Patents

Literature

82results about How to "Error-proof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

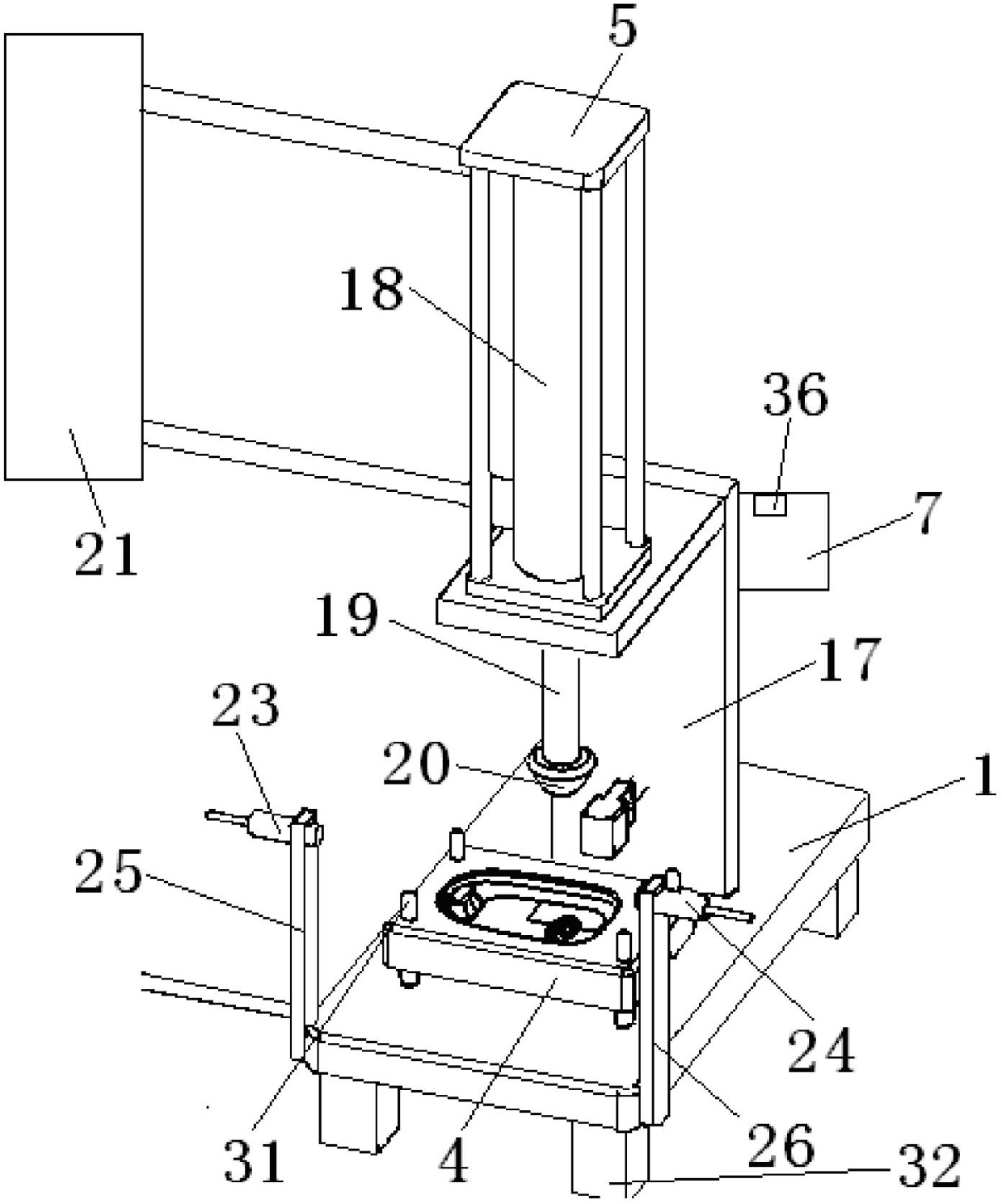

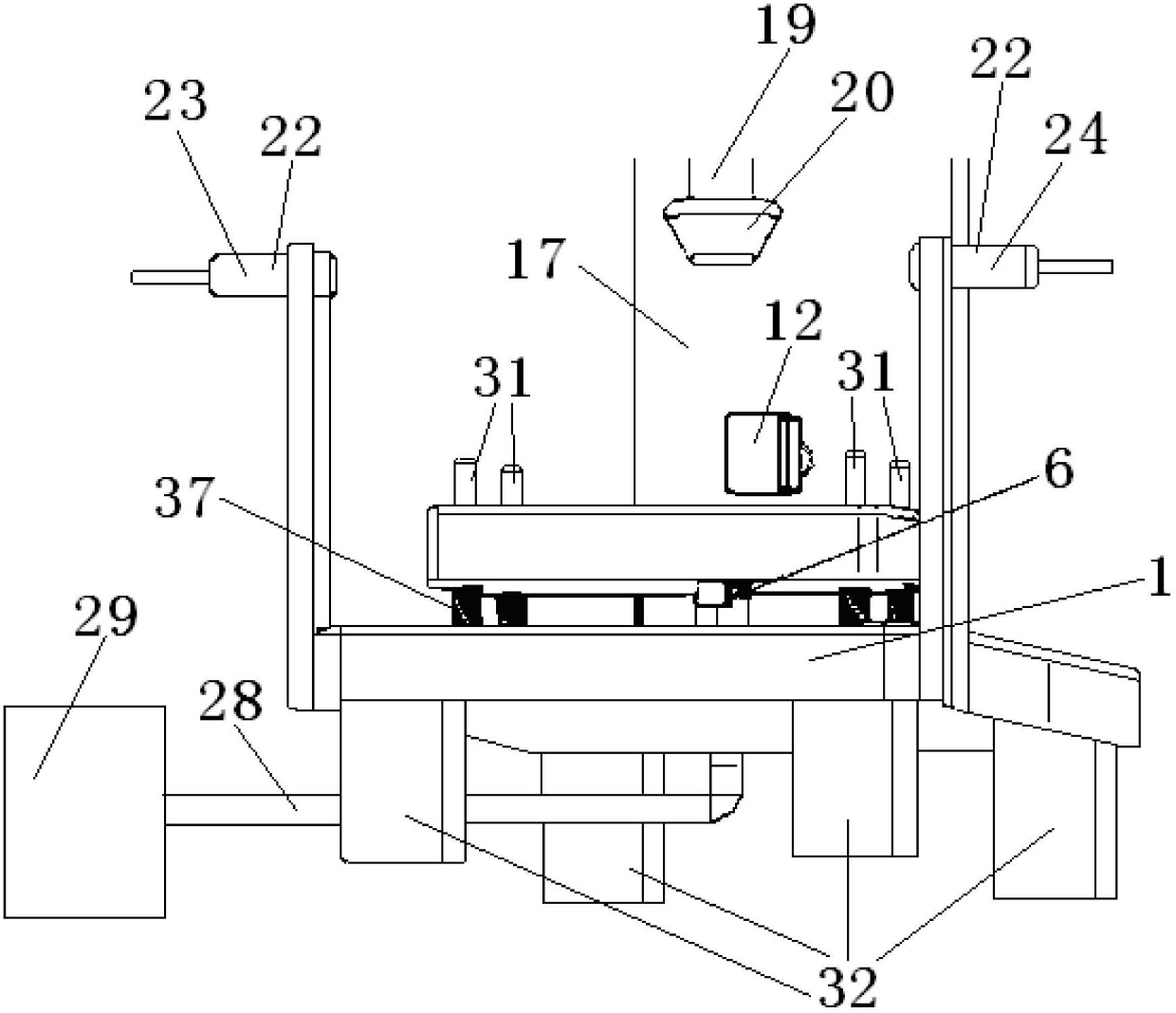

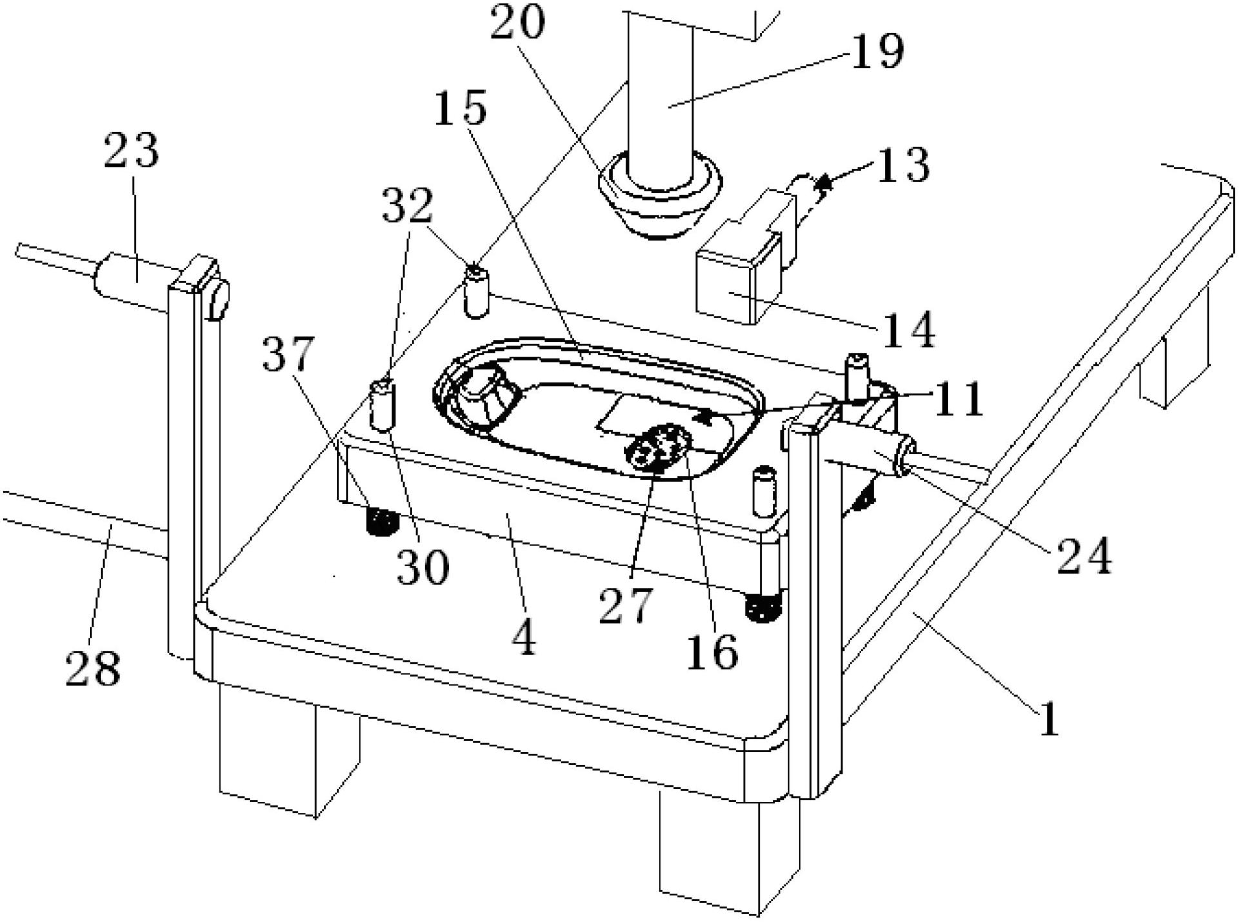

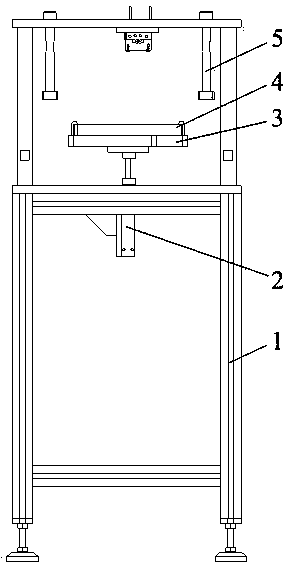

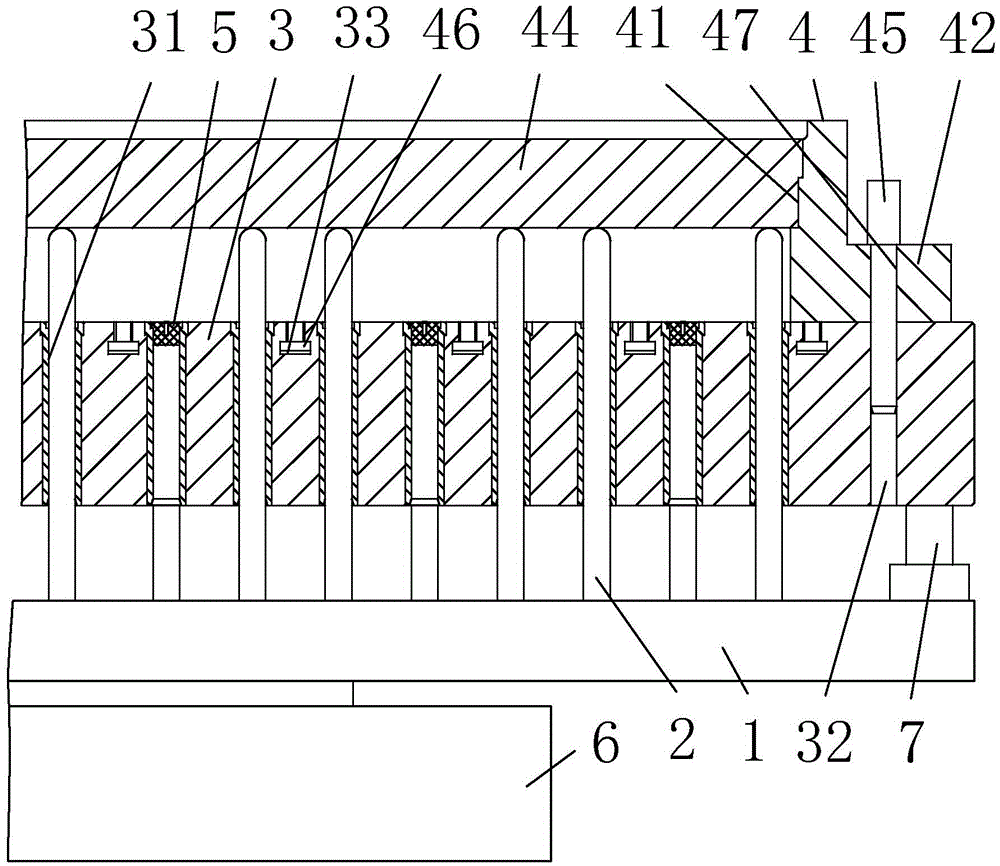

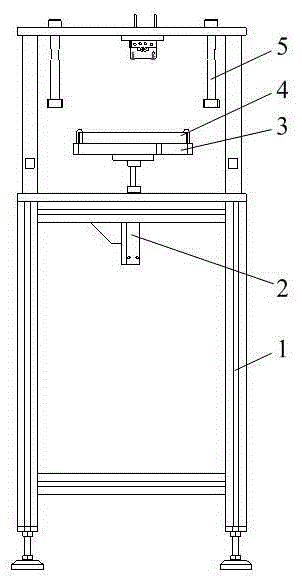

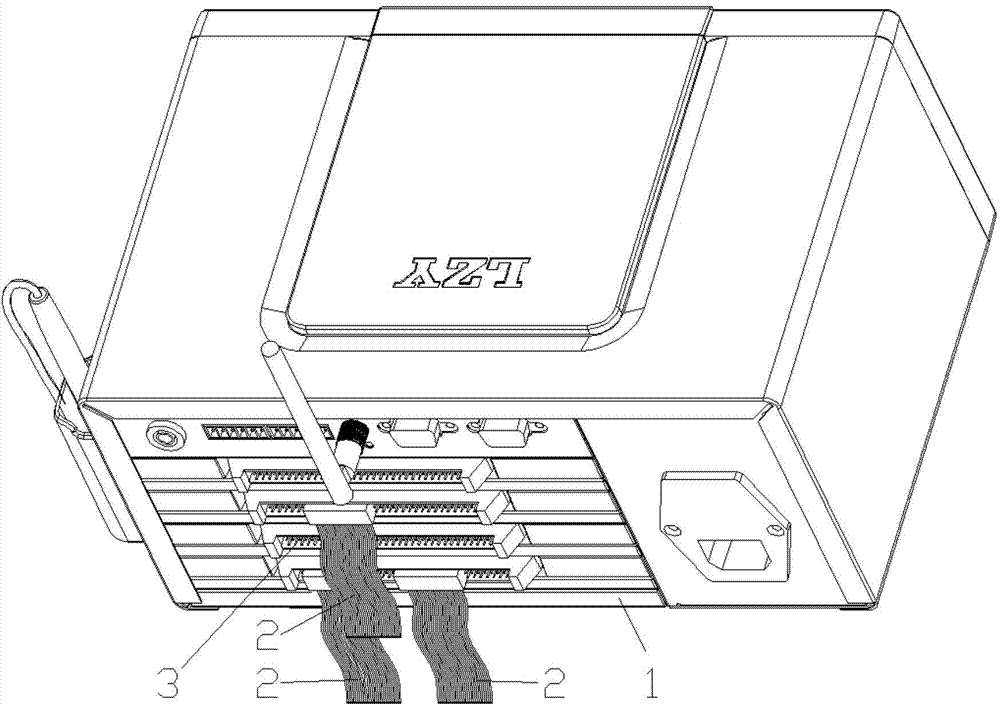

Sign pasting device and sign pasting method using same

InactiveCN102673853AGuarantee paste qualityError-proofLabelling flat rigid surfacesLabelling machinesEngineeringElectric control

