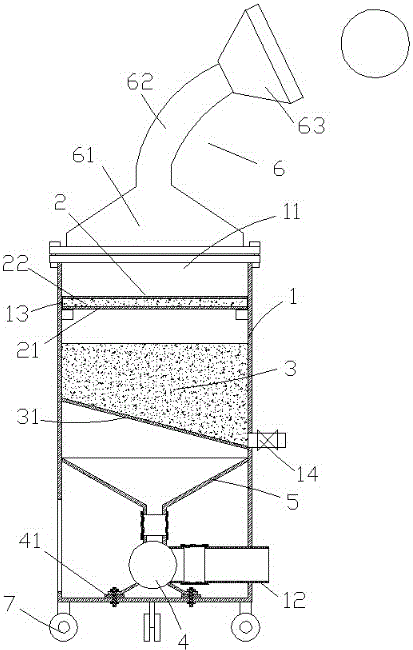

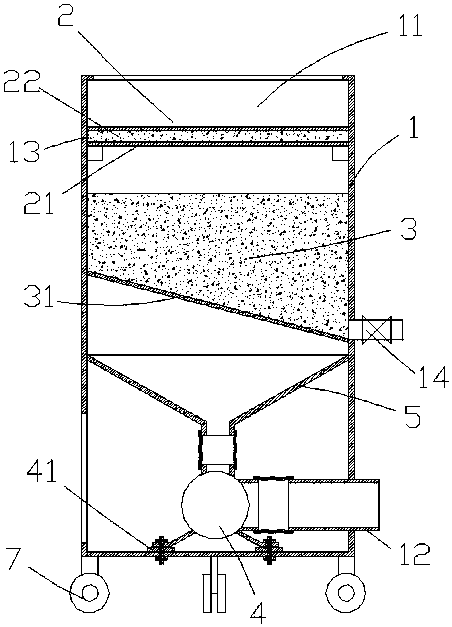

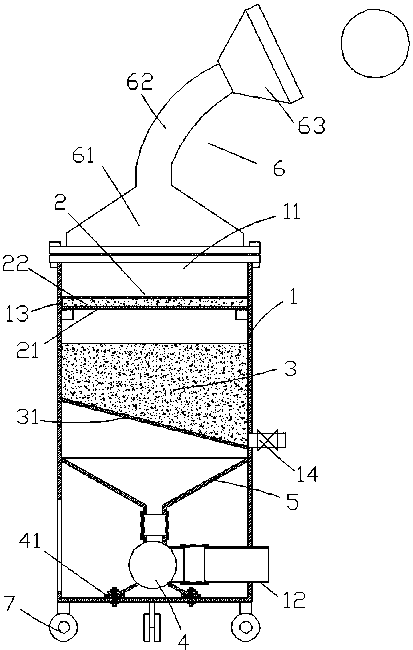

Vertical integrated activated carbon adsorption device

ActiveCN105797533AEasy to operateAvoid cloggingGas treatmentDispersed particle filtrationActivated carbonSmall footprint

The invention discloses a vertical integrated activated carbon adsorption device and belongs to the field of waste gas adsorption and purification in environmental protection.A dust removal filter net, an activated carbon adsorption layer and a fan are sequentially arranged in a device shell from top to bottom.A net plate is arranged at the bottom of the activated carbon adsorption layer in an inclination mode.A layer of fine anti-leakage net is arranged on the net plate.The mesh diameter of the fine anti-leakage net is smaller than the diameter of activated carbon particles in the activated carbon adsorption layer.The net plate is fixed in the device shell.A carbon outlet is formed in the lower end of the net plate and located in the device shell.When the carbon outlet is opened, the activated carbon particles in the activated carbon adsorption layer can be discharged out of the carbon outlet along the inclined net plate.Gas enters the device from top and exhausted from the bottom.The device has the advantages of being simple in structure, easy to machine and manufacture, small in occupied area, convenient to install and maintain, high in adsorption efficiency and the like, and is applicable to waste gas purification treatment engineering in airtight spaces for medicine, health care product production and the like.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

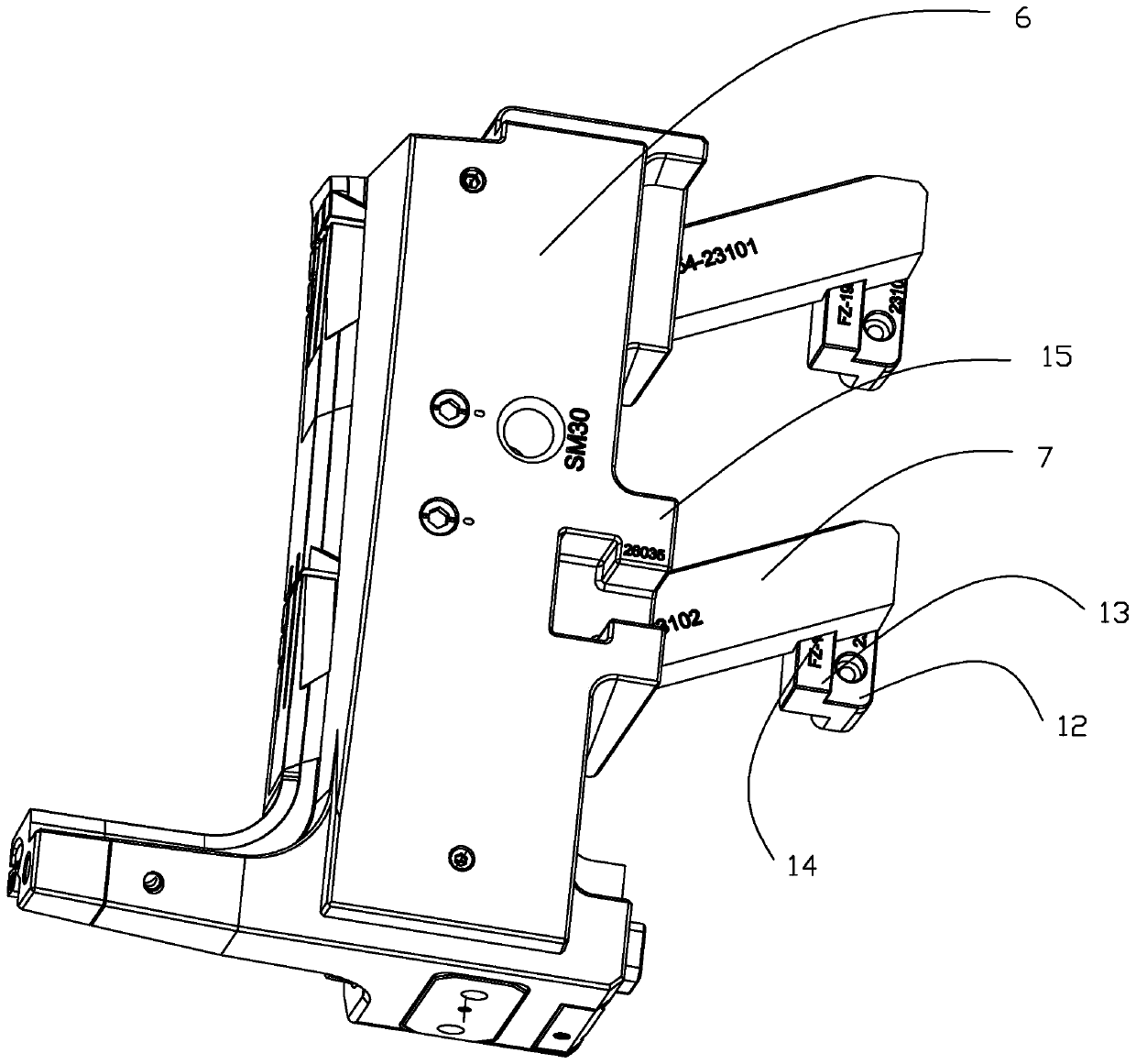

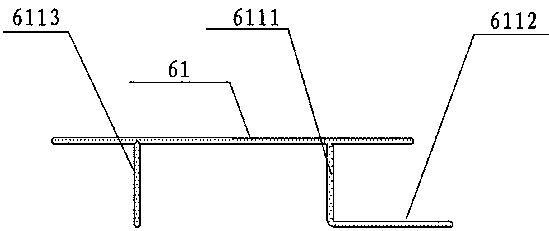

Seat face sleeve and carpet cloth installing and fixing device

The invention discloses a seat face sleeve and carpet cloth installing and fixing device. The seat face sleeve and carpet cloth installing and fixing device is provided with a framework attached to an automobile body and a seat. The framework is provided with grooves, and a buckle is arranged on one side of each groove. The device is provided with multiple first section bars connected with a seat face sleeve, reverse buckles are arranged on the two sides of the lower end of each first section bar, and the reverse buckle on one side of the lower end of each first section bar can be matched with the corresponding buckle. The device is provided with multiple second section bars connected with carpet cloth, and the lower ends of the second section bars are provided with barbs capable of being matched with the reverse buckles on the other sides of the lower ends of the first section bars. The seat face sleeve and carpet cloth installing and fixing device has the beneficial effects that the structure is simple, cost is low, assembly is easy and quick, the seat face sleeve and the carpet cloth can achieve a tight covering effect, and the device is unlikely to be damaged, economical, durable and convenient to detach and wash. The device is particularly suitable for installing and fixing the seat face sleeve and the carpet cloth of a saloon car and other high-grade automobiles.

Owner:MAGNA SEATING (TAIZHOU) CO LTD

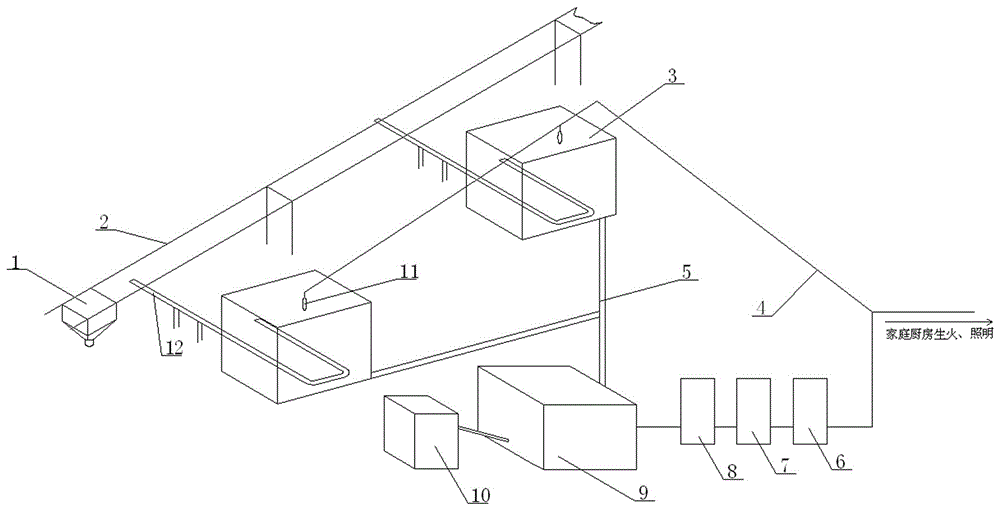

A goat house and goat breeding system

InactiveCN105941166AStay wildImprove meat qualityAnimal feeding devicesAnimal housingDiseaseEngineering

The invention provides a goat house and goat breeding system. The system comprises goat houses, a methane-generating pit and a feed delivery cable car. The feed delivery cable car delivers feed to each goat house via a track; goat excrement generated in the goat houses is conveyed to the methane-generating pit via pipelines; the methane-generating pit generates methane from the excrement through fermentation; the methane can be used for heating or lighting. According to the invention, large-scale culture of goats is realized; automatic feed delivery and feeding is realized, so that manpower and production costs are greatly saved; ecological breeding is realized, and goats are close to nature, so that the wild nature of the goats can be maintained; diseases and pests relating to goats can be prevented and controlled; the yield of goat meat is high; the meat is fresh and tender, and nutrients in the meat are of high value.

