Hollow square tube character pressing device

A technology of hollow square tubes and prefixes, which is applied in the field of pipe embossing, can solve the problems of insufficient strength, easy deformation of embossing, etc., and achieve the effect of high support body strength, avoiding looseness, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and implementation examples.

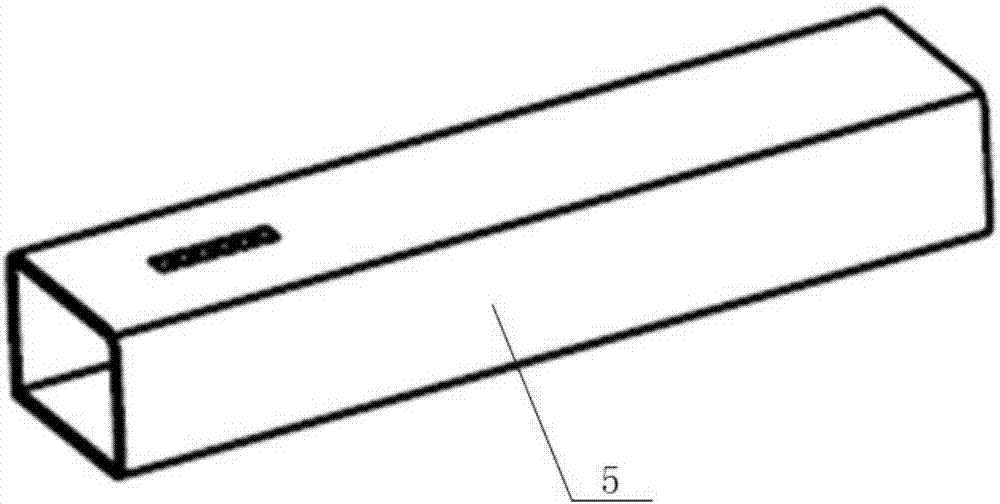

[0023] figure 1 Shown is a 100X140X6 rectangular hollow square tube to be stamped.

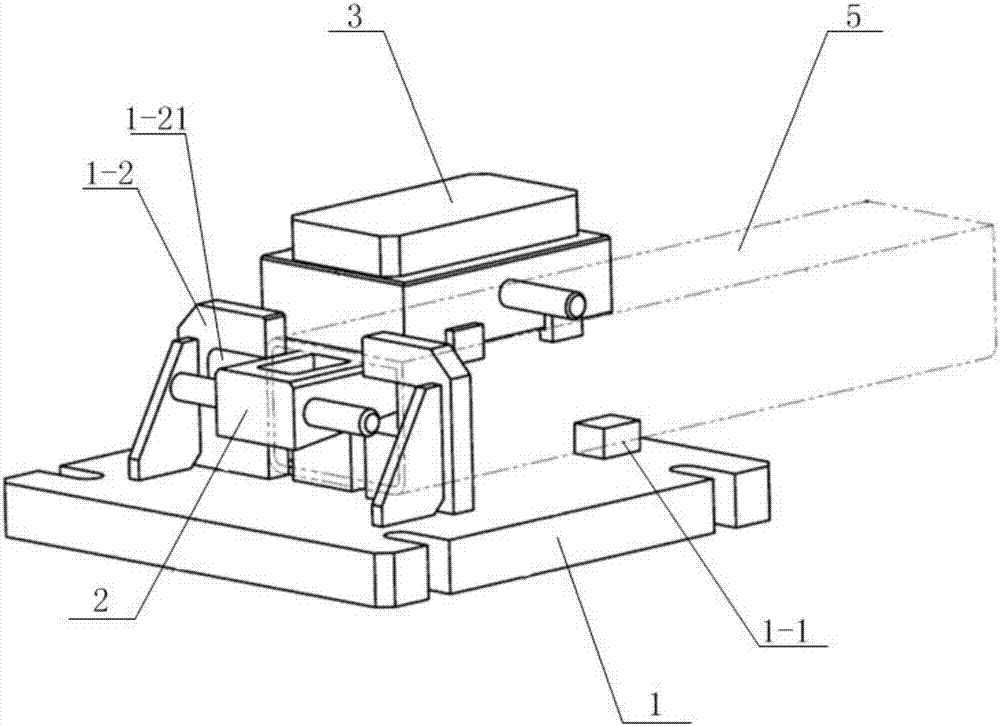

[0024] like Figure 2-7 As shown, a hollow square tube embossing device includes a lower template 1, a wedge support 2, an upper mold component 3, and a mold unloading wedge 4 used in conjunction.

[0025] The lower template 1 is provided with a side positioning gear 1-1 and an end positioning gear 1-2, which are used for positioning the hollow square tube 5 and preventing the center of pressure from shifting.

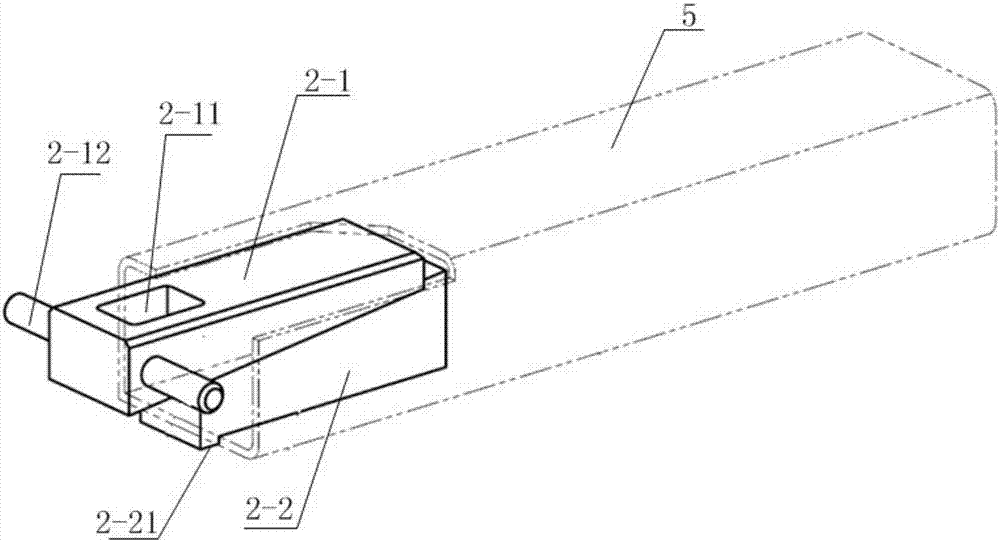

[0026] The wedge support 2 includes an upper wedge 2-1 and a lower wedge 2-2, the lower part of the upper wedge 2-1 and the upper part of the lower wedge 2-2 are processed with mutually matching and self-locking slopes, and the upper wedge 2 -1 and the lower wedge 2-2 are combined to form a solid body, which is wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com