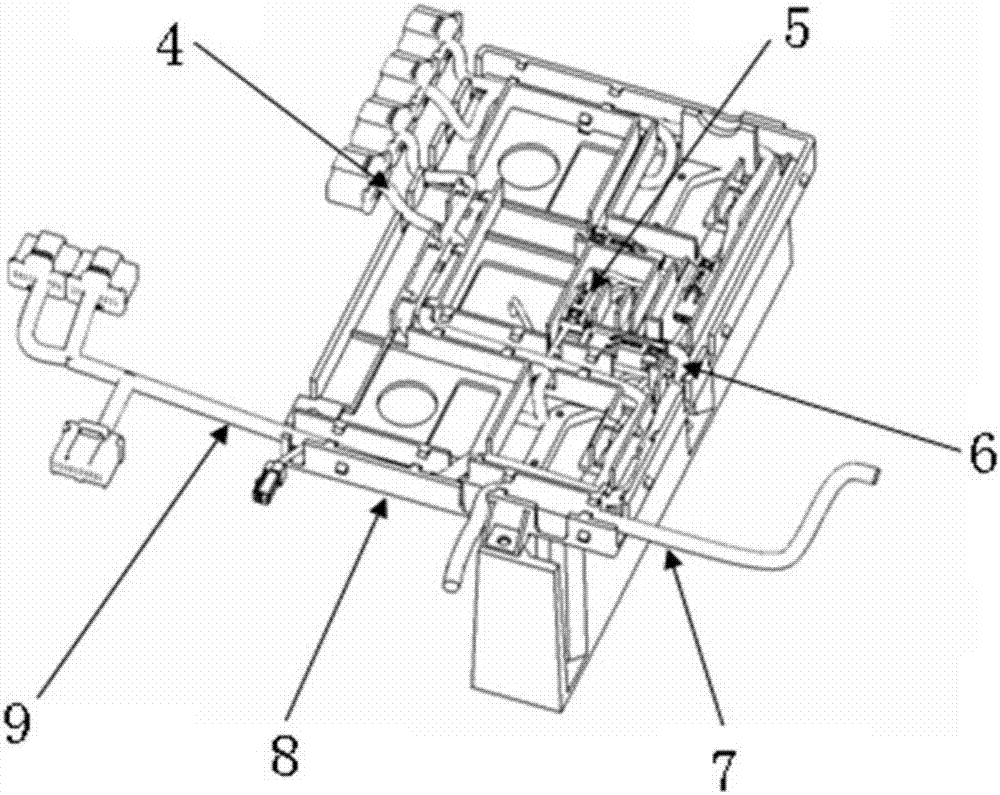

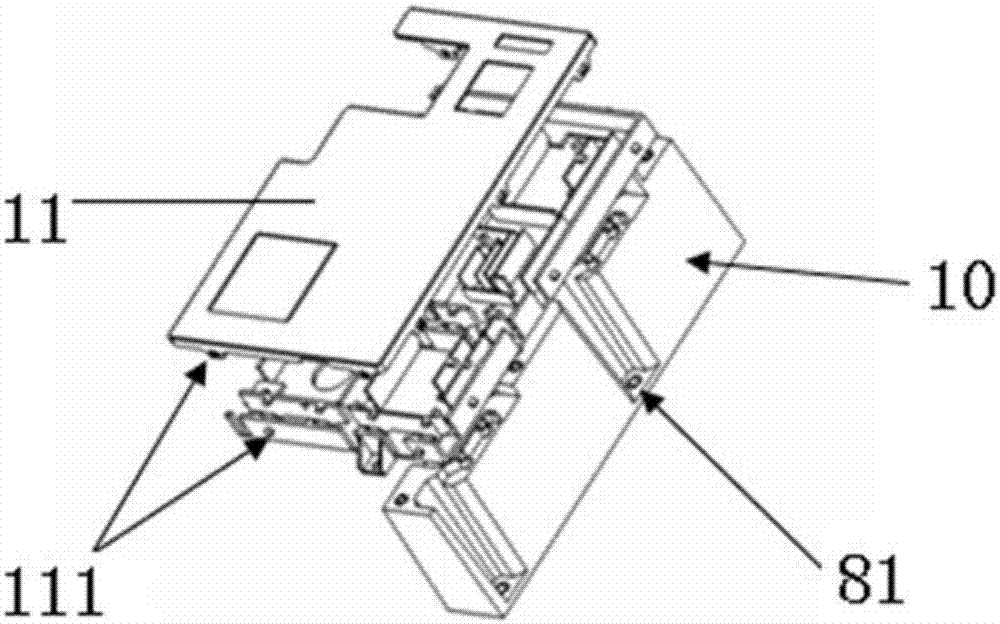

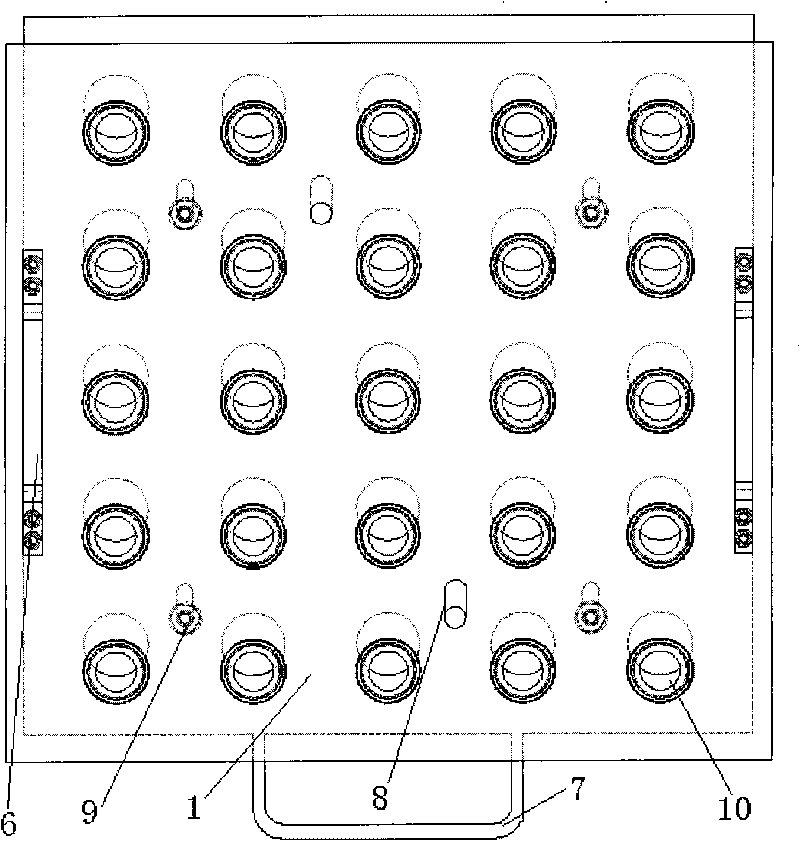

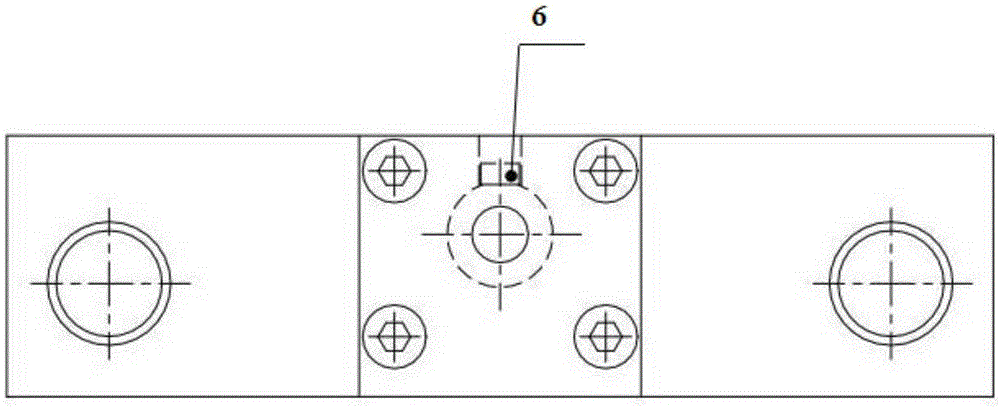

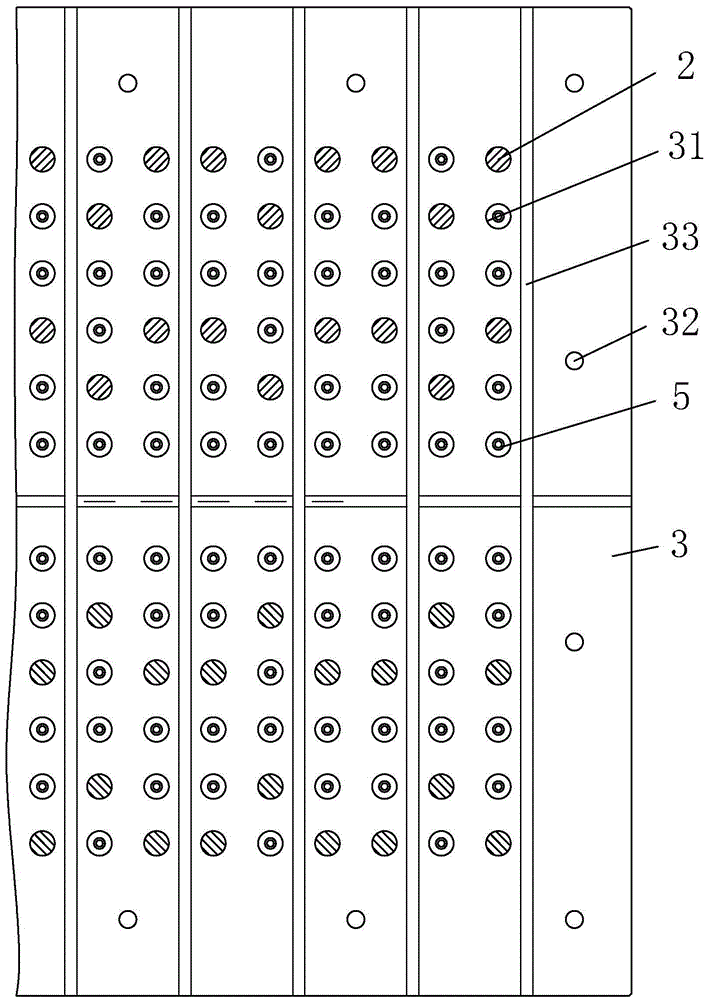

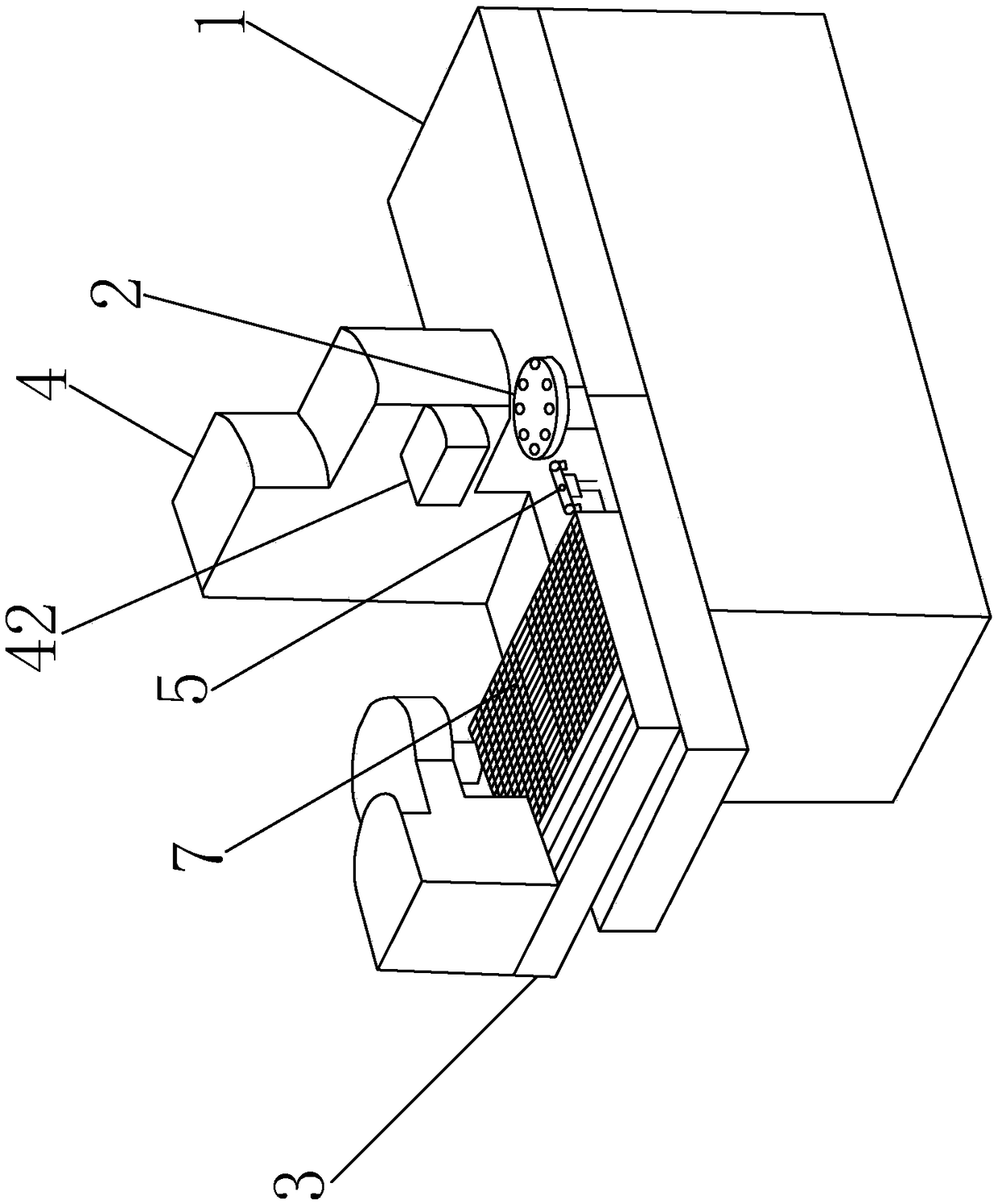

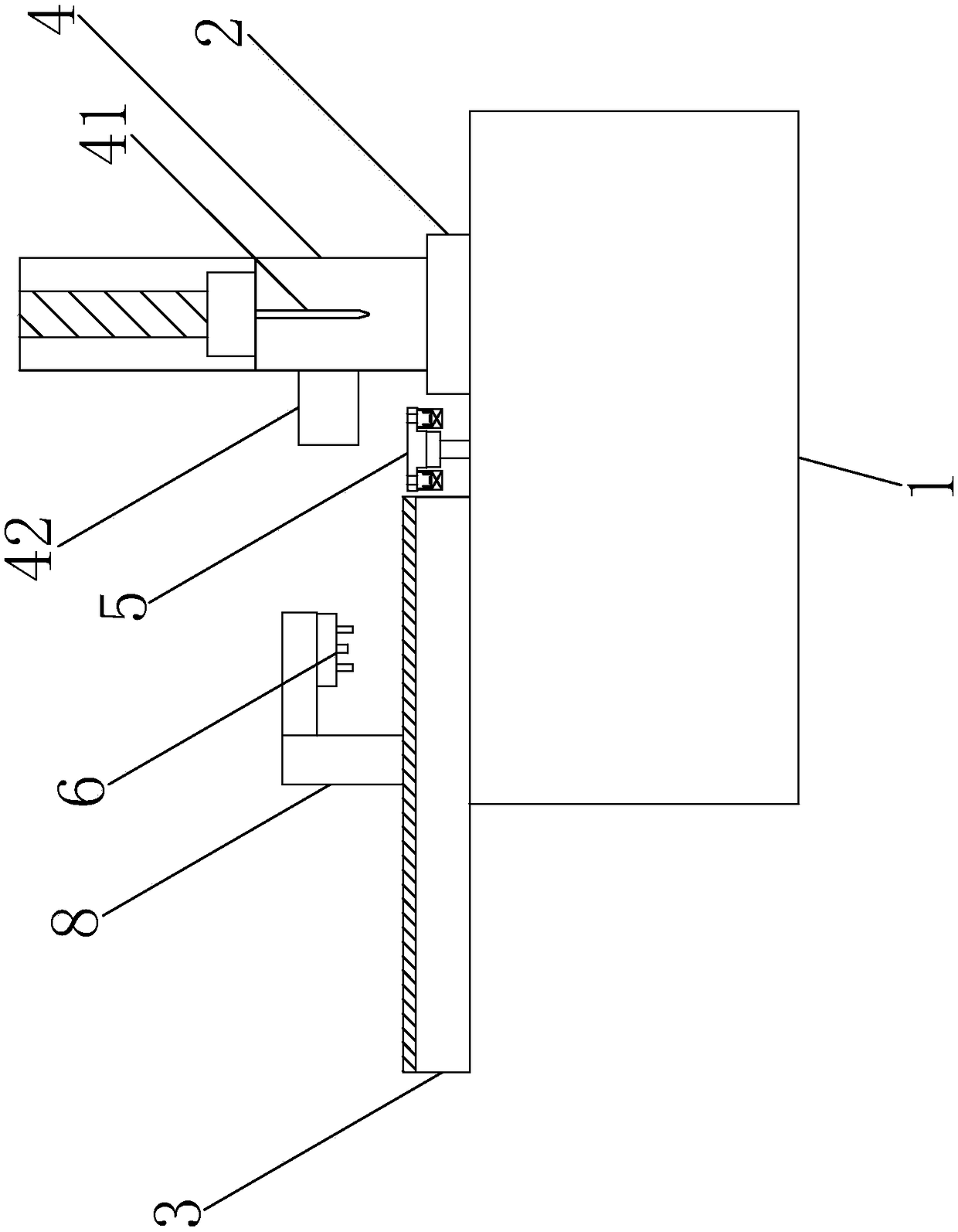

The invention provides a sign pasting device applied to the technical field of sign pasting, and further relates to a sign pasting method using the sign pasting device. The pasting device comprises bases (4) for placing a plastic part (3) to be pasted with a sign, wherein the bases (4) are arranged on a supporting platform (1); a press-fit component (5) is arranged above each base (4) and has a liftable structure; a photo sensor (6) is further arranged on the base (4) and is connected with an alarm component (36); and both the photo sensor (6) and the press-fit component (5) are connected with an electric control component (7). The sign pasting device has stable pressure during sign pasting, and has an error-proofing function so as to solve the problem of omissions and errors caused by visual fatigue of an operator; and furthermore, the sign pasting device is strongly universal and can adapt to the pasting of signs of different shapes on the plastic part.

