Sewing machine and omni-sealed thread-taking-up mechanism thereof

A sewing machine, fully-sealed technology, applied in the field of sewing machines, can solve the problems of easily polluted sewing materials, high noise of thread take-up mechanism, easy machine failure, etc., and achieves the effect of reducing wear and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

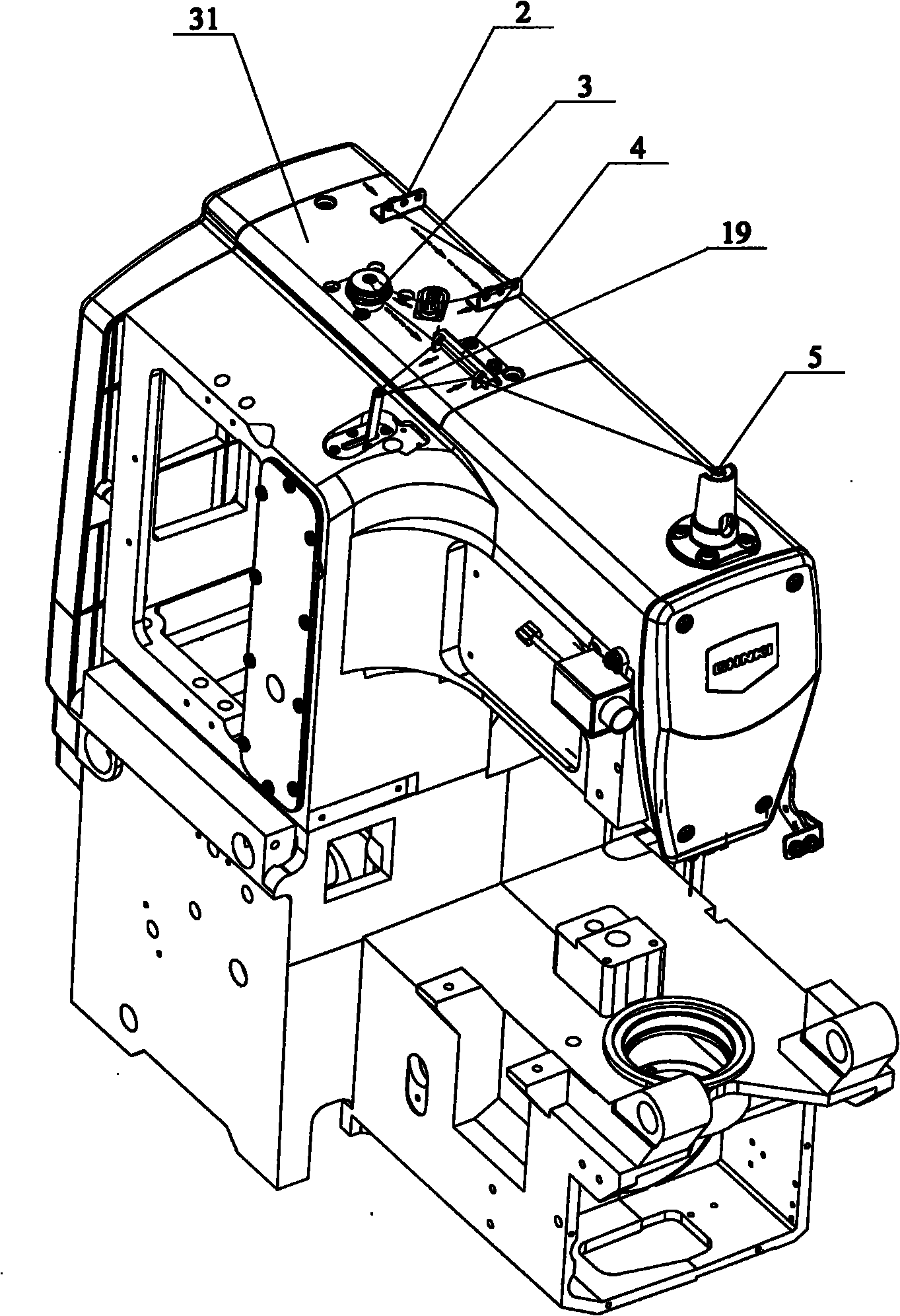

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

