Wiring harness protection structure

A protective structure and wiring harness technology, applied in the direction of electrical components, circuits or fluid pipelines, transportation and packaging, etc., to achieve reasonable distribution, reduce the risk of damage, and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

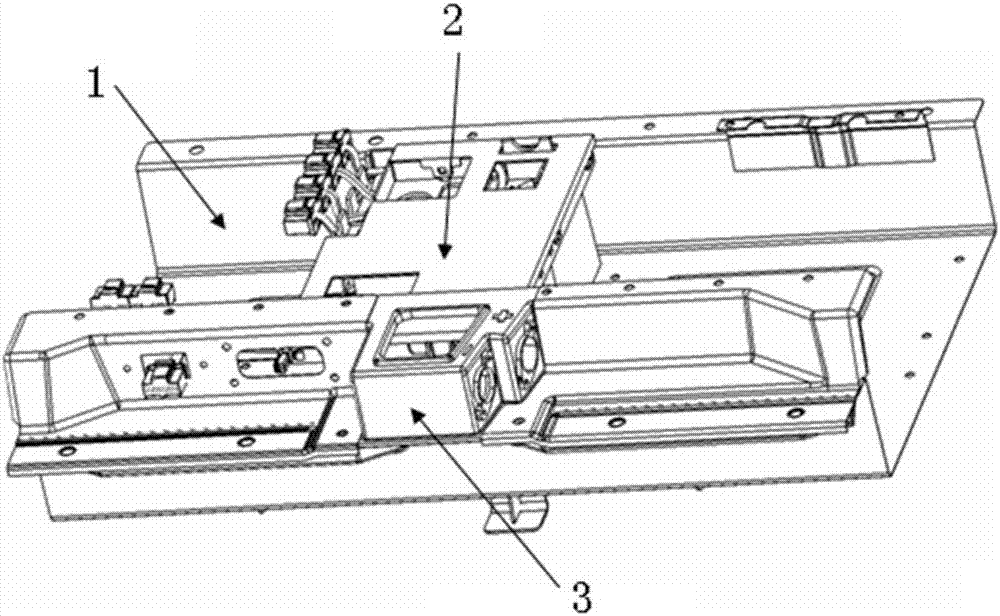

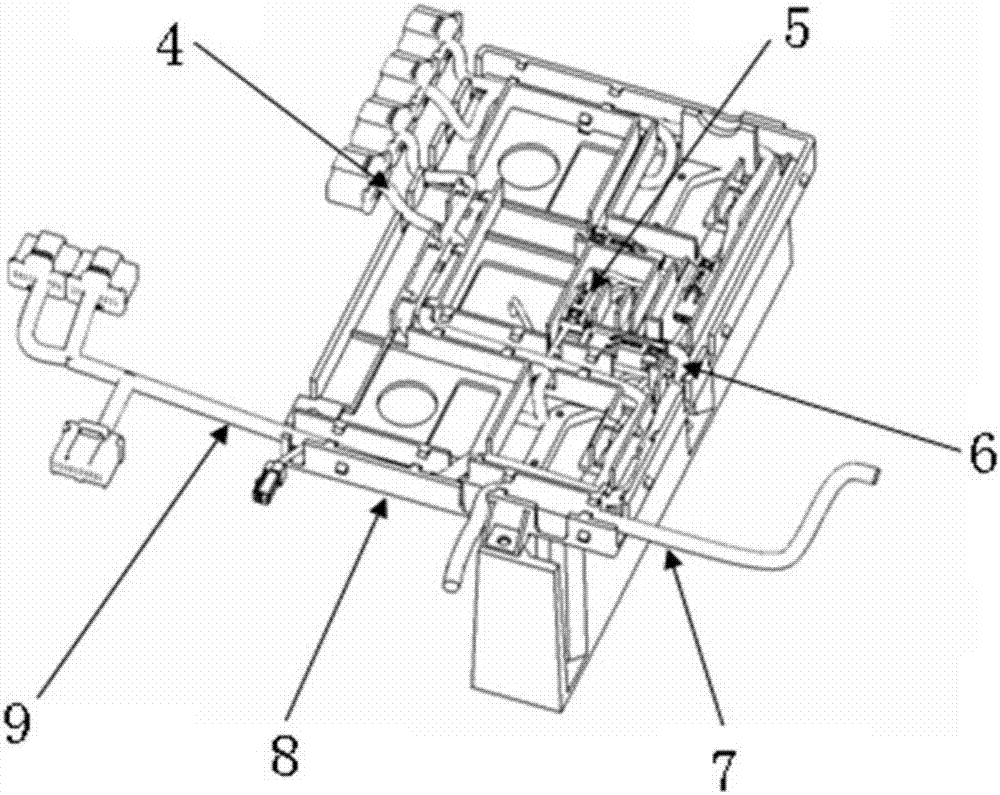

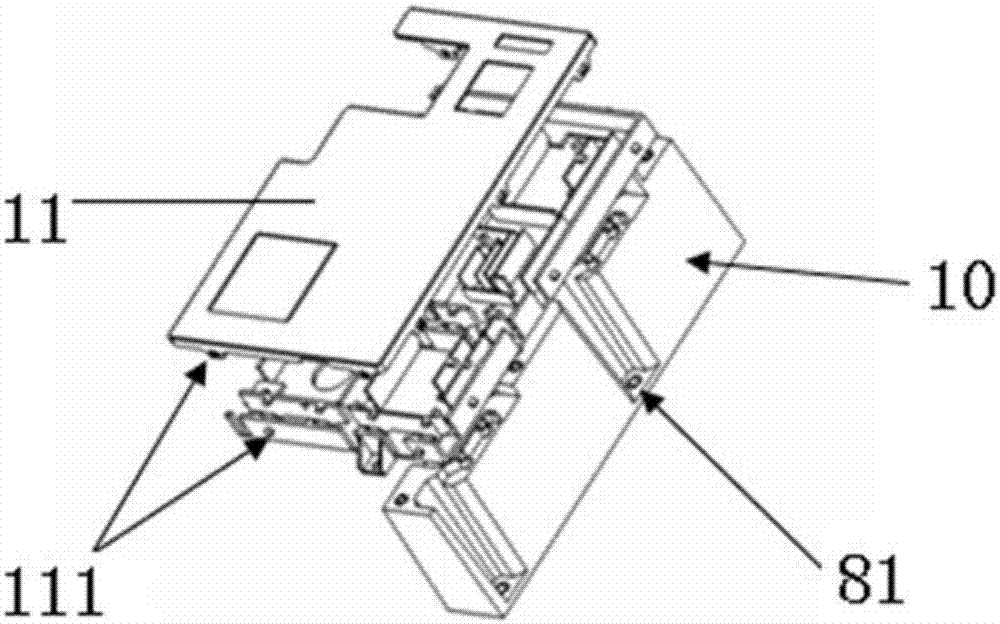

[0035] This application designs a fixing device, which is used to fix the high-voltage wire harness, low-voltage wire harness and low-voltage wire harness connector inside the battery pack. Before the battery pack is assembled, the low-voltage wire harness can be pre-installed on the device first, and then the fixing device is installed In the battery pack, the high-voltage wiring harness is finally fixed and assembled according to the direction set on the fixing device.

[0036] This technical solution solves the problem of fixing and layout of the high and low voltage wiring harness system of the battery pack. Due to the large space l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com