Inner rotor type motor

A rotor type and motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, casing/cover/support, etc., can solve the complicated assembly components and steps, increase the difficulty of positioning, and affect the motor. Assembly efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

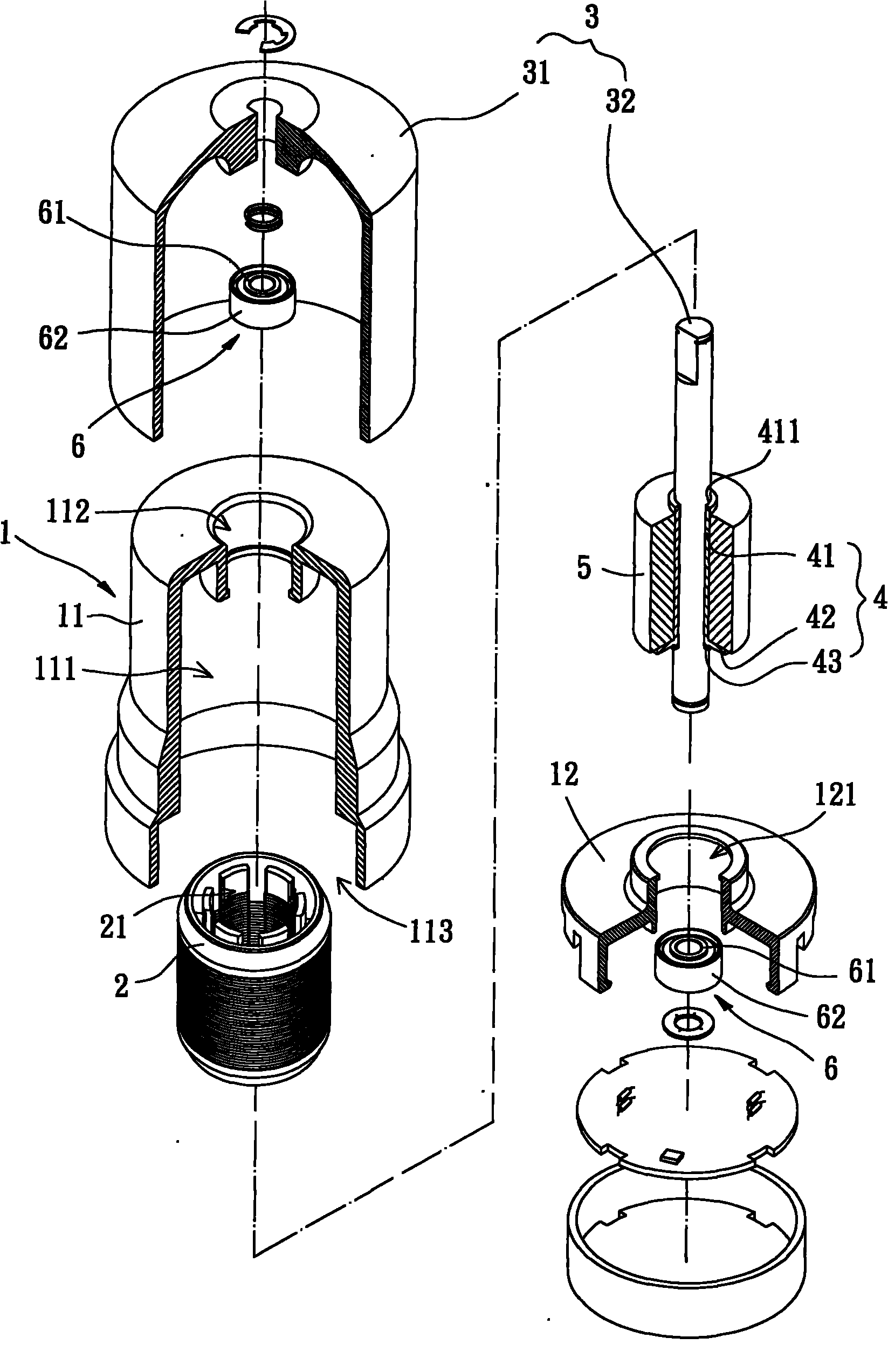

[0036] Please refer to image 3 and 4 As shown, the inner rotor motor of the first embodiment of the present invention includes a shell 1 , a stator 2 , a rotor 3 , a bearing seat 4 , a permanent magnet 5 and two bearings 6 .

[0037] The case 1 of this embodiment is composed of a body 11 and a base 12. The body 11 has an accommodating space 111, a first through hole 112 and an assembly 113. The accommodating space 111 is formed inside the body 11. The stator 2 , the bearing seat 4 , the permanent magnet 5 and the two bearings 6 are all accommodated in the accommodating space 111 . The first through hole 112 and the assembly 113 are respectively disposed on the top and the bottom of the body 11 , and communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com