Owner:广西横县隆泉山羊养殖专业合作社

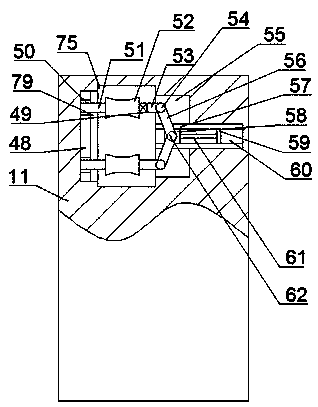

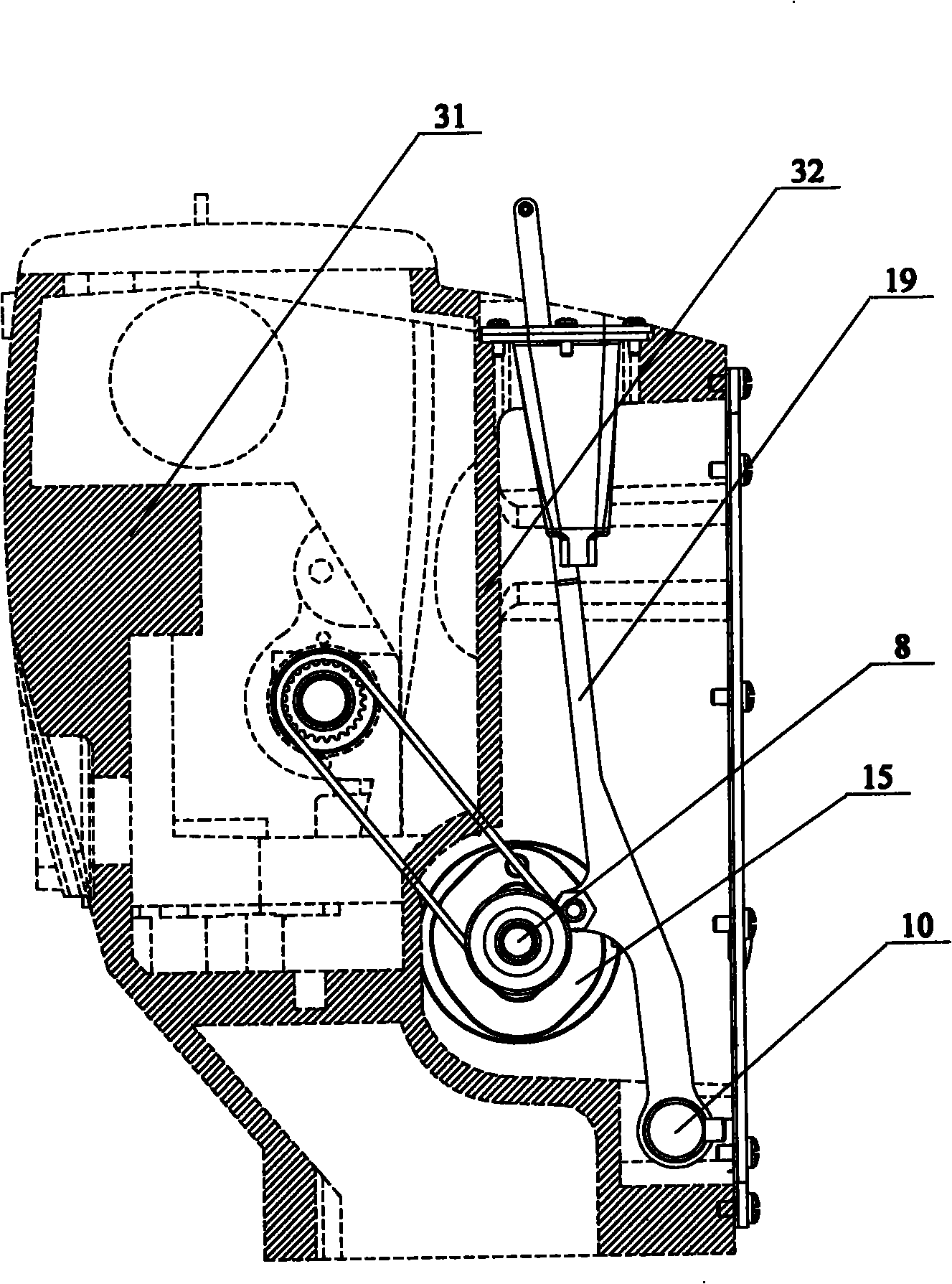

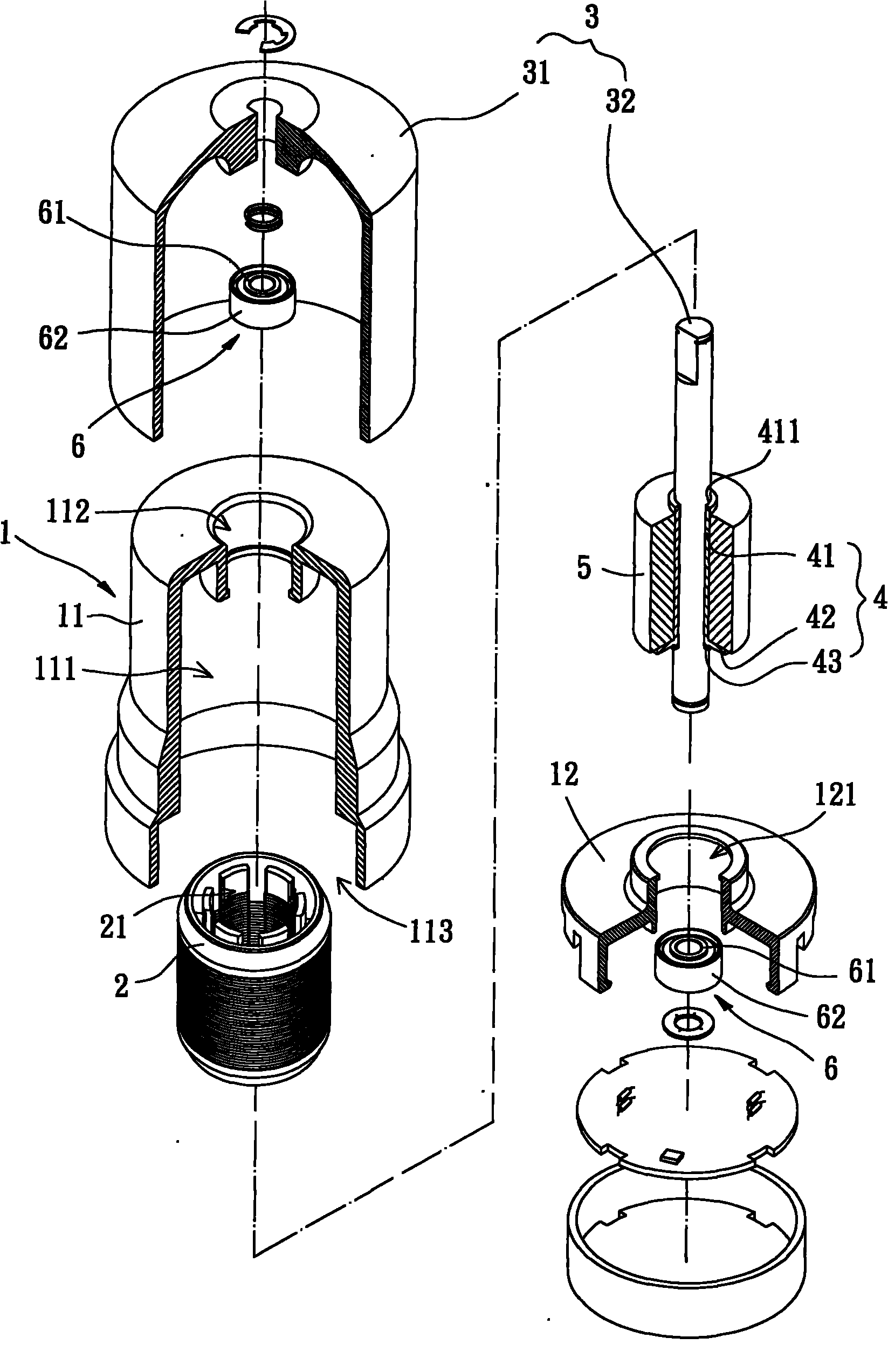

Sewing machine and omni-sealed thread-taking-up mechanism thereof

ActiveCN102182019AReduce noiseReduce wearLubrication/cooling devicesTake-up devicesDrive shaftAeroshell

The invention discloses a sewing machine and an omni-sealed thread-taking-up mechanism thereof. The omni-sealed thread-taking-up mechanism comprises an omni-sealed transmission box, a passive transmission shaft and a thread-taking-up bar which are arranged in a housing of the sewing machine, wherein the passive transmission shaft penetrates in the right side wall of the transmission box; a cam isfixedly arranged at the left end of the passive transmission shaft; a cam slot is arranged on the left end surface of the cam; the lower end of the thread-taking-up bar is hinged on the right side wall of the transmission box; the upper end of the thread-taking-up bar is provided with a threading hole and penetrates out of the upper wall of the transmission box and the upper wall of the housing; the middle part of the thread-taking-up bar is provided with a pin roller; and the pin roller is placed in the cam slot and drives the upper end of the thread-taking-up bar to swing forwards and backwards along with the rotation of the cam. In the omni-sealed thread-taking-up mechanism of the sewing machine, provided by the invention, both the lower part of the thread-taking-up bar and a driving mechanism of the thread-taking-up bar are sealed in the omni-sealed transmission box; the omni-sealed transmission box is filled with machine oil; and therefore, when the sewing machine works, the noise is reduced, the dust cannot fall into the machine oil and the abrasion between the cam and the thread-taking-up bar is reduced.

Owner:四川精上缝纫机有限公司

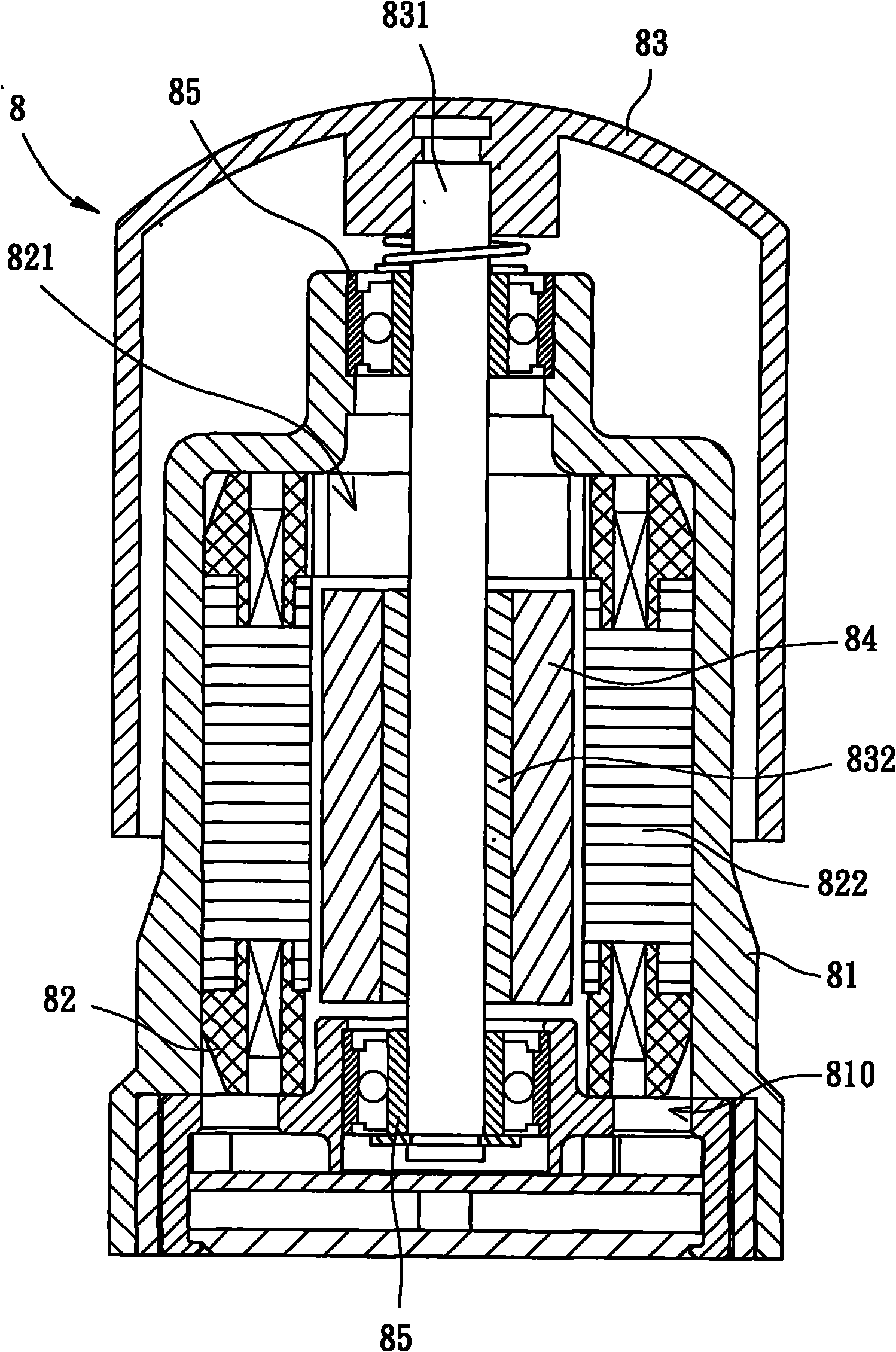

Inner rotor type motor

ActiveCN102055265APowder impurities fall intoWon't fall intoMagnetic circuit rotating partsSupports/enclosures/casingsEngineeringMagnet

The invention provides an inner rotor type motor which comprises a shell, a stator, a rotor, a bearing seat and a permanent magnet, wherein the shell is provided with an accommodating space, the stator is arranged in the accommodating space, the rotor is provided with a rotating shaft, the rotor enables the rotating shaft to be rotatably accommodated in a through hole of the stator by using a bearing, the bearing seat is provided with a seat body and a blocking ring lip, the seat body is arranged on the outer peripheral surface of the rotating shaft, the blocking ring lip radially extends to form an end part of the seat body, and the permanent magnet is arranged on the peripheral surface of the seat body. The blocking ring lip is formed between the permanent magnet and the bearing, thus the bearing seat ensures that impurities can not fall into and accumulate in the bearing or a jointing beam between the bearing and the rotating shaft, further maintains the smoothness of the rotation of the rotating shaft, and prolongs the service life of the rotating shaft.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Long-service-life roller bearing

InactiveCN106321622ADust falls intoWon't fall intoBearing componentsBearingsCircular discHeat conducting

The invention discloses a long-service-life roller bearing which comprises an inner ring, an outer ring and rollers. The rollers are located between the inner ring and the outer ring, containing grooves are formed in the top of the inner ring, a fixing rod is arranged in each containing groove, and arc-shaped movable blocks are symmetrically arranged in each fixing rod; a limiting block is arranged above each arc-shaped movable block and fixedly connected with the inner wall of the corresponding fixing rod; a first disc is fixedly connected to the tops of the fixing rods, the bottom of the first disc is fixedly connected with a first sealing ring, and the first disc is sleeved with a second disc; and a second sealing ring is arranged at the bottom of the second disc, the first sealing ring and the second sealing ring are located on the two sides of a slideway, a heat conducting pipe is arranged on a side wall of the slideway, and the side, away from the slideway, of the heat conducting pipe extends to the outer side of the outer ring. According to the long-service-life roller bearing, dust is prevented from entering a rail, the service life of the roller bearing is prolonged, and the equipment using cost is reduced.