Owner:震宇(芜湖)实业有限公司

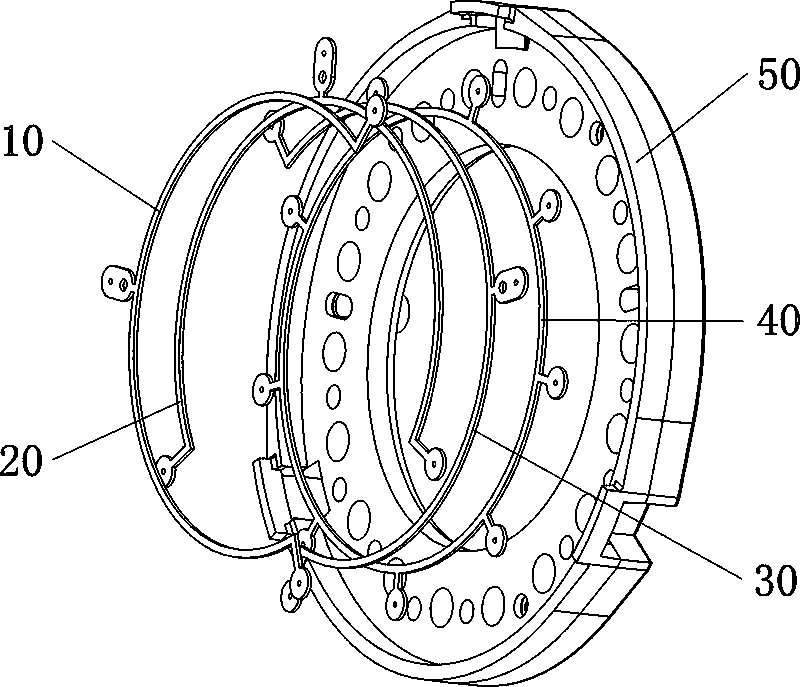

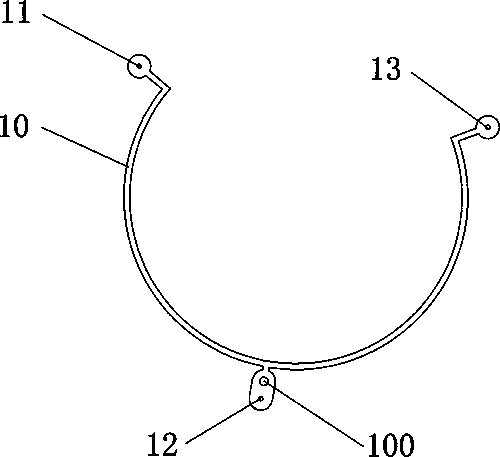

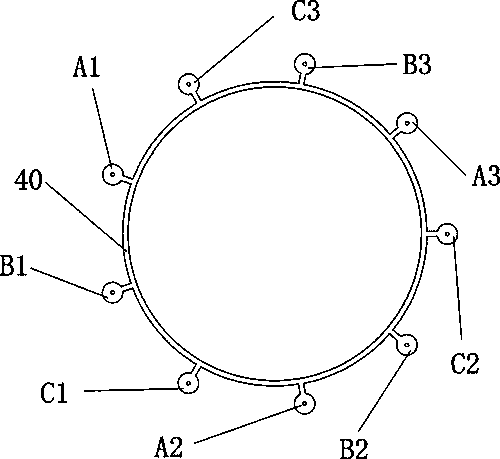

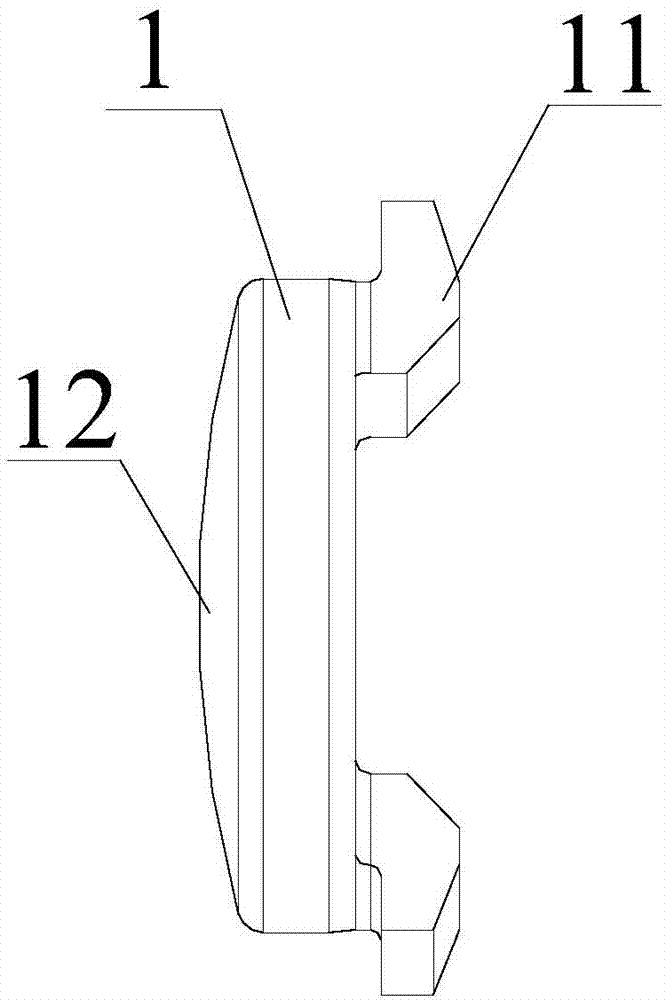

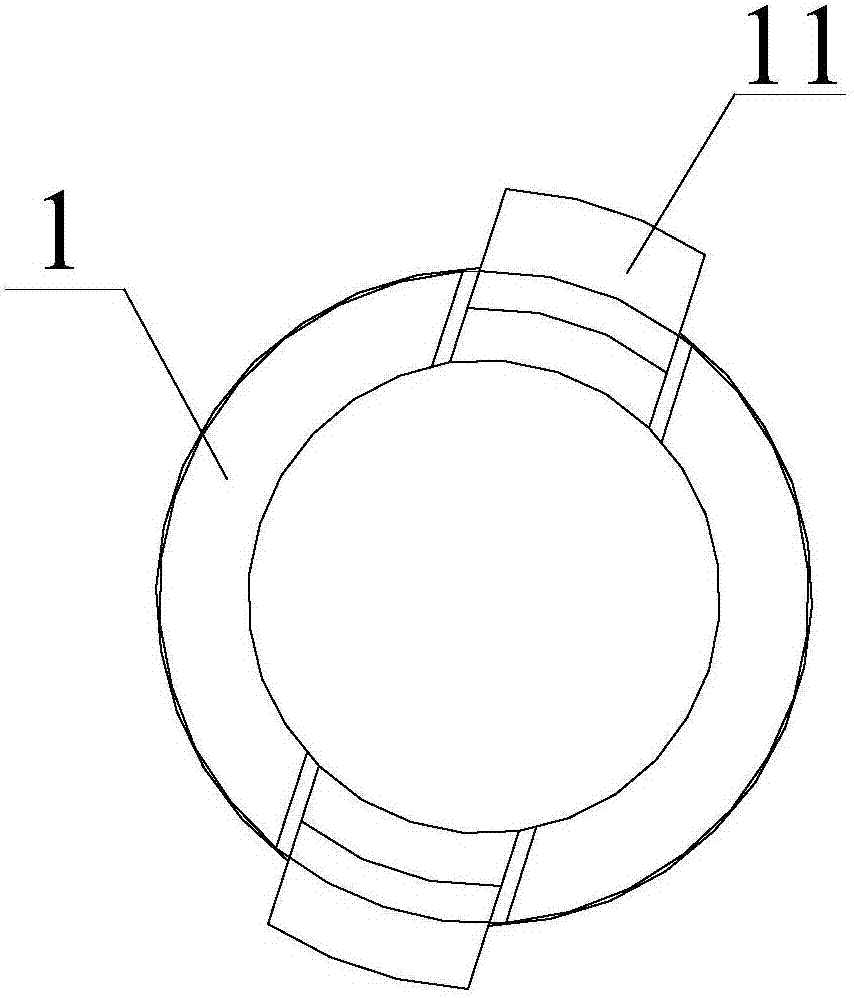

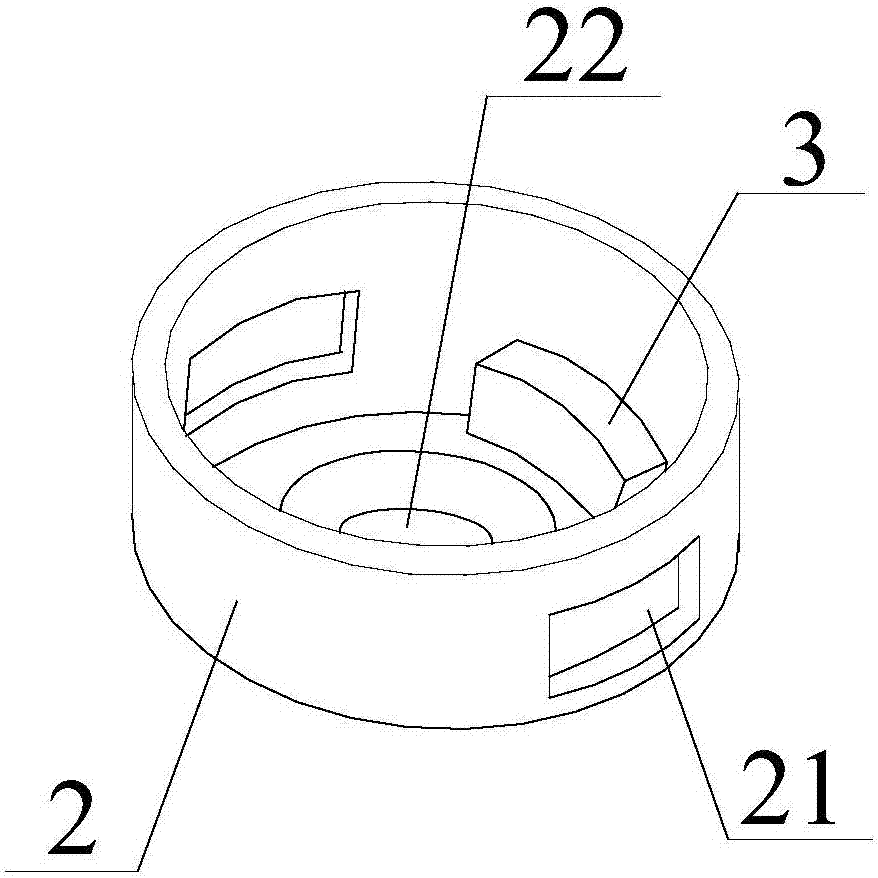

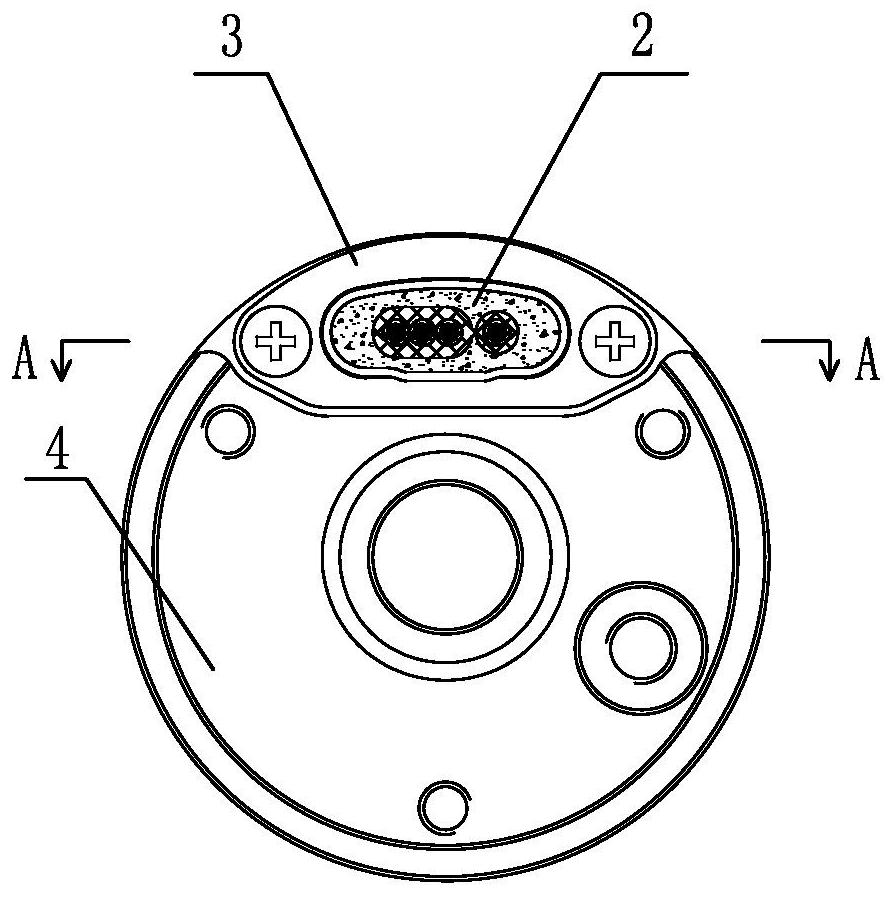

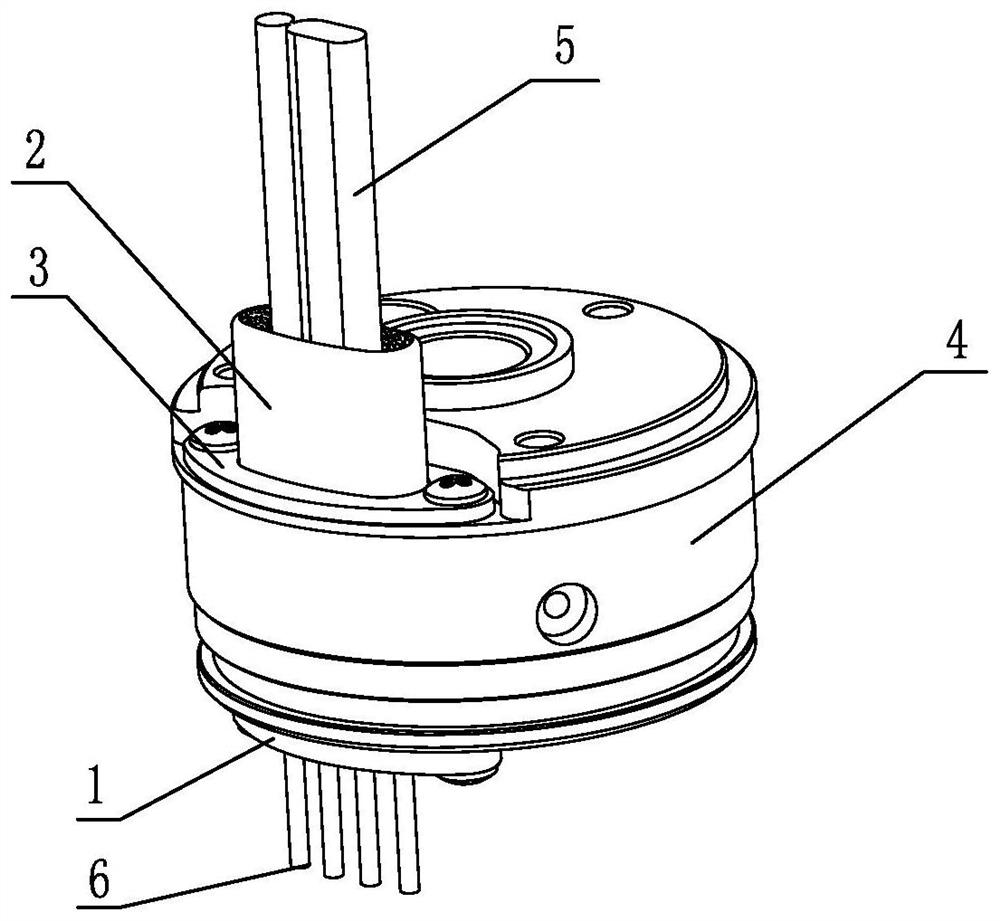

Motor stator and motor with same

InactiveCN103457370AImprove production efficiencyError-proofMagnetic circuit rotating partsWindings conductor shape/form/constructionEngineeringStator

The invention provides a motor stator which comprises a stator iron core, a coil frame, windings, an A-phase wiring piece, a B-phase wiring piece, a C-phase wiring piece and a star point wiring piece. The coil frame is disposed at two axial ends of the stator iron core. Each winding is wound on the stator iron core and the coil frame. Each winding is provided with a wire inlet end and a wire outlet end. Each wire inlet end of the winding is electrically connected with the A-phase wiring piece, the B-phase wiring piece and the C-phase wiring piece. Each wire outlet end of the winding is electrically connected with the star point wiring piece. The invention further provides a motor with the stator. By the arrangement, wiring among motor stator windings in the prior art is avoided, the structure of outward suspension of winding guide-out wires is omitted, manufacturing efficiency of wire outlet ends of motor stator windings is increased, and an anti-fault function is achieved.

Owner:BYD CO LTD

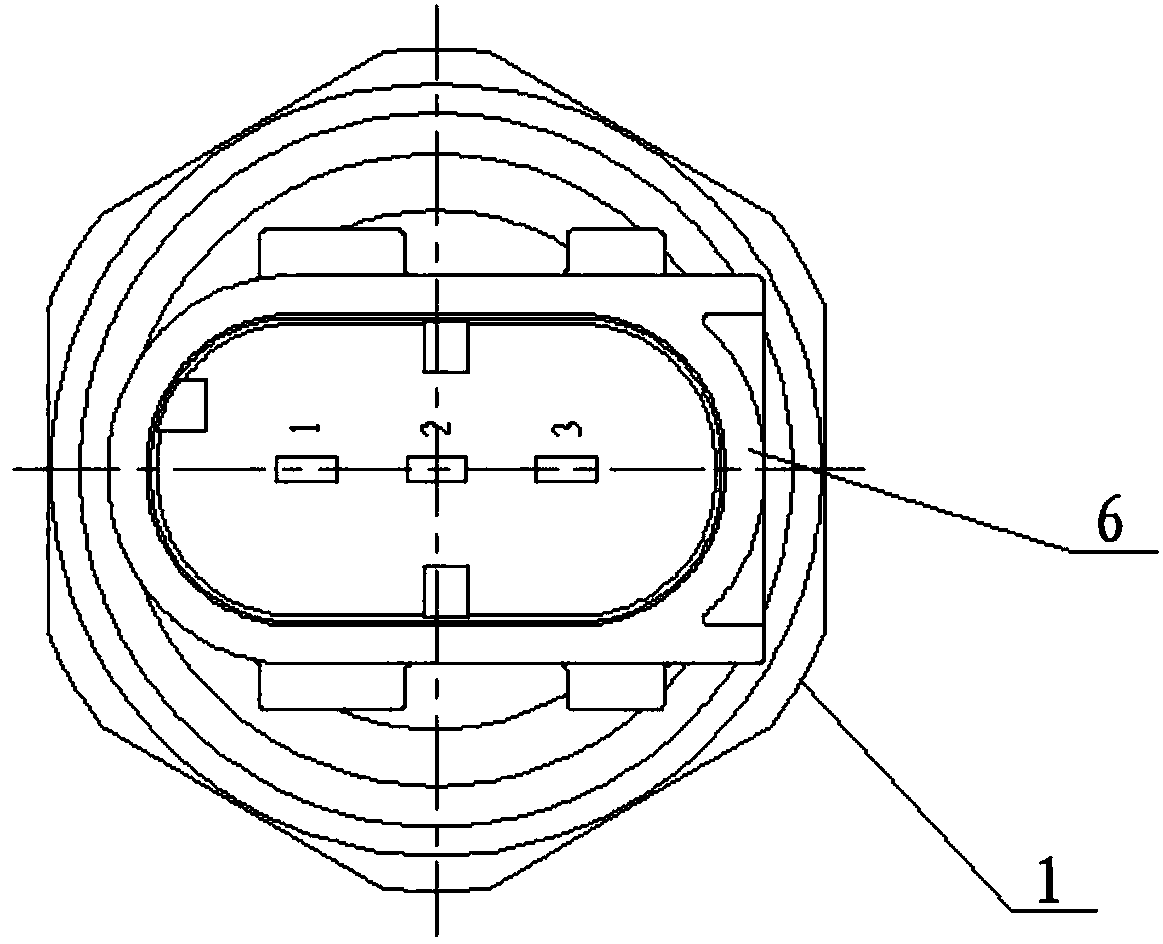

Coding method, coded graph, coded graph reading method and shooting device

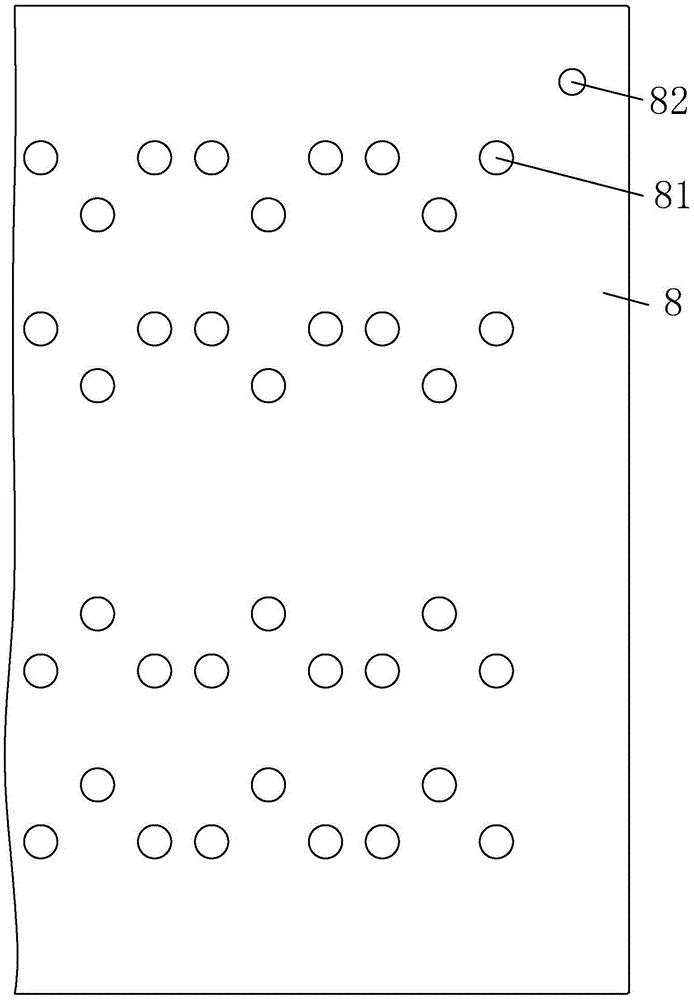

PendingCN112187284AAccurate readingExact searchError correction/detection using multiple parity bitsCode conversionCoding blockCode generation

The invention discloses a coding method, a coded graph, a coded graph reading method and a shooting device. According to the method disclosed in the invention, three of the four positioning blocks inthe coded graph are respectively positioned at three corners of the coded graph, the other positioning block is only tangent to the edge of the coded graph, and therefore an asymmetric distribution configuration of the four positioning blocks is formed. According to the method, the existing two-dimensional code standard is replaced, the authorization cost and the manufacturing cost required by theexisting two-dimensional code generation software are saved, the method is not limited by the use of the existing two-dimensional code generation software, the coded graph can be accurately and quickly positioned, and the position of the initial coded block in the coding area can be quickly found. According to the method disclosed in the invention, the size of the coding graph area and the size of the coding area can be set according to the data size of the application scene, and therefore the data information recorded by the coding graph can be flexibly set. The coding mode of the coding area is simple, and the efficiency of a scene with a small coded data size is high.

Owner:HANGZHOU HIKROBOT TECH CO LTD

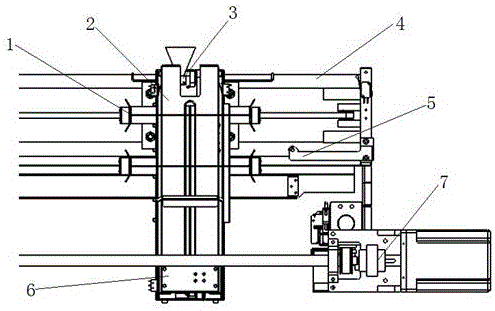

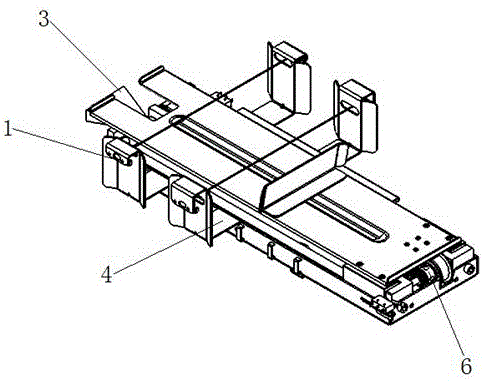

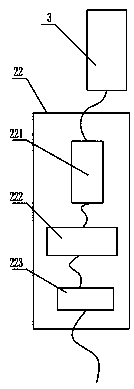

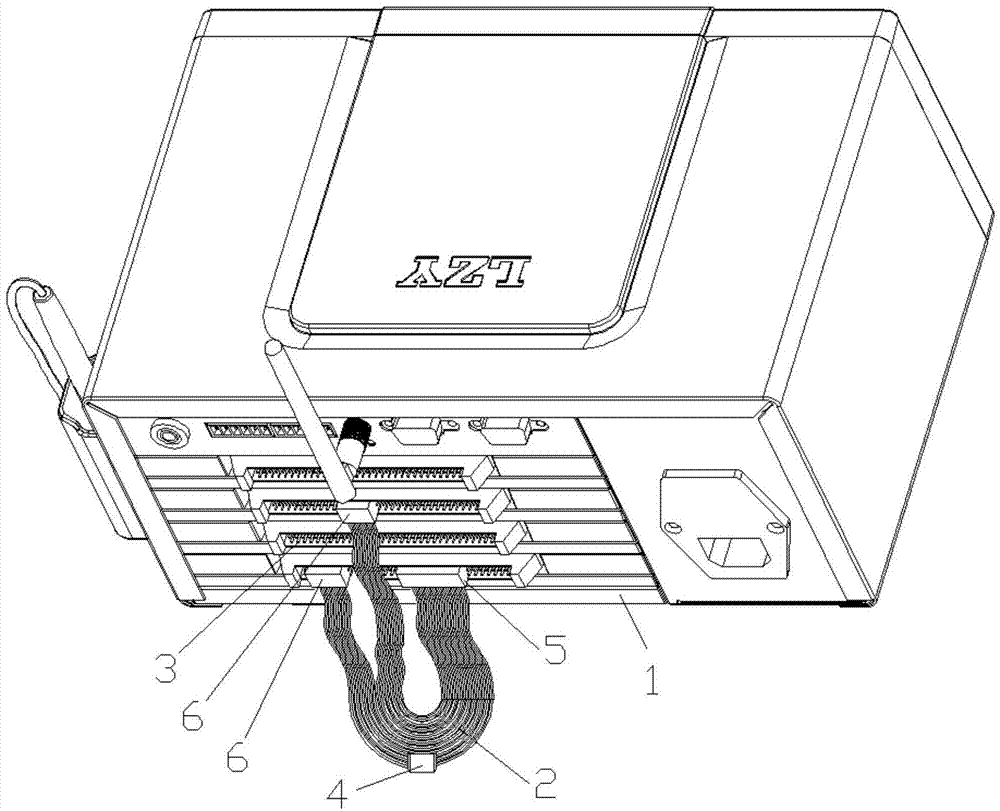

Scanning identification system capable of realizing automatic goods positioning

InactiveCN105930758AOvercome the internal environmentPrevent the wrong goodsCoin-freed apparatus detailsApparatus for dispensing discrete articlesMulti machineRemote control

The invention discloses a scanning identification system capable of realizing automatic goods positioning. The system comprises a material detection device, a material tray, a scanning head, an X-axis guide mechanism, a tray reversing mechanism, a tray telescopic movement driving mechanism and a Y-axis guide mechanism. The front end of the material tray is equipped with the scanning head; the X-axis guide mechanism, the Y-axis guide mechanism and the tray reversing mechanism are arranged under the material tray; the side edge of the material tray is provided with the material detection device; and the back end of the material tray is provided with the tray telescopic movement driving mechanism. The high-quality bar code scanning head is arranged at the place of a mechanical arm, thereby overcoming the complex and changeable internal environment in a vending machine; bar codes of the fetched goods can be confirmed again when the goods is fetched to prevent the cases of wrong goods fetching, and an anti-error function is achieved; and during multi-machine operation, through scanning head remote control, real-time selling situation of each machine can be confirmed and fed back, thereby facilitating replenishment and terminal control and the like.

Owner:SHENZHEN ICHIPSEA INTERCONNECT TECH CO LTD

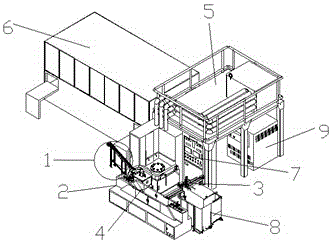

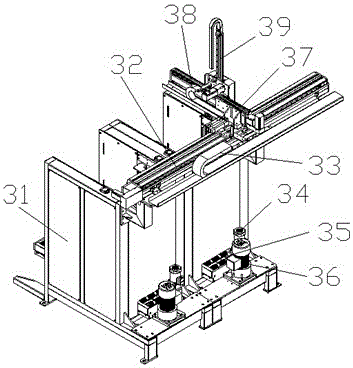

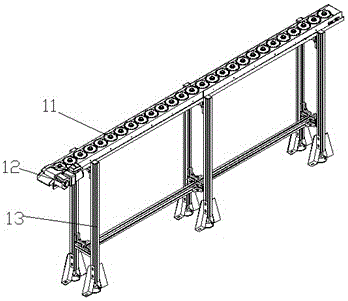

Cleaning, loading and unloading automation device

InactiveCN106269679AImprove working environmentEliminate poor quality outflowCleaning using liquidsConveyor partsQuenchingSolvent

The invention provides a cleaning, loading and unloading automation device. The device comprises a collecting conveyor, a cleaning mechanism, a lifting mechanism, a robot mechanism, an upper-layer cooling system, a water tank, a control panel, a controller, a high-frequency quenching mechanism and a high-frequency quenching power supply; the collecting conveyor is connected with the cleaning mechanism; the lifting mechanism and the robot mechanism are near the cleaning mechanism; the upper-layer cooling system is connected with the water tank, the control panel and the robot mechanism; the high-frequency quenching mechanism is connected with the high-frequency quenching power supply; and the control panel is connected with the controller. The device has an error preventing function to improve the produced product quality. The device changes the cleaning mode as an aisle form and the cleaning solvent as degreasing powder and water, so that the cost of the cleaning solvent is largely reduced when the production efficiency is improved.

Owner:无锡仓佑汽车配件有限公司

Automobile door lock sleeve detection equipment

ActiveCN103542878AStable structureHigh strengthMeasurement devicesEngineeringUltimate tensile strength

