Ratary handle type connector

A connector and rotary handle technology, applied in the direction of connection, parts and electrical components of the connecting device, etc., can solve the problems of difficulty in separating the female connector and the male connector from each other, hindering the operation of the rotary handle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

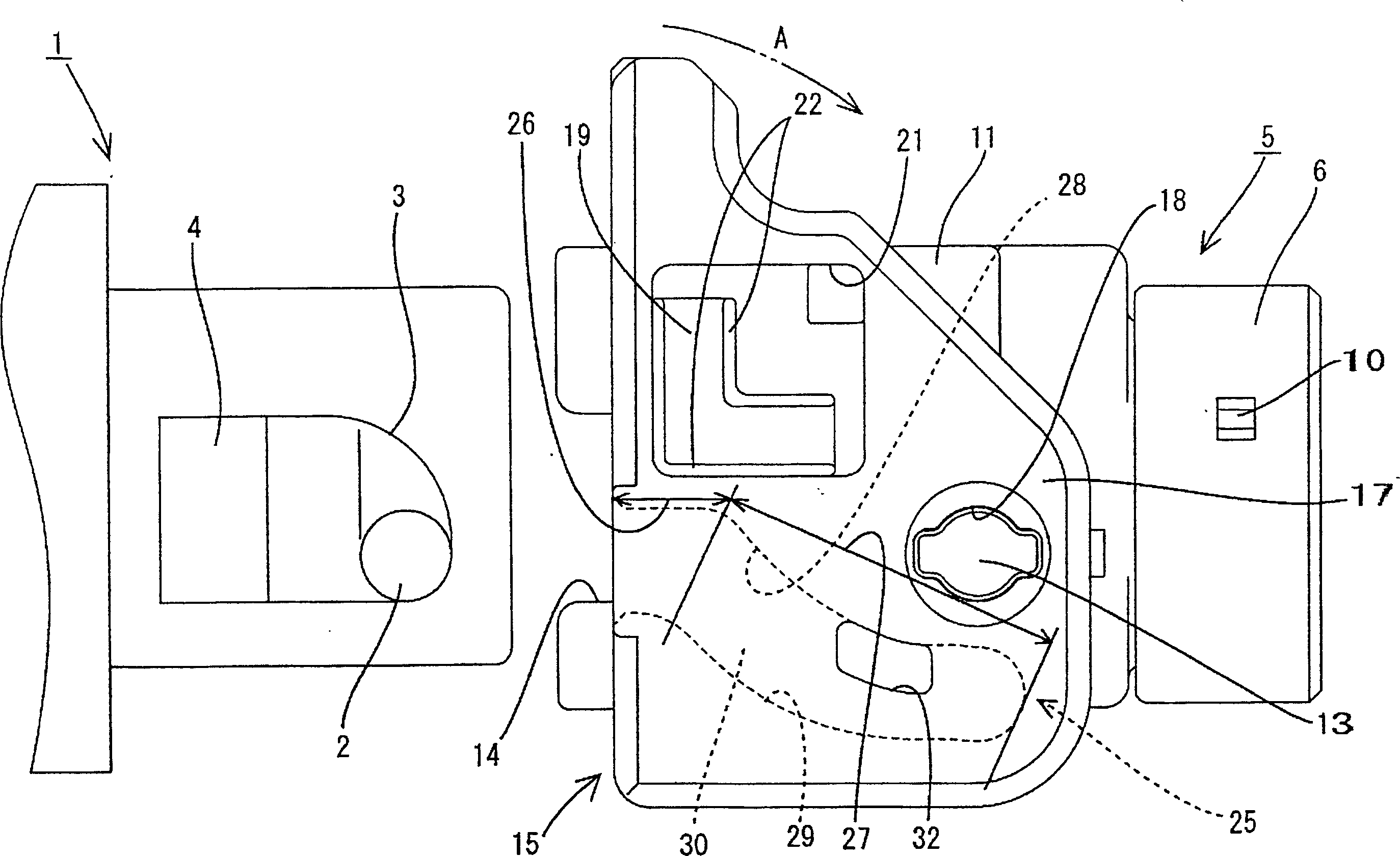

[0020] The following will refer to Figure 1 to Figure 7 An embodiment of the present invention is described. figure 1 A rotary handle connector with a male connector 1 and a female connector 5 is shown.

