Metallorganic chemical vapor deposition reaction chamber used for growth of oxide film

A technology of chemical vapor deposition and metal organics, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of reducing the quality of thin film crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

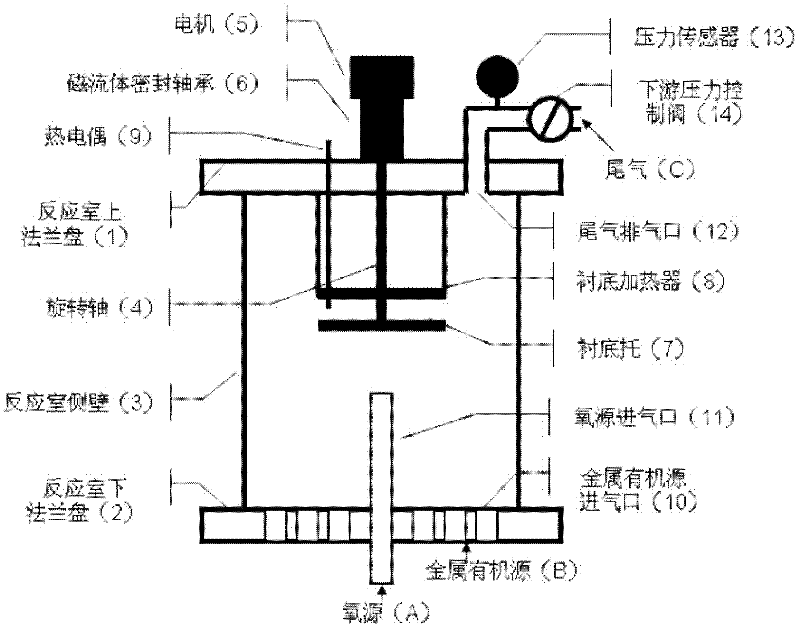

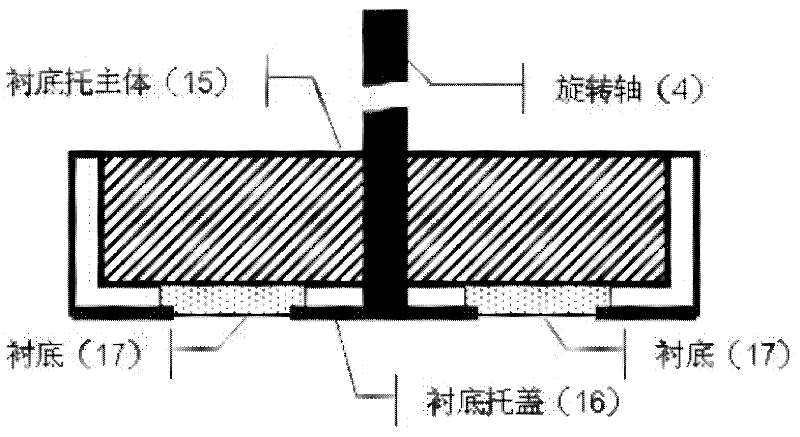

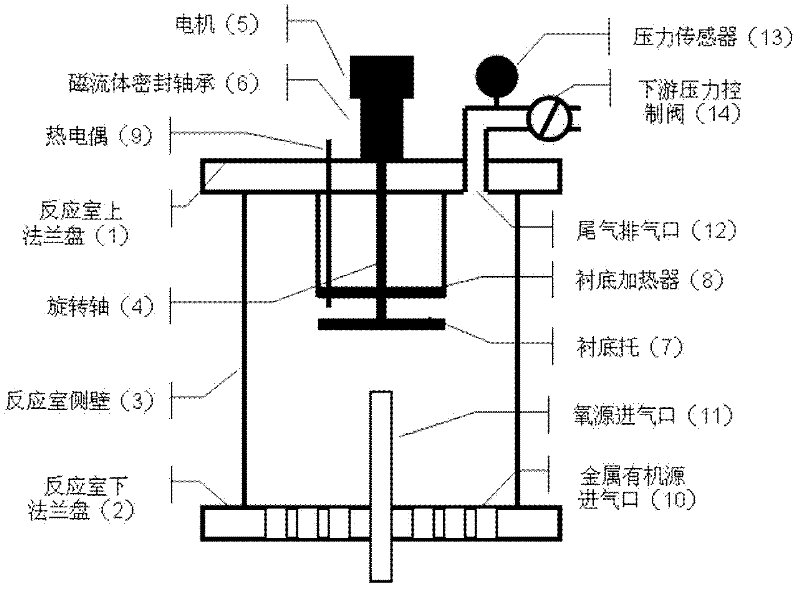

[0020] see figure 1 , a metal organic chemical vapor deposition equipment reaction chamber for oxide film growth in the present invention, comprising: the upper flange (1) of the reaction chamber, the lower flange (2) of the reaction chamber, the side wall of the reaction chamber (3), the rotating Shaft (4), motor (5), magnetic fluid sealed bearing (6), substrate holder (7), substrate heater (8), thermocouple (9), metal-organic source inlet (10), oxygen Source air inlet (11), exhaust gas outlet (12), pressure sensor (13), downstream pressure control valve (14) and other components. Before the growth, the reaction chamber is opened, and the cleaned substrate is placed into the substrate holder (7) with the growth side facing down. figure 2 A specially designed substrate support (7) suitable for the epitaxial growth of oxide thin films with the substrate facing down and the gas flow from bottom to top is given in detail. The substrate holder (7) is composed of two parts: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com