Owner:DEERFU VEHICLE LOCK ANTI THEFT SYST SHANGHAI

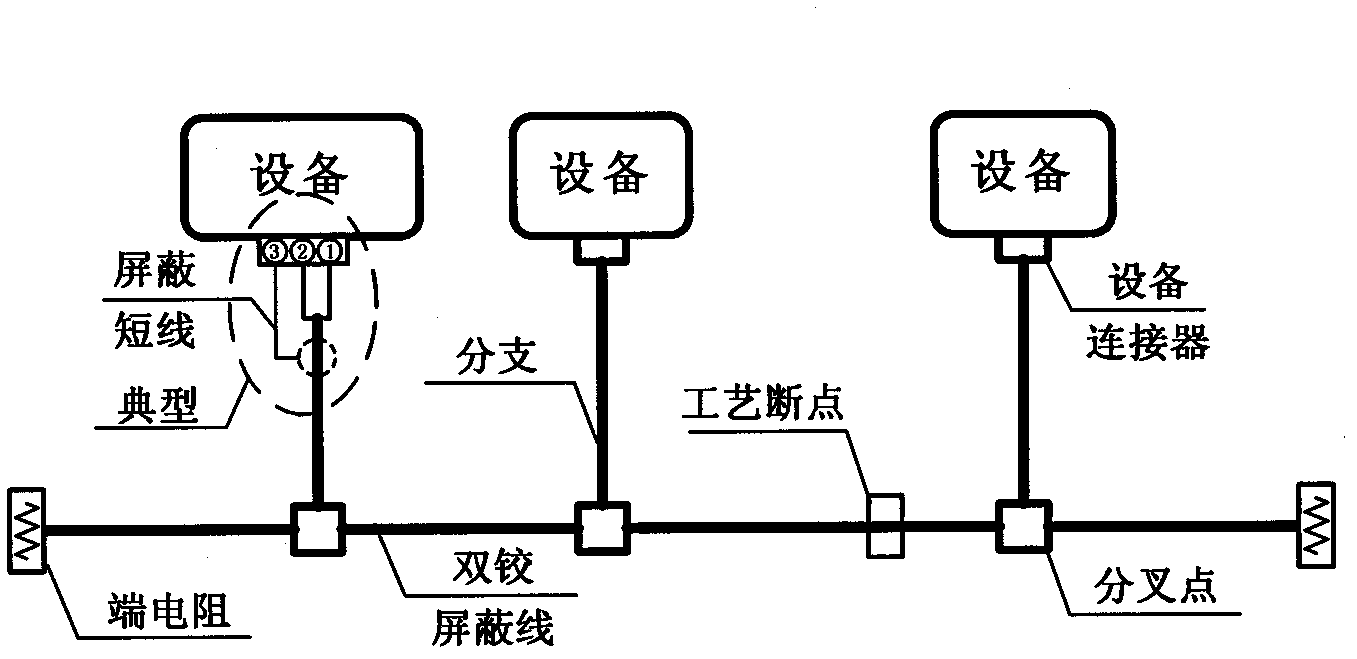

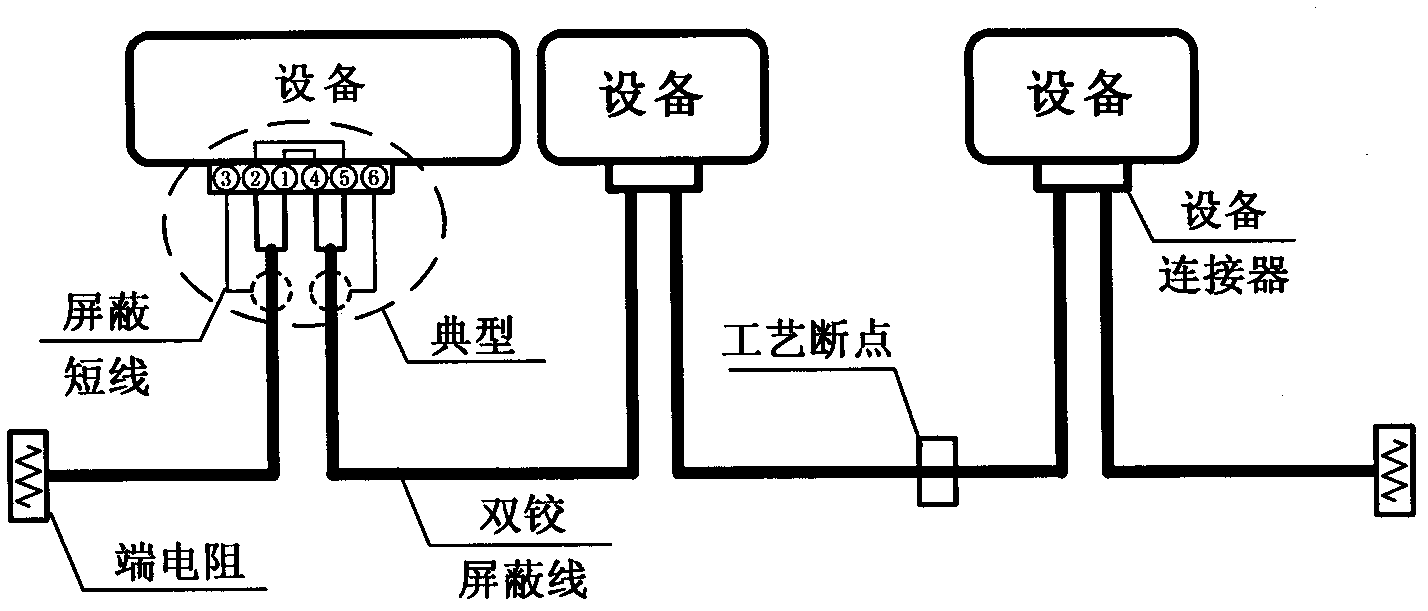

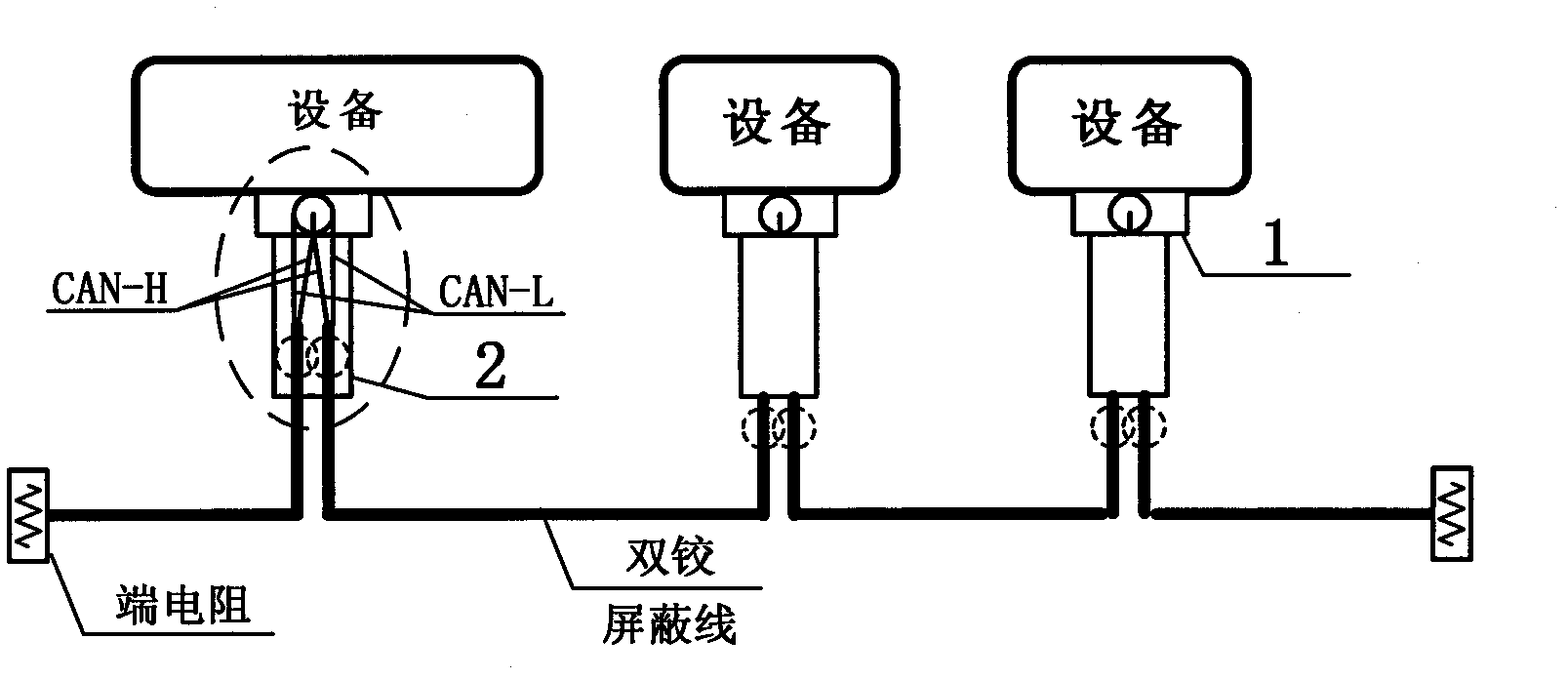

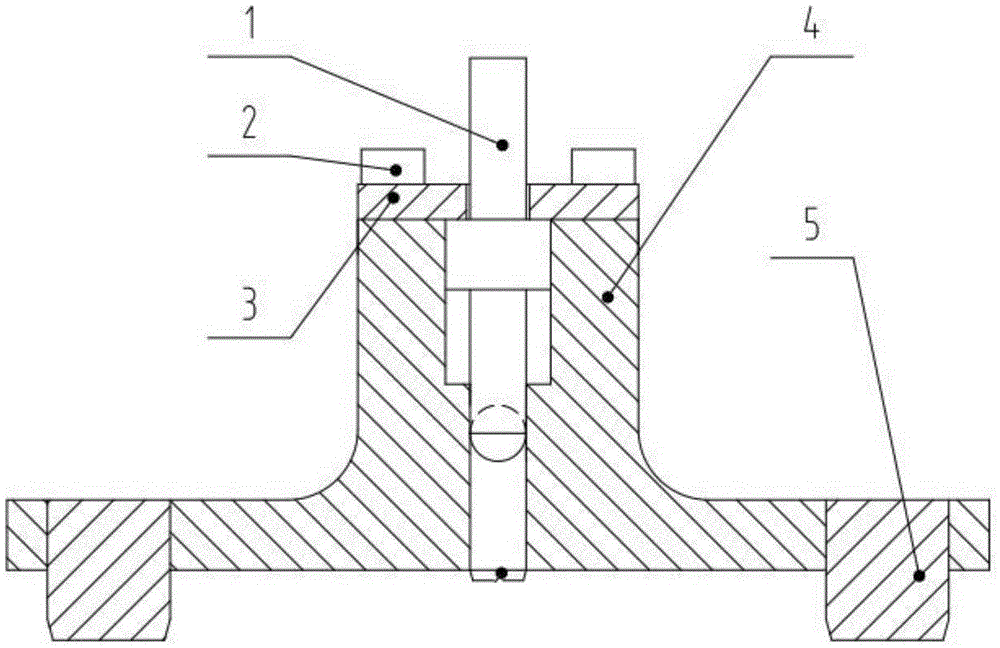

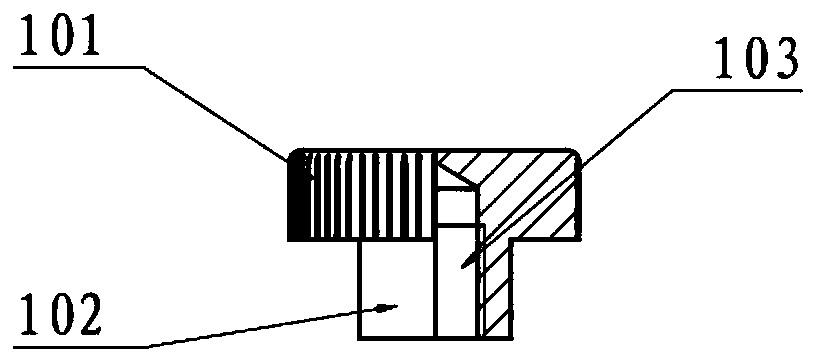

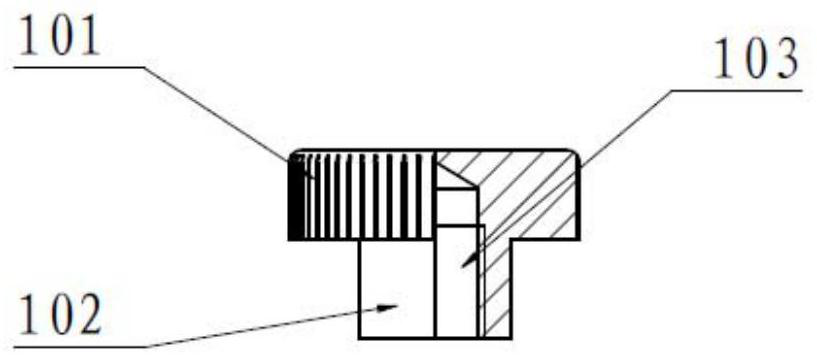

Novel electrical continuous and fully shielded CAN (controller area network) bus connection method

ActiveCN102437483AImprove electrical performanceImprove anti-electromagnetic interference performanceCoupling device detailsElectricityElectrical conductor

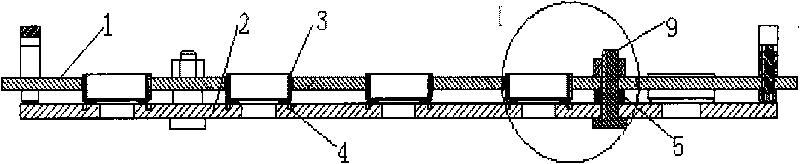

The invention relates to a novel electrical continuous and fully shielded CAN (controller area network) bus connection method, belonging to a communication technology, in particular to an improvement of a bus connection method. The method is characterized in that a coaxial double-wire electrical connector (1) is adopted, CAN-H core wires of two CAN bus cables are connected with an internal contact coupler (core conductor) (5) in a plug of the coaxial double-wire electrical connector (1) and are also connected with an external contact coupler (outer conductor) (6) of the plug of the coaxial double-wire electrical connector (1), two CAN buses are inserted into a shielding tail clamp (2) of the plug of the coaxial double-wire electrical connector (1), a shielding sleeve is connected with the shielding tail clamp (2) of the plug through welding, the shielding tail clamp (2) is connected with a connector plug shell (3) through welding, and the plug shell (3) is connected with a shell of a device through a plug nut (4). The resistance of the CAN buses against electromagnetic interference can be improved greatly, and the reliability and security of a CAN bus network can be enhanced; and the constructed dual-redundant CAN bus network has a physical error prevention function.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

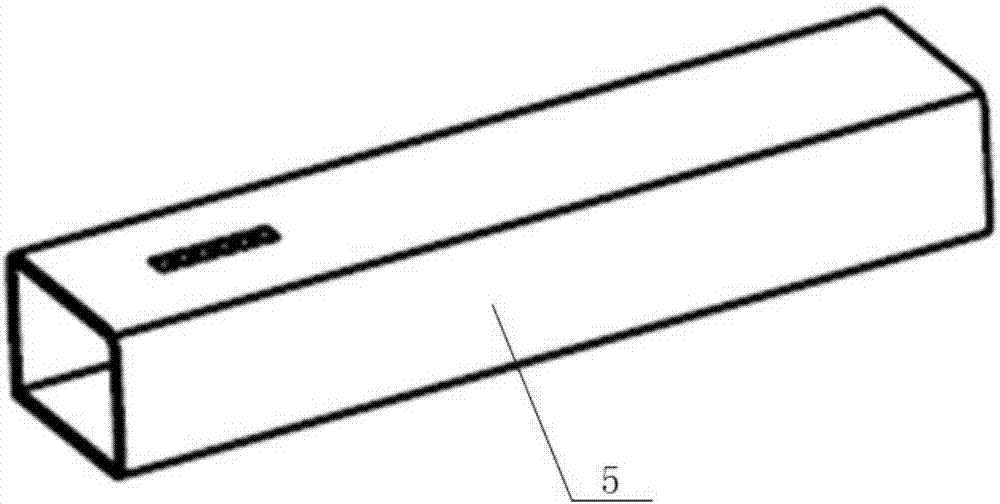

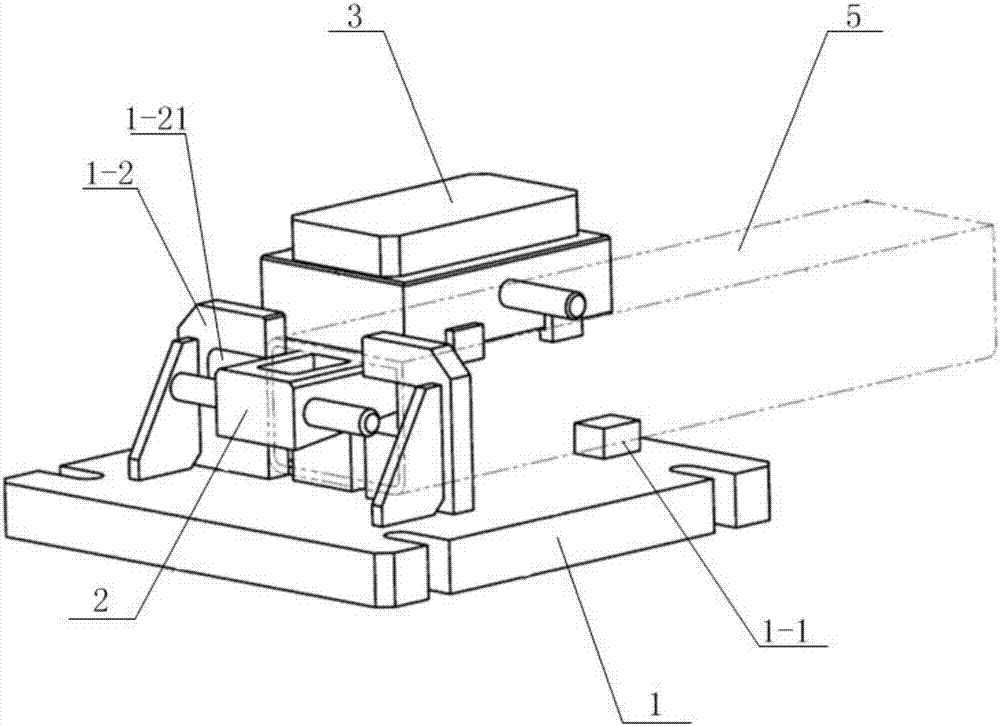

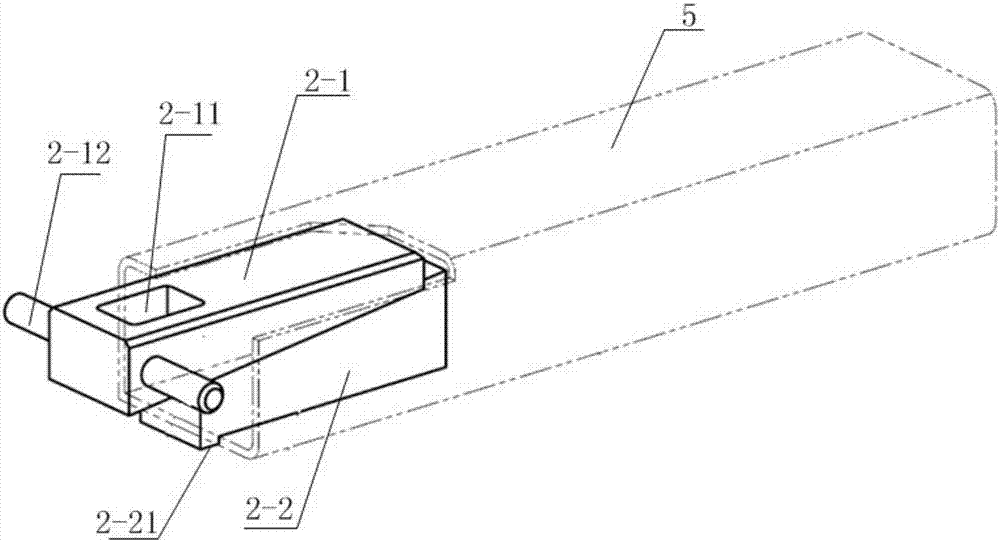

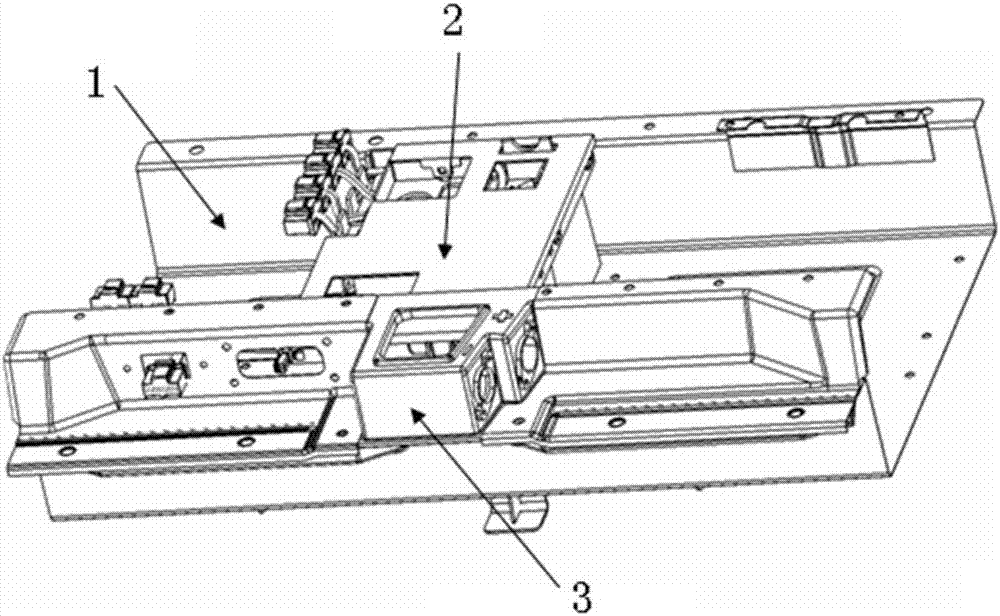

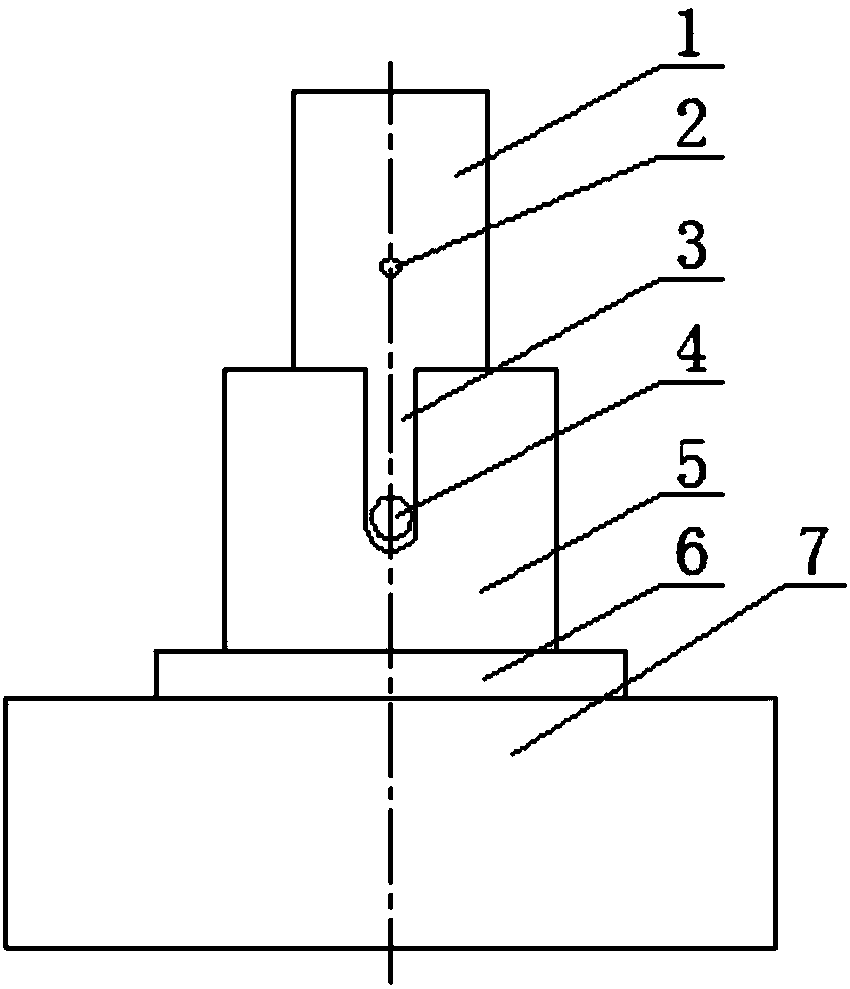

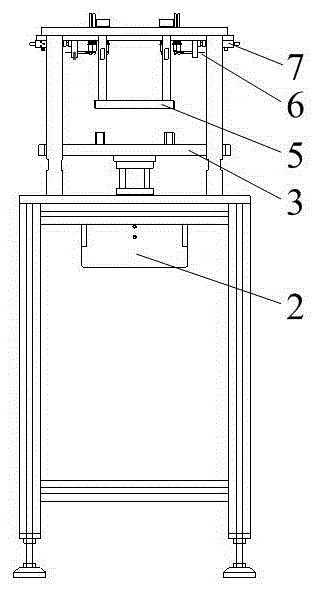

Hollow square tube character pressing device

ActiveCN107234888ARapid positioningEffective positioningStampingGlass productionPermanent markerStructural engineering

The invention relates to a hollow square tube character pressing device. The hollow square tube character pressing device is characterized by comprises a lower mold plate, a wedge block support, an upper mold assembly and a demolding tapered wedge which are used in cooperation; the lower mold plate is provided with a side positioning stopping part and an end positioning stopping part; the wedge block support comprises an upper wedge block and a lower wedge block, self-locking slopes which are matched with each other are machined at the lower portion of the upper wedge block and the upper portion of the lower wedge block, and the upper wedge block is provided with a square hole where the demolding tapered wedge is inserted; and the upper mold assembly comprises a fixing plate, an initial block and a pressing plate, the fixing plate is arranged at the bottom of the pressing plate, and the initial block is installed in a character block square hole in the middle of the bottom face of the fixing plate. The hollow square tube character pressing device is fastened into a hollow square tube in a wedged manner, looseness caused by slippage of the upper wedge block during pressing printing can be avoided, the beneficial effects of being large in support body strength, simple in operation and convenient are achieved, deep type permanent marker pressing can be achieved, and pressing printing deformation can be avoided.

Owner:CRRC MEISHAN

Wiring harness protection structure

ActiveCN107230953AEnsure safetyGood electrical protectionElectrical apparatusElectric/fluid circuitLow voltageEngineering

The invention relates to a wiring harness protection structure. The wiring harness protection structure comprises a wiring harness fixation apparatus, a fixed bracket, a low-voltage wiring harness and a high-voltage wiring harness; the fixed bracket is fixed on the lower shell of a battery pack; the wiring harness fixation apparatus is fixed on the fixed bracket; the low-voltage wiring harness and the high-voltage wiring harness are both arranged in the wiring harness fixation apparatus; the wiring harness fixation apparatus comprises a wiring harness fixation plate and a fixation plate cover plate; the fixation plate cover plate and the wiring harness fixation plate are clamped through inverse buckles in a matching manner; and the wiring harness fixation plate is fixed on the lower shell of the battery pack through the fixed bracket. By virtue of the technical scheme, the problems existing in fixation and protection of the high-voltage cable and the low-voltage wiring harness in the battery pack, and in fixation and routing arrangement of the high-voltage and low-voltage wiring harness system of the battery pack are solved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

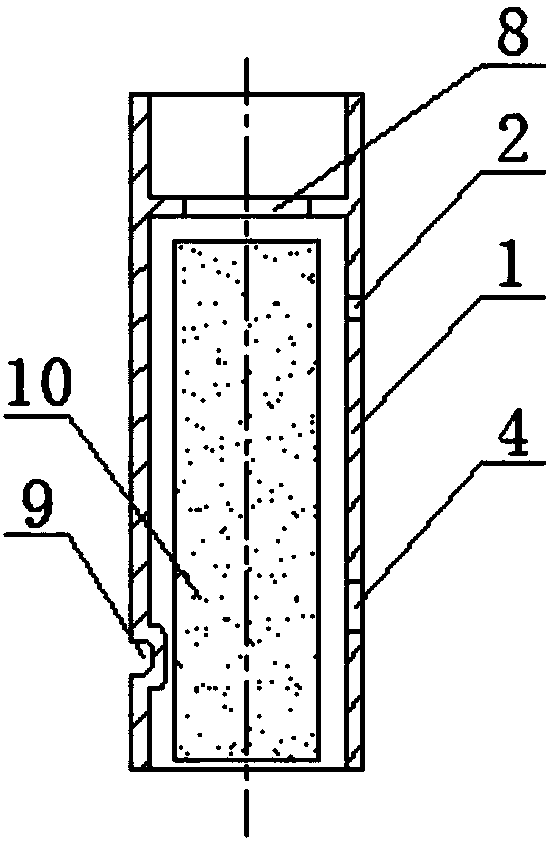

Framework charging device

The invention discloses a framework charging device, which comprises an upper cover plate and a lower drawing plate, wherein a bushing ring is arranged between the upper cover plate and the lower drawing plate, the upper cover plate and the lower drawing plate are respectively provided with strip-shaped positioning pin holes, bolts respectively penetrate through the positioning pin holes, the upper cover plate and the lower drawing plate are fixedly connected via the bushing ring, framework arranging holes are distributed on the upper cover plate, and the lower drawing plate under the framework arranging holes is provided with annular mistake-proof grooves. The invention greatly reduces the auxiliary time for production, changes different bushing rings, saves cost to a certain extent, and has the mistake-proof function.