Owner:ZHEJIANG CHUNBAO CAPSULES

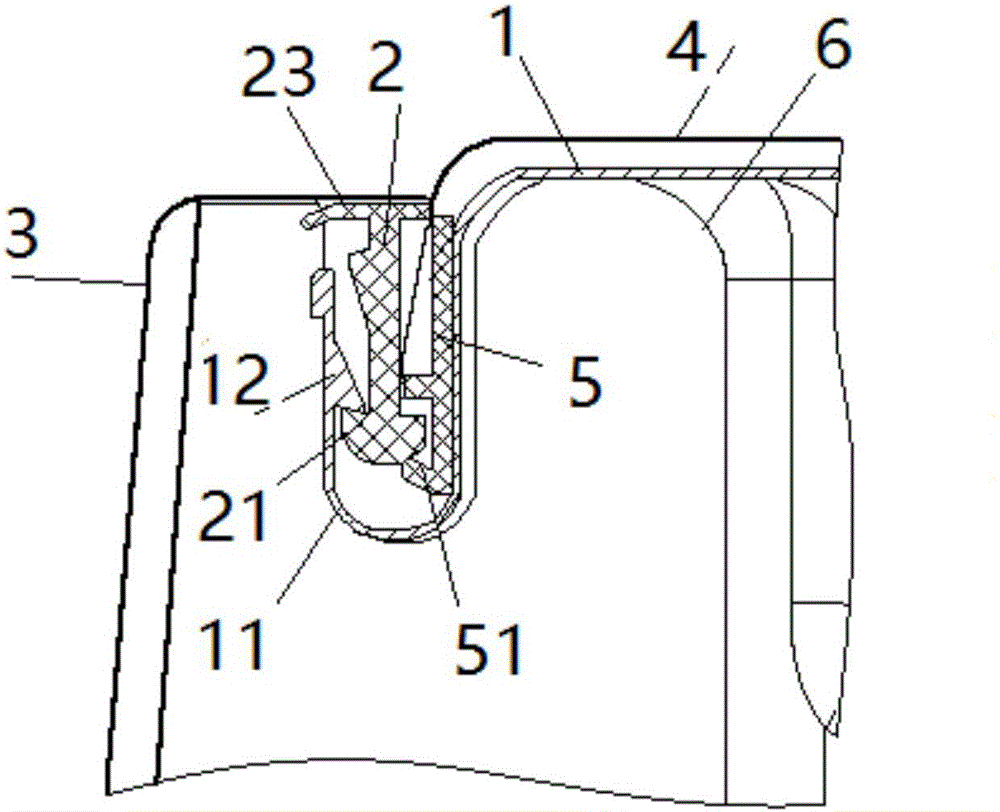

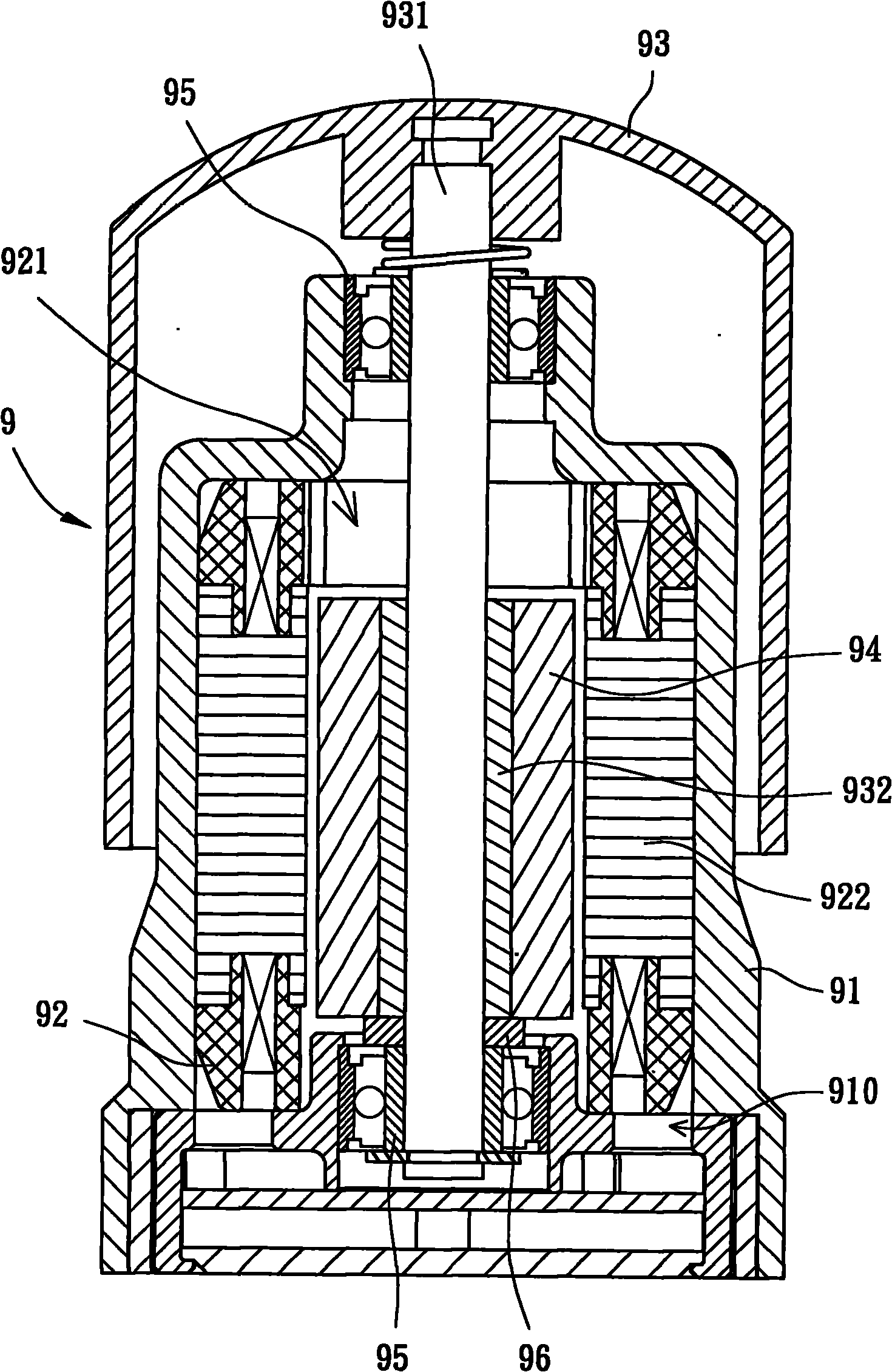

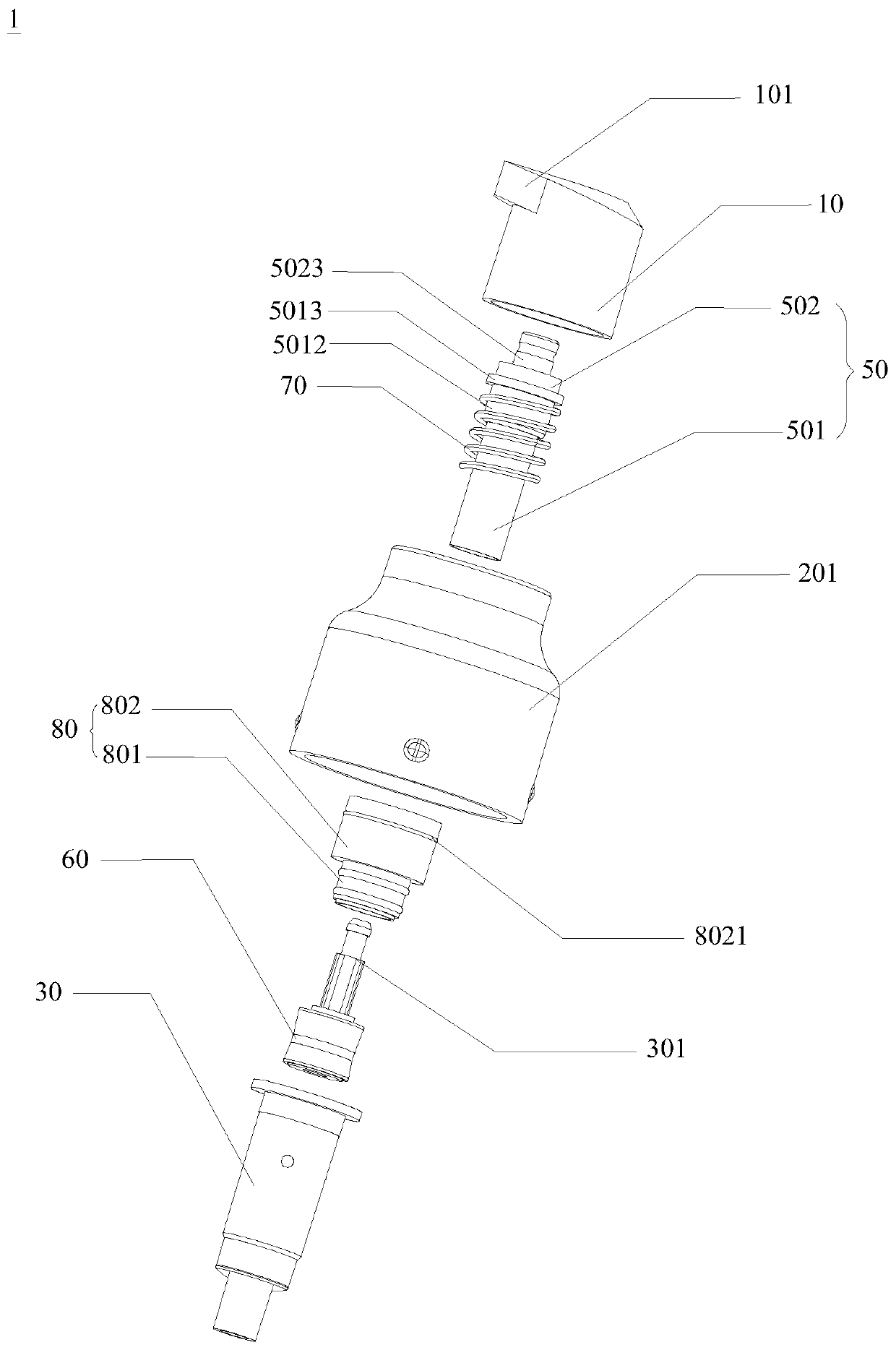

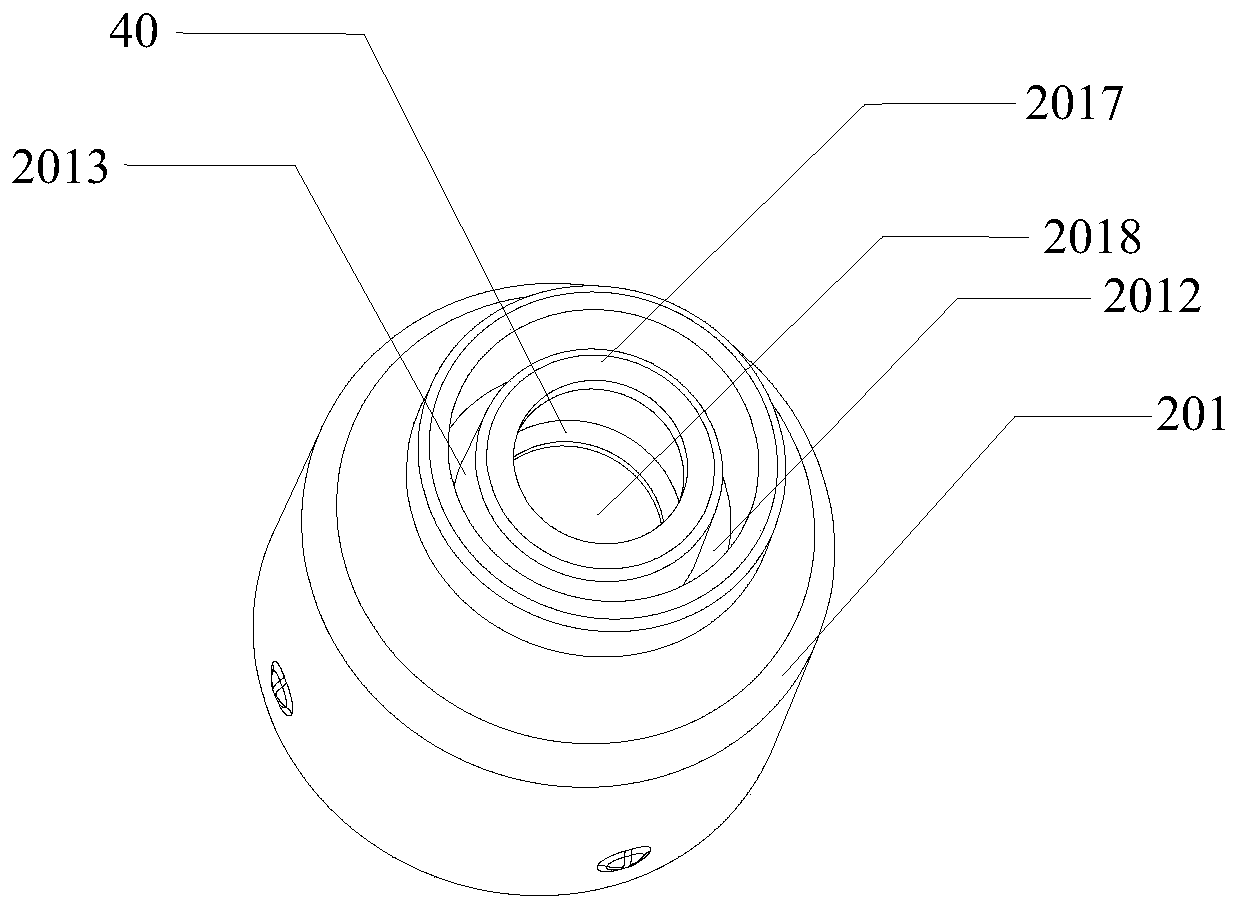

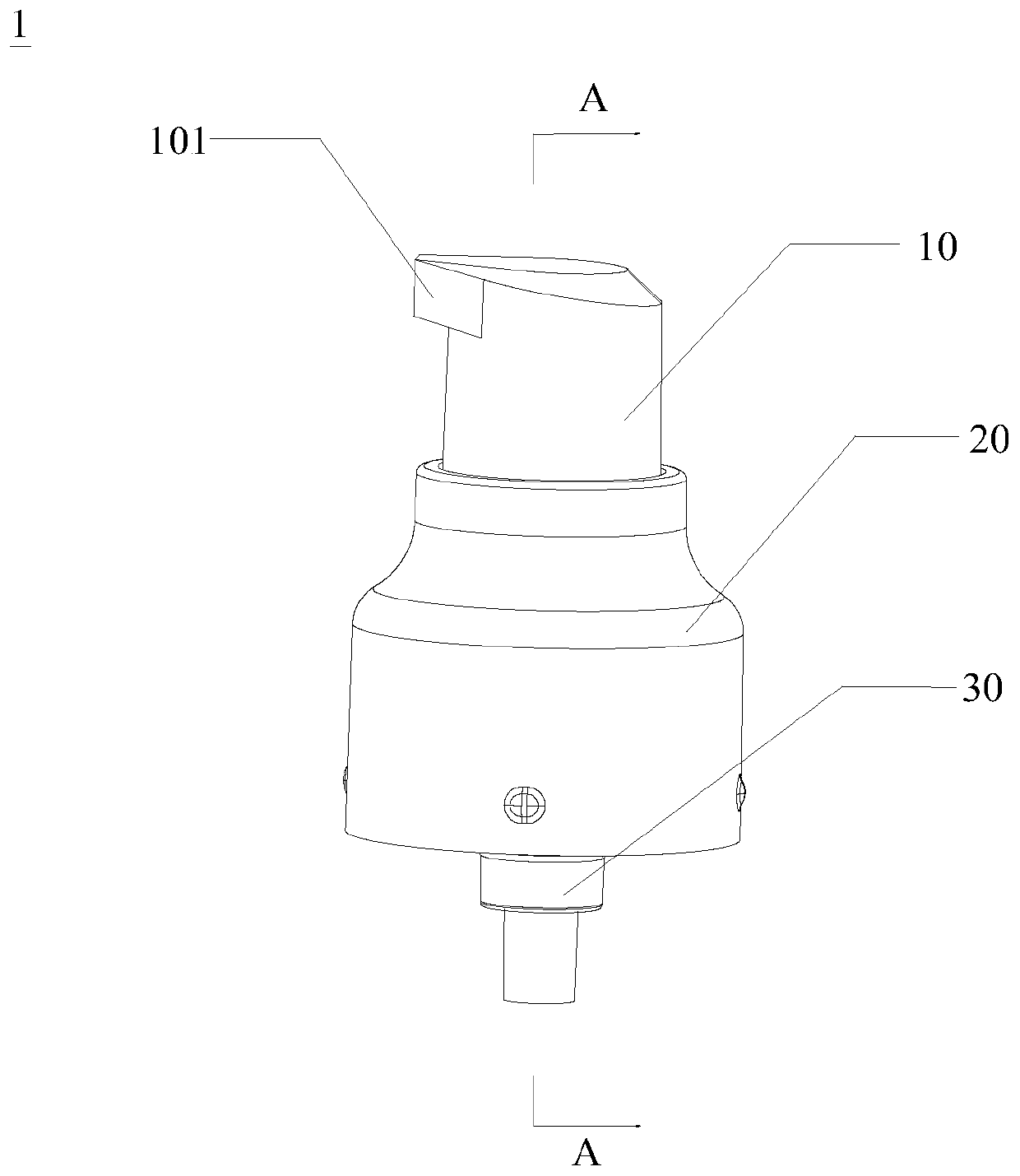

Pump head and bottle body with pump head

PendingCN109896144ANot easy to shiftWon't fall intoClosuresSingle-unit apparatusEngineeringPump head

The invention discloses a pump head. The pump head comprises a pressing head, a tooth cover and a pump body arranged in sequence from top to bottom, wherein a first mounting position is arranged at the inner end of the tooth cover; a gasket is fixed in the first mounting position, and is made of an elastic material; the gasket and the tooth cover are integrally molded through injection molding bya bicolor injection molding machine; the pump body penetrates through the gasket, and the tail end extends out of the tooth cover; a pump core is arranged in the pump body, and a valve is arranged inthe tail end; the pump core is slidingly connected with a piston; a connecting piece sleeves the pump core; a return spring is clamped between the connecting piece and the pump body; and the connecting piece communicates with a liquid outlet mouth of the pressing head for pumping out liquid. The gasket and the tooth cover are integrally molded through injection molding by the bicolor injection molding machine, so that the gasket is tightly pressed between the tooth cover and a bottle opening of a bottle body when the tooth cover is connected with the bottle opening of the bottle body without easily displacing, the sealing effect during connecting between the tooth cover and the bottle body is improved, and the leakage of liquid from the bottle body can be prevented.

