Pump head and bottle body with pump head

A pump head and pump body technology, applied in the field of pump head and the bottle with the pump head, can solve the problems of bacterial infection, easy leakage of liquid, contamination of liquid in the bottle, etc., to prevent bacterial infection, prevent liquid leakage, The effect of enhancing the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order for those skilled in the art to more clearly understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments.

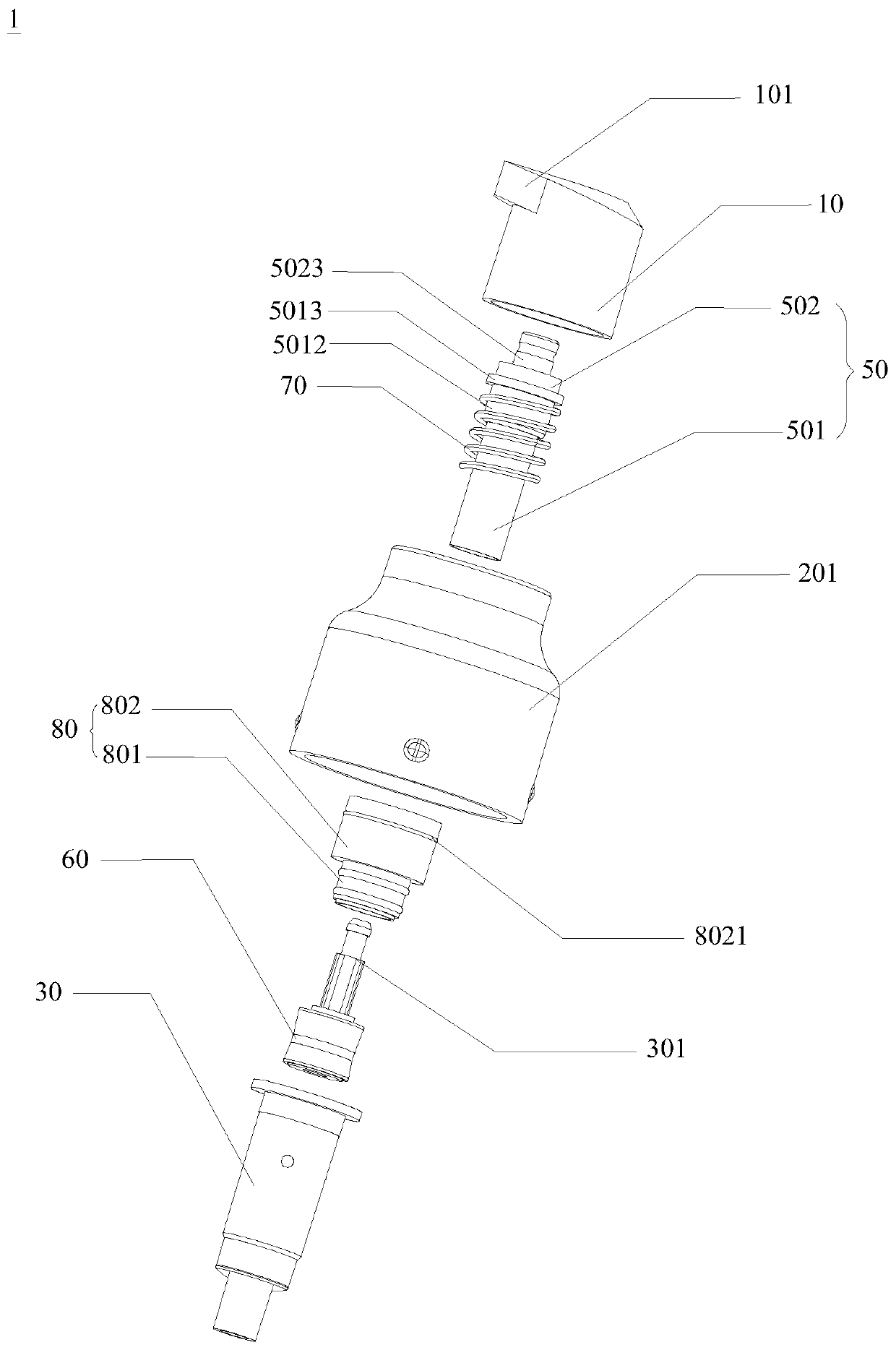

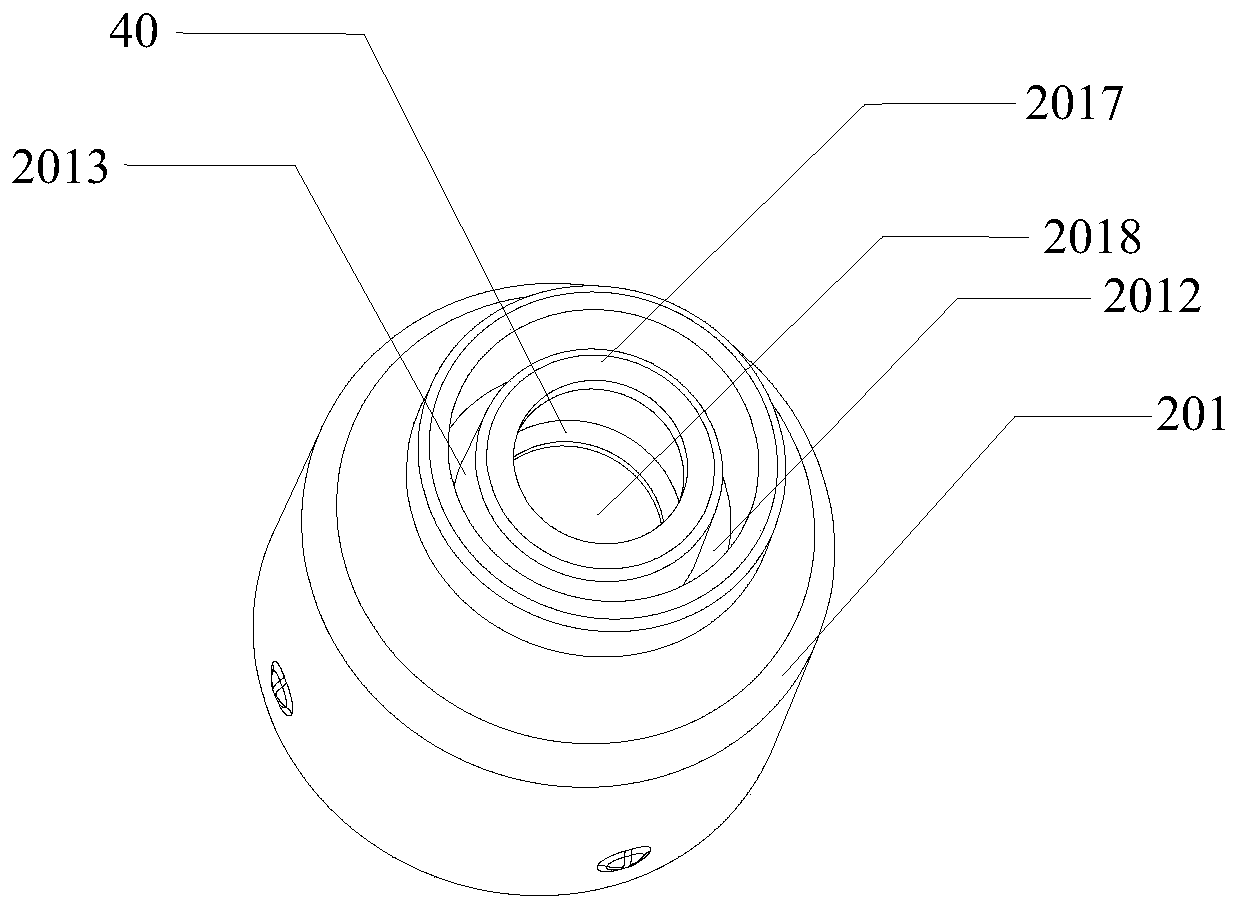

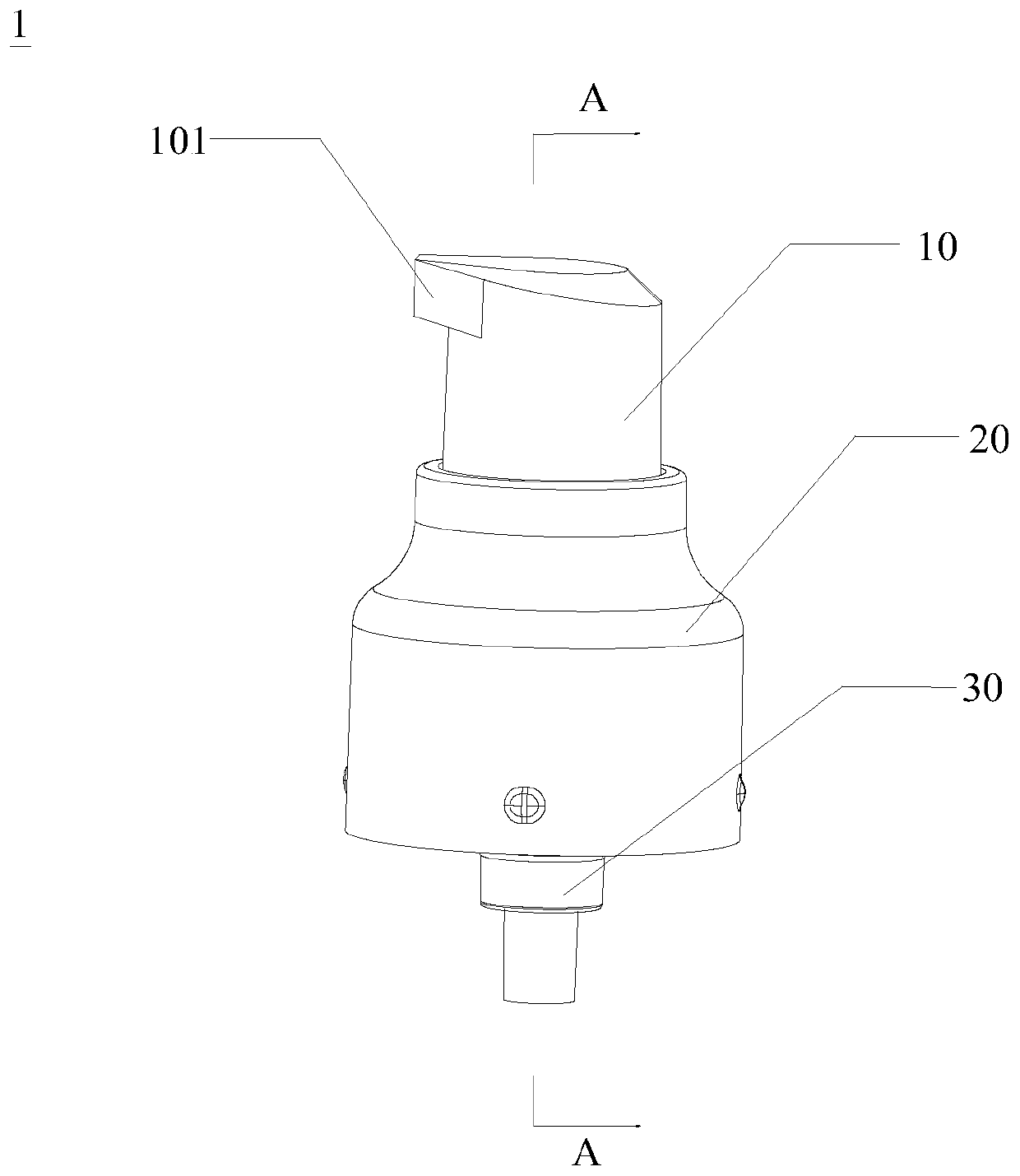

[0021] refer to Figure 1 to Figure 4 , Figure 1 to Figure 4 A specific embodiment of the pump head 1 of the present invention is shown. In the embodiment shown in the drawings, the pump head 1 includes a pressing head 10, a tooth cover 20 and a pump body 30 arranged in sequence from top to bottom, wherein the inner end of the tooth cover 20 is provided with a first installation At position 2011, a gasket 40 is fixed in the first installation position 2011. The gasket 40 is made of elastic material. The gasket 40 and the tooth cover 20 are integrally molded by a two-color injection molding machine. The elastic material can be silica gel or soft glue, etc. The pump body 30 is installed in the tooth cover 20 , which p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com