Die ejection rod structure and ejection rod installation method

A die ejector and ejector technology, applied in the field of stamping dies, can solve the problems that ejector pins cannot be used universally, ejector pin positions cannot be adjusted, etc., and achieve the effects of improving installation efficiency and installation quality, convenient and quick installation, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the drawings.

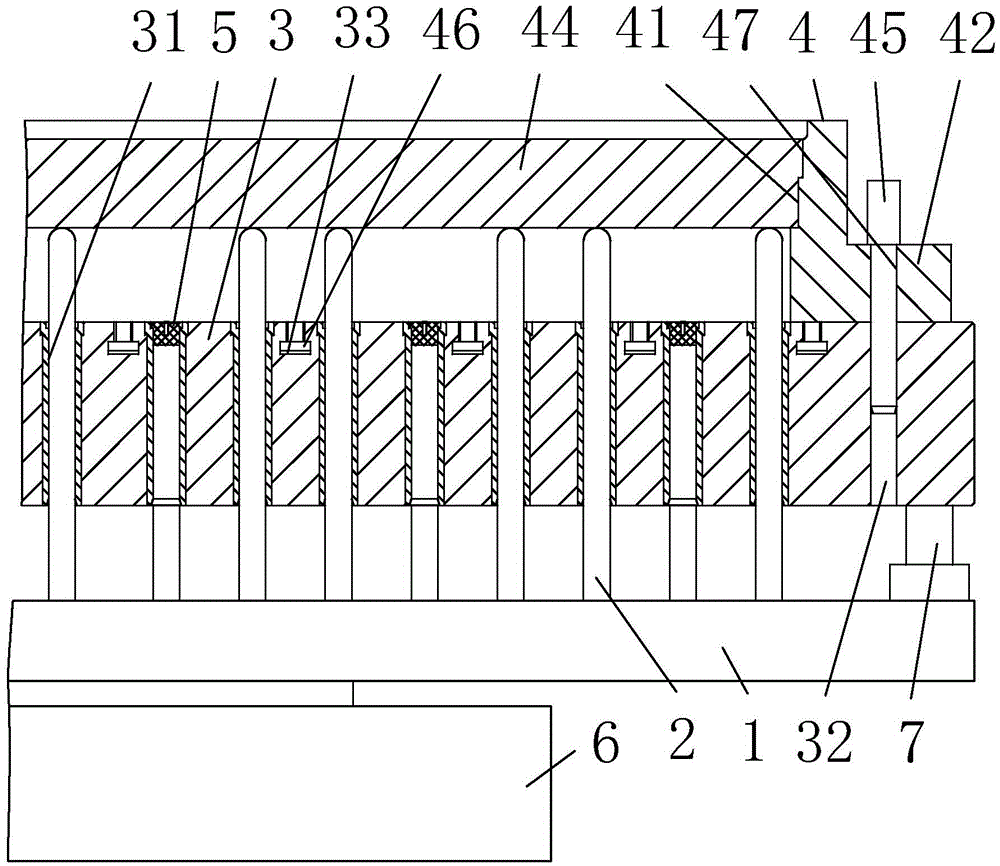

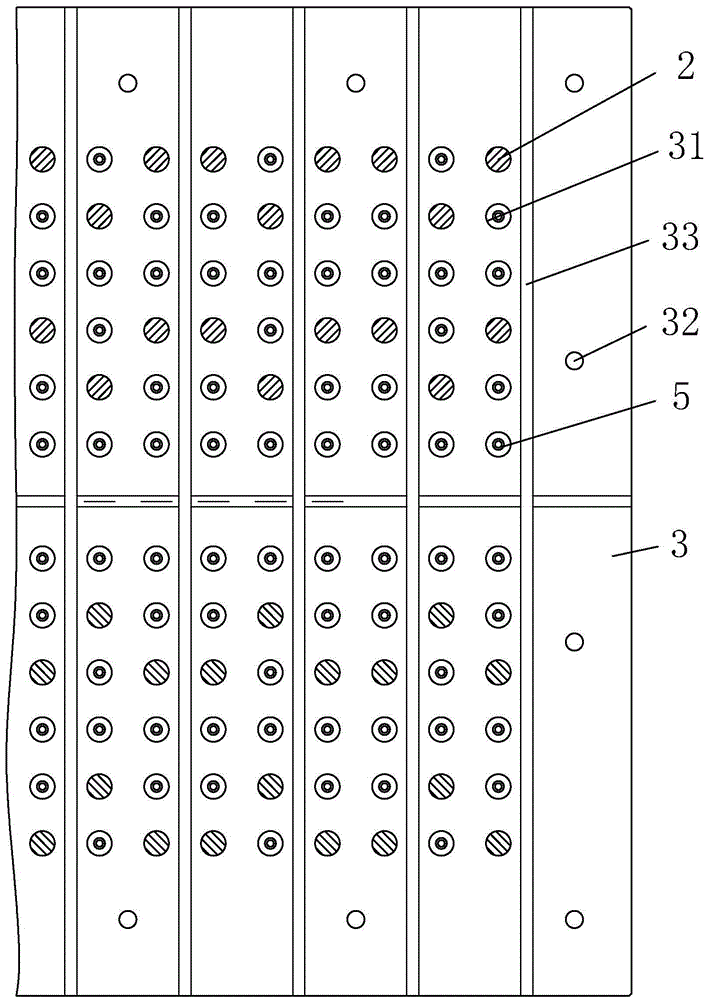

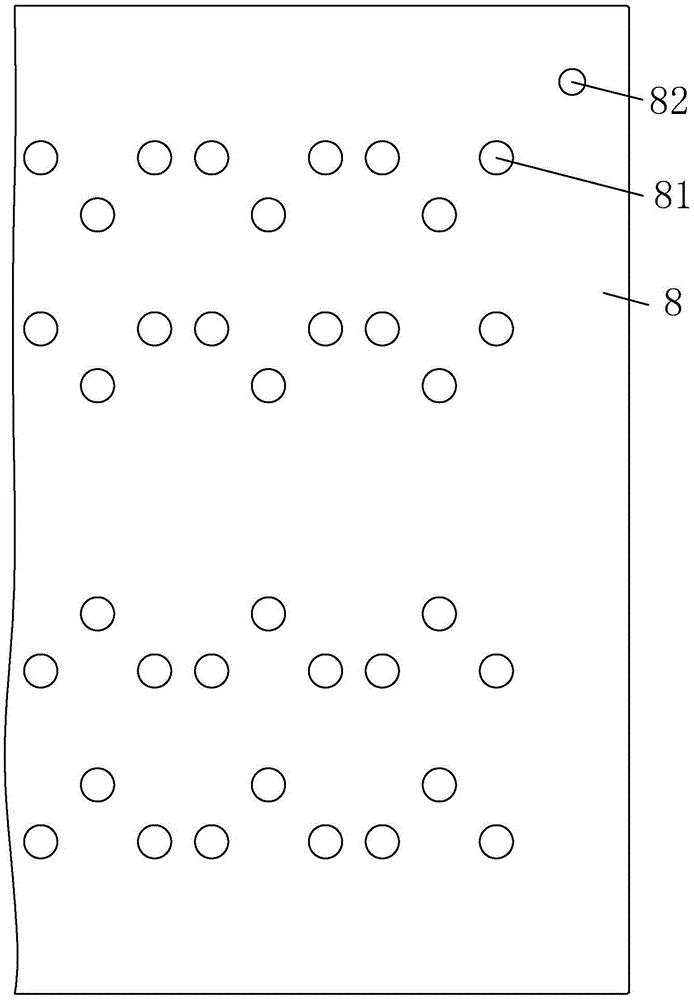

[0016] As attached figure 1 , Attached figure 2 , Attached image 3 Shown: a mold ejector rod structure, including: a workbench 3, a pallet 1 located on the lower side of the workbench 3, an ejector rod group composed of multiple ejector pins 2, a pallet lifting device, and a lower mold 4; The upper end of the worktable 3 is provided with twelve rows of guide holes 31 penetrating the lower end of the worktable 3 and having a diameter clearance fit with the diameter of the mandrel 2; the lower mold 4 includes: a lower mold with sliding holes 41 penetrating the upper and lower ends The seat 42, the side wall is in clearance fit with the sliding hole 41 and the lower mold core 44 is located in the sliding hole 41, two positioning pins 45 and twenty T-shaped screws 46 and twenty nuts (not shown in the drawings); The lower mold base 42 is detachably connected to the upper end of the workta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com