Owner:广东美妆优品科技有限责任公司

Concrete scraping robot

ActiveCN110725521AIncrease contact support areaImprove the contact area is too smallBuilding constructionsStructural engineeringMechanical engineering

The invention provides a concrete scraping robot. The concrete scraping robot is used for scraping unhardened concrete on the surface of a road surface foundation and the edges and corners of a building. The concrete scraping robot comprises a base and a traveling steering part, wherein the base is movably arranged on the road surface foundation, a scraping part is arranged on the base, and the scraping part is located at the first end,in the first direction A, in the horizontal plane of the base; and the traveling steering part comprises a moving driving disc rotatably arranged at the bottomof the base, the moving driving disc comprises a disc body and a rotating shaft which are connected, and the rotating shaft is inclined in the vertical direction. The concrete scraping robot solves the problems that in the prior art, the contact area between the scraping robot and the soft concrete layer is small, so that the contact point between the scraping robot and the concrete layer is highin pressure, the scraping robot is prone to falling into the concrete layer, the scraping robot cannot continuously and stably work, and the construction efficiency of the concrete scraping operationis reduced.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

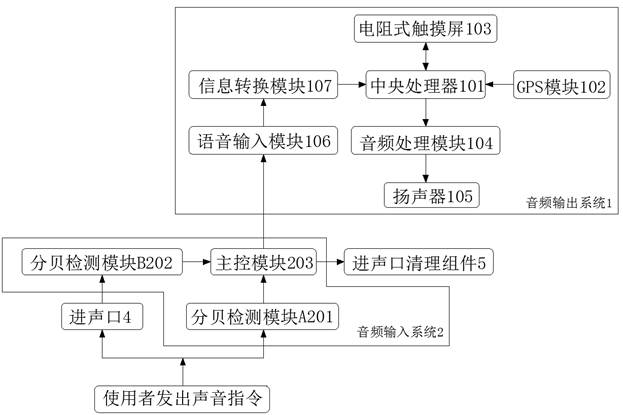

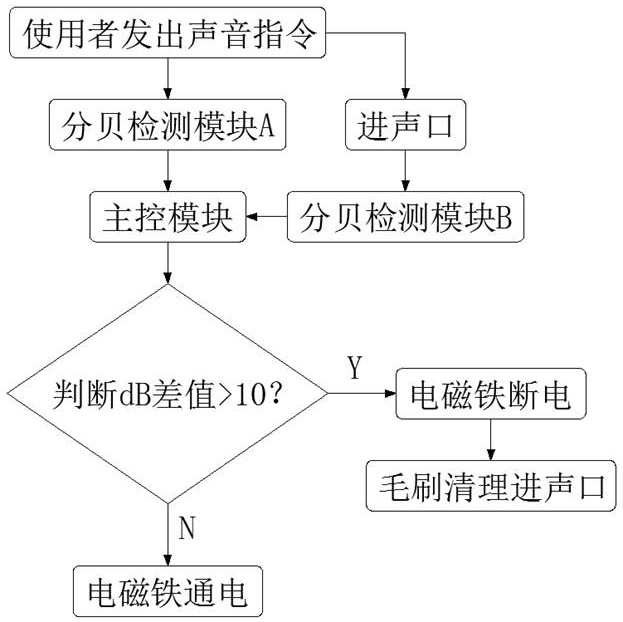

Vehicle-mounted navigation system adopting voice control

InactiveCN113460071AAccurate measurementAutomate cleanupCleaning using toolsSpeech recognitionIn vehicleEngineering

The invention discloses a vehicle-mounted navigation system adopting voice control. The system comprises an audio output system and an audio input system, the audio input system comprises a main control module, and a decibel detection module A and a decibel detection module B which are electrically connected with the main control module, the decibel detection module B is arranged on the inner side of a sound inlet, the decibel detection module A is arranged on the outer side of the sound inlet, and the main control module and the decibel detection module B are separately arranged in an inner cavity of the navigation shell. When a user sends an instruction to the vehicle-mounted navigation device, through the arrangement of the decibel detection module A, the decibel detection module B and the main control module, the sound on the inner side and the outer side of the sound inlet can be accurately measured, so that the dust blocking degree of the sound inlet can be judged, the power-on and power-off of an electromagnet can be controlled, and the sound inlet can be cleaned by using a brush.

Owner:南京越然汽车用品有限公司

Grinding device for outer wall of petroleum screen pipe

ActiveCN108044423AImplement auto-rotationRealize repeated polishingGrinding carriagesRevolution surface grinding machinesCamPetroleum

The invention discloses a grinding device for the outer wall of a petroleum screen pipe, and specifically relates to the technical field of casting. Support columns are arranged under the support frame, the support frame is slidably connected with a grinding mechanism, two ends of wedge plates are provided with limiting columns, the wedge plates are slidably connected with working vehicles, firstsprings are connected between the working vehicles and abutting blocks, connecting frames are rotatably connected with connecting rods which are provided with second springs, and the second springs are connected with grinding blocks which are rotatably connected with grinding plates; and the abutting blocks penetrates through a fixed block, a second motor is provided with a cam, a wedge rod is provided with a fixed plate and a friction portion, third springs are arranged between the fixed plate and the support frame, a through-hole is formed in a support rod, a rotating shaft is provided withan external thread and is connected with a through hole threaded mode, and the rotating shaft is provided with blades. The technical scheme overcomes the problem that screen holes adsorb mental dust during petroleum screen pipe grinding, and can be used for grinding the outer surface of the petroleum screen pipe and screen holes.

Owner:东方光源集团有限公司

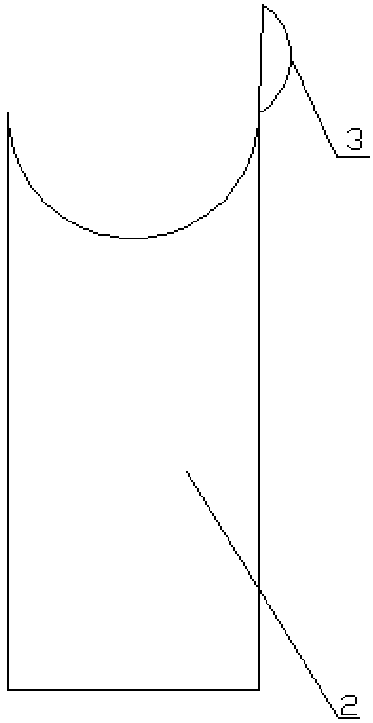

A vertical integrated activated carbon adsorption device

ActiveCN105797533BEasy to operateAvoid cloggingGas treatmentDispersed particle filtrationActivated carbonEngineering

The invention discloses a vertical integrated activated carbon adsorption device and belongs to the field of waste gas adsorption and purification in environmental protection.A dust removal filter net, an activated carbon adsorption layer and a fan are sequentially arranged in a device shell from top to bottom.A net plate is arranged at the bottom of the activated carbon adsorption layer in an inclination mode.A layer of fine anti-leakage net is arranged on the net plate.The mesh diameter of the fine anti-leakage net is smaller than the diameter of activated carbon particles in the activated carbon adsorption layer.The net plate is fixed in the device shell.A carbon outlet is formed in the lower end of the net plate and located in the device shell.When the carbon outlet is opened, the activated carbon particles in the activated carbon adsorption layer can be discharged out of the carbon outlet along the inclined net plate.Gas enters the device from top and exhausted from the bottom.The device has the advantages of being simple in structure, easy to machine and manufacture, small in occupied area, convenient to install and maintain, high in adsorption efficiency and the like, and is applicable to waste gas purification treatment engineering in airtight spaces for medicine, health care product production and the like.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