[0021] The male connector 1 accommodates a terminal male fitting (not shown). A boss 4 protrudes from each outer wall of the male connector 1 . A cam pin 2 protrudes from the upper surface of each boss 4 . The front edge of each boss 4 is made into a roughly arc shape, forming a loosening portion 3 .

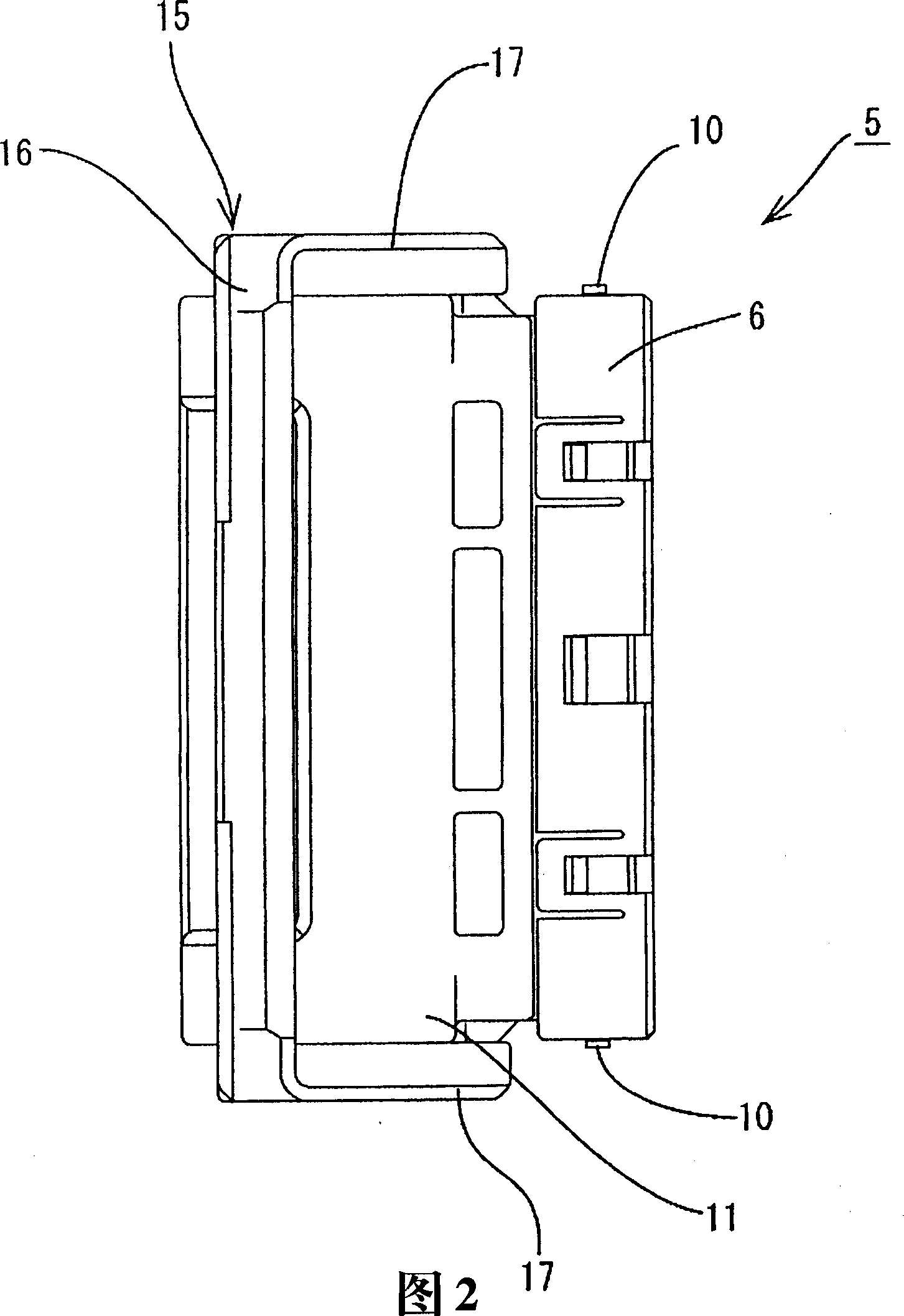

[0022] The female connector 5 has a main body 6 , a cover portion 11 located on the front side of the main body 6 , and a knob 15 rotatably mounted on the cover portion 11 .