Owner:邱强

Detection device with mistake-proofing function

InactiveCN108246960AEasy to operateOvercome bad problemsMeasurement devicesSurface mountingEngineering

Owner:林德英利(天津)汽车部件有限公司

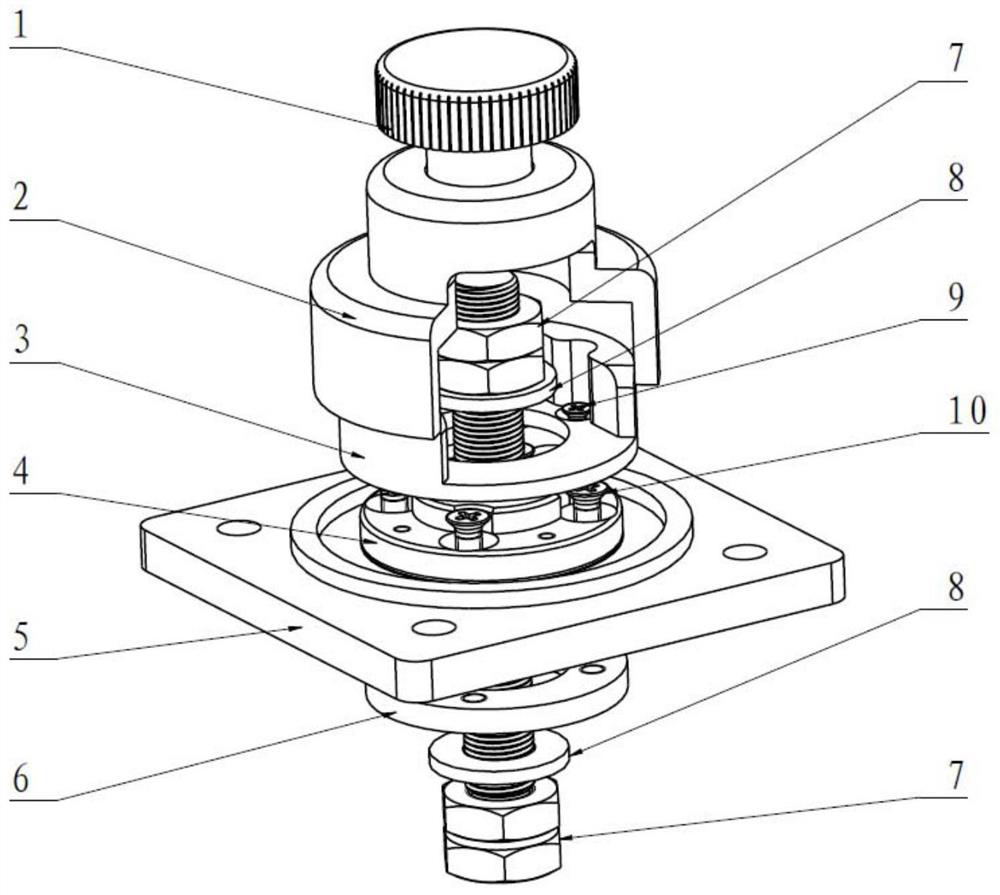

Mounting tool of inclined plane locating pin

InactiveCN105345721AEasy to operateError-proofMetal-working hand toolsEngineeringMechanical engineering

Owner:TIANJIN TEEK TRANSMISSION

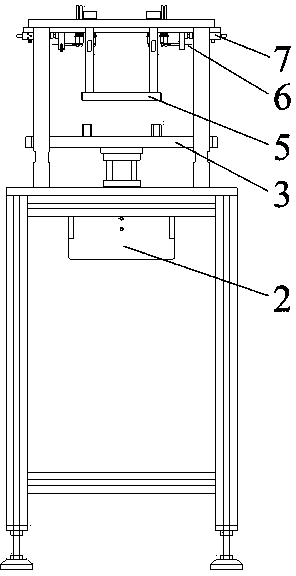

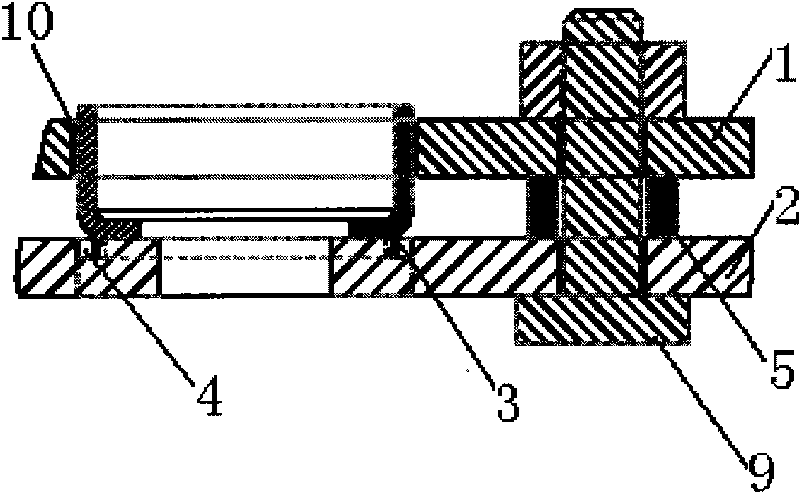

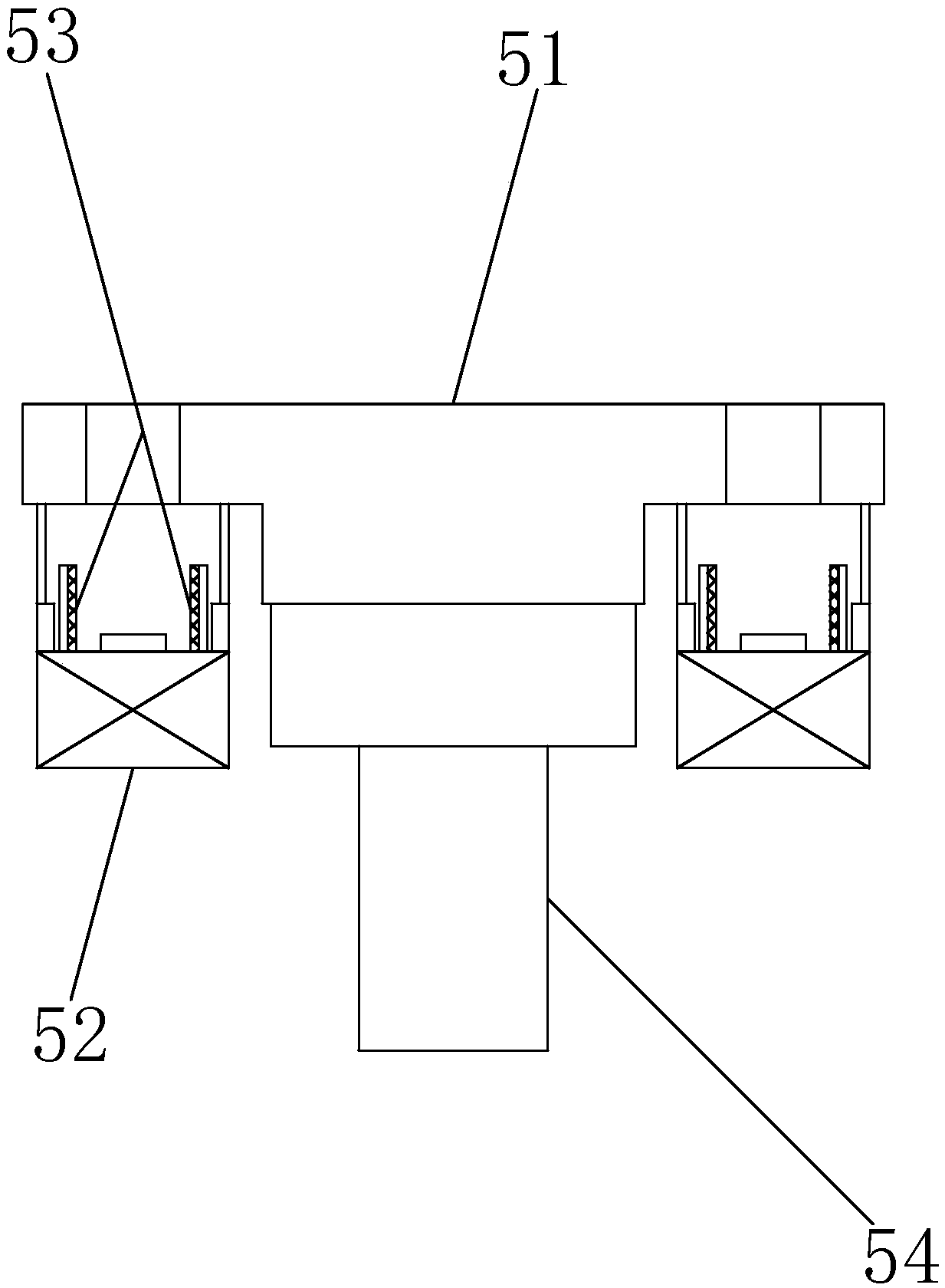

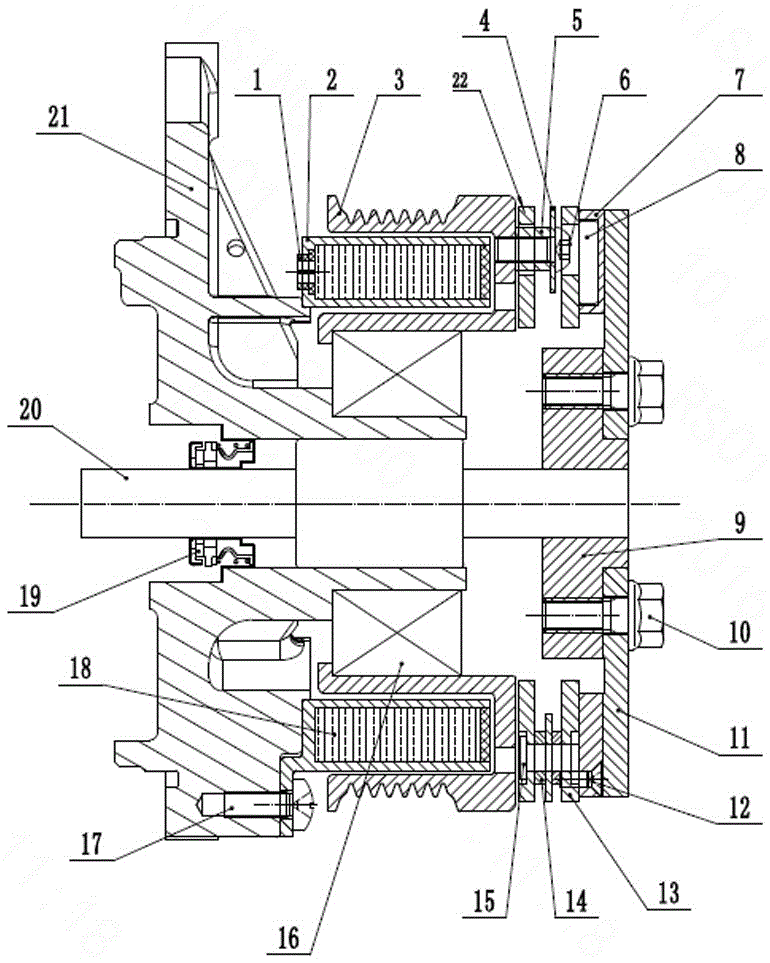

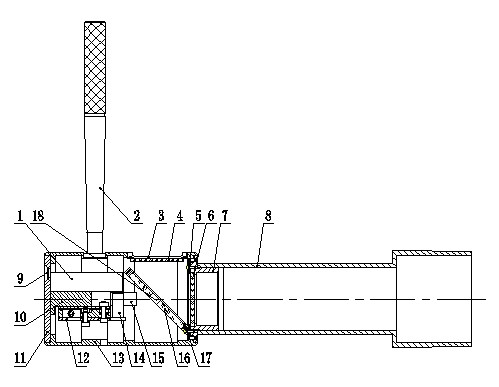

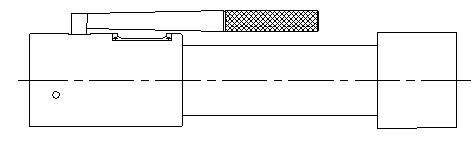

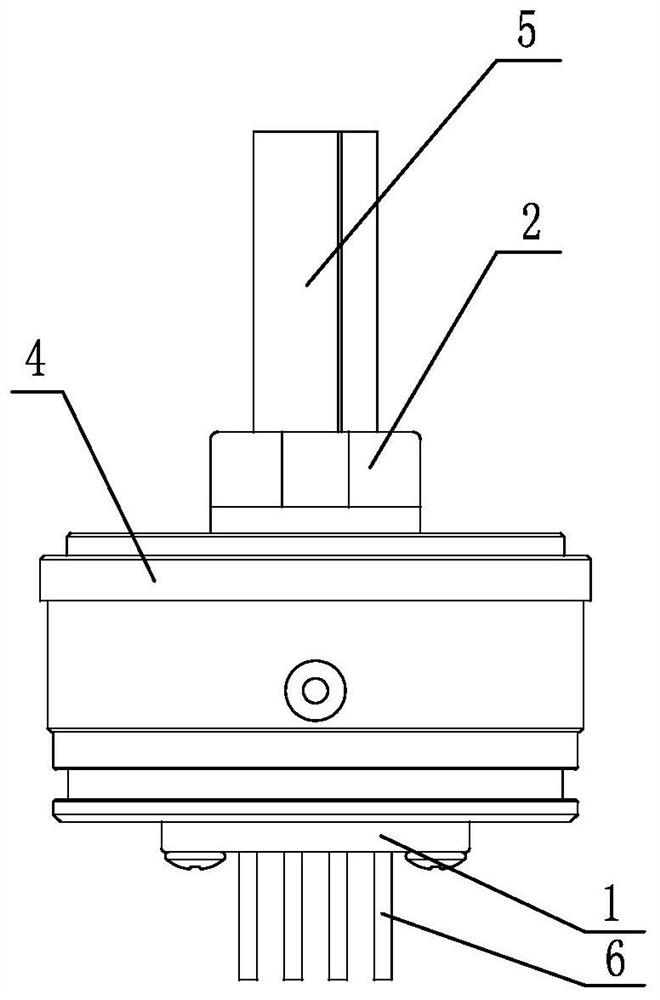

Tapered roller bearing press-fitting mechanism, press-fitting method and press-fitting mistake-proofing method thereof

InactiveCN109500569AStable and correct installationEnsure personal safetyMetal working apparatusFixed frameMedial axis

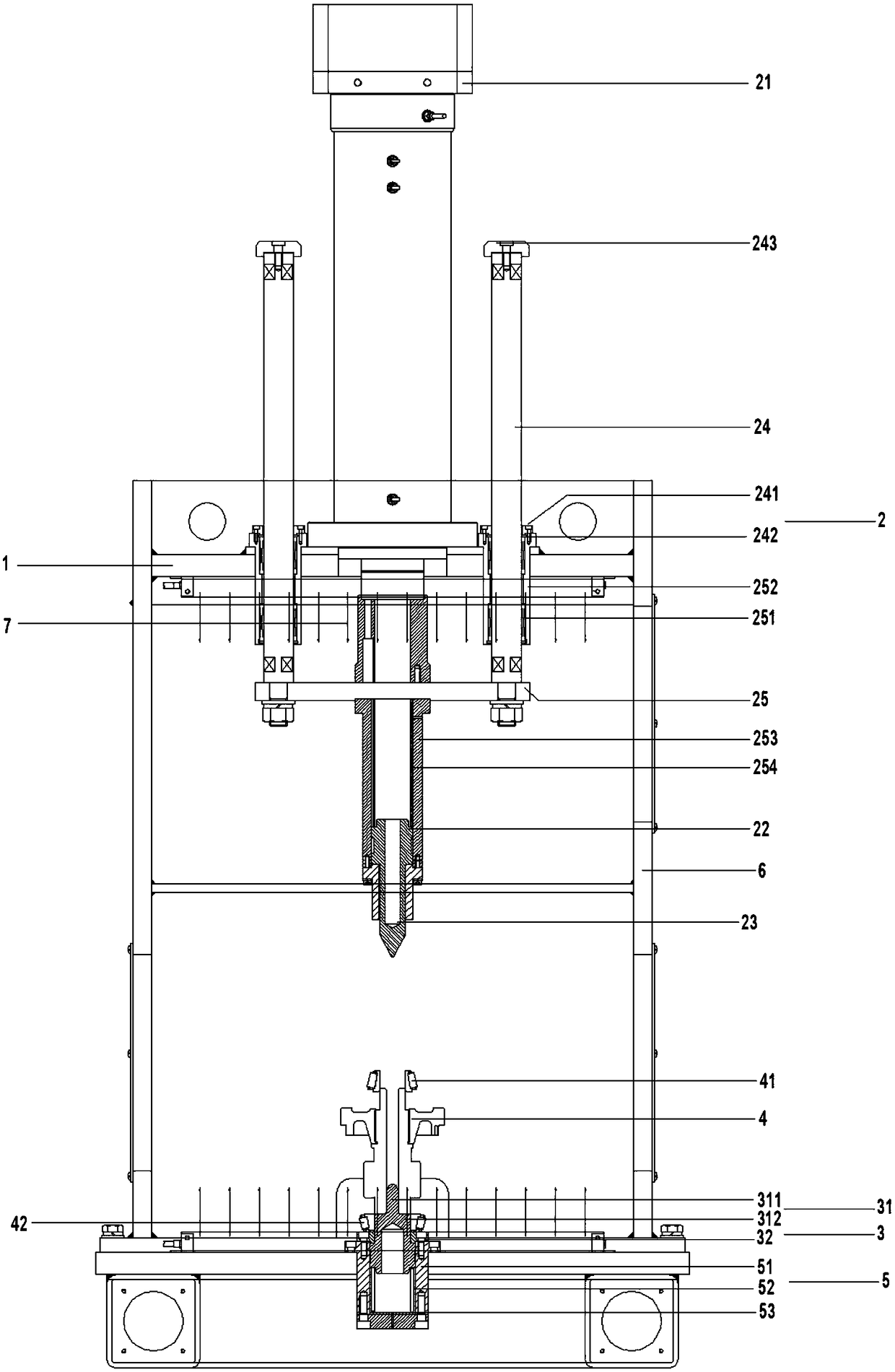

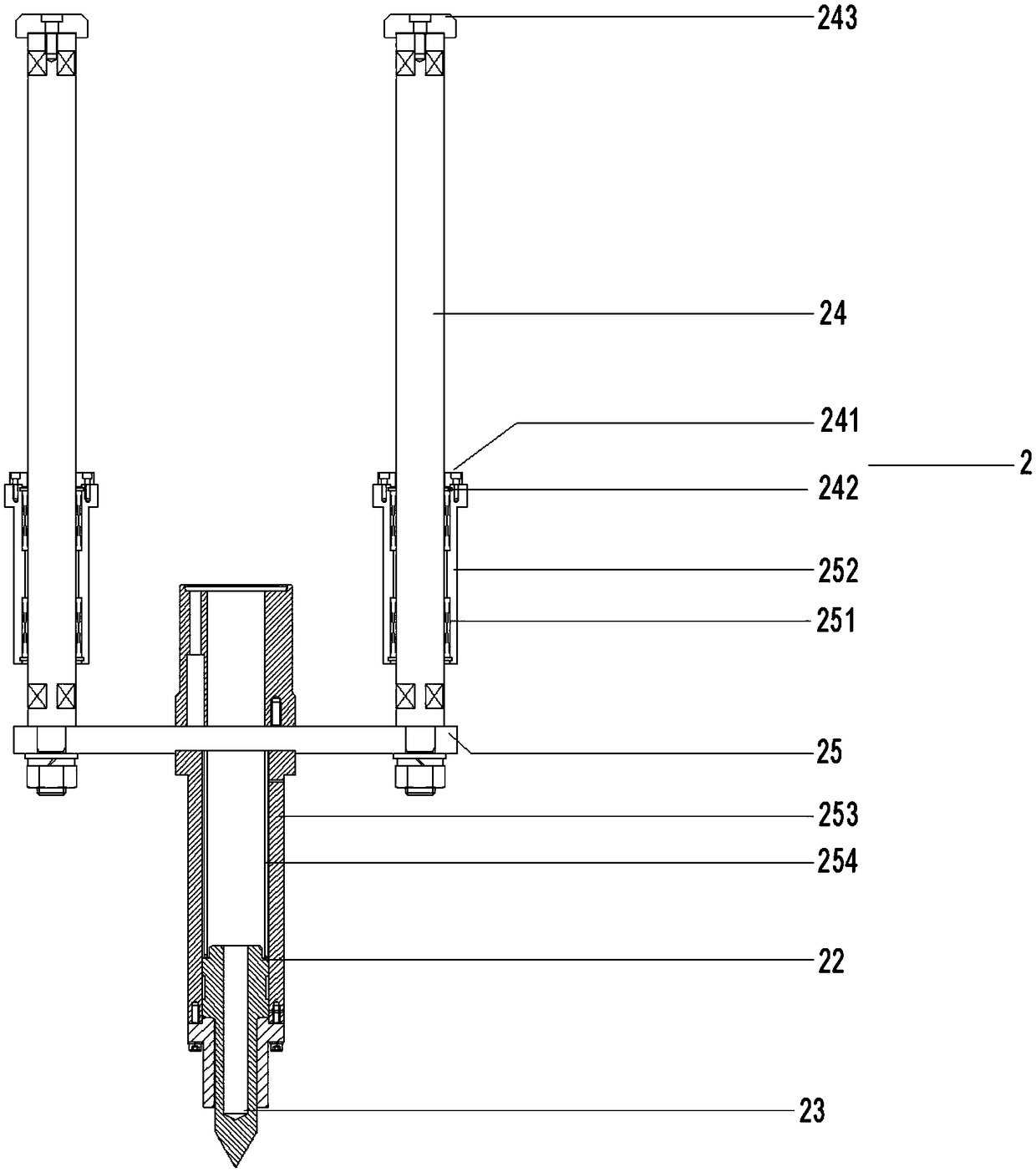

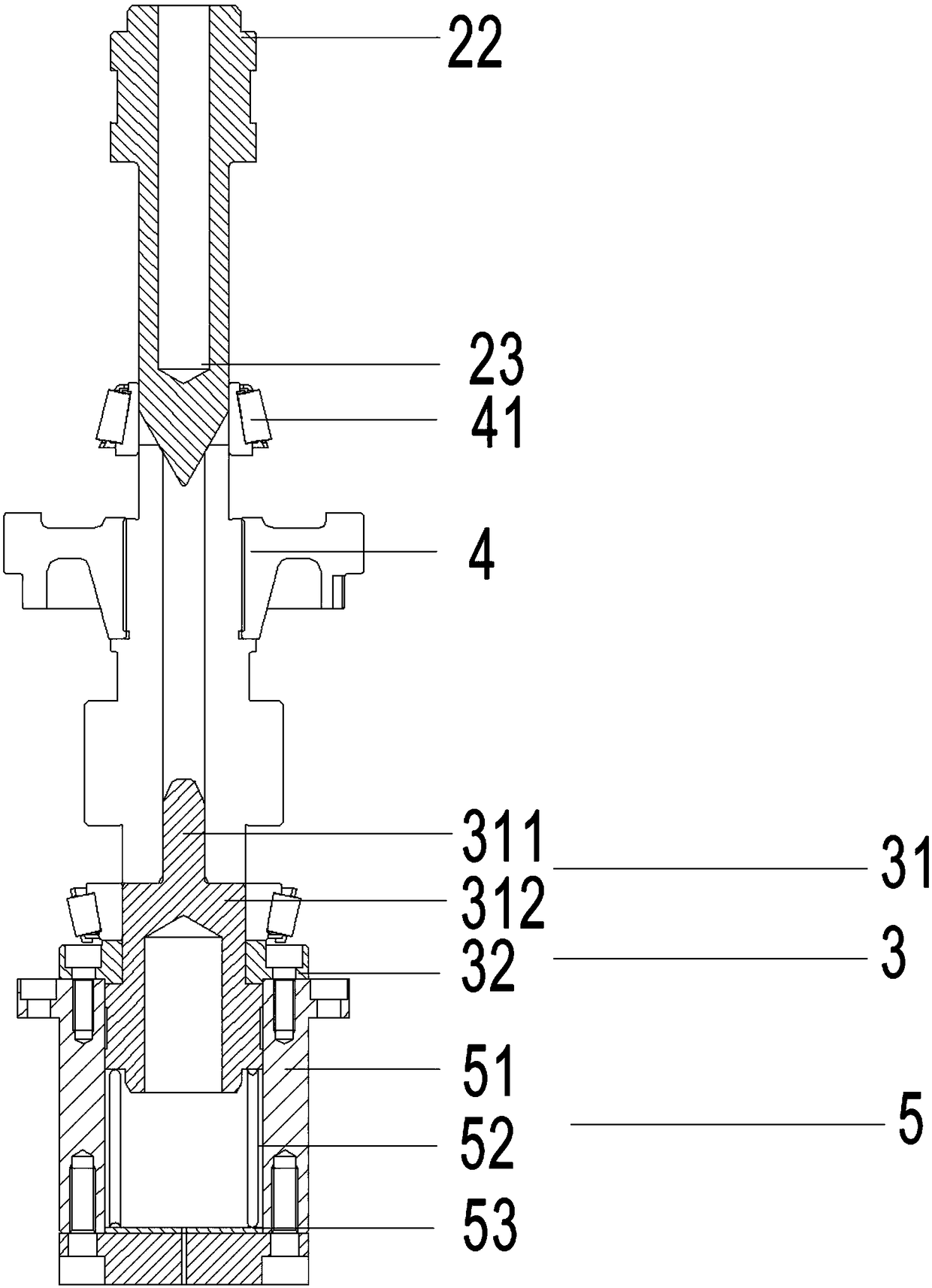

The invention discloses a tapered roller bearing press-fitting mechanism, a press-fitting method and a press-fitting mistake-proofing method thereof. The tapered roller bearing press-fitting mechanismcomprises a fixing frame, the top and the bottom of the fixing frame are provided with a stamping part and a press-fitting part which are press-fitted with each other respectively, the stamping part,a middle shaft to be pressed and the press-fitting part are in coaxial abutting connection at the pressing moment; the stamping part comprises a driving part, a stamping clamp and a centering cone which are connected in sequence, the two sides of the driving part are connected with two guide shafts respectively, the two guide shafts are arranged on the fixing frame in a mirror symmetry mode, thestamping clamp, the centering cone and the guide shafts move up and down along with the driving part relative to the press-fitting part; the press-fitting part comprises a guide clamp, and the guide clamp is arranged at the bottom of the fixing frame. Compared with the prior art, according to the actual situation of the middle shaft to be pressed, the middle shaft is pressed through the stamping part to enable the middle shaft to complete press fitting of the size tapered roller bearing at one time, through the matching of the stamping part and the press-fitting part, so that the size taperedroller bearing can be stably and accurately installed on the middle shaft.