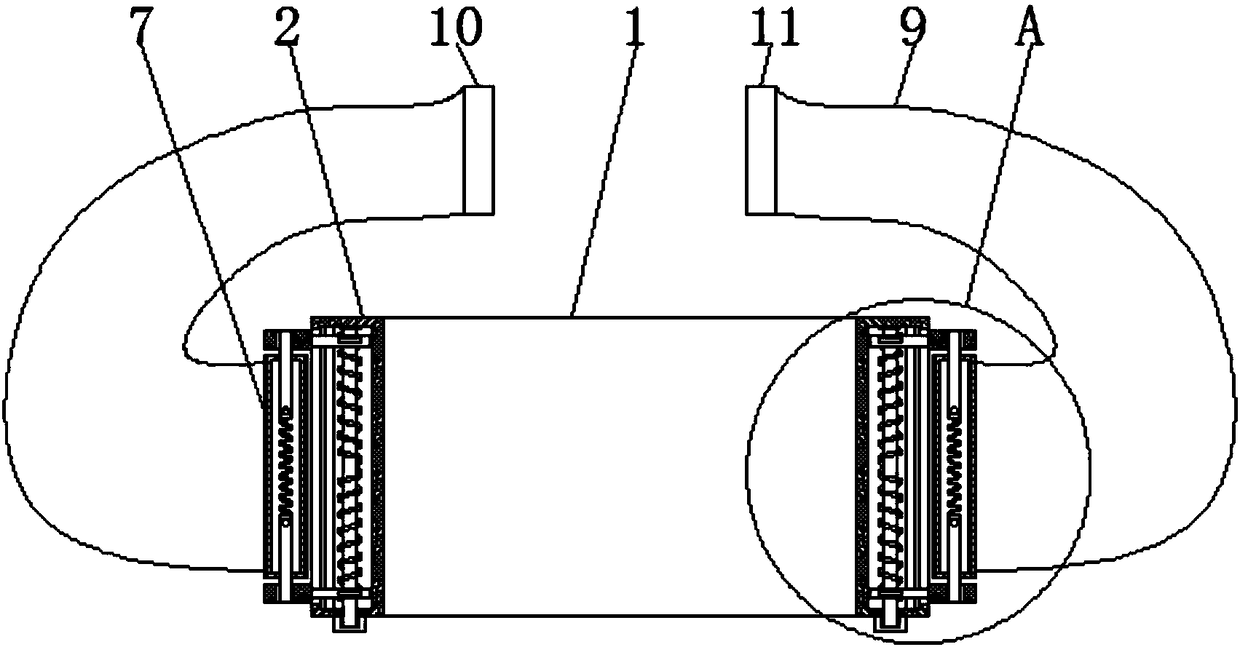

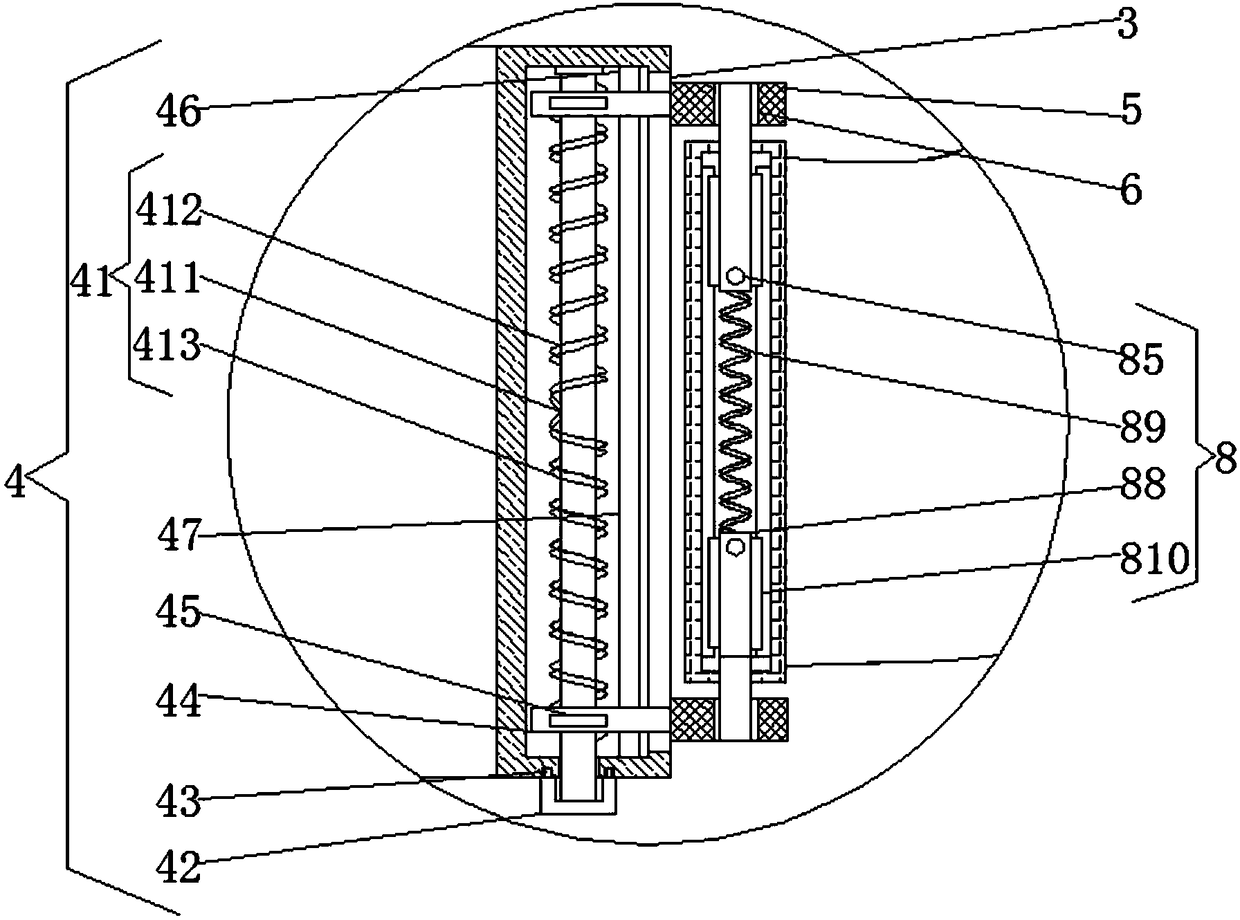

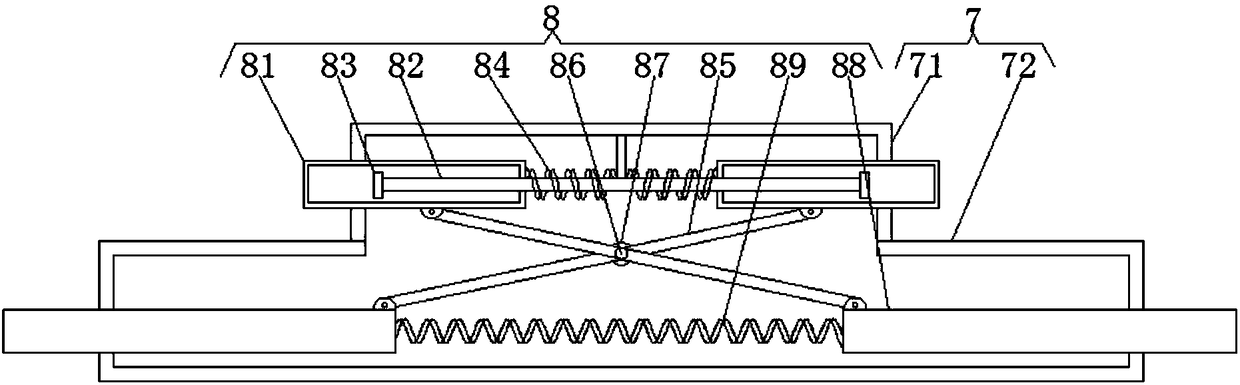

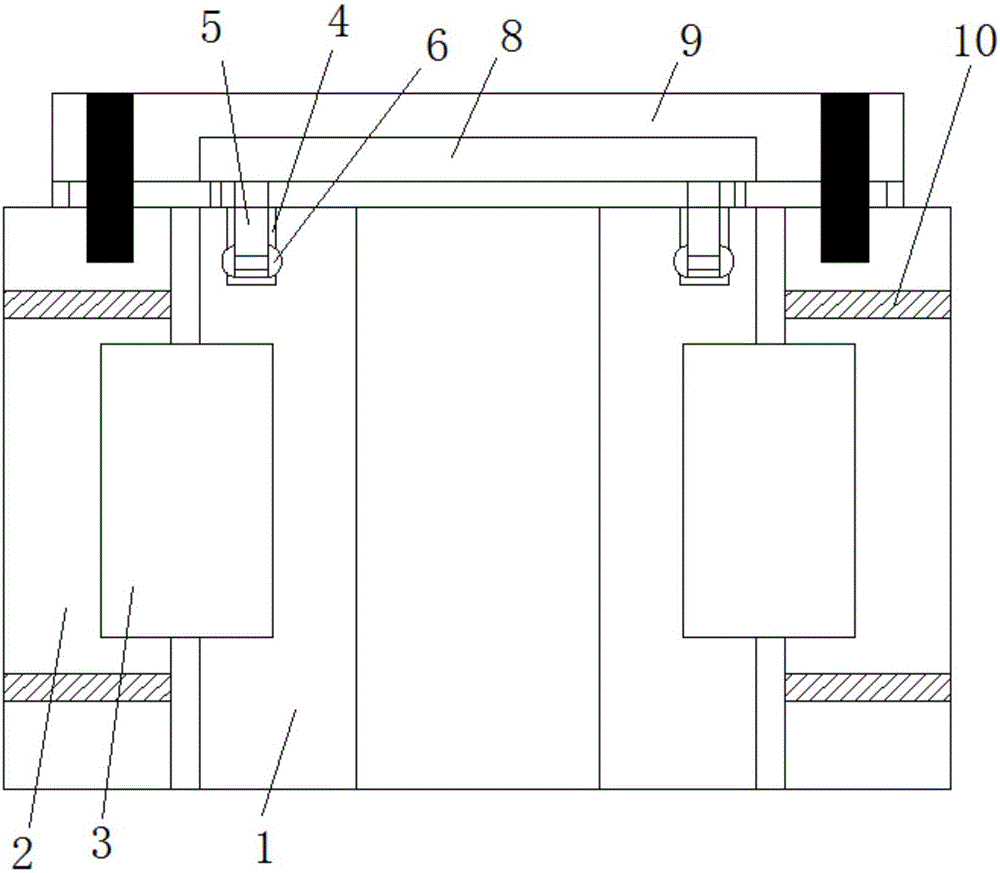

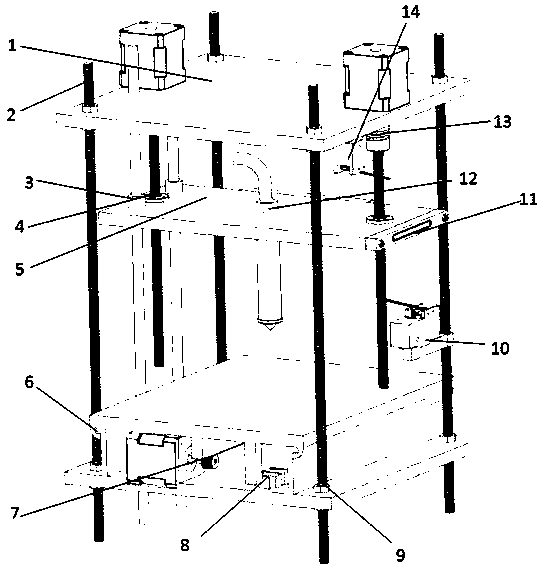

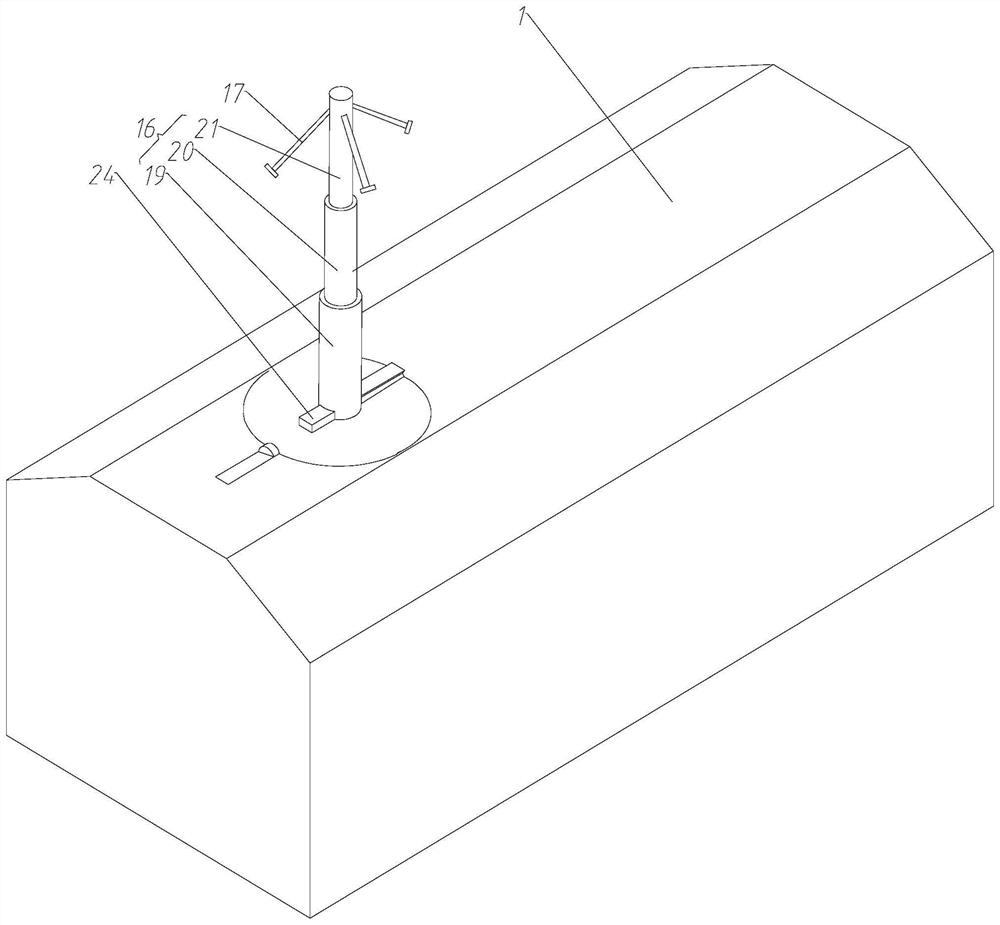

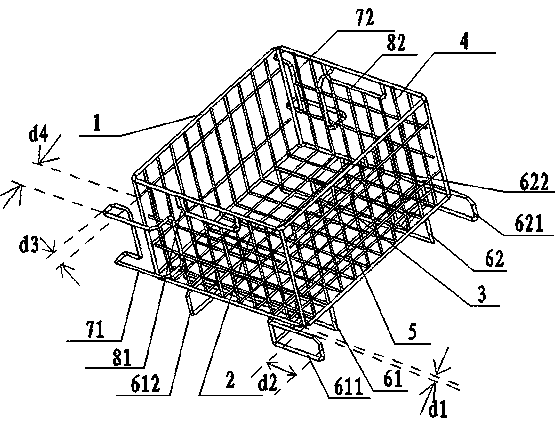

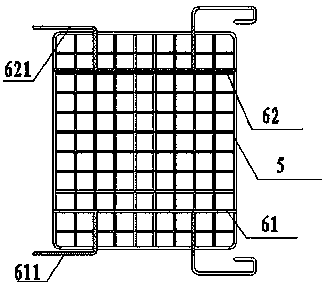

Detection device for evaporation from water surface

PendingCN109000755AHigh degree of automationReduce manpower consumptionMachines/enginesLevel indicatorsLeveling mechanismEvaporation

The invention relates to a detection device for evaporation from water surface and belongs to the technical field of detection of evaporation from water surface. The detection device for evaporation from water surface comprises a fixing module, a probe detecting module and a bottom plate sliding-out module, wherein the fixing module comprises a top plate, a top plate fixing mechanism, a bottom surface fixing plate and a bottom plate fixing mechanism; the probe detecting module comprises an optical bar sliding mechanism, a screw rod transmission mechanism I, a detecting probe platform, a detecting probe platform down stroke control mechanism, a liquid bead levelling mechanism, a detecting probe fixing mechanism, a screw rod transmission mechanism II, a detecting probe platform up stroke control mechanism, a detecting probe, a step motor I and a step motor II; the bottom plate sliding-out module comprises a groove plate, a bottom plate sliding-out mechanism, a gear transmission mechanismand a bottom plate sliding-out travel control mechanism. The device is high in working efficiency, high in automatic degree and simple in operations; the manpower is greatly saved; the cost is saved;meanwhile, precise irrigation of crops can be guided.

