Multi-station multi-type hybrid wire harness testing method for intelligent wire harness tester

A test method and multi-model technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high test cost, low versatility, low degree of intelligence, etc., and achieve the effect of low cost and rapid test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

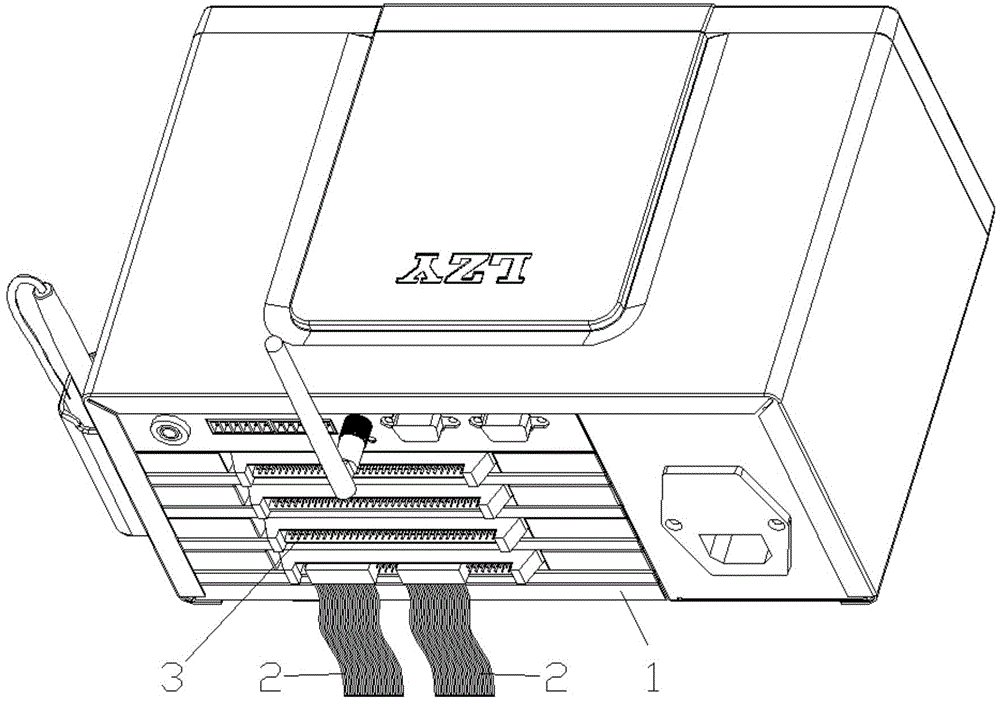

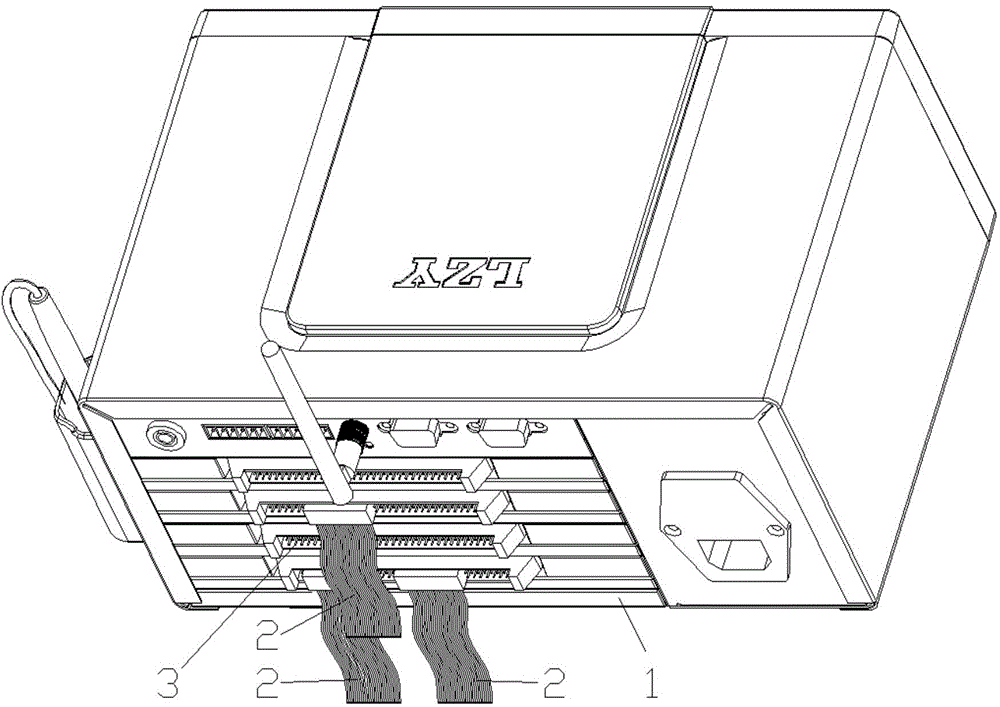

[0034] refer to Figure 1-Figure 2 As shown, the multi-station and multi-type hybrid wire harness testing method of the wire harness intelligent testing machine includes a wire harness intelligent testing machine 1 and a multi-type mixed wire harness product 2 to be tested, and the simultaneous detection number of the multi-type mixed wire harness product 2 to be tested is More than two, the multi-type mixed wire harness product 2 to be detected is produced by multiple stations in multiple steps, and the several different multi-type wire harness products 2 to be detected are integrated together and then divided into several Each part is produced by different stations and inserted into the wiring harness intelligent testing machine 1 to complete the test alone. The multi-station single-model multi-step wiring harness testing metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com