Owner:HUNAN JISHENG INT POWER TRANSMISSION SYST

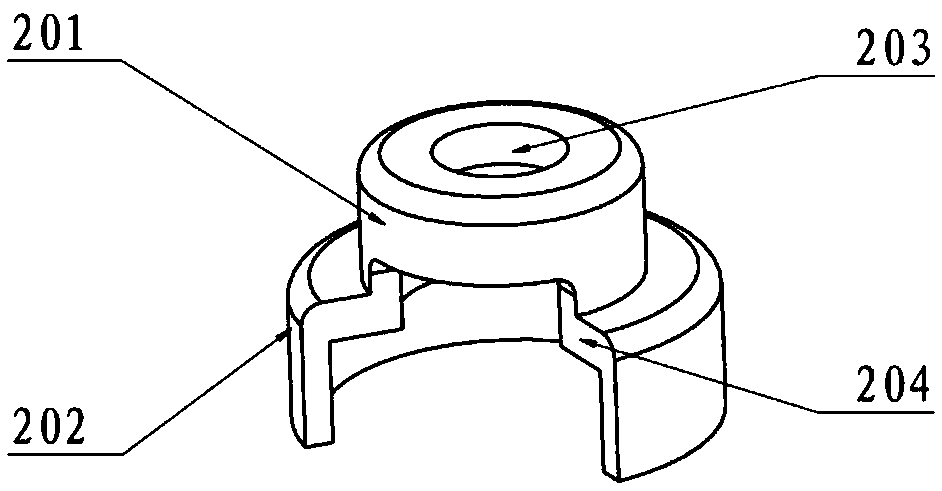

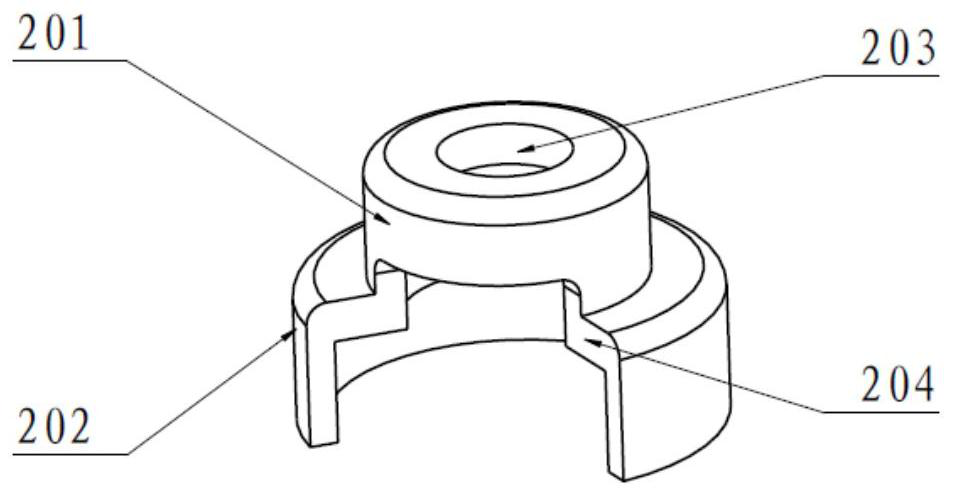

Screw cover assembly and washing machine

InactiveCN107304781AGuaranteed support effectImprove versatilityPinsNutsPulp and paper industryError prevention

The invention relates to the technical field of screw covers, and particularly relates to a screw cover assembly and a washing machine with the screw cover assembly. The screw cover assembly comprises a cover body and a groove body connected with the cover body, wherein a clamping jaw horizontally extending to the outside is arranged at a bottom of the cover body, and a clamping port connected with the clamping jaw is formed in a sidewall of the groove body; and a bulged platform used for supporting the bottom of the cover body is arranged between the cover body and the groove body, and is arranged at a bottom of the groove body. The screw cover assembly and the washing machine are high in universality and multifunctionality, and capable of increasing production efficiency and lowering a production cost during a production and manufacturing process, and have an error prevention function during use.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

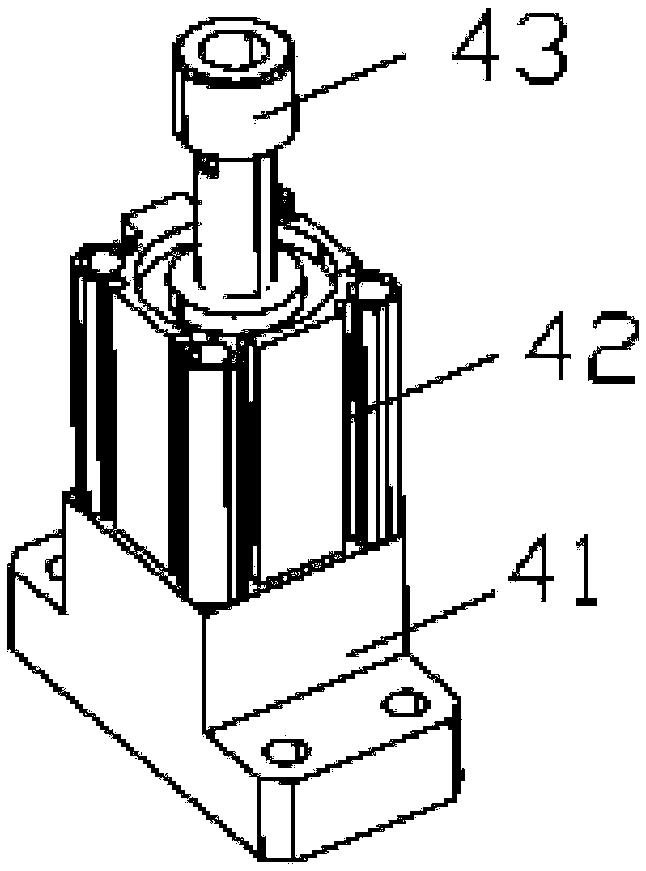

Die ejection rod structure and ejection rod installation method

InactiveCN105817532AEasy to assemble and disassembleEasy to installShaping toolsStripping-off devicesEngineeringMechanical engineering

The invention relates to the field of stamping dies, and aims to provide a die ejector pin structure and an ejector pin installation method. A mold ejector structure, comprising: a workbench, a supporting plate located at the lower side of the workbench, a ejector group consisting of a plurality of ejector pins, a lifting device for the supporting plate, and a lower die; the upper end of the workbench is provided with: Several rows of guide holes that penetrate the lower end of the worktable and match the diameter of the mandrel; the lower mold includes: a lower mold base with sliding holes passing through the upper and lower ends; The mold core; the lower mold base is detachably connected to the upper end of the worktable; the supporting plate supports the lower end of the ejector rod; the upper end of each ejector rod passes through a guide hole and extends into the sliding hole. The ejector pin structure of the mold can be adjusted according to the needs of processing workpieces, and the ejector pins can be used in common for different large stamping dies.

Owner:ZHEJIANG GEELY AUTOMOBILE +2

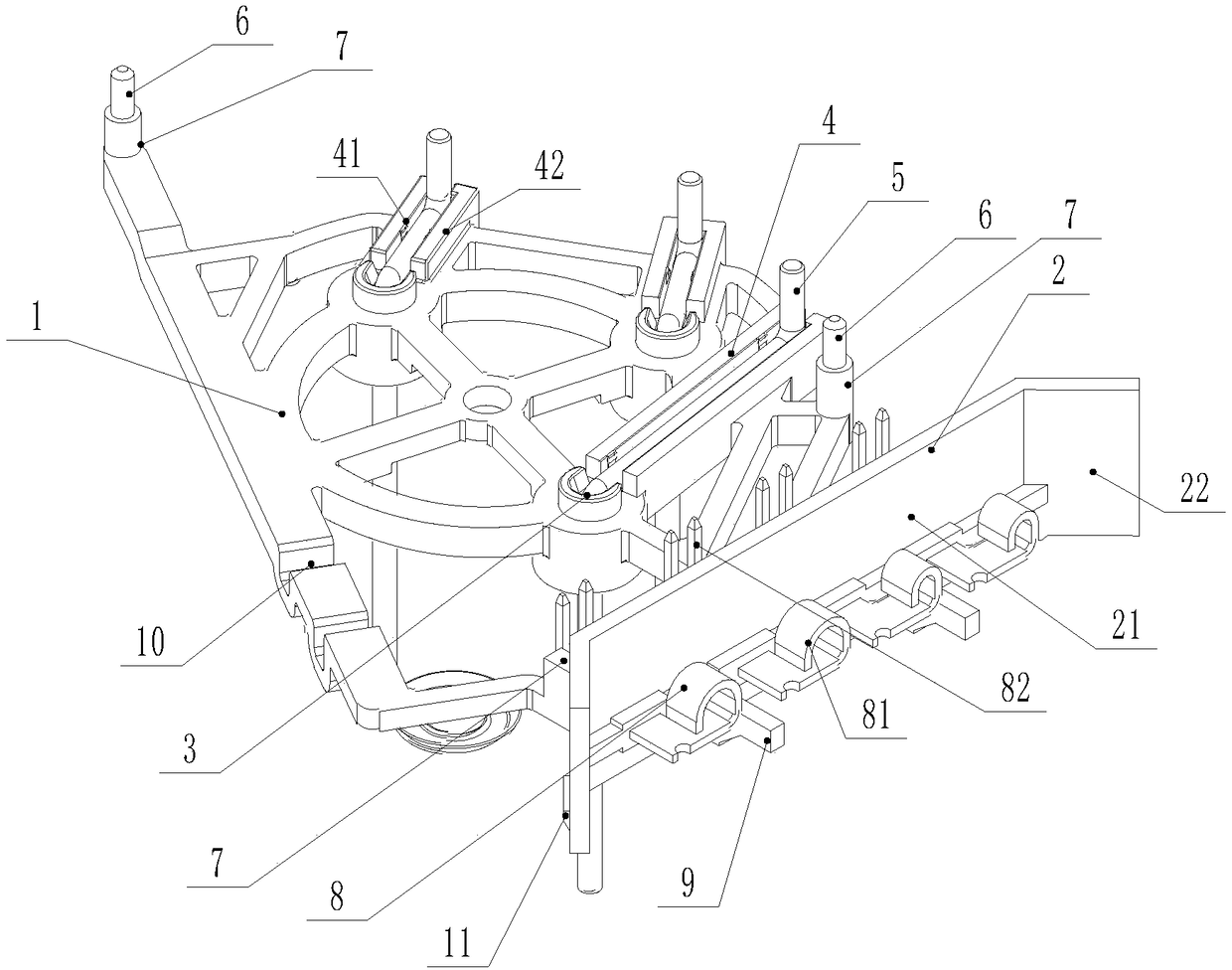

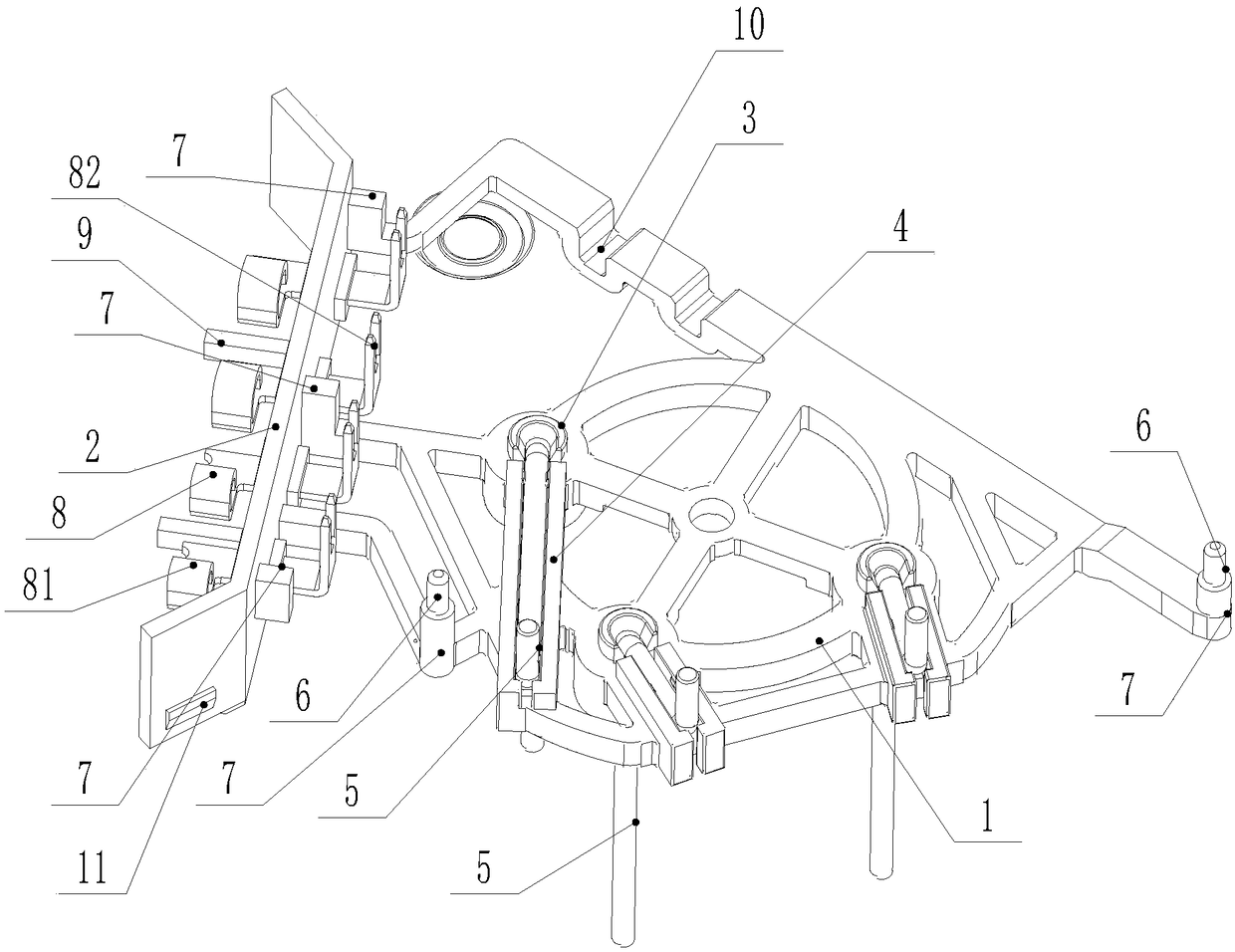

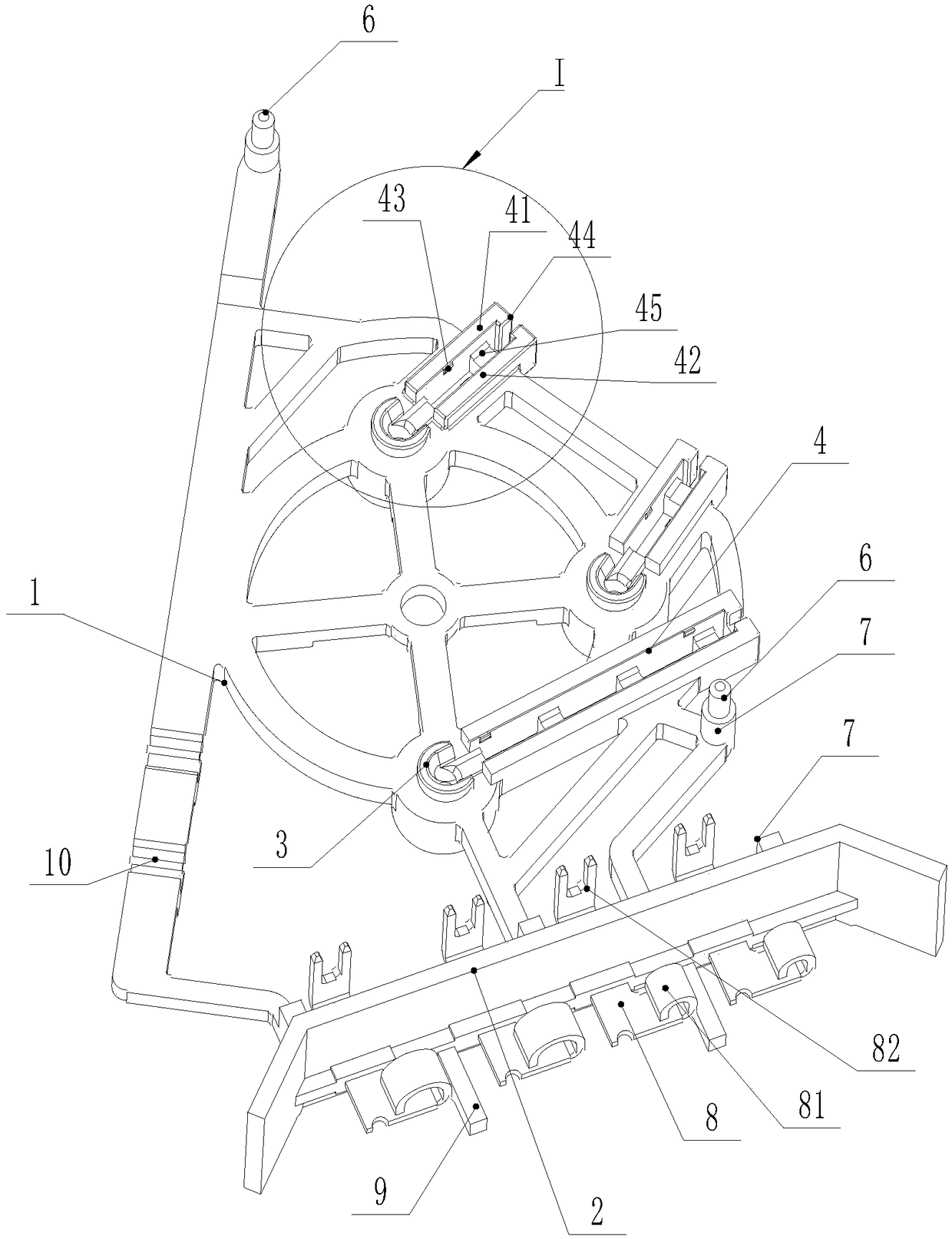

Chromatographic analyzer for automatically sampling

The invention relates to the field of experimental detection equipment and especially relates to a chromatographic analyzer for automatically sampling. The chromatographic analyzer comprises a frame and further comprises a turntable, a material-moving platform and an operation platform which are respectively arranged on the frame; the operation platform is arranged above the turntable; a sample displacing mechanism is arranged between the material-moving platform and the turntable; the material-moving platform comprises a liquid moving gripper, a loading platform capable of moving along horizontal direction and a moving component for driving the liquid moving gripper to move; the sample displacing mechanism comprises a horizontally arranged rotatable slab and clamping components respectively arranged at the two ends of the rotatable slab; a sampling component capable of moving along vertical direction and a clamping component used for clamping a reagent are arranged on the operation platform. The chromatographic analyzer is capable of realizing automatic sampling and detection, increasing detection efficiency and reducing labor intensity of workers and has a certain mistake-proof function.