Owner:KUNMING UNIV OF SCI & TECH

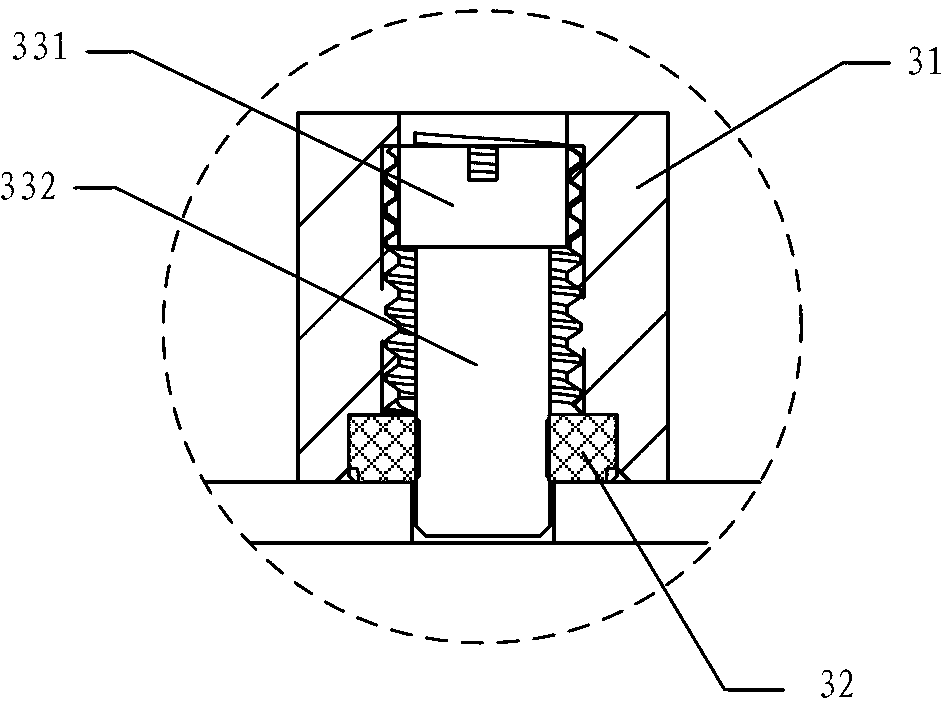

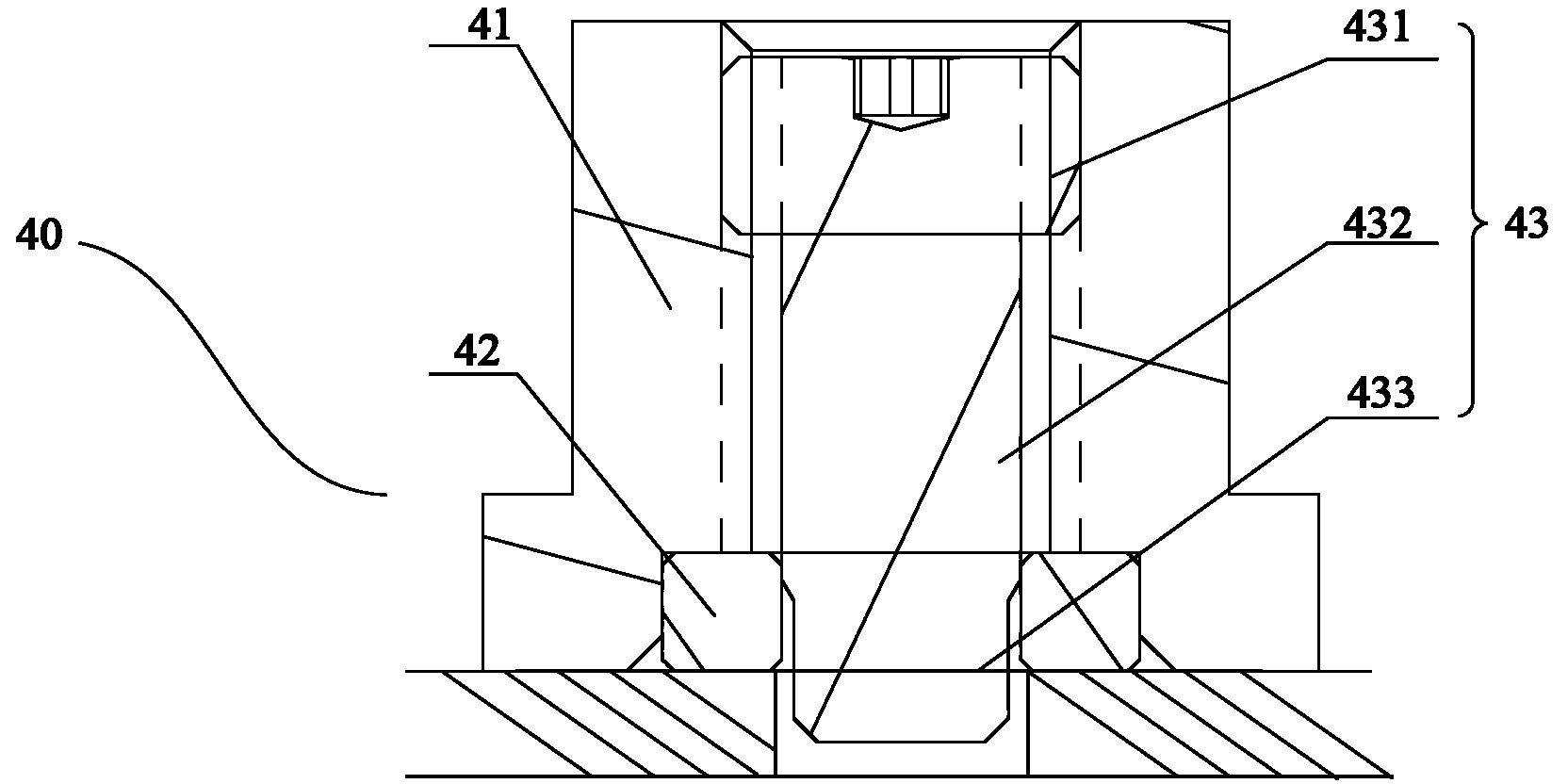

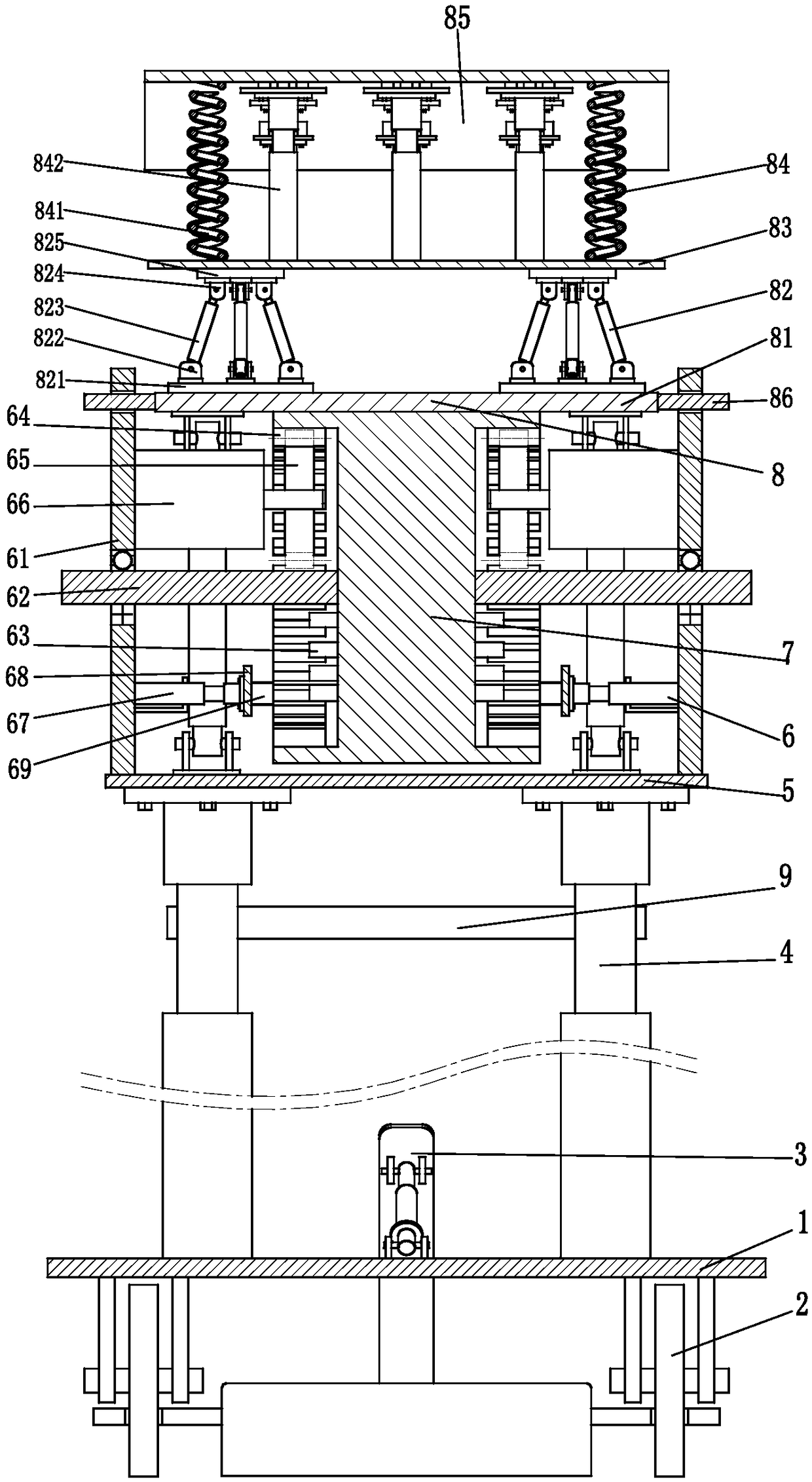

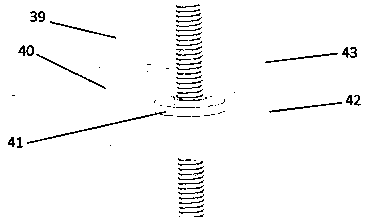

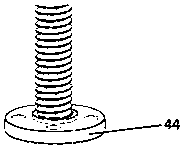

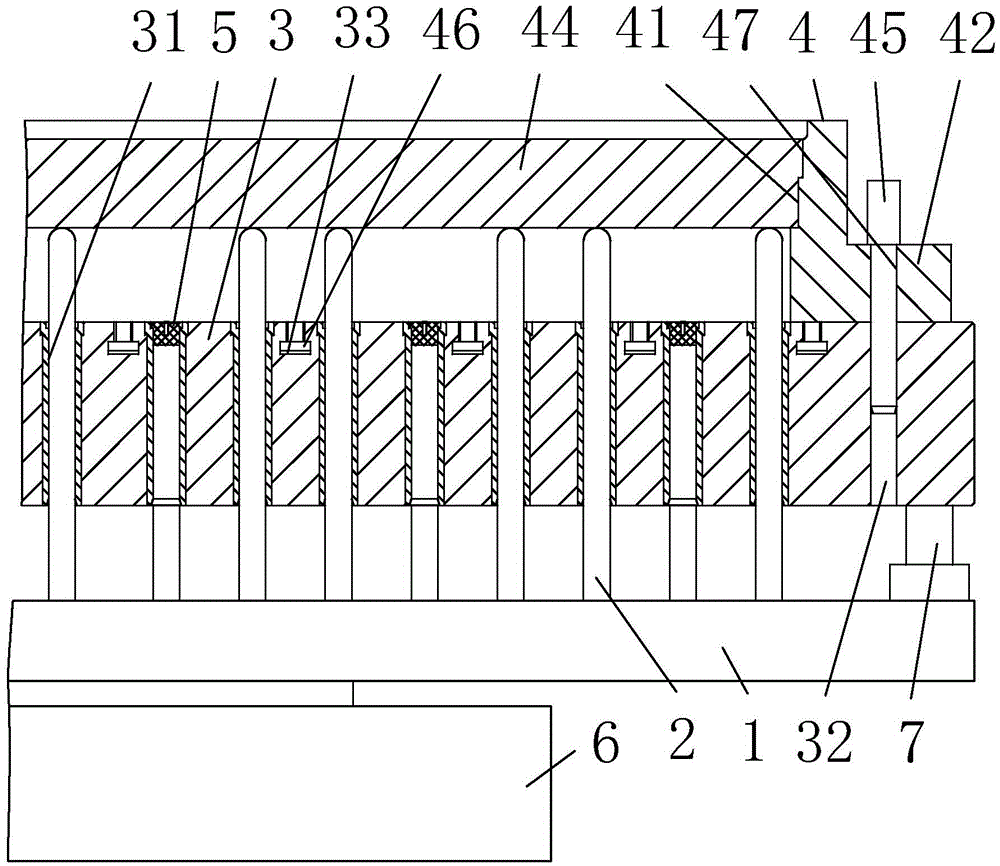

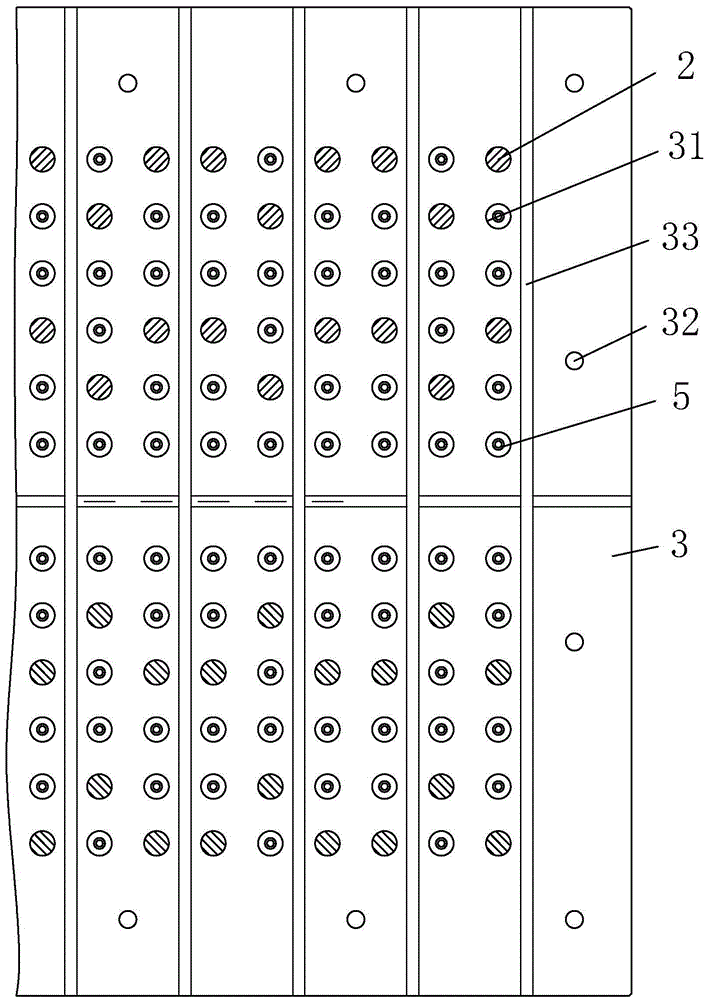

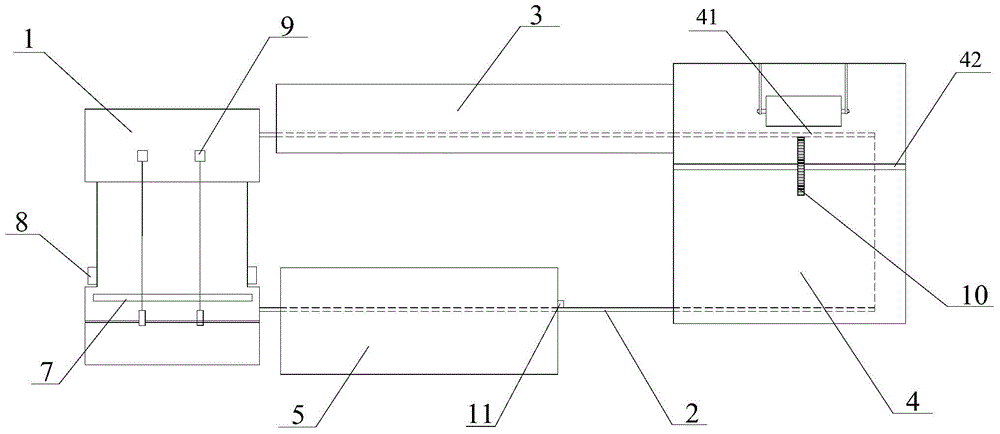

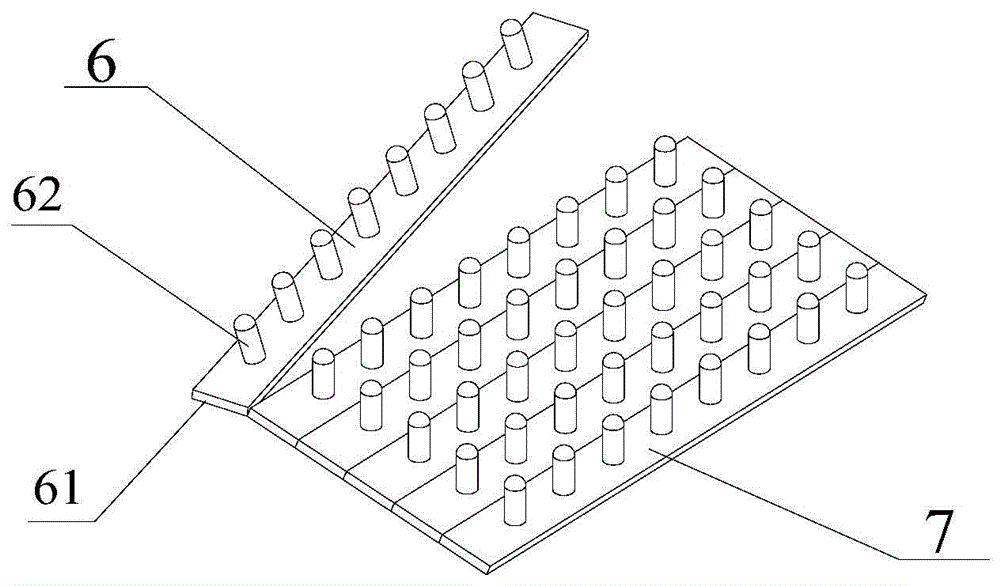

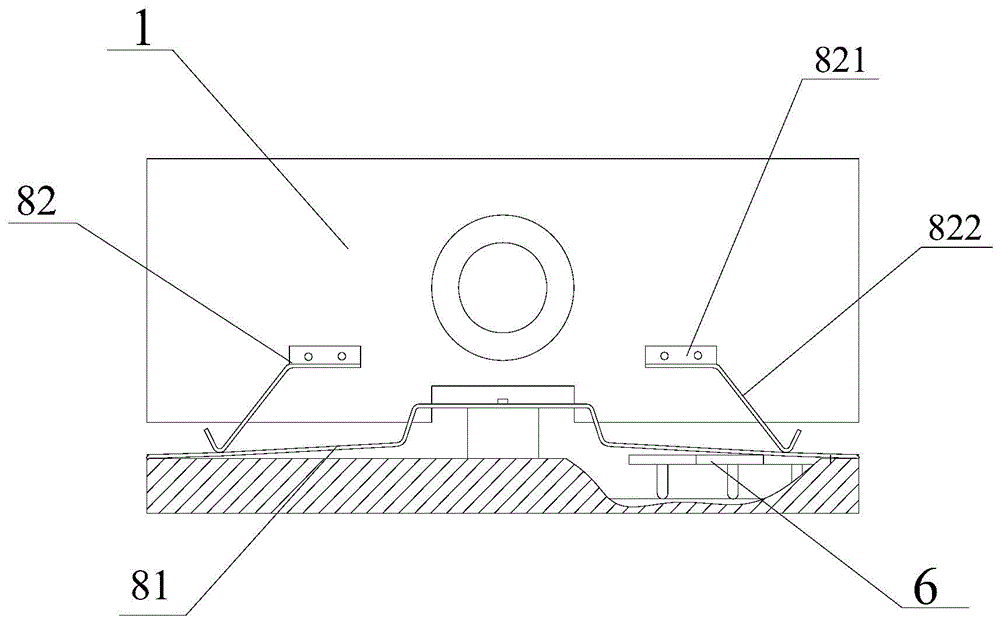

Die ejection rod structure and ejection rod installation method

InactiveCN105817532AEasy to assemble and disassembleEasy to installShaping toolsStripping-off devicesEngineeringMechanical engineering

The invention relates to the field of stamping dies, and aims to provide a die ejector pin structure and an ejector pin installation method. A mold ejector structure, comprising: a workbench, a supporting plate located at the lower side of the workbench, a ejector group consisting of a plurality of ejector pins, a lifting device for the supporting plate, and a lower die; the upper end of the workbench is provided with: Several rows of guide holes that penetrate the lower end of the worktable and match the diameter of the mandrel; the lower mold includes: a lower mold base with sliding holes passing through the upper and lower ends; The mold core; the lower mold base is detachably connected to the upper end of the worktable; the supporting plate supports the lower end of the ejector rod; the upper end of each ejector rod passes through a guide hole and extends into the sliding hole. The ejector pin structure of the mold can be adjusted according to the needs of processing workpieces, and the ejector pins can be used in common for different large stamping dies.

Owner:ZHEJIANG GEELY AUTOMOBILE +2

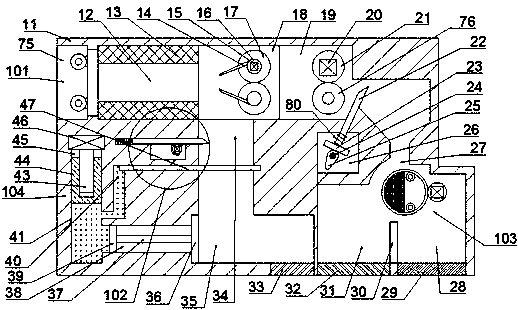

Hollow capsule manufacturing device

ActiveCN105030542ASolve the problem of easy fatigue and deformationIncrease clamping forceCapsule deliveryCooling chamberEngineering

The invention discloses a hollow capsule manufacturing device. The hollow capsule manufacturing device comprises a glue dipping unit, a circular type mold plate conveying track, a drying and cooling chamber, an electrostatic eliminating reaction chamber, a demolding device and a small mold shifting strip, wherein the glue dipping unit comprises a large mold shifting plate, small mold shifting barrier strip devices and a mold plate anti-dropping device; the small mold shifting barrier strip devices are arranged on a body of the glue dipping unit and positioned at the front end and the rear end of the large mold shifting plate; the mold plate anti-dropping device is arranged on the bottom of the large mold shifting plate; a mold base jacking chain wheel conveying device is arranged in the electrostatic eliminating reaction chamber and is mounted on a supporting beam below a mold base of the electrostatic eliminating reaction chamber; and a mold strip guiding anti-collision device is arranged at the position of an entrance of the circular type mold plate conveying track of the demolding device. The hollow capsule manufacturing device has the advantages that shortcomings of the existing hollow capsule manufacturing device are overcome; the hollow capsule manufacturing device is simple in structure and is stable and reliable; and the running efficiency of the device is improved effectively.

Owner:ANHUI HUANGSHAN CAPSULE CO LTD

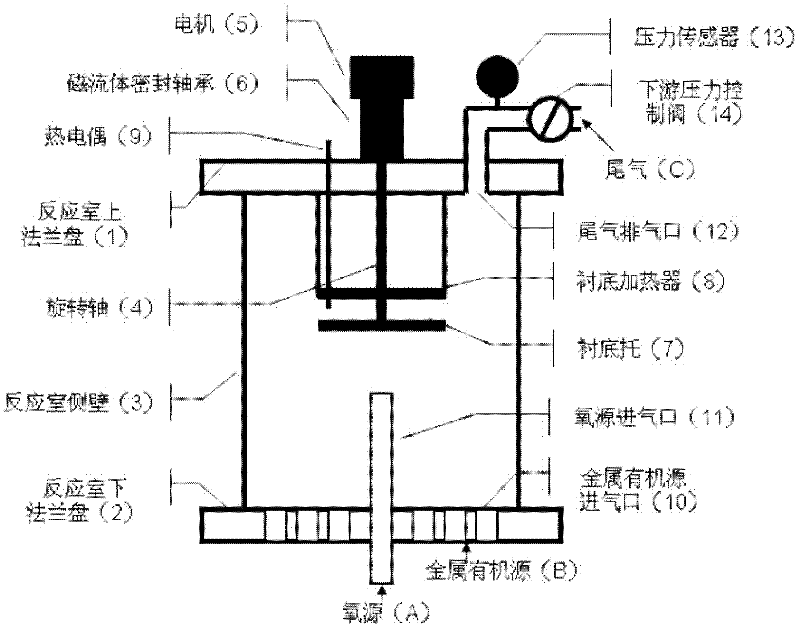

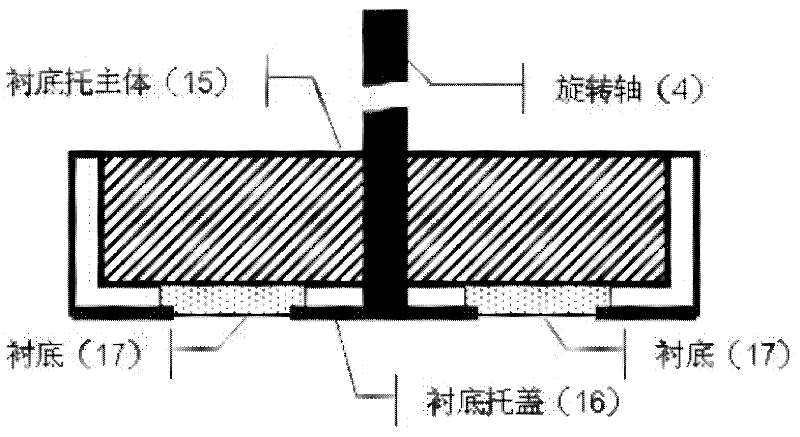

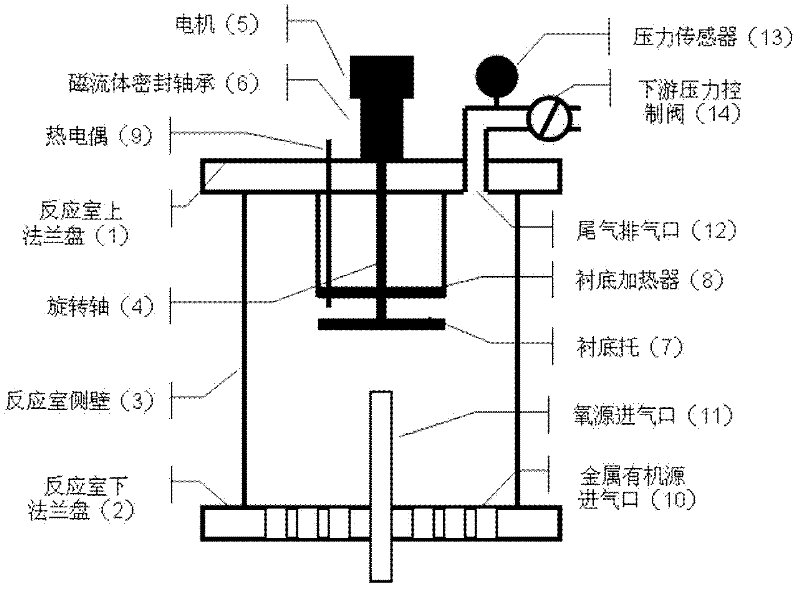

Metallorganic chemical vapor deposition reaction chamber used for growth of oxide film

InactiveCN102337517AQuality improvementWon't fall intoChemical vapor deposition coatingOxygenChemical vapor deposition

The invention discloses a metallorganic chemical vapor deposition reaction chamber used for the growth of an oxide film, which comprises an upper flange plate (1) of the reaction chamber, a lower flange plate (2) of the reaction chamber, a reaction chamber side wall (3), a rotary shaft (4), a motor (5), a magnetofluid sealing bearing (6), a substrate support (7), a substrate heater (8), a thermocouple (9), a metal organic source air inlet (10), an oxygen source air inlet (11), a tail gas vent (12), a pressure sensor (13), a downstream pressure control valve (14) and the like. According to the reaction chamber disclosed by the invention, reaction air can be vertically transported from bottom to top so as to effectively inhibit adverse impacts on the quality of the oxide film crystal by the pre-reaction of the metal organic source and the oxygen source, and the reaction chamber is favorable for obtaining the oxide film with high quality.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Vehicle filter outer shell core pulling mechanism

