Tapered roller bearing press-fitting mechanism, press-fitting method and press-fitting mistake-proofing method thereof

A tapered roller bearing and press-fitting technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that ordinary mechanisms cannot meet the requirements, achieve the effect of reliable operation of equipment and guarantee of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

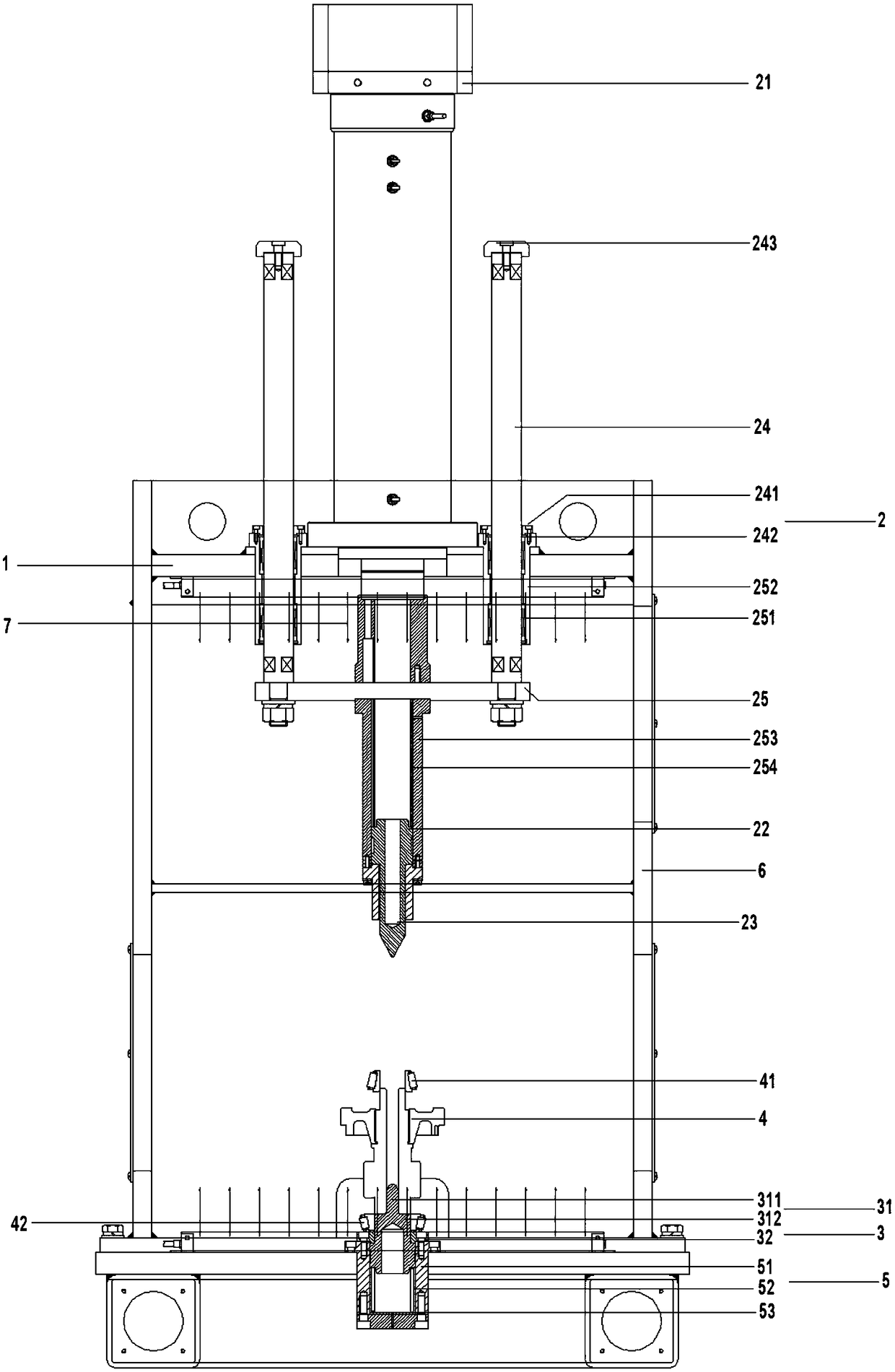

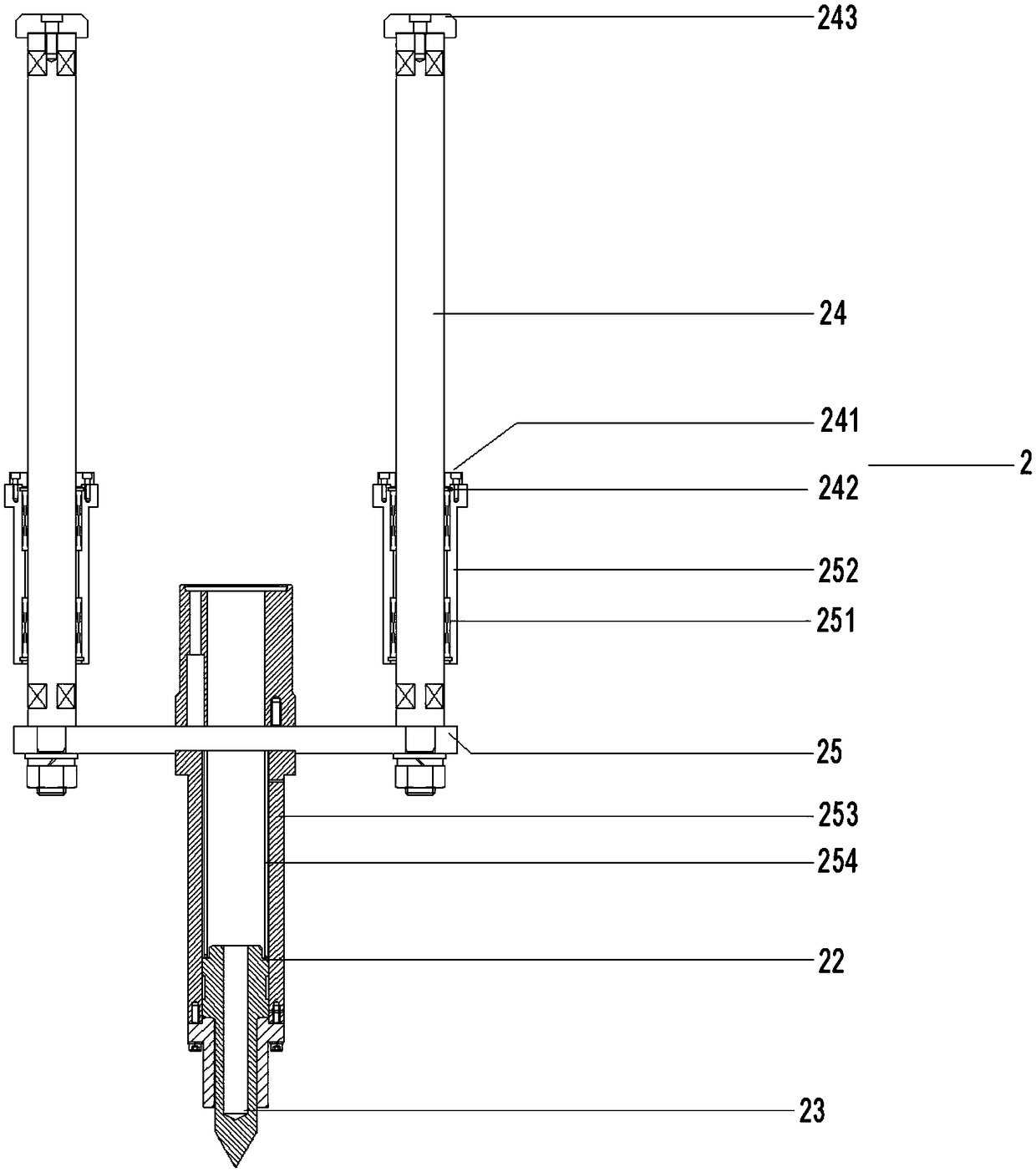

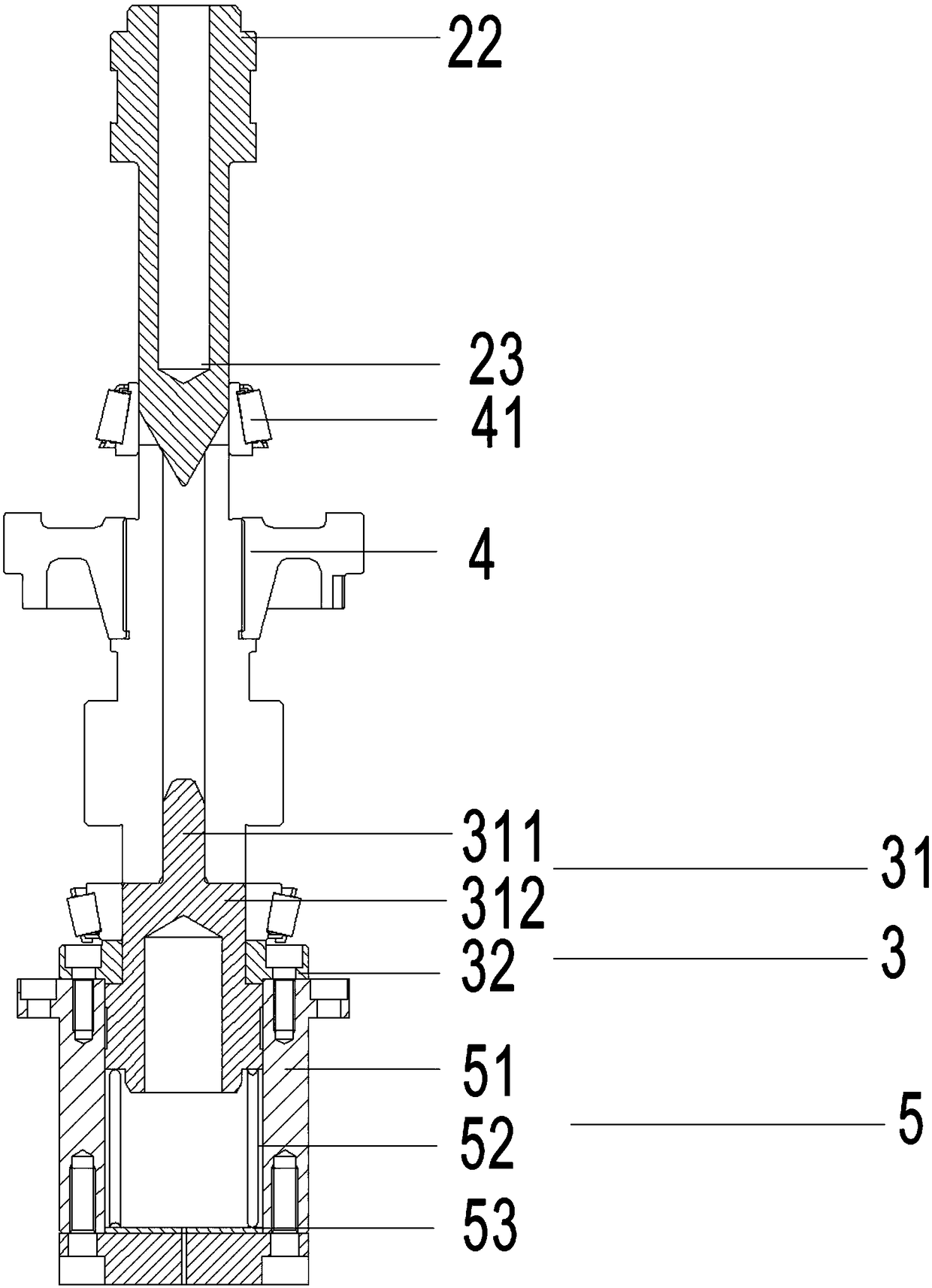

[0030] The tapered roller bearing press-fitting mechanism provided in this embodiment includes a fixed frame 1, and the top and bottom of the fixed frame 1 are respectively equipped with a stamping part 2 and a press-fitting part 3 for press-fitting. The press-fitting intermediate shaft 4 and the press-fitting part 3 are coaxially abutted; wherein, the stamping part 2 includes a driving part 21, a punching fixture 22 and a centering cone 23 connected in sequence, and the two sides of the driving part 21 are respectively connected with two guide shafts 24 , the two guide shafts 24 are mirror-symmetrically slidably mounted on the fixed frame 1, the stamping fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com