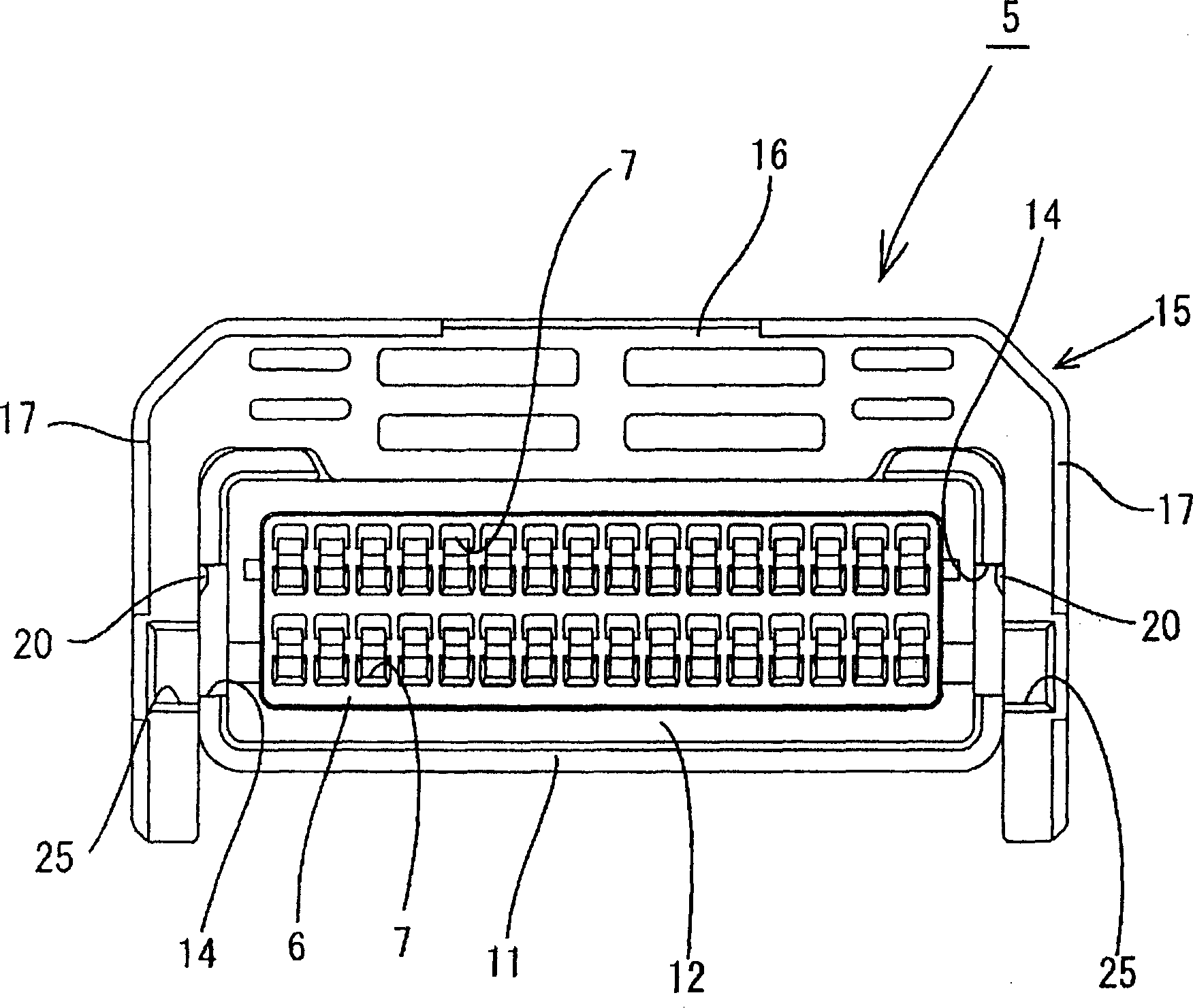

[0023] Such as image 3 As shown, a plurality of slots 7 capable of accommodating terminal female joints (not shown) pass through the main body 6 in a front-to-back direction (ie, the mating direction of the connector). It can be inserted therein from the opening at the back of the slotted hole 7 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com