Owner:NINGBO FANGZHENG TOOL

Shelter sliding cover system

PendingCN114401023AAchieve airtightnessWon't fall intoAntenna adaptation in movable bodiesPower-operated mechanismHydraulic cylinderStructural engineering

The invention relates to the technical field of communication square cabin sliding covers, and provides a square cabin sliding cover system which comprises a cabin body provided with an opening, a cabin cover used for sealing the opening, an antenna arranged on the cabin cover in a sliding mode and located in the cabin body, and a purging assembly arranged on the cabin cover and used for cleaning the periphery of the opening 2 in the cabin top. The turnover device is arranged on the cabin body and connected with the cabin cover, the turnover device comprises a swing rod and a hydraulic cylinder, the swing rod is arranged on the cabin body in a swing mode, the cabin cover is arranged on the swing rod, the swing rod is rotationally arranged on the cabin body at the same time, the two ends of the hydraulic cylinder are hinged to the swing rod and the cabin body respectively, and the hydraulic cylinder is used for driving the swing rod to swing. According to the technical scheme, the problem that in the prior art, in rainy and snowy days, an antenna needs to extend out of a shelter for communication, and the interior and the exterior of the shelter are in a communicated state, so that the interior of the shelter is moist is solved.

Owner:河北九丛科技有限公司

Waste glass fiber recovery device

PendingCN110407464AWon't burn outWon't fall intoCharging furnaceGlass furnace apparatusGlass fiberEngineering

The invention relates to the field of glass fiber manufacturing, and concretely relates to a waste glass fiber recovery device. The device comprises a frame, a high temperature reaction furnace, a feeding hopper, a feeding channel, a rake, a driving assembly and a feeding tube, the rake is horizontally rotatably arranged just below the feeding hopper, the rake is located at the middle portion of the frame, the feeding tube is vertically inserted in the feeding channel, the bottom of the feeding tube extends into the high temperature reaction furnace, and the output end of the driving assemblyis in transmission connection with the rake; and the feeding channel includes a first slide way and a second slide way, the second slide way is provided with a first mounting hole, and the top of thehigh temperature reaction furnace is provided with a second mounting hole corresponding to the first mounting hole. The device realizes feeding at regular intervals, the feeding tube is made from a tungsten-molybdenum steel tube material, has resistance to high temperature, and is not prone to be easily melted, and a cooling water tube provides circulating cooling water for the feeding tube, so the lower portion of the feeding tube is avoided from being burnt by the high temperature in a waste wire furnace, impurities are avoided from falling into a hearth, and he device is practical and environmentally friendly.

Owner:NANKANG LUOBIAN GLASS FIBER

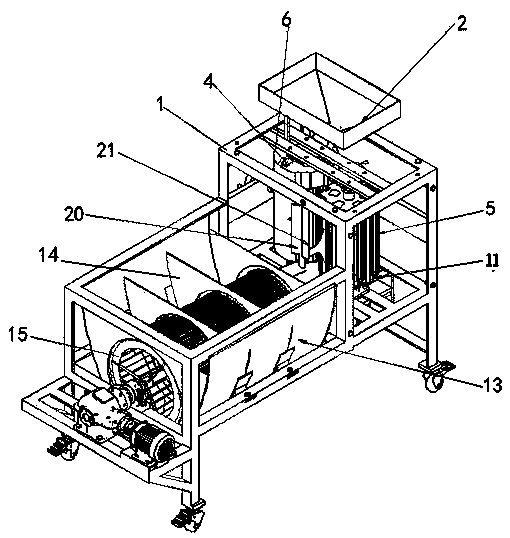

Novel energy-saving charcoal-burning machine

InactiveCN104545508AReduce usageSave energyClimate change adaptationRoasters/grillsCombustion chamberAir blower

The invention relates to a novel energy-saving charcoal-burning machine which comprises a frame, a cooling ash box, an air supply device, a burning chamber, a motor, an air blower, a control box, an air supply pipe, a control valve and a charcoal-burning stove, wherein the corresponding cooling ash box is mounted at the bottom of the frame; the air supply device, the air supply pipe and an underlying mixing burning chamber are mounted on the upper part on the right side of the frame; the charcoal-burning stove is arranged on the lower part of an ash cover of the burning chamber; the control box is arranged on the upper part on the left side of the frame; an alarm is arranged at the top of the control box; a display screen is arranged on an inclined side face of the control box; a ventilating device is arranged on the lower part of the control box. The invention has the beneficial effects that the novel energy-saving charcoal-burning machine is designed for realizing the saving for the charcoal and burned materials, more effectively ensuring the work safety in kitchen, settling the potential sanitary and safety hazards generated by the burning of the charcoal and reducing the operating cost.

