Tank flange

一种燃料容器、法兰的技术,应用在燃料容器法兰领域,达到节省结构空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

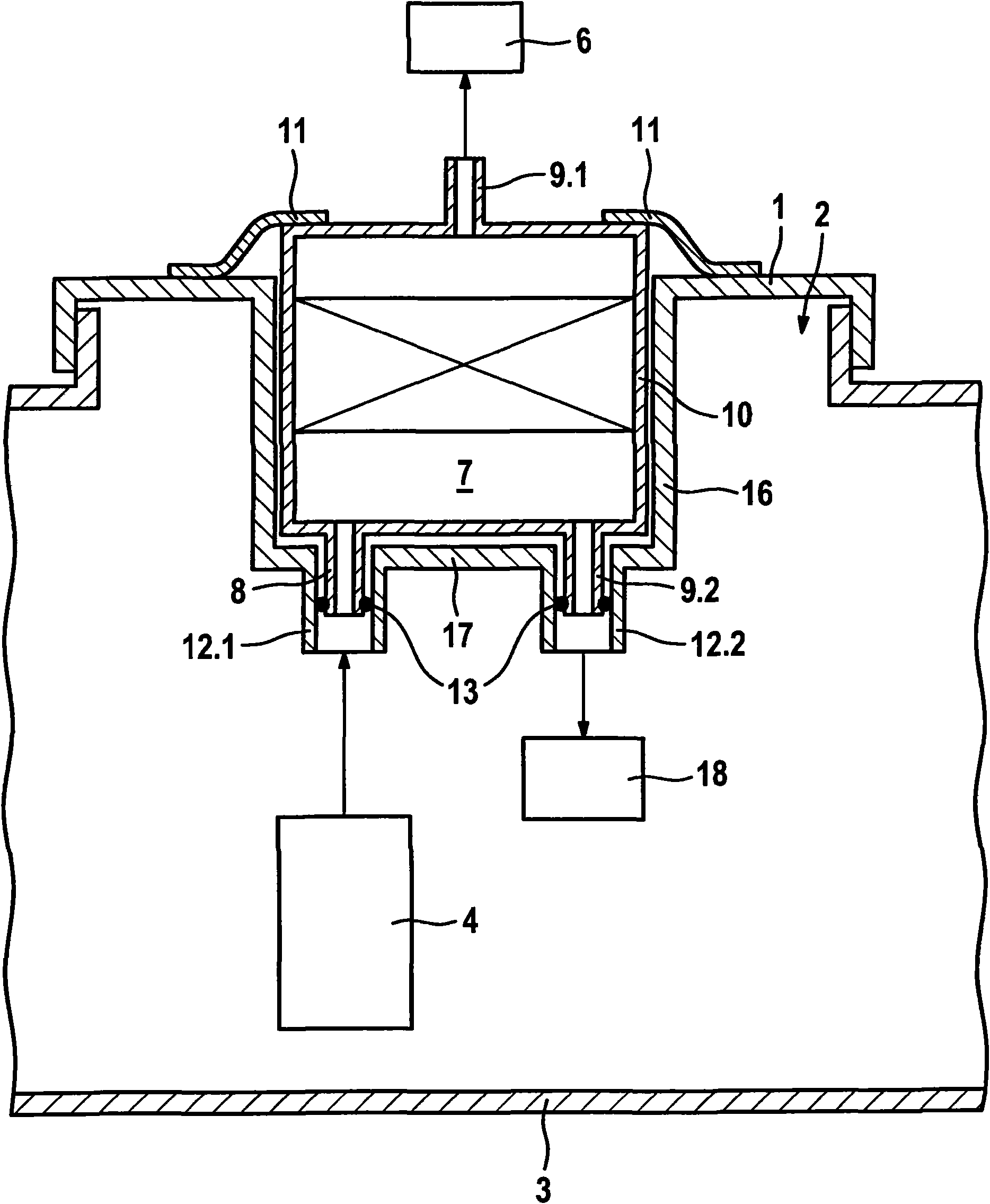

[0011] The drawing shows a fuel container flange according to the invention.

[0012] The fuel container flange 1 according to the invention is designed as a cover closing the fuel container opening 2 of a fuel container 3 . The fuel container opening 2 is necessary in order to allow a device for delivering fuel, for example a so-called fuel delivery module, to be inserted into the fuel container 3 . The device for delivering fuel comprises at least one delivery device 4 , for example an electric fuel pump. After these components have been installed in the fuel container 3 , the fuel container opening 2 is hermetically closed by the fuel container flange 1 . Delivery device 4 delivers fuel from fuel container 3 to internal combustion engine 6 . Between the delivery device 4 and the internal combustion engine 6 there is a main filter 7 which filters out fine dirt particles from the fuel. The main filter 7 has an inlet 8 and at least one first outlet 9 . 1 and is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com