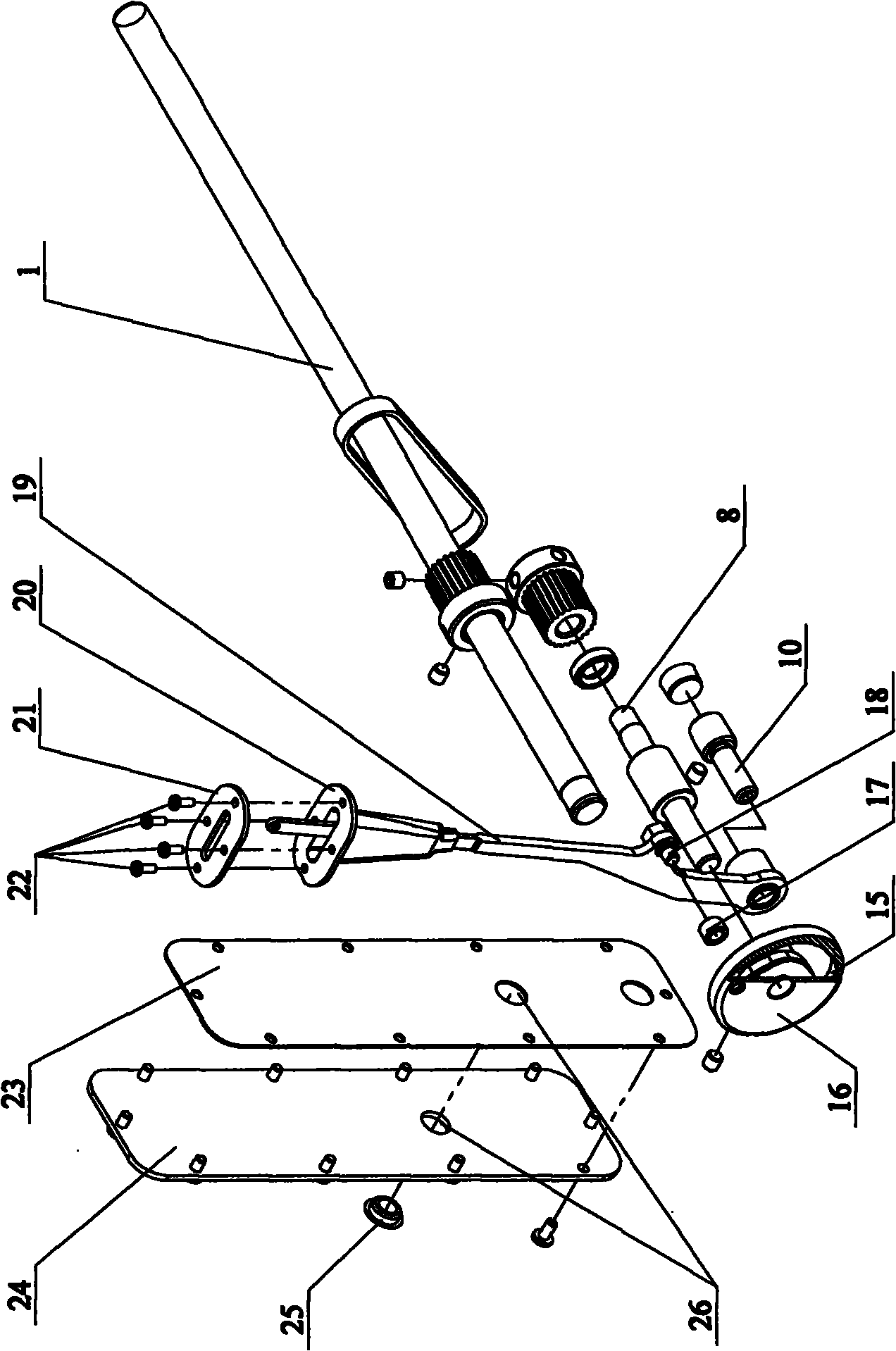

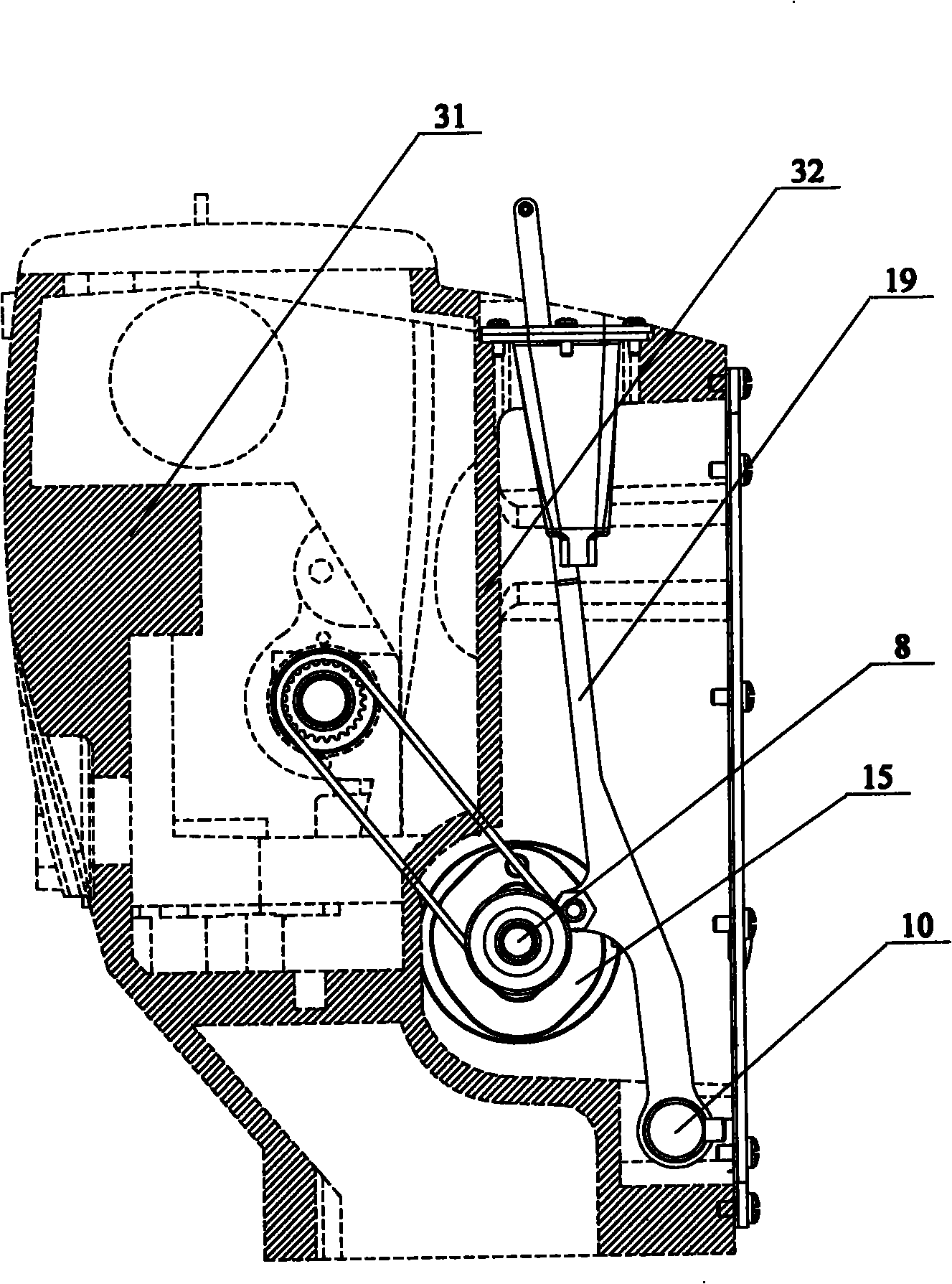

[0013] Such as figure 1 , figure 2 As shown, the fully sealed thread take-up mechanism of the sewing machine provided by the present invention includes a transmission case 32 and a thread take-up lever 19 arranged in the transmission case 32 .

[0014] Transmission box body 32 is made up of the housing of front opening and the cover plate 24 that is fixed on the opening of described housing, is provided with gasket 23 between cover plate 24 and the front end face of housing, cover plate 24 and The sealing pad 23 is provided with an oil filling hole 26, and a sealing cover 25 is fastened on the oil filling hole 26. The transmission case 32 is arranged in the casing. The passive transmission shaft 8 is mounted on the right side wall of the transmission case 32 , the left end of the passive transmission shaft 8 is fixedly provided with a cam 16 , and the left end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com