Owner:吴成

Automatic hydraulic garbage dehydrator

PendingCN112944817AReduce wasteFlexible useDrying solid materials without heatDrying chambers/containersHydraulic ramProcess engineering

The invention relates to the field of household garbage treatment devices, in particular to an automatic hydraulic garbage dehydrator which comprises a rack. A water tank is arranged on the rack, a drainage hole is formed in the water tank, a compression bin with two open ends and a hydraulic oil cylinder are arranged above the rack, and the hydraulic oil cylinder is communicated with the rear end of the compression bin. A movable baffle is arranged at the front end of the compression bin and rotatably connected to the upper portion of an opening in the front end of the compression bin, the water tank is arranged below the compression bin, the upper portion of the compression bin is communicated with a feeding bin, and the feeding bin is in a funnel shape. A hydraulic station is further arranged below the rack and used for providing working power for the hydraulic oil cylinder, and a PLC control cabinet is further arranged on the outer side of the rack and used for controlling the operation of all elements of the hydraulic garbage dehydrator. The reciprocating type automatic hydraulic garbage dehydrator capable of achieving efficient dehydration is provided so as to solve the problems that in the prior art, the solid matter dehydration capacity is low, and the dehydration efficiency is poor.

Owner:福建龙迪环保设备科技有限公司

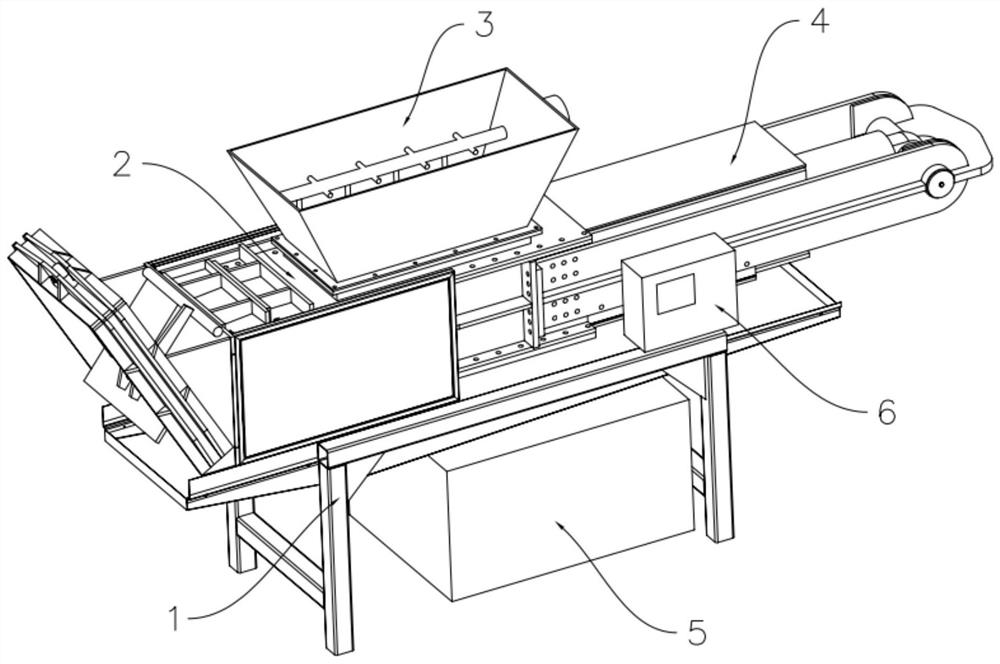

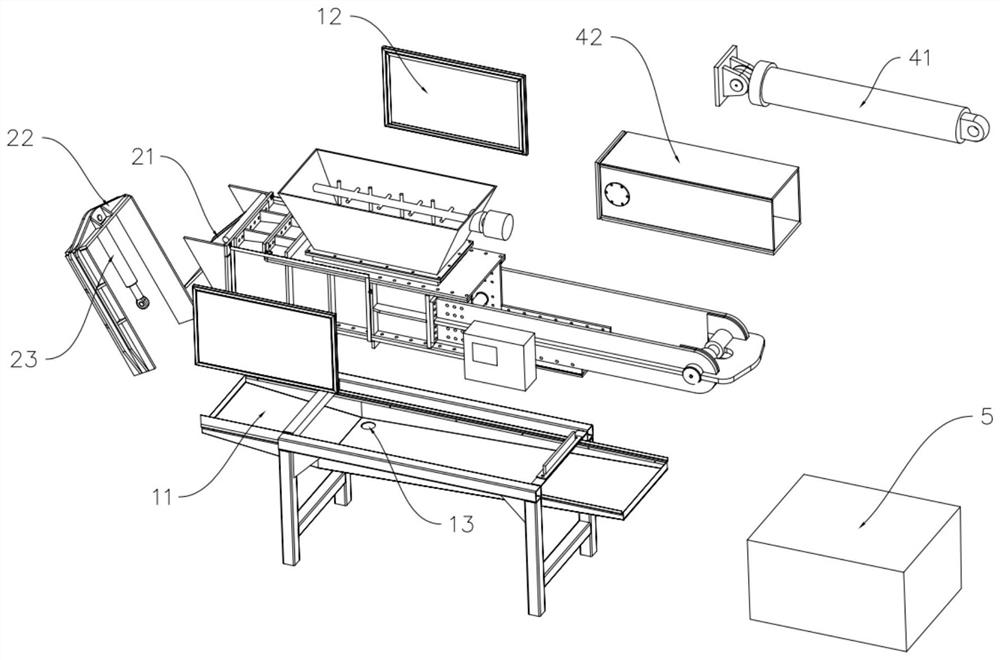

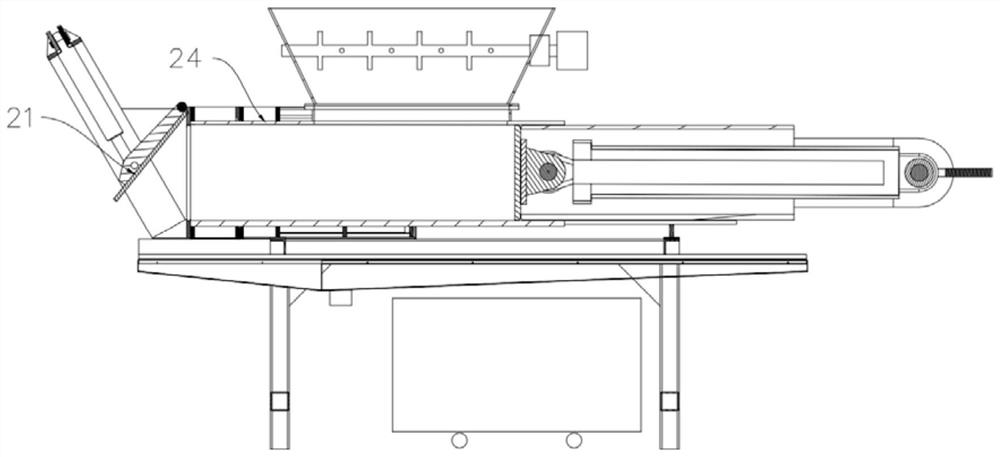

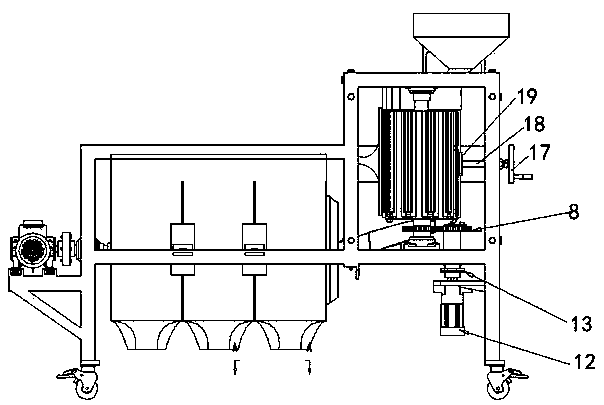

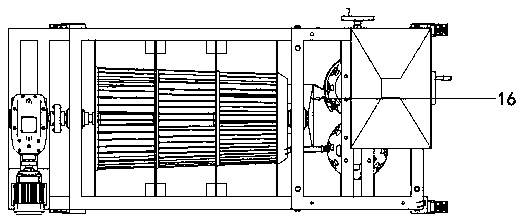

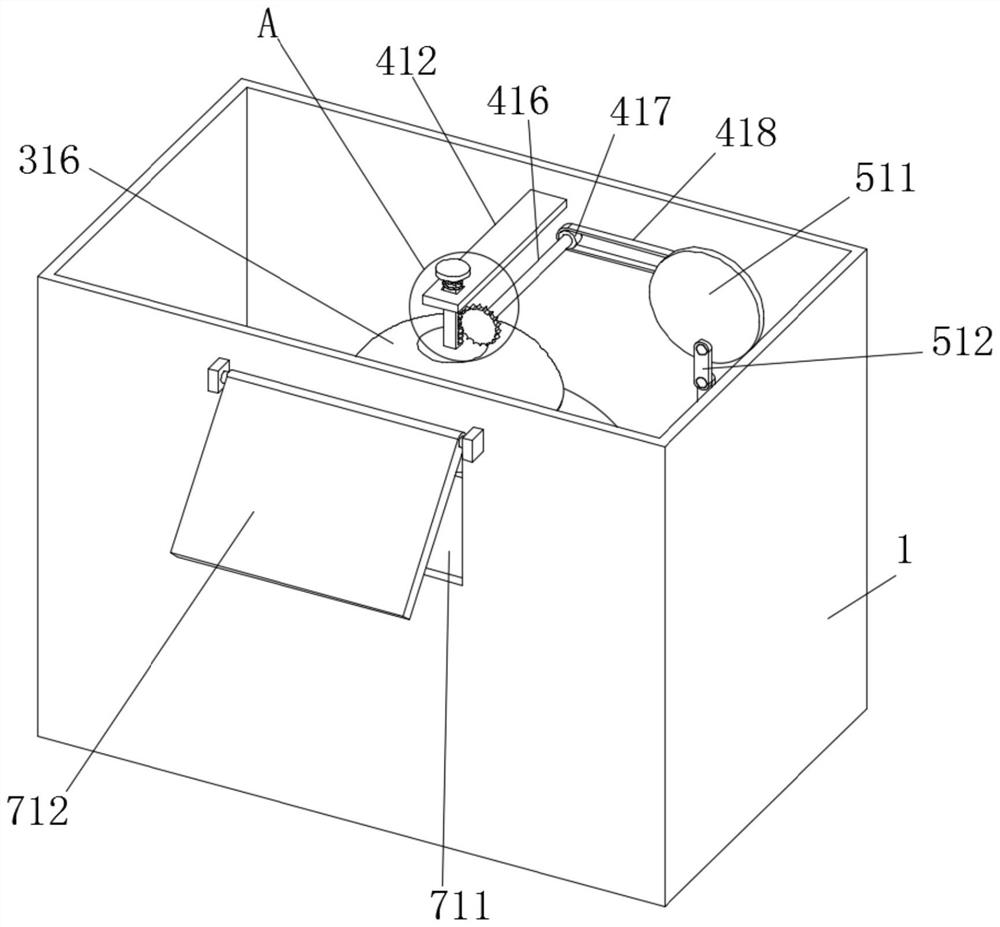

Shell breaking machine

ActiveCN105249490AImprove efficiencyLow kernel rateHuskingHullingThree stageAgricultural engineering

The invention discloses a shell breaking machine which comprises a rack, a feed hopper, a shell breaking device, a transmission device, a three-stage separation screen and a speed reducer, wherein the feed hopper is fixed on the rack; the shell breaking device is arranged at the lower end of the feed hopper, and comprises a main shell breaking roller, a sub shell breaking roller and a material blocking ring; the main shell breaking roller and the sub shell breaking roller are fixed on the rack in the radial direction; the material blocking ring sleeves the main shell breaking roller; the transmission device is fixed at the lower end of a rack body I and is connected with the shell breaking device; a separation screen material blocking ring is fixed on the rack; the three-stage separation screen passes through the separation screen material blocking ring to be fixed on the rack; the speed reducer is fixed on a rack body II, and is connected with the separation screen material blocking ring; a guide groove is formed between the shell breaking device and the three-stage separation screen. According to the shell breaking machine, the integral function of shell breaking and separation is achieved, batch shell breaking is achieved, the efficiency is high, the kernel breaking rate is low, the structure is compact, and the machine is used for multiple purposes and is adaptable to processing of walnuts of different varieties; the shell breaking and separation procedures are integrated on one machine, and compared with a traditional single-use machine, the shell breaking machine has the advantage that the production cost is greatly reduced.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Temperature control mechanism for cosmetic refrigerator

PendingCN114440542AEasy to operateImprove work efficiencyLighting and heating apparatusCooling fluid circulationPhysicsEngineering

The invention relates to the technical field of temperature control mechanisms, and discloses a temperature control mechanism for a cosmetic refrigerator, which comprises a refrigerator shell, a cooling fan mounted on the inner wall of the refrigerator shell, and a control button mounted in the refrigerator shell and used for controlling the cooling fan to be turned on or turned off, a vertical plate with an opening in the top is fixedly connected to the bottom end of the refrigerator shell, and a storage cavity used for storing mercury is formed in the vertical plate. According to the temperature control mechanism for the cosmetic refrigerator, mercury is stored in the storage cavity, when the temperature in the refrigerator rises, the mercury can be driven to be heated to rise, at the moment, the mercury can push a movable block and a sealing plug to move upwards, and at the moment, air in the storage cavity can enter an air bag and jack up the air bag; a worker can control the cooling fan to be opened or closed according to the state of the air bag, it is ensured that the cooling fan is not in an opened state when not used, and the energy-saving effect is achieved.

Owner:合肥芳容智能科技有限公司

Combinable racks and freezers

ActiveCN106679316BGuaranteed effective distanceGuaranteed flow distanceLighting and heating apparatusSupportEngineeringRefrigerated temperature

Owner:QINGDAO HAIER SPECIAL ICEBOX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com