Connecting clamp for template splicing

A formwork assembly and clamping technology, which is applied in the direction of formwork/formwork/work frame connectors, connecting components, mold auxiliary parts, etc., can solve the problems of easy damage, slow construction speed, looseness, etc., and achieve simple connection, The effect of firm connection and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

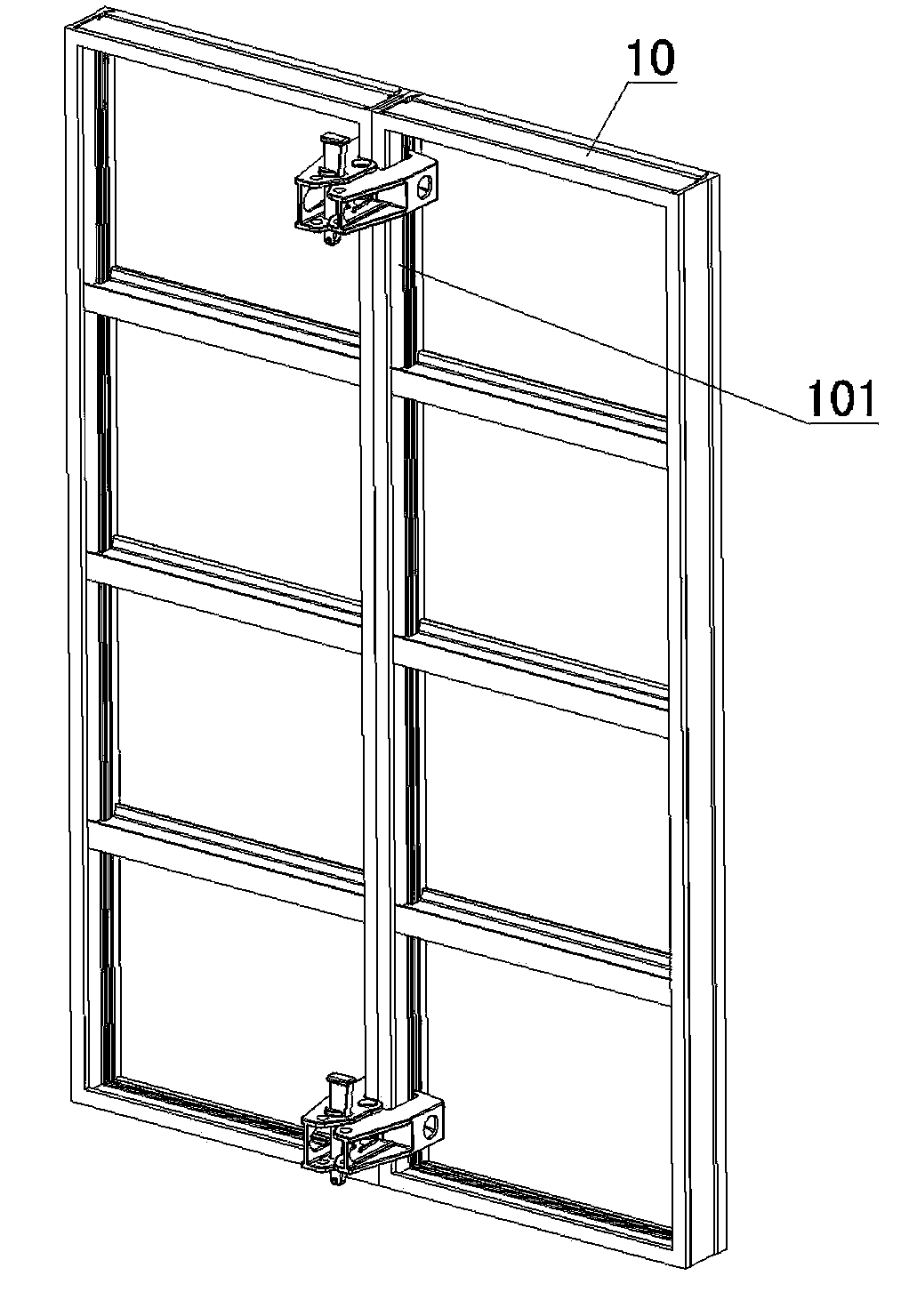

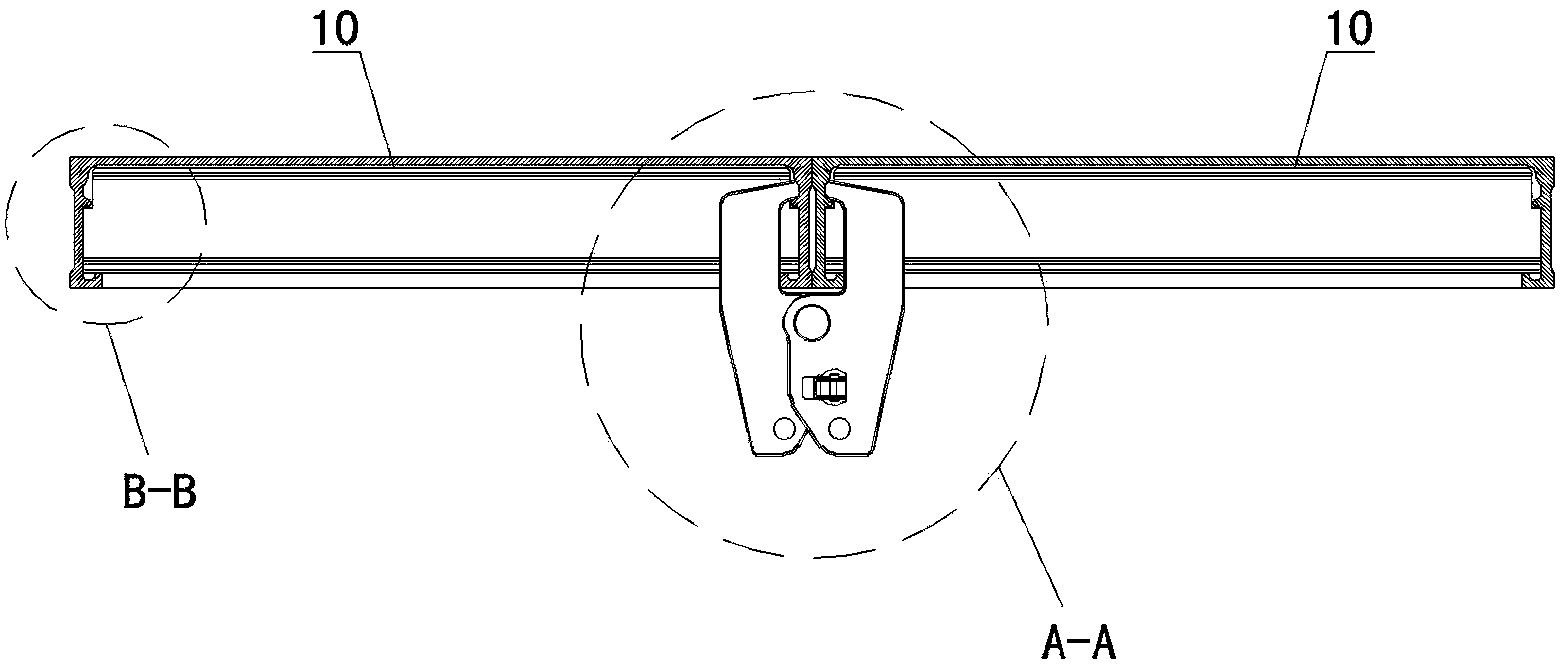

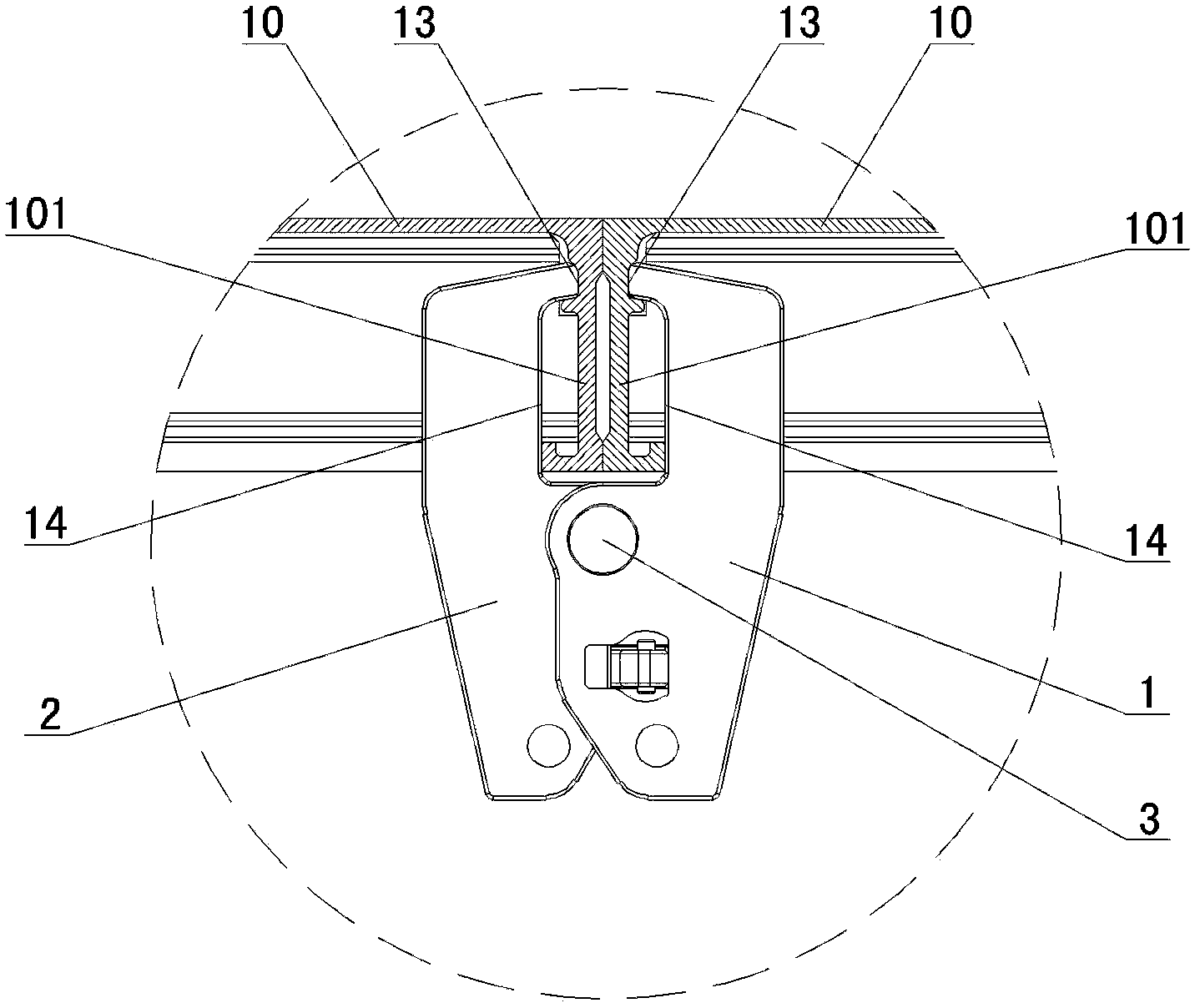

[0025] Such as Figure 1-Figure 11 As shown, the connecting jig for template assembly according to the present invention includes a left clip 1 and a right clip 2, and the left clip 1 and the right clip 2 are rotatably connected together through a rotating shaft 3, and the left The front chuck parts of the clip 1 and the right clip 2 have a clamping surface 13 and a positioning and alignment surface 14 corresponding to the frame 101 of the template 10, and the rear parts of the left clip 1 and the right clip 2 are provided with The front clamp parts of the left clip 1 and the right clip 2 can form a locking device for clamping the frames 101 of two adjacent templates 10 . In order to make the structure of the present invention various, it is possible that the locking device includes a perforation 11 arranged at the rear of the left clip 1, and an oblique wedge 4 that can move up and down and is inserted in the perforation 11, wherein the One side of the oblique wedge 4 corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com