Owner:广东诚爱检测技术有限公司

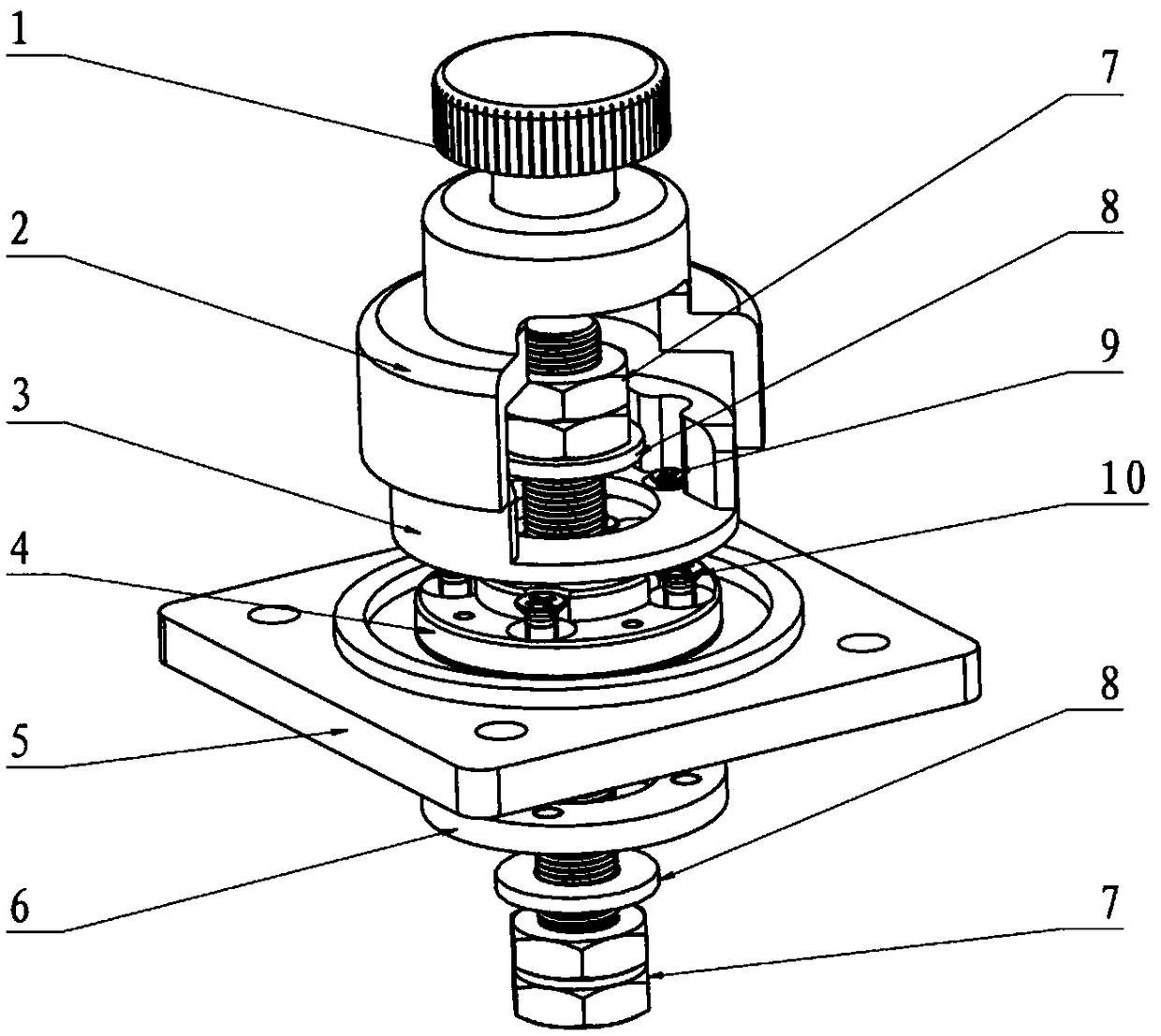

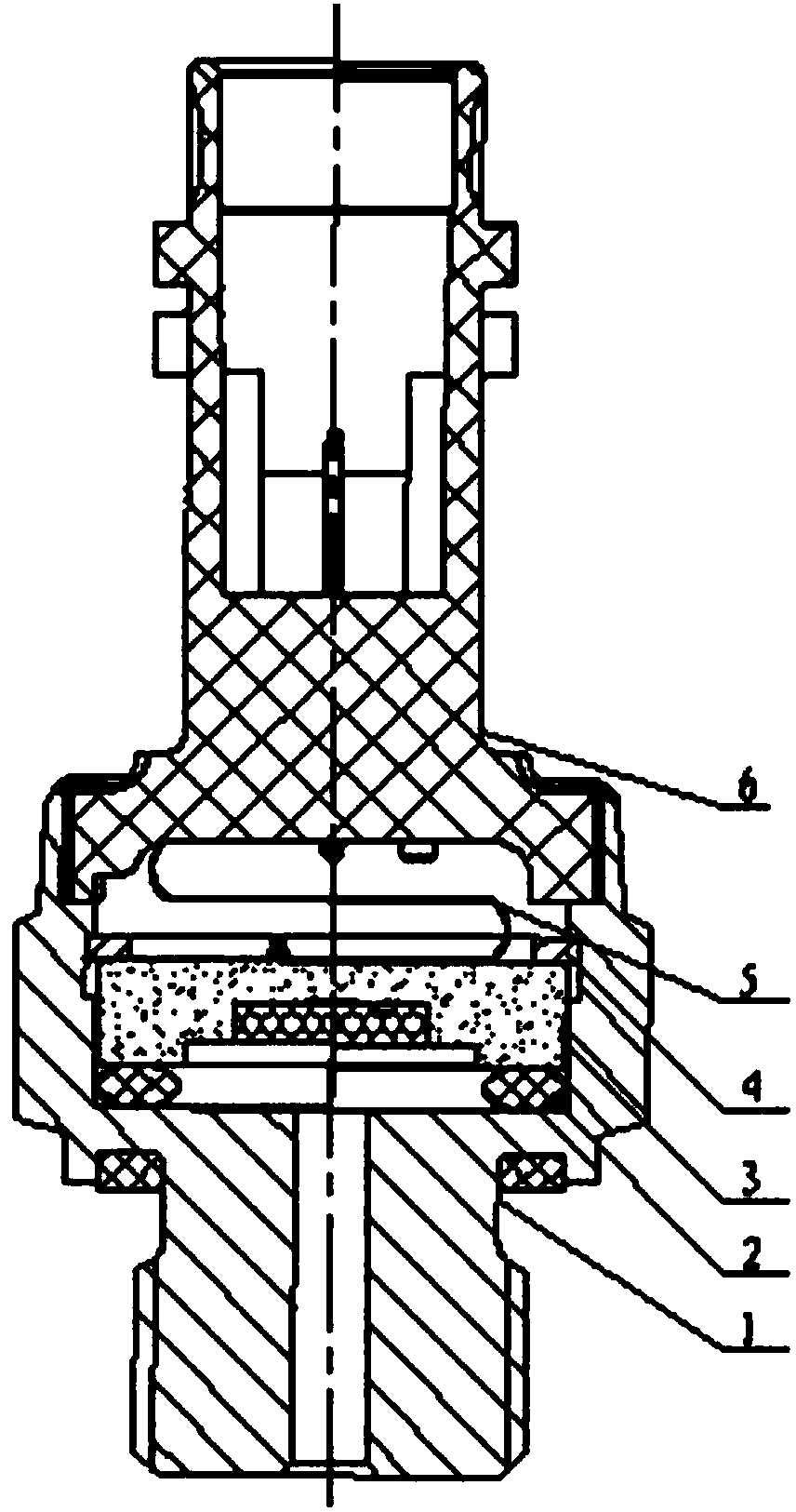

A large current pole assembly with error prevention function for a battery pack

ActiveCN109065824AAvoid short circuitConnection contact resistance is smallSmall-sized cells cases/jacketsPower flowError prevention

The invention discloses a large current pole assembly with error prevention function for a battery pack, comprising a fastening cap, a protective cover, a stopper, a pole, a flange seat, a mounting ring, a conductive nut, a conductive washer, a countersunk screw and a countersunk screw. Generally speaking, the output of positive and negative poles of many batteries is realized by stud, which is simple, but it is easy to cause reverse short circuit and damage of batteries or equipments, and constitutes a potential safety hazard. Therefore, measures should be taken to prevent pole connection errors. The pole designed by the invention has a disk, the disk protrudes from both sides of the boss, the screw pole is protruded from the boss, and the external conductive terminal is fixed to the bossplane by a nut to realize plane conductive function. Compared with the threaded conductive mode of the common pole, the provided pole assembly has smaller contact resistance, and therefore has the capability of excessive current.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

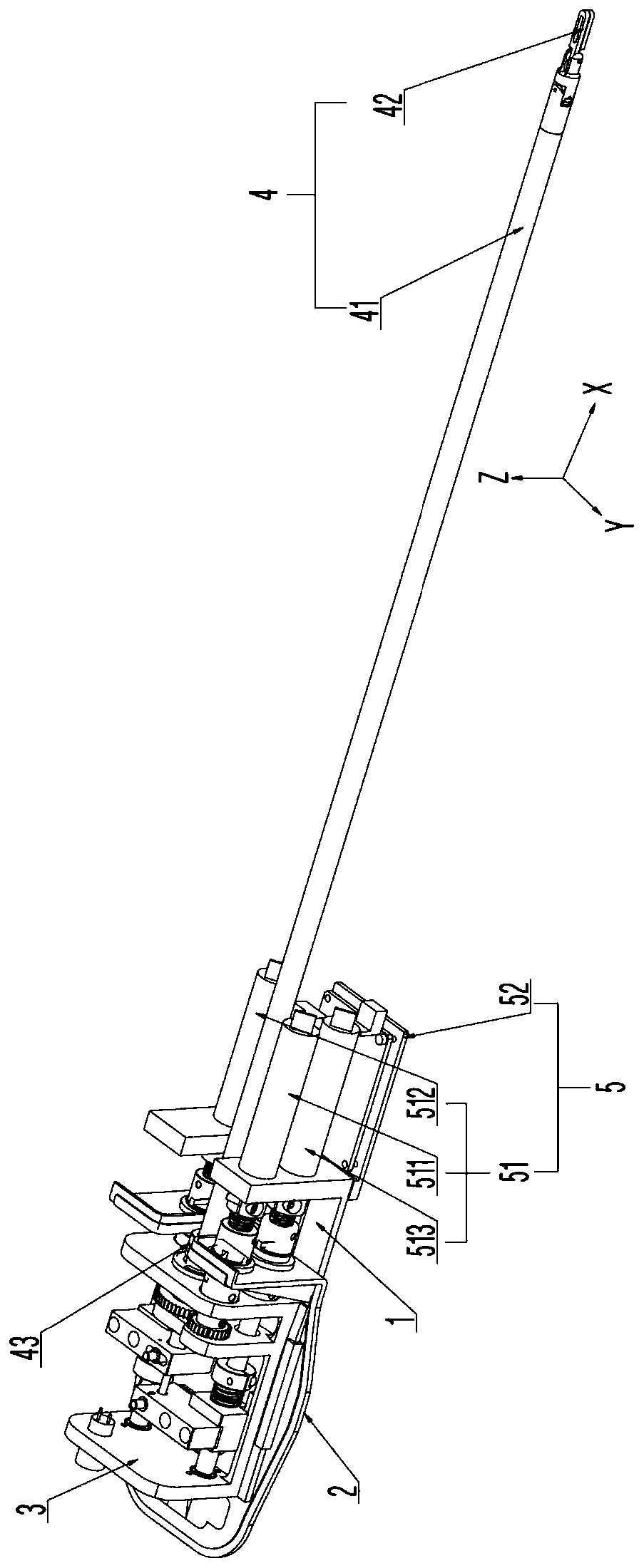

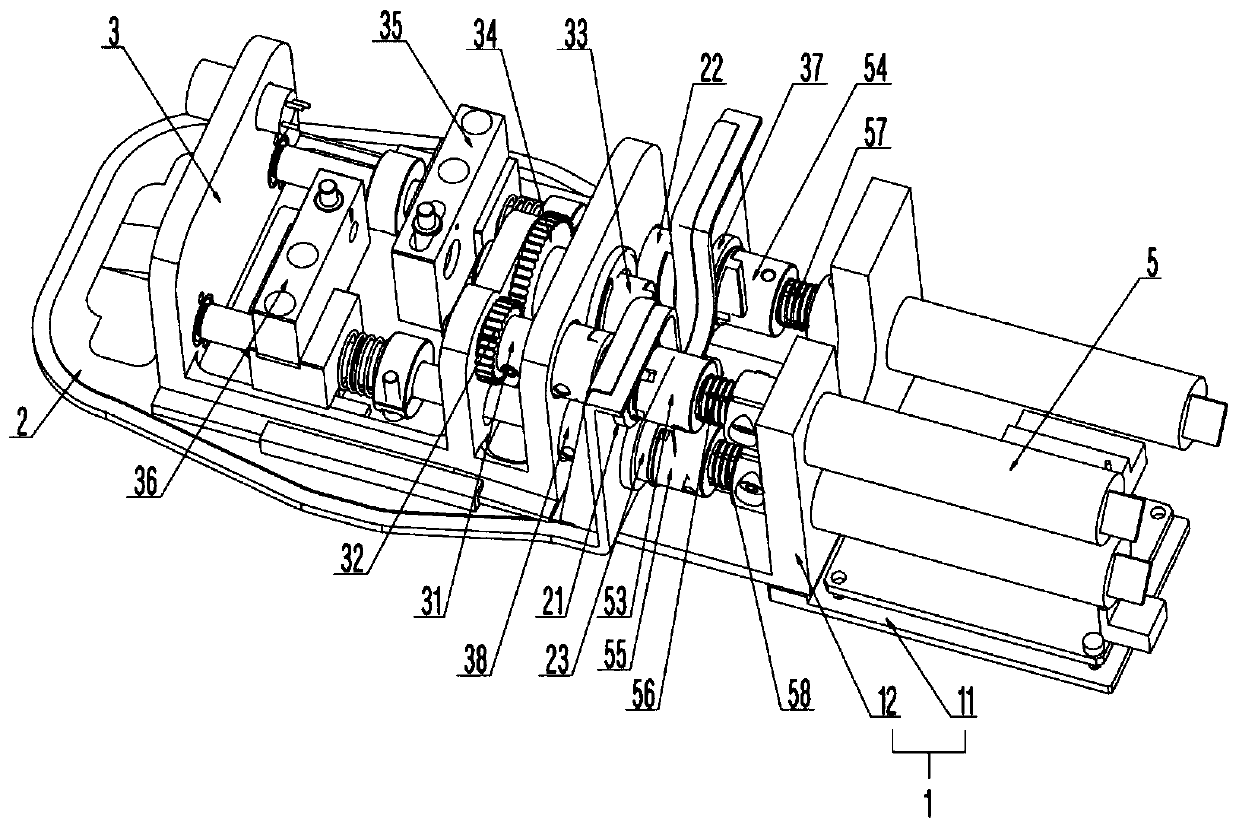

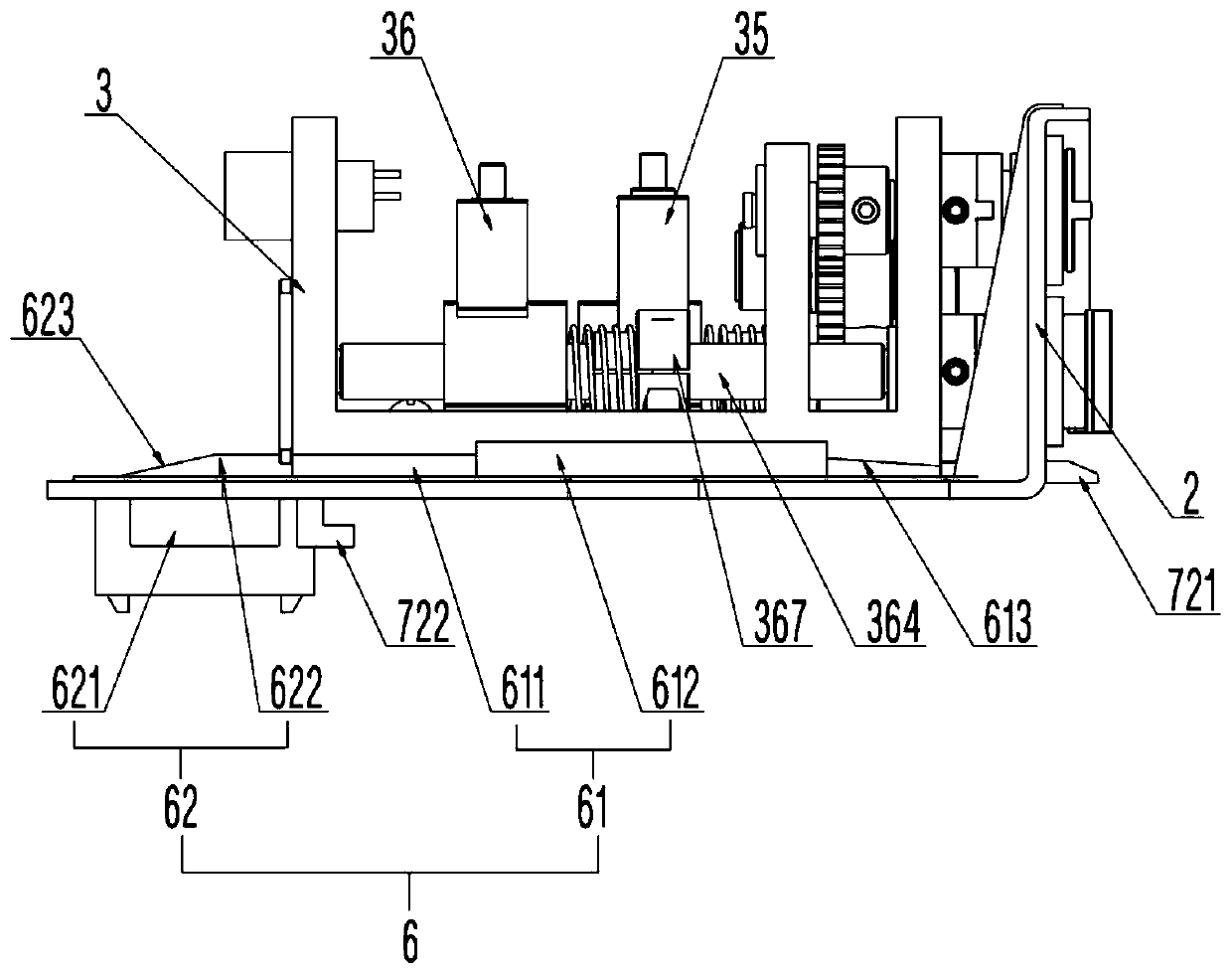

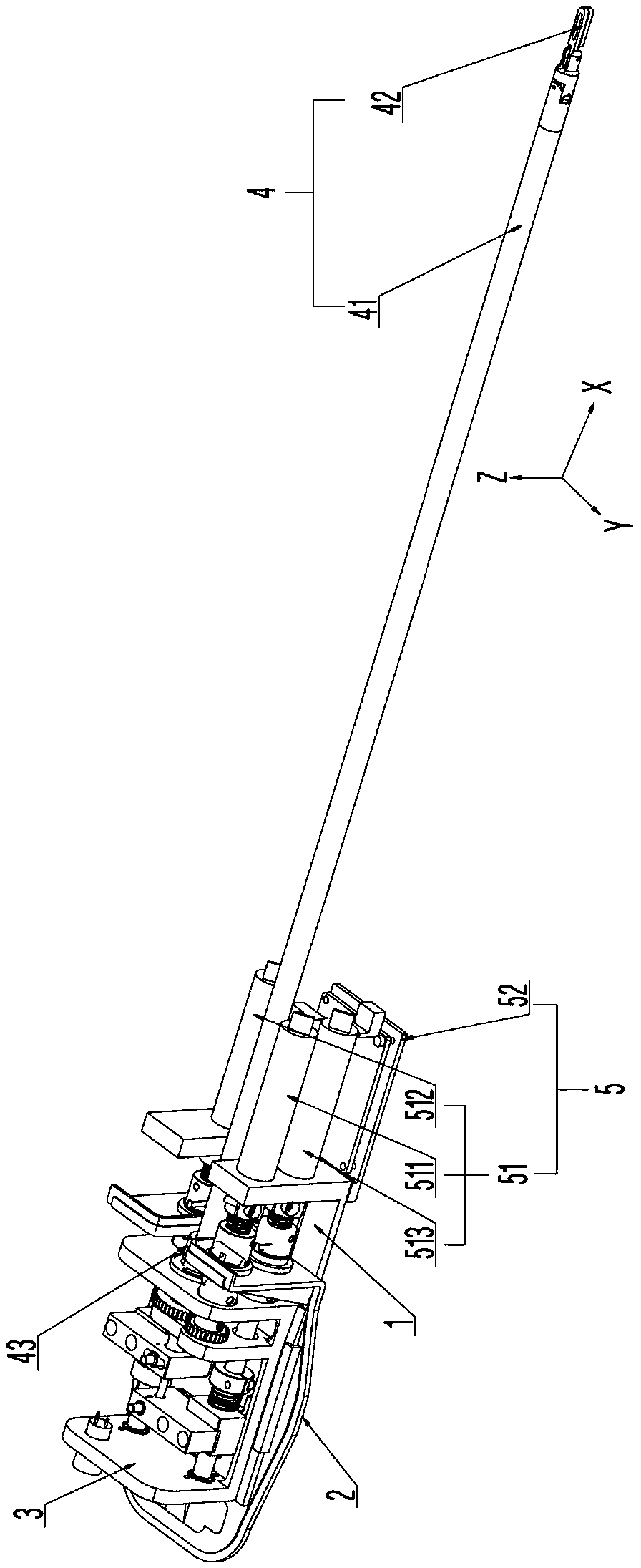

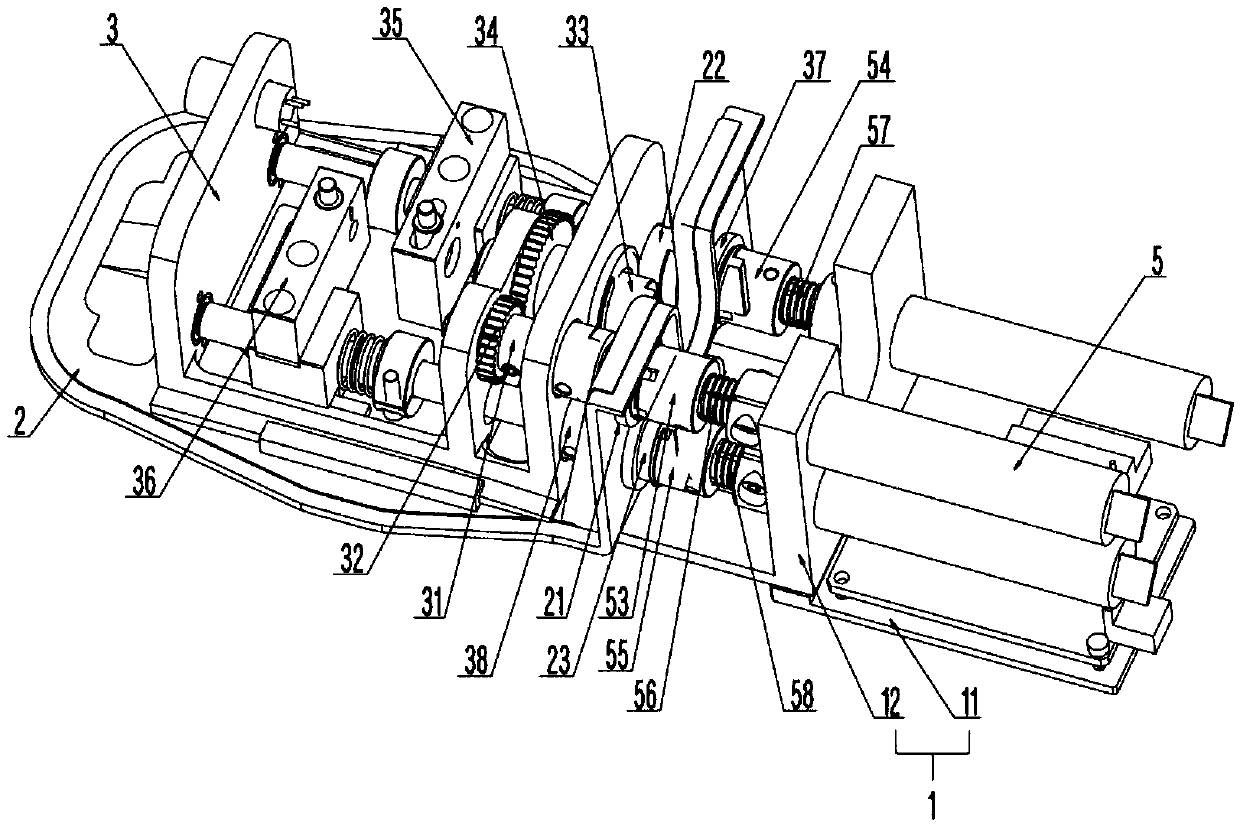

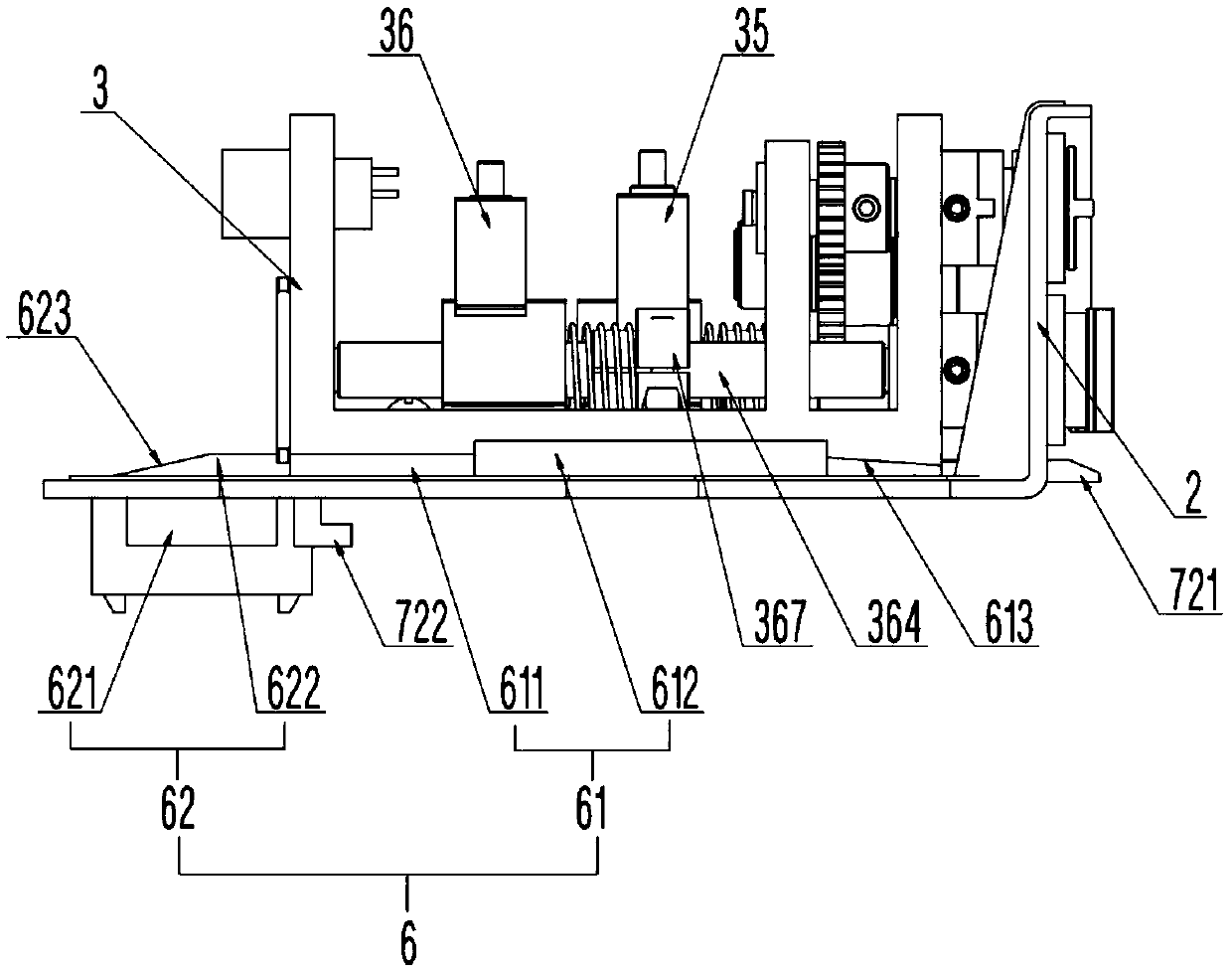

Surgical instrument control method for laparoscopic surgery robot

ActiveCN111358558AReduce difficultyMaintain stabilitySurgical manipulatorsSurgical robotsPhysical medicine and rehabilitationElectric machinery

The invention relates to a surgical instrument control method for a laparoscopic surgery robot. The surgical instrument control method comprises the following steps: adjusting the height and the frontand back positions of a mechanical arm, collecting corresponding deflection angle information of a control handle by monitoring equipment when an operator deflects a wrist, and transmitting the collected deflection angle information to a main control unit; analyzing the received deflection angle information by the main control unit, determining a wrist deflection angle of the operator from the deflection angle information, and then outputting a corresponding deflection control instruction to a slave control unit; controlling the rotation of a second motor by the slave control unit according to the received deflection control instruction, driving surgical instruments to deflect through the rotation of the second motor, and enabling the surgical instruments and the wrist of the operator todeflect synchronously; and controlling the sliding of a instrument fixing device provided with the surgical instruments on a sliding table by controlling the revolution number of a sliding control motor, so as to replace the surgical instruments at the starting position.

