Sealing and fixing device for power plug cord of submersible motor for well

A technology for power plugs and submersible motors, which can be used in cable entry sealing devices, cable installation, motor generator connectors, etc. It can solve problems that affect sealing and safety, complex wiring and positioning processes, and affect production efficiency. , to prevent wrong insertion direction, improve production efficiency and product quality, and prevent wiring errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

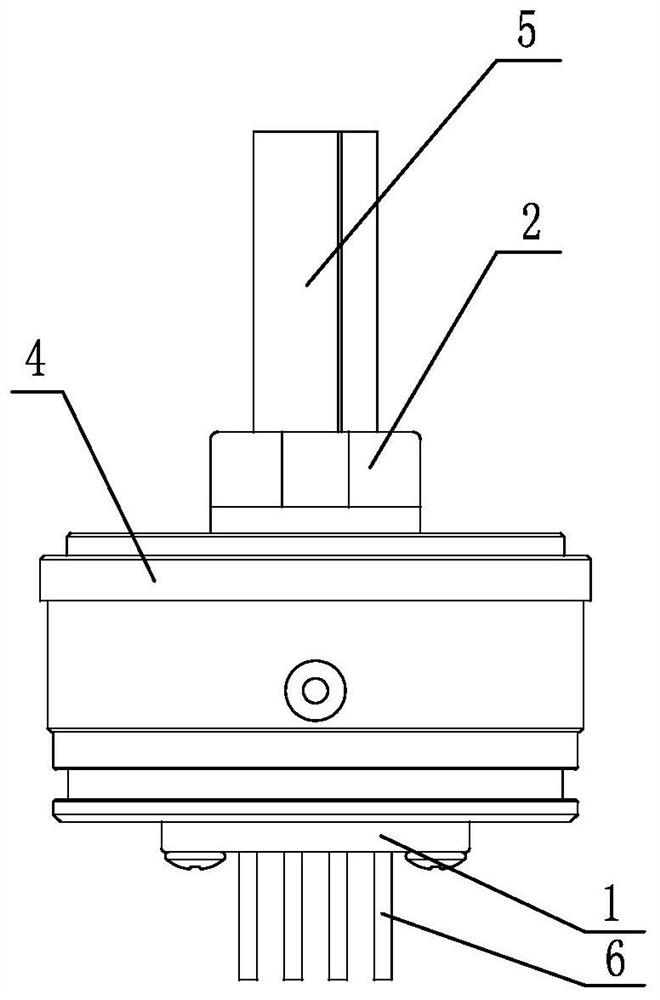

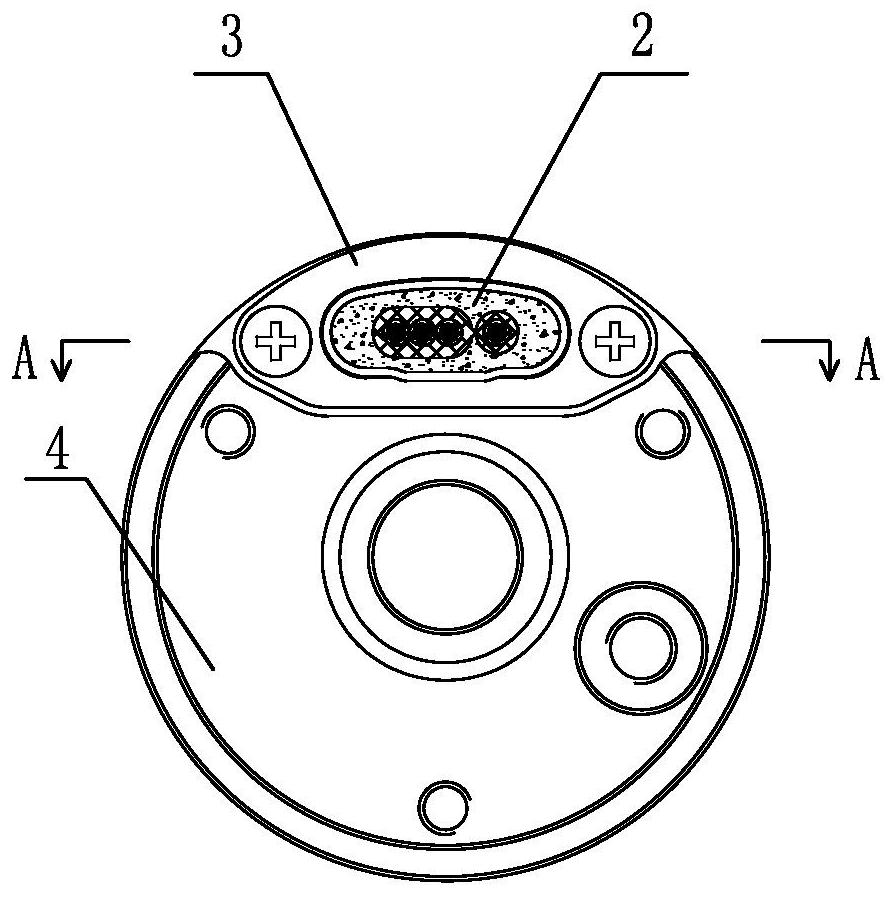

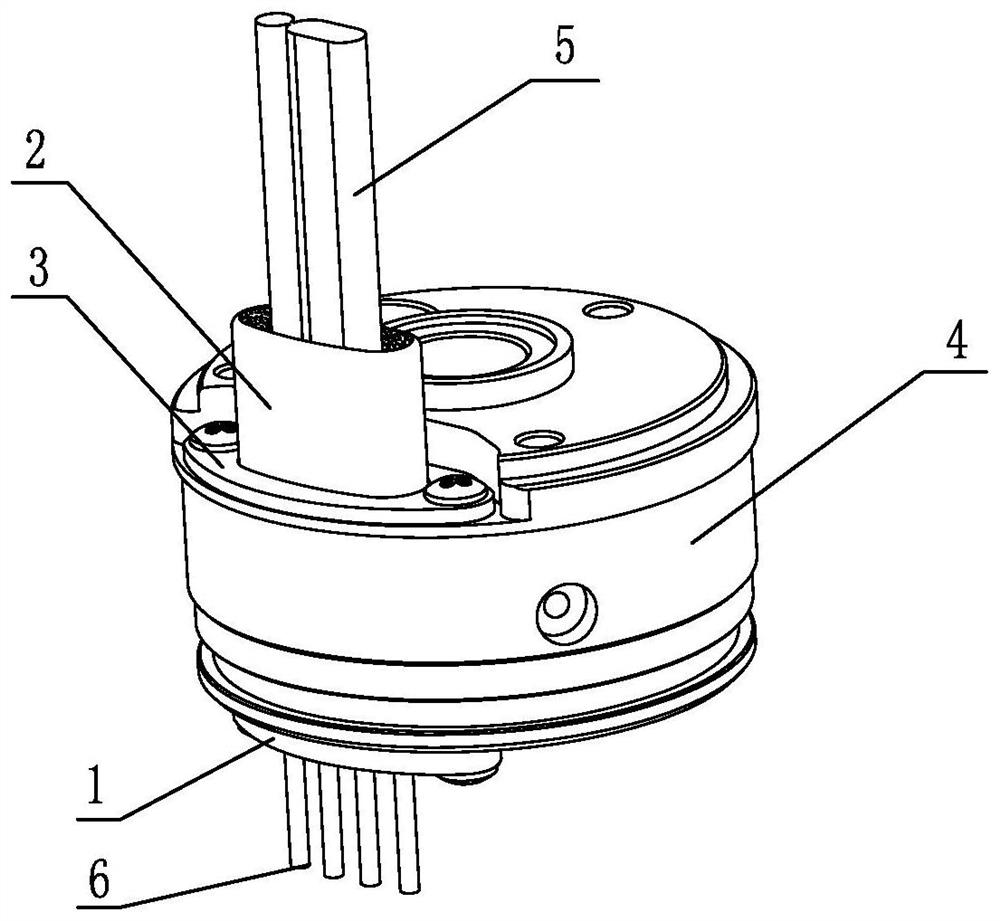

[0053] Depend on Figures 1 to 37 As shown, the embodiment of the sealing and fixing device for the power plug wire of the submersible motor for a well according to the present invention is: The power cord outlet 41 is connected in parallel with the power socket 1 of the motor drive lead wire 6 and the power plug 2 connected with the power cable flat wire 5, and the power plug 2 is fixed on the upper head 4. The sealing plate 3, Depend on Figures 4 to 9 As shown in 27-32, the power socket 1 includes an insulating plastic seat 11, and 3-4 conductor ferrule pins 12 with the same protruding height, which are arranged and packaged on the plastic seat side by side. The tail of 12 is connected to the motor drive lead wire 6, which is connected by Figures 4 to 5 As shown in 10 to 16, the power plug 2 includes an insulating rubber plug 21 and 3 to 4 conductor jack pins 22 of the same height that are arranged in parallel and packaged in the insulating rubber plug. The tail of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com