Owner:CHENGDU BORNS MEDICAL ROBOTICS INC

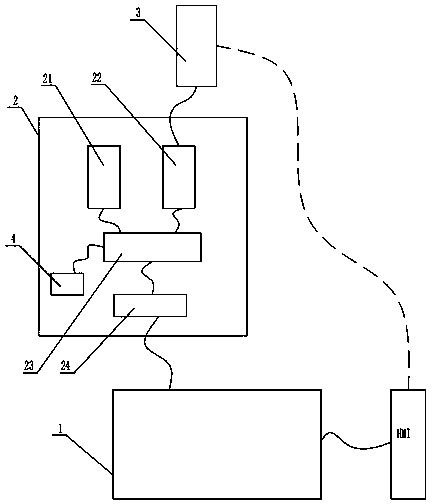

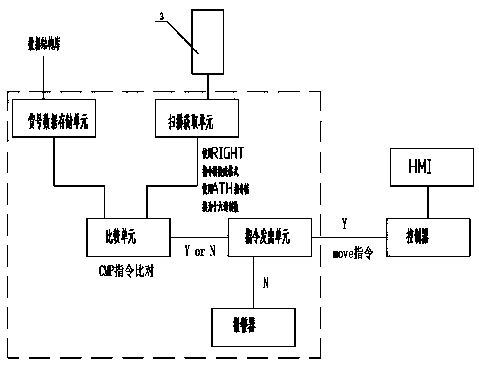

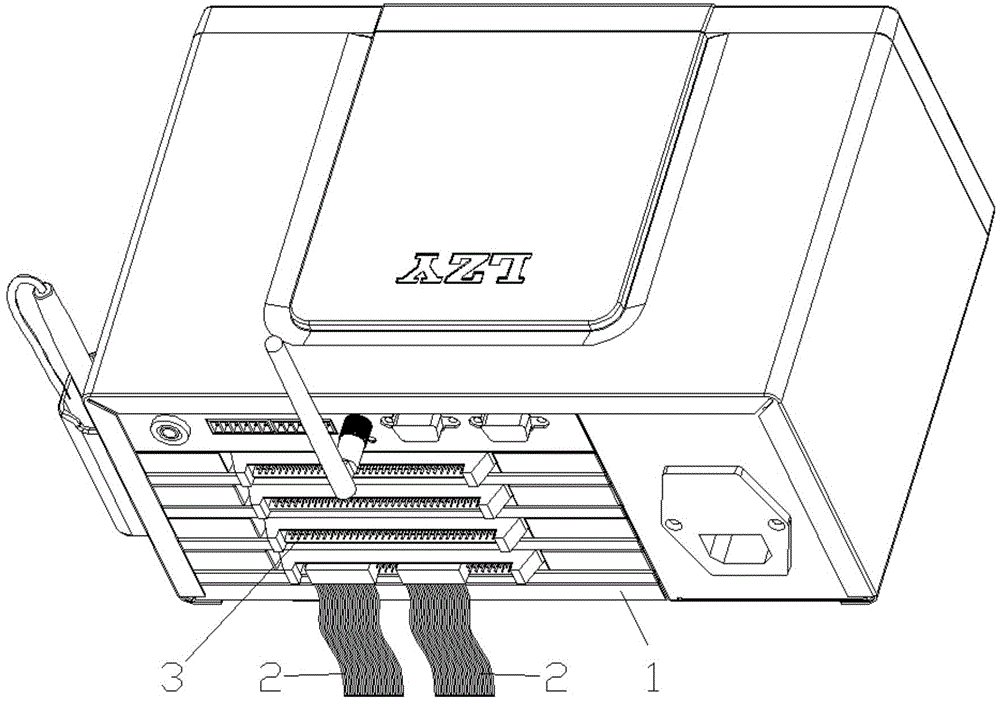

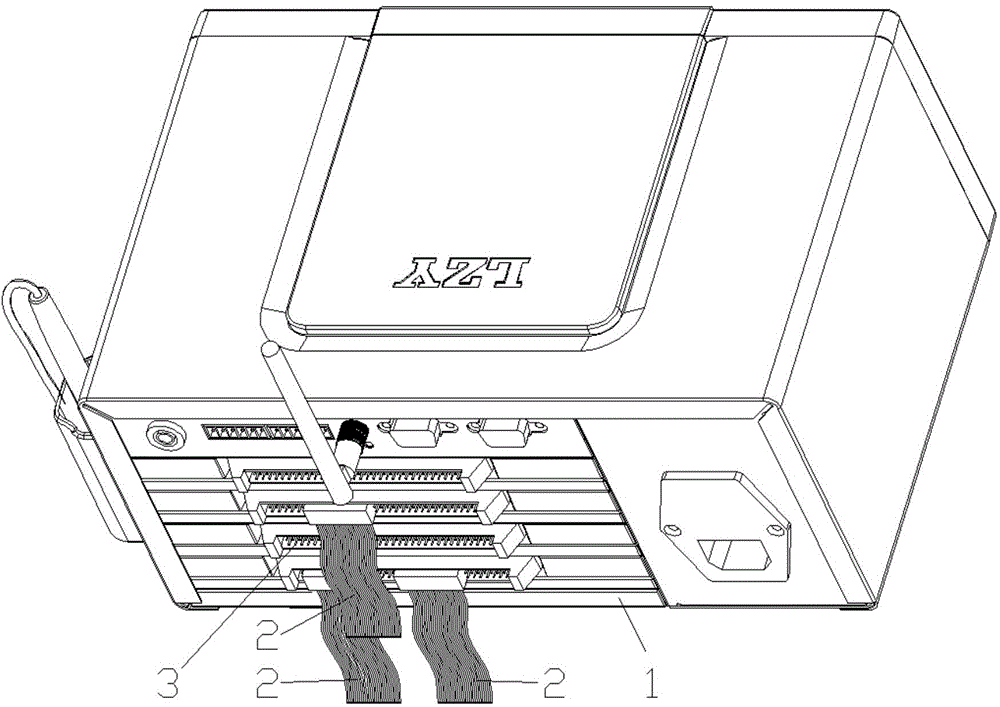

Engine oil on-line automatic filling system and method

PendingCN109505675AEliminate errors, omissions and risksImprove filling efficiencyMachines/enginesLubricant filling/drainingEngineeringData structure

The invention discloses an engine oil on-line automatic filling system and method. The engine oil on-line automatic filling system includes an engine oil on-line automatic filling device, wherein theengine oil on-line automatic filling device is provided with a controller and an HMI, the controller is connected with a PLC, and the PLC is connected with a card scanning machine and further connected with an alarm capable of emitting an alerting signal. The engine oil on-line automatic filling method is achieved through using the engine oil on-line automatic filling system, the method includes the following steps that 1) a data structure library is input to the PCL in advance; 2) the on-line engine information is acquired and transferred to the PLC by using the card scanning machine; 3) a comparing element carries out comparing, and then the PLC emits commands of engine oil filling and oil filling quantity or emits an alerting signal to the alarm. The engine oil on-line automatic fillingsystem and method can achieve automatic engine oil filling of an on-line engine and have the advantages of improving the efficiency of engine oil on-line filling and preventing engine oil wrong addition or missing addition.

Owner:WEICHAI POWER YANGZHOU DIESEL ENGINE

Multi-station multi-type hybrid wire harness testing method for intelligent wire harness tester

The invention discloses a multi-station multi-type hybrid wire harness testing method for an intelligent wire harness tester. The intelligent wire harness tester and multi-type hybrid wire harness products to be tested are adopted in the method; two or more multi-type hybrid wire harness products to be tested are tested at the same time; the multi-type hybrid wire harness products to be tested are produced through multiple steps by multiple stations and are divided into several parts, and all the parts are produced by different stations, and the intelligent wire harness tester is inserted to complete testing independently. The multi-station multi-type hybrid wire harness testing method is started, and the intelligent wire harness tester performs a series of testing steps, completes testing of the wire harnesses to be tested and outputs testing results to remind testing of a new turn of wire harnesses. According to the multi-station multi-type hybrid wire harness testing method, a software recognition and intelligent judgment system is utilized; according to the combinatorial arrangement of the wire harnesses, the wire harnesses needing to be tested are compared, and corresponding testing programs are called; testing is quick, the cost is low, and the method has fool-proof, error-proof, warning and universal functions and other excellent functions.

Owner:SUZHOU LUZHIYAO TECH

Permanent magnet speed governing water pump electromagnetic clutch

InactiveCN106065805AGood energy savingSimple structureCoolant flow controlMagnetically actuated clutchesEngineeringPulley

The invention discloses a permanent magnet speed governing water pump electromagnetic clutch. The permanent magnet speed governing water pump electromagnetic clutch comprises a belt pulley, a leaf spring, screws, a magnetic pole ring, a magnetic pole, a fixed seat, a friction disk, a driving disk, rivets, a water pump shell and a suction disk, wherein the fixed seat is arranged on a bearing, the friction disk is fixed to the fixed seat through an M8 bolt, the suction disk, the leaf spring and the driving disk are fixedly connected together in sequence through the rivets, the screws penetrate through the driving disk, the leaf spring and the suction disk in sequence and fix the suction disk to the belt pulley, the belt pulley is connected with the water pump shell through the bearing, and the magnetic pole ring and the magnetic pole are fixed to the driving disk in a threaded connection manner. The permanent magnet speed governing water pump electromagnetic clutch can adapt to the requirement of the changeful working process of an engine, and is suitable for different loads and rotating speeds of the engine, thereby achieving the effects of high efficiency, energy saving and safe operation.

Owner:SUZHOU RISING AUTO PARTS

Air pressure sensor

PendingCN107741293AIncrease or decrease the voltage valueGood flexibilityFluid pressure measurementFlexible circuitsElectrical connection

The invention provides an air pressure sensor. A clamping groove is formed in a metal shell, a ceramic sensitive element assembly is clamped into the clamping groove in the metal shell through a holeelastic check ring, and an end button assembly is arranged at the end of the metal shell, seals the clamping groove and is arranged on and matched with the ceramic sensitive element assembly; the ceramic sensitive element assembly and the bottom surface of the clamping groove in the metal shell are sealed through an O-shaped sealing ring, an air inlet is formed in the bottom of the metal shell, the air inlet is communicated with a sealed cavity which is defined by the ceramic sensitive element assembly and the clamping groove in the metal shell. According to the air pressure sensor, the hole elastic check ring is used for pressing the ceramic sensitive element assembly so that the O-shaped sealing ring can be deformed, and the sealed cavity is formed; the ceramic sensitive element assemblyand the end button assembly are electrically connected by adopting a flexible circuit board. The air pressure sensor has the advantages of compact structure, low weight, small output error, long service life of products, and high working reliability, and is mainly applied to sensors which automatically detect the braking pressure of an air storage tank of a commercial vehicle.

Owner:DONGFENG AUTOMOBILE ELECTRONICS

A kind of detection equipment of automobile door lock sleeve

ActiveCN103542878BStable structureHigh strengthMeasurement devicesUltimate tensile strengthElectrical and Electronics engineering

Owner:DEERFU VEHICLE LOCK ANTI THEFT SYST SHANGHAI

Optical calibrator

The invention discloses an optical calibrator. The technical scheme is that: the optical calibrator comprises a protective cover; the front and rear ends of the protective cover are provided with a front cover and a rear cover; the front cover is a cylinder; the front end of the front cover is provided with a conical surface positioning sleeve; the rear end of the front cover is provided with light-transmitting glass; the protective cover is provided with a view window; the rear end of the front cover is fixedly provided with a reflecting mirror fixing seat; a semi-passing semi-reflecting mirror is embedded into the reflecting mirror fixing seat and corresponds to the view window; an included angle of 45 degrees is formed between the semi-passing semi-reflecting mirror and the conical surface positioning sleeve; a light passing hole is formed in the middle of the semi-passing semi-reflecting mirror; a laser is arranged in the protective cover; and the emergent light of the laser can pass through the light passing hole. The optical calibrator has the advantages of compact and reasonable structure, high positioning accuracy, long service life and novel appearance design.

Owner:山东神戎电子股份有限公司

Control method for surgical instrument of endoscope surgical robot

PendingCN111096800AReduce difficultyMake sure the surgery is performed safelySurgical robotsElectric machinerySurgical instrument

The invention relates to a control method for a surgical instrument of an endoscope surgical robot. The endoscope surgical robot comprises a control handle, monitoring equipment, a master control unit, a slave control unit and a second motor; the control method comprises the following steps that deflection angle information corresponding to the control handle when an operator deflects the wrist iscollected by the monitoring equipment, and the collected deflection angle information is transferred to the master control unit; the received deflection angle information is analyzed by the master control unit to determine a wrist deflection angle of the operator, and thus, a corresponding deflection control command is output to the slave control unit; and the second motor is controlled by the slave control unit according to the received the deflection control command to rotate, the surgical instrument is driven through the rotation of the second motor to deflect, and the surgical instrumentand the wrist of the operator deflect synchronously.

Owner:CHENGDU BORNS MEDICAL ROBOTICS INC

Multi-position single-model wire harness testing method for wire harness intelligent test machine

The invention discloses a multi-position single-model wire harness testing method for a wire harness intelligent test machine. According to the method, the wire harness intelligent test machine and single-model wiring harness products to be detected are used; the number of the single-model wiring harness products to be detected simultaneously is more than one; the single-model wiring harness products are independently produced by multiple working positions and multiple steps; the number of the independent steps is more than one; after the single-model wiring harness products are inserted, the multi-position single-model multi-step wire harness testing method is started; and he wire harness intelligent test machine performs a series of testing steps to complete the test of the wiring harnesses to be detected, outputs a test result and reminds of the next test for the wire harnesses. According to the method, a soft identification and intelligent judgment system is used, a corresponding test program is used on the basis of the wire harnesses to be detected and according to the combinatorial arrangement of the wire harness, and the method is quick in test and low in cost, and has functions of fool-proofing, mistake-proofing, warning and universality.

Owner:SUZHOU LUZHIYAO TECH

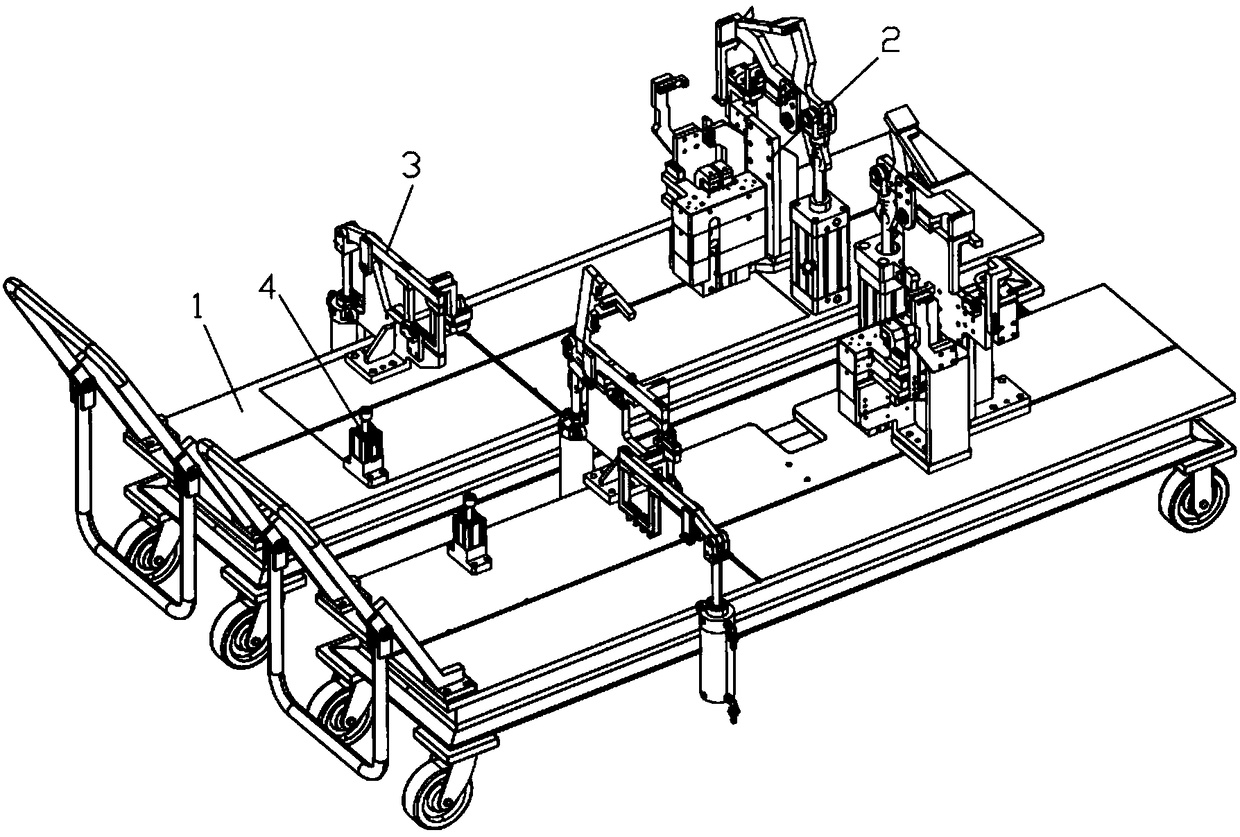

Clamp with error prevention function

The invention discloses a clamp with an error prevention function. The clamp with the error prevention function is characterized by comprising a bottom plate, front fixing devices and side fixing devices, wherein the front fixing devices and the side fixing devices are arranged on the bottom plate for clamping a mounting piece, and error prevention devices which can control lifting are further arranged on the bottom plate. The clamp with the error prevention function is convenient to use and good in applicability, can meet the use of various vehicle types, effectively avoids the occurrence ofmisfitting of the various vehicle types, and has good applicability and better application prospect.

Owner:ANHUI RUIXIANG IND

Sealing and fixing device for power plug cord of submersible motor for well

PendingCN114583655AWon't looseGuaranteed tightnessElectrically conductive connectionsClimate change adaptationPower cableElectrical conductor

The invention discloses a sealing and fixing device for a power plug cord of a submersible motor for a well, which comprises a power socket which is tightly fixed at a power cord outlet and is connected with a motor driving outgoing line, a power plug which is connected with a power cable flat wire, and a pressing and sealing plate for fixing the power plug, the power plug comprises an insulating rubber plug, 3-4 conductor jack needles and a protective sleeve which is internally filled with insulating sealant to package the conductor jack needles and the end part of the power cable flat wire together, the press sealing plate is sleeved at the outer end part of the protective sleeve to press and fix the insulating rubber plug, the insulating plastic seat is arc-shaped, and the waist part of the insulating plastic seat is provided with a sealing groove and a rubber sealing ring. A fixing lug is arranged at the tail part of the insulating plastic seat, the power line outlet is an arc-shaped long hole matched with the insulating plastic seat, the insulating rubber plug is arc-shaped, a sealing convex ring is arranged at the waist part of the insulating rubber plug, and the rubber sealing ring and the sealing convex ring are elastically sealed in the power line outlet; the sealing structure has the advantages of being good in sealing performance and not prone to disengagement.

Owner:GUANGDONG RUIRONG PUMP IND

A high-current pole assembly with error-proof function for a battery pack

ActiveCN109065824BAvoid short circuitConnection contact resistance is smallSmall-sized cells cases/jacketsCell lids/coversCircular discElectrical resistance and conductance

The invention discloses a high-current pole component with error-proof function for a battery pack, which includes a fastening cap, a protective cover, a limit piece, a pole, a flange seat, a mounting ring, a conductive nut, a conductive washer, and a countersunk head Screw one, countersunk screw two. In general, the positive and negative poles of many battery packs use studs to realize external output. This method is simple, but it is prone to reverse short circuit phenomenon, causing damage to the battery pack or equipment, and posing a safety hazard. Therefore, measures need to be taken to prevent pole connection errors. There is a disc on the pole designed by the present invention, and the disc protrudes from both sides of the boss, and the stud is protruded from the boss, and the external conductive terminal is fixed to the plane of the boss through the nut to realize the plane conduction function, which is different from the ordinary pole. Compared with the threaded conductive method of the post, it has a smaller contact resistance, so it has the ability to over-current.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Conductive bracket for motor

PendingCN108667222AReduce the difficulty of productionLow production costStructural associationEngineeringCable harness

The invention discloses a conductive bracket for a motor. The comprising a bracket body, wherein the bracket body is provided with three mounting holes, the back side of the bracket body is provided with a positioning insertion groove, each mounting hole is plugged with a conductive connecting rod, the tail end of each conductive connecting rod is bent and inlaid in the positioning insertiongroove, the tail end of each conductive connecting rod is bent and stretches out to the back side from the positioning insertion groove, the front end of each conductive connecting rod stretches out of thecorresponding mounting hole, one end of the bracket body is provided with a harness mounting plate, the harness mounting plate is provided with a harness conductive pin, and the bracket body is provided with a supporting structure for positioning on the back side. The conductive bracket has a reasonable structure, the mounting holes and the positioning insertion groove are formed in the conductivebracket to better mount the conductive connecting rods, the conductive connecting rods and a PCBA board are prevented from being displaced when assembled, the assembly precision is higher, a conductive connecting piece is not needed, the welding operation is reduced, and the conductive efficiency is improved.

Owner:JIANGSU LANGXIN ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com